Professional Documents

Culture Documents

7.OWC CLASS G HSR AKCC TDS v2

Uploaded by

jami yosryCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

7.OWC CLASS G HSR AKCC TDS v2

Uploaded by

jami yosryCopyright:

Available Formats

Oil Well CEMENT

Class 'G' High sulfate-resistant grade (HSR)

Technical Data Sheet

AKCC Test Certificate Data complying

With

API 10A Specs for Class 'G' High sulfate-resistant grade (HSR)

Class G Grade HSR Well Cement is with all the requirements of American Petroleum

manufactured locally to comply with the Institute (API) standards (Specification for

requirements of American Petroleum Institute Cements & Materials for Well Cementing API

(API) standards (Specification for Cements & Spec 10A) for Class G grade HSR.

Materials for Well Cementing API Spec 10A) and Reports of tests providing data on Thickening

(API Recommended Practice for Testing Well time test, Maximum consistency (15-30 min),

Cement API RP 10B-2). Free fluid content, Compressive Strength 8h,

Class G Grade HSR Well Cement is 38°C and 60°C, chemical composition including

manufactured by grinding clinker with calcium Magnesium Oxide, Sulfur tri Oxide, Loss on

sulfate. The product Class G grade HSR is Ignition, Insoluble Residue, Tricalcium Silicate,

intended for use as a basic well cement and will TricalciumAluminate,Tetracalcium Aluminoferrite

meet chemical (clause 4.1.2) and physical + twice (C3A), Chloride and Alkali levels are

clause (4.1.3) requirements mentioned in API available on a batch wise production.

10A Spec and10B-2.

Applications Strength

Oil well cements are extensively used in the Optimum performance in terms of strength and

exploration for and the production of oil and durability is achieved by making slurry from

gas. They can also be utilized for sealing water cement and water with fixed water cement ratio

wells, waste disposal wells and geothermal of 44% according to API 10A (4.1.3)

wells. Cement plays an important part in the Other factors affecting strength include

successful drilling of a well. It is used primarily to conditions of curing.

seal the annulus between the walls of the

borehole and the steel casing in order to isolate

the pressured or weak zones encountered whilst

drilling.

Quality

AKCC’s Oil well cement is produced using

carefully selected raw materials. Strict quality

control throughout each stage of the

manufacturing process ensures that a consistent

final product is achieved. It confirms that in

addition to applying a system of factory

production, control independent sampling and

testing of the cement has confirmed conformity

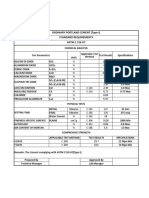

Major Mineral Constituents in Class 'G' High sulfate-resistant grade (HSR)

Compound Abbreviation Chemical Formula Typical Concentration %

Tricalcium Silicate C3S 3CaO*SiO2 48.0 min- 65.0 max

Tetracalcium Aluminoferrite 4CaO*Al2O3*Fe2O3

C4AF+2C3A 24.00 max

+ twice (C3A) + 2*3CaO*Al2O3

Tricalcium Aluminate C3A 3CaO*Al2O3 3.00 max

Oil Well CEMENT

Class 'G' High sulfate-resistant grade (HSR)

Technical Data Sheet

AKCC Test Certificate Data complying

With

API 10A Specs for Class 'G' High sulfate-resistant grade (HSR)

API Standard

UNITS RESULTS requirement 10A

Magnesium Oxide MgO % 3.40 6.00 max

Sulfur tri Oxide SO3 % 2.60 3.00 max

Alkalies (Na2O + 0.658 K2O) % 0.45 0.75 max

Loss on Ignition LOI % 1.60 3.00 max

Insoluble Residue IR % 0.56 0.75 max

Tricalcium Silicate C3S % 62.00 48.0 min- 65.0 max

Tricalcium Aluminate C3A % 2.46 3.00 max

C4AF+2C3A % 19.85 24.00 max

Chloride Cl % 0.01 0.10 max

PHYSICAL TEST

Free fluid content % 2.20 5.90 max

Compressive Strength 8h, 38°C MPa 3.10 2.10 min

Compressive Strength 8h, 60°C MPa 12.60 10.30 min

Thickening time Minutes 110.00 90.0 min-120.0 max

Maximum consistency (15-30 Bc 20.00 30.00 max

min)

Fineness(Blaine Air Permeability M2/Kg 327.00 -

method)

Technical Support:

For further advice please contact Technical Support at

technicalsupport@alkhalijcement.qa

For further information please contact:

Tel: 00974 4444 59 00

Fax: 00974 4444 69 00

WWW.alkhalijholding.com

You might also like

- Philippine National Standard - Portland Cement SpecificationDocument12 pagesPhilippine National Standard - Portland Cement SpecificationMariel Villaluna100% (2)

