Professional Documents

Culture Documents

AgilePID - User Manual - Ver10 - 20210113

Uploaded by

Raj GaneshOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

AgilePID - User Manual - Ver10 - 20210113

Uploaded by

Raj GaneshCopyright:

Available Formats

Sineng Electric Co., Ltd.

AgilePID

User Manual

Sineng Electric Co., Ltd.

Data Version A01

Filing Date: January 13, 2021

BOM Code 28010080

AgilePID User Manual A00 1

Sineng Electric Co., Ltd.

The manual is applicable to AgilePID products of Sineng Electric Co., Ltd.

The manual uses the labels shown in the following table for different purposes, and different labels

may be used in combination.

Identification sign Identification definition

Warning signs that need attention

Danger of electric shock that may cause personal

injury

Dangerous! Please take care

This manual will be upgraded irregularly due to product upgrade and other reasons, without prior

notice.

The copyright of this manual is reserved by Sineng Electric Co., Ltd., and reproduction is prohibited

without authorization.

AgilePID User Manual A00 2

Sineng Electric Co., Ltd.

Safety Precautions

This manual contains important precautions and instructions that must be observed during installation,

operation and maintenance of AgilePID products, and you must read this manual carefully before

installation.

Warning

Install AgilePID products in strict accordance with the instructions in this manual, otherwise

it may cause equipment damage or endanger the safety of operators!

The AgilePID product must be installed, debugged and maintained by the engineer appointed

by the manufacturer or its agent, otherwise it may endanger personal safety and cause equipment

failure. Equipment damage caused by this is not covered by warranty.

Operators shall be fully familiar with the relevant standards and operational safety regulations

of their region/country, and operate according to relevant regulations.

Make sure to read this manual and the surface safety signs and instructions of AgilePID

products carefully before doing any operations on AgilePID products.

Danger

The AgilePID products must be grounded reliably. Grounding of equipment must comply

with local electrical regulations. Otherwise, it will endanger the personal safety of operators

There is dangerous voltage inside AgilePID products during normal operation! Do not

disassemble the internal cover without authorization or permission, so as to avoid equipment

damage or personal injury!

AgilePID User Manual A00 3

Sineng Electric Co., Ltd.

Contents

Chapter I Product Introduction ............................................................................................................................. 6

1.1 Product Functions ...................................................................................................................................... 6

1.2 Appearance Introduction .......................................................................................................................... 6

1.2.1 Brief introduction of appearance ...................................................................................................... 6

1.2.2 Description of panel indicator light .................................................................................................. 7

1.2.3 Nameplate and label.......................................................................................................................... 7

1.3 System Application .................................................................................................................................... 8

Chapter II Product Installation .............................................................................................................................11

2.1 Storage before Installation .......................................................................................................................11

2.2 Handling and Packaging Disassembly ....................................................................................................11

2.3 Product Installation ..................................................................................................................................11

2.3.1 Installation tools...............................................................................................................................11

2.3.2 Installation environment requirements ............................................................................................11

2.3.3 Installation angle ............................................................................................................................. 12

2.3.4 Installation requirements................................................................................................................. 12

Chapter III Electrical Connection........................................................................................................................ 14

3.1 Connecting Protective Grounding Wire ................................................................................................ 14

3.2 Connecting AC Cables ............................................................................................................................. 16

3.3 Connecting the Communication Cable .................................................................................................. 17

3.4 Checking after Installation ..................................................................................................................... 19

Chapter IV Product Operation............................................................................................................................. 20

4.1 On-off Operation ..................................................................................................................................... 20

4.1.1 Start-up operation ........................................................................................................................... 20

4.1.2 Shutdown operation ........................................................................................................................ 20

4.2 Disconnection ........................................................................................................................................... 20

Chapter V Product Specifications ........................................................................................................................ 21

5.1 General Parameters ................................................................................................................................. 21

5.2 Electrical Characteristics (Input) ........................................................................................................... 21

5.3 Electrical Characteristics (Output) ........................................................................................................ 21

5.4 Electrical Characteristics (System Characteristics) ............................................................................. 21

Chapter VI Product Maintenance ........................................................................................................................ 22

AgilePID User Manual A00 4

Sineng Electric Co., Ltd.

Introduction to the Manual

Please read this manual completely before unpacking and installing the product. This

manual contains the following chapters:

Label Description - This chapter summarizes various labels appearing in the manual and

explains them for better reading.

Safety Precautions - important safety precautions before operation.

Chapter I Product Introduction - This chapter briefly describes PID products and

working principle.

Chapter II Product Installation - This chapter introduces the storage conditions,

handling instructions and installation instructions required for reliable operation of PID

products.

Chapter III Electrical Connection - This chapter provides corresponding instructions for

connecting PID products to external power cables, communication cables, protective

grounding cables and functional grounding cables.

Chapter VI Product Operation - This chapter introduces the on-off and off-line

operation of PID products.

Chapter V Product Specifications - This chapter provides the specifications and

parameters of PID products.

Chapter VI Product Maintenance - This chapter introduces the maintenance of PID

products, including periodic maintenance and routine maintenance.

After-sales Service Information - This chapter provides contact information for

after-sales service of products.

AgilePID User Manual A00 5

Sineng Electric Co., Ltd.

Chapter I Product Introduction

1.1 Product Functions

The AgilePID of this product aims at the PID (potential induced degradation) problem in photovoltaic power generation

system, and may automatically adjust the rising voltage of PID device to raise or lower the PV- to-ground potential

according to the panel voltage and inverter state, thereby suppressing the PID effect of the panel. The application of this

product may significantly increase the power generation of the power station.

1.2 Appearance Introduction

1.2.1 Brief introduction of appearance

Figure 1-1 Overall Dimensions and Appearance

Table 1-1 Description of Agile PID Outline Structure

S/N Name S/N Name S/N Name

Upper cover plate of

① Upper cover plate ② auxiliary cabin

③ Chassis support foot

External grounding

④ Top lug ⑤ Nameplate ⑥ point

⑦ Switch ⑧ Ac input cable lock ⑨ AC output cable lock

Communication

⑩ cable lock

⑪ Breather valve

AgilePID User Manual A00 6

Sineng Electric Co., Ltd.

1.2.2 Description of panel indicator light

Table 1-2 Description of Panel Indicator Light

Symbol Color State Meaning

ON Working

Green Flickering Standby

OFF Not working

Flickering Communication normal

Blue OFF No communication

ON Equipment abnormality

Red Flickering Abnormal AC side

OFF No abnormalities

1.2.3 Nameplate and label

Figure 1-2 Nameplates and Labels

Table 1-3 Marking Instructions

S/N Indication Name Meaning

① PID product model

② Main technical parameters

If the user intends to discard this product, it must be

③ EU WEEE label sent to an appropriate place for recovery and

recycling, and cannot be treated as domestic garbage.

PID products belong to power electronic products,

especially after power-on, there will be potential risks,

④ Danger warning

which must be operated by professionals, and safety

protection shall be done well.

Professionals shall refer to the user manual when

⑤ Check the user manual label

installing or maintaining PID products.

AgilePID User Manual A00 7

Sineng Electric Co., Ltd.

PID products may only be discharged to safe voltage

Indication of delayed electric

⑥ discharge

after being powered down for 10 minutes, and

professionals may operate them.

⑦ Serial No. PID product serial number information

Scan the QR code and follow the WeChat official

⑧ QR code

account of Sineng Electric Co., Ltd.

⑨ Manufacturers’ information Manufacturer’s name & address

1.3 System Application

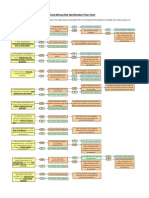

AgilePID products are generally used in conjunction with intelligent subarray controllers, which may take power from

PID products. This product supports the application of double winding transformer (PV sub-lineup ≤12.5MW) and double

split transformer (PV sub-lineup ≤25MW). In the double winding transformer scenario, a PID product is configured and a

knife fuse switch is reserved on the low voltage bus. In the double split transformer scenario, two PID products are

configured, and two knife melting switches are reserved on the low voltage bus. The working principles of double

winding and double split transformer scenes are shown in Figures 1-3 and 1-4.