- Fo Analysis Reports Prabhu YuvikaDocument17 pagesFo Analysis Reports Prabhu YuvikaSumit ChandwaniNo ratings yet

- 01 Introduction RefractoriesDocument38 pages01 Introduction RefractoriesRizwanKhan100% (1)

- Product Specifications Octane 95Document3 pagesProduct Specifications Octane 95Vishnu PillaiNo ratings yet

- Experiment 8 and 9 PDFDocument17 pagesExperiment 8 and 9 PDFKrizzi Dizon GarciaNo ratings yet

- Heavy-Duty Diesel Engine Test Category For API CI-4 and CI-4 PLUSDocument1 pageHeavy-Duty Diesel Engine Test Category For API CI-4 and CI-4 PLUSsreehariNo ratings yet

- API Engine Oil Classifications 2010Document6 pagesAPI Engine Oil Classifications 2010amsoilromaniaNo ratings yet

- Cement Mill Test - Fairborn Cement Company Type-IA - Jan2022Document2 pagesCement Mill Test - Fairborn Cement Company Type-IA - Jan2022mohamed ElsayedNo ratings yet

- Ordinary Portland Cement (Type-I) Standard Requirements ASTM C 150-07Document2 pagesOrdinary Portland Cement (Type-I) Standard Requirements ASTM C 150-07Arsath Nazeem RizwiNo ratings yet

- Cement Mill CertificateDocument1 pageCement Mill CertificateKaycee candelaria100% (1)

- 3-Cement Test ReportDocument2 pages3-Cement Test ReportAhsan Farid100% (1)

- Cement Mill Test Report3Document3 pagesCement Mill Test Report3MT JasonNo ratings yet

- Type 1 BricksDocument20 pagesType 1 Bricksprachi410No ratings yet

- Screenshot 2023-08-02 at 2.39.08 PMDocument10 pagesScreenshot 2023-08-02 at 2.39.08 PMvinay chinniNo ratings yet

- API Engine Oil Classifications - 1110Document14 pagesAPI Engine Oil Classifications - 1110hhahn01No ratings yet

- Product: Penetration Grade Bitumen Cutback MC 70 Packing: New Steel Drum 180 5Kgs / BulkDocument2 pagesProduct: Penetration Grade Bitumen Cutback MC 70 Packing: New Steel Drum 180 5Kgs / BulkvinayaiyappaNo ratings yet

- 3.4 Bituminous Materials: 3.4.1 DescriptionDocument5 pages3.4 Bituminous Materials: 3.4.1 DescriptionSujon AhmmedNo ratings yet

- Datasheet-Sanicro-35-En-V2022-10-26 06 - 00 Version 1Document12 pagesDatasheet-Sanicro-35-En-V2022-10-26 06 - 00 Version 1akbarul muttaqinNo ratings yet

- Infineum - API Engine Oil Classifications PDFDocument12 pagesInfineum - API Engine Oil Classifications PDFAnca DanNo ratings yet

- Strip Seal Expansion JointDocument13 pagesStrip Seal Expansion JointsmithNo ratings yet

- Portland Cement I-II Mill CertDocument1 pagePortland Cement I-II Mill CertFiras Ashraf100% (1)

- API Test Data For Distribution 1 1Document6 pagesAPI Test Data For Distribution 1 1Avyan KelanNo ratings yet

- ESW - Type I II 2017 04 PDFDocument2 pagesESW - Type I II 2017 04 PDFVictor MontaNo ratings yet

- Astm C618 19Document2 pagesAstm C618 19maniharimeenaNo ratings yet

- PNS Ceramic - CementDocument13 pagesPNS Ceramic - CementDoobeng Duds100% (1)

- Fuel Lub #1Document141 pagesFuel Lub #1Hasan CosalevNo ratings yet

- Physical Testing of Clinker & CementDocument61 pagesPhysical Testing of Clinker & CementDineshNo ratings yet

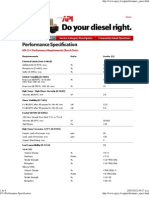

- CJ-4 Performance SpecificationDocument4 pagesCJ-4 Performance SpecificationolguinrfNo ratings yet

- API Engine Oil Classifications Infineum 2017Document12 pagesAPI Engine Oil Classifications Infineum 2017iosalcido100% (1)

- TDS Castrol Perfecto XPG - Power VersionDocument2 pagesTDS Castrol Perfecto XPG - Power VersionTeguh SNo ratings yet

- Tests On Portland Cement PDFDocument27 pagesTests On Portland Cement PDFAnonymous NxpnI6jC100% (2)

- GRANIT-MAXIMUM-15W40 EN Vja21Document1 pageGRANIT-MAXIMUM-15W40 EN Vja21Jolie AbarcaNo ratings yet

- Housing Development Project Office: Construction & Supervision DepartmentDocument6 pagesHousing Development Project Office: Construction & Supervision DepartmentSemNo ratings yet

- TTN3512 3e2aDocument1 pageTTN3512 3e2aMarcos RojasNo ratings yet

- SCF Series (Ms-02-156) r0Document4 pagesSCF Series (Ms-02-156) r0Heryanto SyamNo ratings yet

- SNI 15-2049-2004 in EnglishDocument95 pagesSNI 15-2049-2004 in EnglishMey LinaNo ratings yet

- TDS Turbonycoil TN600 1E19Document2 pagesTDS Turbonycoil TN600 1E19Emad The EnthusiastNo ratings yet

- Turbine EngDocument1 pageTurbine EngPeter_Phee_341No ratings yet

- Construction & Quality Control of Flexible Pavement: Dr. N.K.S. Pundhir Senior Principal Scientist E-MailDocument84 pagesConstruction & Quality Control of Flexible Pavement: Dr. N.K.S. Pundhir Senior Principal Scientist E-MailMohd Ali100% (1)

- QBC CRMB TDS Rev 0Document2 pagesQBC CRMB TDS Rev 0nainaNo ratings yet

- A PDFDocument4 pagesA PDFVerenice CentenoNo ratings yet

- Aashto M 85-20Document16 pagesAashto M 85-20reza acbariNo ratings yet

- IOCL - 001 CS CastingsDocument3 pagesIOCL - 001 CS CastingsKamal ThummarNo ratings yet

- HPF Fan - AnshanDocument28 pagesHPF Fan - AnshanDangolNo ratings yet

- Raw MixDocument22 pagesRaw Mixmahendra senNo ratings yet

- 21app0808 MTR-14Document1 page21app0808 MTR-14gmendoza.logistica3No ratings yet

- Datasheet-Sanicro-41-En-V2019-09-19 07 - 09 Version 1Document7 pagesDatasheet-Sanicro-41-En-V2019-09-19 07 - 09 Version 1Rubén Leal RuizNo ratings yet

- Nabll Mix DesignDocument29 pagesNabll Mix DesignPIDCL WITH SUBUDHINo ratings yet

- Compliance Statement - chINATE sTATEDocument2 pagesCompliance Statement - chINATE sTATEOMAR MUKTHAR JAMAL MOHAMEDNo ratings yet

- Specifiaction - PROKDocument5 pagesSpecifiaction - PROKAjit AgrawalNo ratings yet

- Fire Extinguisher DetailsDocument4 pagesFire Extinguisher DetailspruthviNo ratings yet

- Technical Specification - Patratu-3LPE CoatingDocument24 pagesTechnical Specification - Patratu-3LPE CoatingAJAY PatilNo ratings yet

- Element Warren A2LA 0038 01 Mechanical PDFDocument21 pagesElement Warren A2LA 0038 01 Mechanical PDFAndre CasteloNo ratings yet

- Hercules EngDocument1 pageHercules EngTAREK HAMADNo ratings yet

- Optigear 1100 RangeDocument3 pagesOptigear 1100 RangeResistenciaDisidenteNo ratings yet

- H Proc Notices Notices 030 K Notice Doc 28521 682090824 PDFDocument14 pagesH Proc Notices Notices 030 K Notice Doc 28521 682090824 PDFŞăźàdă MùhămmãdNo ratings yet

- Annex 4.1 - Technical Specifications - Civil WorksDocument6 pagesAnnex 4.1 - Technical Specifications - Civil WorksMW ALSABRINo ratings yet

- Specifications Asfalto 50-80-2023Document1 pageSpecifications Asfalto 50-80-2023H JNo ratings yet

- 001 - Shell Turbo Oil CC 32Document2 pages001 - Shell Turbo Oil CC 32Irvan NandaNo ratings yet

- Advanced and Refractory Ceramics for Energy Conservation and EfficiencyFrom EverandAdvanced and Refractory Ceramics for Energy Conservation and EfficiencyHua-Tay LinNo ratings yet

- Mechanical Properties and Performance of Engineering Ceramics and Composites X: A Collection of Papers Presented at the 39th International Conference on Advanced Ceramics and CompositesFrom EverandMechanical Properties and Performance of Engineering Ceramics and Composites X: A Collection of Papers Presented at the 39th International Conference on Advanced Ceramics and CompositesDileep SinghNo ratings yet