This product supports inverter systems with three-phase AC voltages of 500VAC, 540VAC, 630VAC and 800VAC and

DC side voltages of 1000V, 1100V and 1500V.

This product is only applicable to IT systems, that is, there is no electrical connection between AC side and DC side and

the ground. It is forbidden to connect the neutral lines of inverter and AC distribution cabinet, otherwise there will be high

voltage danger. When the AC side is connected, the AC input cable needs to be directly connected with the bus bar on the

low voltage side of the box transformer, and it is forbidden to connect with the built-in isolation transformer of the box

transformer.

When applying PID products, it is necessary to pay attention to the selection of lightning arresters on the low voltage side

of AC bus box and box transformer. The selection requirements are shown in Table 1-4:

Table 1-4 Requirements for Type Selection of Lightning Protector

Maximum continuous operation voltage of

Rated voltage Wiring method

lightning arrester

500VAC

≥385V AC

540VAC 3+1 connection mode

800VAC ≥750V AC

Note: varistor is selected as lightning protector, and gas discharge tube is prohibited

AgilePID User Manual A00 8

Sineng Electric Co., Ltd.

SAU

RS485

数

P

/PLC

Data collector

据 I

采

集

D

器 1

Middle voltage

中压电网

1 network

逆变器

Inverter

…… 交流汇流箱

AC combiner

box

n

逆变器

Inverter

Figure 1-3 Working Principle of Double Winding Transformer

SAU

数

P P

RS485 I I

collector

据

Data

/PLC 采

集

D D

器 2 1

Middle voltage

1 AC combiner 中压电网

逆变器

Inverter 交流汇流箱 network

box

……

n

逆变器

Inverter

1 AC combiner

逆变器

Inverter 交流汇流箱

box

……

n

逆变器

Inverter

Figure 1-4 Working Principle of Double Split Transformer

AgilePID User Manual A00 9

Sineng Electric Co., Ltd.

Bus bar 1 of Three-phase

box air switch 1

transformer

PGND

Functional

grounding

Sub-array

controller

Bus bar 2 of box Three-phase

transformer air switch 2

Communication Grounding

AC cable cable cable

Figure 1-5 Wiring Diagram of Double Split Transformer

AgilePID User Manual A00 10

Sineng Electric Co., Ltd.

Chapter II Product Installation

This chapter introduces the on-site environmental conditions, installation steps and other relevant instructions required for

the storage and reliable operation of PID products.

2.1 Storage before Installation

Warning

PID products shall be stored indoors, and the package shall be complete. It is strictly forbidden to store PID products

without packaging, otherwise the damage, service life reduction or other losses of PID products caused by this will have

nothing to do with our company.

It is forbidden to stack more than 3 units! It is forbidden to store PID products horizontally or upside down!

PID products shall be stored in the temperature range of -40 ~ 70℃, relative humidity of 0 ~ 100% and no condensation.

2.2 Handling and Packaging Disassembly

Warning

Before handling, make sure that the packaging of PID products is complete and undamaged! If the package is damaged,

please stop the follow-up operation! And contact our company or freight company.

Please carefully observe the instructions and warning signs on PID product packaging before operation!

Please keep balance when disassembling and handling PID products, so as to avoid personal injury caused by falling.

When PID products are placed on the ground, cushion materials such as foam or paper skin shall be placed at the bottom

to avoid damaging the shell.

Unpack PID products according to the steps in fig. 2-1, and place the taken-out products in a flat environment to avoid

inclination or impact.

Fig. 2-1 Schematic Diagram of PID Product Disassembly and Packaging

2.3 Product Installation

Warning

Before installation, make sure that the packaging of PID products is complete and undamaged!

2.3.1 Installation tools

S/N Name S/N Name S/N Name

① Tool knife ② Tape measure or level ③ Marking pen

Cross screwdriver: M3,

④ Electric drill (bit Ф12/Ф14) ⑤ Hexagon wrench M6 ⑥ M4, M5, M6, M8

Hexagon socket wrench M8,

⑦ M10

⑧ Diagonal pliers ⑨ Wire stripper

Wire pressing pliers Wrench for removing DC plug Multimeter (measuring

⑩ (H4TC0001)

⑪ terminal (H4TC0001)

⑫ range ≥1500V)

Wire clamp (output cable Heat shrinkable sleeve,

⑬ terminal, etc.)

⑭ insulating tape

⑮ Heat gun

Note: Operators need to bring their own insulating shoes, insulating gloves, dust masks and protective glasses

2.3.2 Installation environment requirements

● The protection level of PID products is IP65, which may be installed indoors and outdoors.

AgilePID User Manual A00 11

Sineng Electric Co., Ltd.

● The installation area of PID products shall be far away from flammable, explosive and high-voltage interference

equipment.

● The mounting frame or wall of PID products shall have certain fireproof performance.

2.3.3 Installation angle

When installing PID products, please be vertical to the ground and install them forward.

Vertical Tilt back Upside down Lean forward

Figure 2-2 Schematic Diagram of Installation Angle of PID Products

2.3.4 Installation requirements

See Figure 2-3 for the dimensions of PID product installation backplane:

The installation process of PID product bracket is shown in Figure 2-4. According to the installation dimension drawing,

measure the position of installation hole on the bracket and mark it with a marker pen; use a ф10 drill bit to drill holes at

the positions marked by the marker pen; pre-tighten the bracket with two M8 combination bolts; hang the PID product on

the combination bolt and tighten it; take two M8 combination bolts to fasten the chassis support foot on the bracket, and

the installation is completed.

Figure 2-3 Installation Dimension Drawing

AgilePID User Manual A00 12

Sineng Electric Co., Ltd.

Draw dot Draw dot Pre-installed bolt

Tighten the fixing Secure the bottom

Take out the machine lug bolts support bolt

Figure 2-4 Schematic Diagram of PID Product Bracket Installation

Note: 1. The combined bolt here needs two flat pads and one elastic pad, and a flat pad is placed between the nut and the

bracket to increase the contact area, thus increasing the fastening reliability.

2. M8×60 combination bolts are provided in the accessory package of the product. If the length cannot meet the

installation requirements, users shall bring their own M8 combination bolts.

3. If it is installed against the wall, the customer shall bring four M8 expansion bolts.

4. It is recommended that the bearing capacity of the bracket be ≥100KG.

AgilePID User Manual A00 13

Sineng Electric Co., Ltd.

Chapter III Electrical Connection

Danger

Insulation layer of power cable must be kept intact, without damage and scratch. Otherwise, it may lead to short circuit and

fire!

Before connecting PID products, it must be checked and confirmed that all connecting cables of the equipment are free of

dangerous voltage, and obvious warning signs must be set at the external distribution switches of the equipment to avoid

misoperation of the external switches of the equipment and threaten the personal safety of operators!

Before connecting PID products, make sure that the AC connection port is disconnected from the power grid and there is no

voltage at the AC port!

Warning

Cable connection shall be carried out in strict accordance with the labels in PID products, otherwise the equipment will be

damaged.

Cable connection of PID products must be safe and reliable. Cable selection and tightening torque must meet the

requirements of this manual, otherwise it may lead to fire and equipment damage.

Operators shall not open the upper cover of the main cabin without permission. If the tamper-proof label is torn and PID

products are damaged, it will not be covered by our warranty.

When the operator opens the upper cover of the wiring compartment, please pay attention to the foaming of the upper cover,

and do not scratch or damage it, otherwise it will cause the PID product to enter the water.

Please try not to open the connection compartment of PID products in rain and snow to avoid the risk of water ingress.