- Geochemistry in The Exploration of Nickeliferous Laterite Pablito M. Ong and Arturo C. Sevillano A. Soriano Corporation, Makati, Rizal (Philippines)Document5 pagesGeochemistry in The Exploration of Nickeliferous Laterite Pablito M. Ong and Arturo C. Sevillano A. Soriano Corporation, Makati, Rizal (Philippines)Belle Estal PalajosNo ratings yet

- Iodometric Determination of GlucoseDocument2 pagesIodometric Determination of GlucoseAnuj jainNo ratings yet

- Solubility ActivitiesDocument2 pagesSolubility ActivitiesRayian MactalNo ratings yet

- Review of Pummerer Rearrangement, Padwa, Chem. Rev. 2004Document32 pagesReview of Pummerer Rearrangement, Padwa, Chem. Rev. 2004Victor CiocalteaNo ratings yet

- Astm D1141 98 2021Document2 pagesAstm D1141 98 2021NettyNo ratings yet

- Cheminform PDFDocument182 pagesCheminform PDFmadden08No ratings yet

- Assay of Sodium Bicarbonate After DryingDocument1 pageAssay of Sodium Bicarbonate After DryingNas HosawiNo ratings yet

- Acids and BasesDocument26 pagesAcids and BasesGaayathiriNo ratings yet

- Effect of Acidity and Basicity of Organic CompoundsDocument34 pagesEffect of Acidity and Basicity of Organic Compoundsajibolaakorede20No ratings yet

- Microbiology 101: Laboratory Exercise #22: Carbohydrate MetabolismDocument16 pagesMicrobiology 101: Laboratory Exercise #22: Carbohydrate Metabolismmaraki998No ratings yet

- Water-Based Polyurethane DispersionsDocument6 pagesWater-Based Polyurethane DispersionsDan RoskeNo ratings yet

- 11 - Isomerism in TMCDocument18 pages11 - Isomerism in TMCMohit KambojNo ratings yet

- Unit 7 TestDocument6 pagesUnit 7 TestmamazookeeprNo ratings yet

- Preparatory Problems PDFDocument3 pagesPreparatory Problems PDFGerel BayrmagnaiNo ratings yet

- Association of Ions and Fractional Crystallization: General Chemistry ExperimentDocument2 pagesAssociation of Ions and Fractional Crystallization: General Chemistry ExperimentCaca MenNo ratings yet

- Introduction To NMR Spectroscopy: Part II (C-NMR)Document21 pagesIntroduction To NMR Spectroscopy: Part II (C-NMR)andi evi febriantiNo ratings yet

- Periodic Properties of Elements - JEE NotesDocument31 pagesPeriodic Properties of Elements - JEE NotesKrishna RaajanNo ratings yet

- Ways of Expressing Concentrations of SolutionsDocument28 pagesWays of Expressing Concentrations of Solutionspaguyojayjay75No ratings yet

- Chemtex Speciality Limited Offers Wide Range of Corrosion Inhibitors For Industrial UsageDocument6 pagesChemtex Speciality Limited Offers Wide Range of Corrosion Inhibitors For Industrial UsagesinughoshNo ratings yet

- Golden Rain 2022YDocument18 pagesGolden Rain 2022YShrijithNo ratings yet

- 04 QuizDocument5 pages04 QuizMani MuruganNo ratings yet

- Lab Lecture 1Document13 pagesLab Lecture 1shiamNo ratings yet

- June 2016 (IAL) QP - Unit 3 Edexcel ChemistryDocument16 pagesJune 2016 (IAL) QP - Unit 3 Edexcel ChemistryKithnula KitulagodaNo ratings yet

- Biology FSC Chapter 2Document15 pagesBiology FSC Chapter 2Diana PriyaNo ratings yet

- JACS, Vol. 108, 1986, 452Document10 pagesJACS, Vol. 108, 1986, 452rrgodboleNo ratings yet

- ARTICLEJMSrev Macromolchemphys HEMA1992Document35 pagesARTICLEJMSrev Macromolchemphys HEMA1992Milda Syakilla ZaharaNo ratings yet

- Evaluation of A Synthesis Process For The Production of Calcium Nitrate Liquid FertilizerDocument6 pagesEvaluation of A Synthesis Process For The Production of Calcium Nitrate Liquid FertilizerLeandro QuevedoNo ratings yet

- Table of Common Functional GroupsDocument11 pagesTable of Common Functional GroupsSarah MorenoNo ratings yet

- Question Bank 3051Document3 pagesQuestion Bank 3051Ashish AmbekarNo ratings yet