Table 3-1 List of User Operation Cables for PID Products

User cable classification Cable function description Remarks

Protective grounding cable Grounding cable Approximate grounding

AC input cable Connect the box transformer to the input side of PID Armored multi-strand cable

products

Communication cable RS485 communication signal cable Shielded cable

3.1 Connecting Protective Grounding Wire

Warning

PID products must be grounded reliably, otherwise it will cause personal injury or abnormal operation of the products!

PID products need to be grounded nearby, and the connection steps of protective grounding wire are as follows:

(1) Before PID product installation, lead the ground wire from the ground wire bus to the product

installation position;

(2) Use wire stripping pliers to strip a section of bare copper core from the ground wire with

corresponding specifications, and the length of bare copper core is 3 mm longer than the terminal of OT

terminal;

(3) Crimp the OT terminal to the bare copper core with wire crimping pliers;

(4) Heat shrinkable sleeve with suitable size is sleeved on the terminal of OT terminal, and the

length is generally recommended to be 1.5-2 times of the terminal;

(5) Blow the heat shrinkable sleeve tightly with a hot air gun to wrap the terminal and cable tightly,

and the cable is manufactured (the manufacturing process is shown in Figure 3-2);

(6) Fasten the OT terminal of grounding wire at the grounding interface with M6 screws. Please

refer to Table 3-2 for fastening torque.

AgilePID User Manual A00 14

Sineng Electric Co., Ltd.

Figure 3-1 Schematic Diagram of Protective Grounding Wire Connection

Note:

After the grounding terminal is fastened, it is recommended to apply silica gel or brush outdoor paint on the outside

of the terminal to improve the anticorrosion performance of the terminal.

OT Heat-shrin

terminal kable

sleeve

Ground

wire

Wire stripping Tighten the heat

Line pressing

shrinkable sleeve

Figure 3-2 Schematic Diagram of Cable Making (OT terminal)

Note:

1. Users need to prepare OT terminals, cables and heat shrinkable sleeves for protecting grounding wires by

themselves.

2. Users need to use tools--diagonal pliers, wire stripping pliers, wire pressing pliers, hot air gun and M6 Phillips

screwdriver.

Table 3-2 Recommended Table for Specifications of Protective Ground Wire Cable

Cross-sectional

Conductor area of Terminal

Cable type Tightening torque (N.m)

attribute conductor specifications

(mm2)

Copper core

Protective grounding cable ≥10 OT terminal: 5

wire

Note: All copper core wires are multi-stranded.

AgilePID User Manual A00 15

Sineng Electric Co., Ltd.

3.2 Connecting AC Cables

Warning

The lock head and fixing screw of AC cable must be tightened, otherwise there is a risk that PID products will be

damaged or caught fire!

When connecting the AC cable, make sure that the AC circuit breaker is open!

The specific connection steps of AC cable are as follows:

(1) Remove the cable lock on AC side and the tail plug;

(2) Pass the cable through the waterproof cable lock, as shown in Figure 3-3;

(3) Use wire stripping pliers to strip the insulation layer and cable sheath according to the dimensions

shown in Figure 3-3-○

1 -○

2 , and select the corresponding terminal according to the cable used to make

the AC output cable, where two layers of heat shrinkable sleeves are required. Refer to Figure 3-2 for the

cable making process;

(4) Connect the AC cable from the low-voltage distribution cabinet to the left terminal block L1/L2/L3

through the AC INPUT cable lock. Refer to Table 3-2 for the fastening torque of the terminal fastening

screws;

(5) Connect the PE on the terminal block to the block for low-voltage distribution function;

(6) After the connection is completed, tighten the plastic nut at the tail of the cable lock to ensure

waterproof;

(7) Repeat the above steps to connect the right terminal block L1/L2/L3 with the subarray controller input

by using AC cable. After the connection is completed, tighten the plastic nut at the tail of the cable lock to

ensure waterproof.

AgilePID User Manual A00 16

Sineng Electric Co., Ltd.

Making AC input Making AC output

cable cable Open the top cover

Passing through the cable

lock and pre-locking Installing AC cable

Sub-array

controller

Three-phase

air switch

Rubber rings must be

installed correctly

Figure 3-3 Cable Connection on AC Side

Note:

1. Cable terminals shall be installed along the direction of terminal row;

2. Users need to provide their cable and heat shrinkable sleeve for AC input line.

3. Users need to use tools-diagonal pliers, wire stripping pliers, wire pressing pliers, hot air gun, M8

screwdriver and M8 outer hexagonal sleeve.

Table 3-3 AC Cable Specification Recommendation Table

Withstand Outside

Cable Conductor Cross-sectional area Terminal Tightening

voltage of cable diameter of

type attribute of conductor (mm2) specifications torque (N.m)

(V) cable (mm)

Ac ≥1.2* rated

Copper core L1\L2\L3:10

power voltage of Tubular terminal 1.2

wire PE:10

cable three-phase AC

3.3 Connecting the Communication Cable

Warning

Please connect the communication cable strictly according to the PID product communication port label!

PID products need to be connected with the 8th 485 of intelligent subarray controller through RS485 communication port

(A+/A-). It is recommended to use double-core reinforced insulated cable with shielding layer, which is fastened to the

grounding point. Connect the communication cable as follows:

(1) Remove the lock head of communication cable and the tail plug;

(2) Pass the communication cable through the cable lock;

(3) Use wire stripping pliers to strip off the insulation and protective layer of the cable as shown in Figure

3-4- ○

1 ; select an OT terminal with a suitable size to make a communication cable. The shielding layer

AgilePID User Manual A00 17

Sineng Electric Co., Ltd.

needs to be wrapped with insulating tape, and the end is reserved with 15mm for fixing screws;

(4) There is a 6-bit terminal row on the communication board near the machine inlet, which is marked with

DO+/DO-,A+/A-, B+/B- from left to right (as shown in Figure 3-4);

(5) Connect the completed communication cable to the corresponding terminal and fasten it with a Phillips

screwdriver. Refer to Table 3-2 for the fixed torque. The shielding layer is directly locked at the grounding

point with a torque of 1.4N.M;

(6) After the connection is completed, tighten the plastic nut at the tail of the cable lock to ensure

waterproof.

Table 3-4 Recommendation Table of Communication Cable Specifications

Cross-sectional Outside

Conductor Terminal Terminal Tightening

Cable type area of conductor diameter of

attribute specifications width (mm) torque (N.m)

(mm2) cable (mm)

Communication Double-core

≤6.5 0.8

cable copper wire

Note:

1. Users need to bring their own communication cables, OT terminals, heat shrinkable sleeves and

insulating tapes.

2. Users need to use tools-diagonal pliers, wire stripping pliers, wire pressing pliers, hot air gun and

M3\M4 Phillips screwdriver.

3. The copper wire of the shielding layer of communication cable needs to be arranged and wrapped with

insulating tape, so please ensure that the distance between the exposed copper wire and electronic components

is greater than 15mm.

Making signal cable Open the top cover Passing through the cable

lock and pre-locking

Insulation

tape

Rubber rings must be

installed correctly

Installing communication cable

Sub-array

controller

Figure 3-4 Schematic Diagram of Communication Cable Installation

AgilePID User Manual A00 18

Sineng Electric Co., Ltd.

3.4 Checking after Installation

S/N Inspection item Inspection result: Yes√/No×

1 Check whether the switch is in "OFF" state. □

Check whether the PID products are installed firmly and whether the screws

2

on both sides of the installation backboard are fastened. □

3 Check whether operating tools and unused screws are left in the cabin. □

Check whether the external grounding wire is connected correctly, whether

4 the terminals are fastened and whether the grounding is reliable, so as to □

ensure no open circuit or short circuit.

Check whether the AC input cable is connected correctly and the terminals

5

are fastened to ensure no open circuit or short circuit. □

Check whether the communication cable is connected correctly and the

6

terminals are fastened to ensure no open circuit or short circuit. □

Check whether the plastic nuts on the AC side and the tail of RS485 cable

7 lock are tightened, and whether they have been sealed (such as fireproofing □

mud) when a single cable cannot be tightened.

Check whether the waterproof plug at the tail of the cable lock which is not

8

needed is inserted properly, and whether the nut at the tail is locked tightly. □

Check whether the upper cover of the junction box is installed in place and

9

whether the screws are tightened. □

AgilePID User Manual A00 19

Sineng Electric Co., Ltd.

Chapter IV Product Operation

Danger

Non-professionals shall not open the panel of PID products, because there is a danger of high voltage!

When PID products work normally, there is dangerous voltage in the equipment! Be sure to operate PID products

according to the instructions in this manual!

Only professionals may operate PID products, and others are not allowed to operate without authorization!

4.1 On-off Operation

4.1.1 Start-up operation

Please confirm the following items before powering on PID products for the first time:

(1) The installation site environment meets the relevant requirements in Chapter II of this manual;

(2) The connection of input and output power cables, communication cables and ground cables shall meet

the requirements of Chapter III of this manual;

(3) The box transformer breaker connected with the AC side of PID products is in disconnected state;

(4) Turn the knob switch to the "OFF" position;

(5) The voltage and frequency of the access point shall be measured before starting up to ensure that the

grid-connected specifications of PID products meet the requirements of Chapter VI.

After meeting the above conditions, start the machine according to the following steps:

(1) Close the circuit breaker connected between the box transformer and PID products;

(2) Turn the knob switch to the "ON" position;

(3) The connection with PID products is established through 485 communication. If the PID products have

no fault and alarm information, the PID products will be automatically turned on and connected to the grid

without human intervention; if PID products have fault and alarm information, please contact customer

service personnel.

4.1.2 Shutdown operation

Shut down as follows:

(1) Perform shutdown operation through 485 communication or other communication methods;

(2) Disconnect the circuit breaker connecting the box transformer and PID products;

(3) Turn the PID product SWITCH to "OFF".

4.2 Disconnection

Before performing the disconnection operation on PID products, it is necessary to ensure that the PID products are in a

complete power-down state. The operation steps are as follows:

(1) Disconnect the circuit breaker connected between the box transformer and PID products, and make

warning signs to prevent other people from misoperation!

(2) Remove waterproof parts with the words "AC INPUT" and "AC OUTPUT" on the AC side, remove AC

power lines and functional grounding lines, and properly handle the removed power cables.

(3) Remove waterproof parts of communication ports and communication cables, and properly handle the

removed communication cables.

(4) Remove protective grounding wire.

AgilePID User Manual A00 20

Sineng Electric Co., Ltd.

Chapter V Product Specifications

5.1 General Parameters

Table 5-1 General Parameters

Item Specification

Model AgilePID

Dimension 475 (width) ×602 (height) × 173 (thickness)

Net weight 15kg

Working temperature -30~60℃

Storage temperature -40~70℃

Relative humidity 0~100%, no condensation

Altitude 4000m (it may be operated at 5000m altitude)

Class of pollution Class III

5.2 Electrical Characteristics (Input)

Table 5-2 AC Input

Item Specification

Input rated voltage 500VAC/540VAC/630VAC/800VAC

Startup voltage 400 VAC

Network type IT

Output working voltage range -20%~+15%

Max. input current 0.5 Aac

Rated frequency 50 Hz /60 Hz

Maximum supported square matrix power 12.5MW (double winding) /25MW (double split)

5.3 Electrical Characteristics (Output)

Table 5-3 AC Output

Item Specification

Max. output current 1.1 Adc

Maximum output power

5.4 Electrical Characteristics (System Characteristics)

Table 5-4 System Characteristics

Item Specification

Standby power consumption <5 W

Display the operation interface Indicator light

Insulation resistance >10 MΩ(1000Vdc)

IP grade IP65

Incoming line mode Down-in and down-out

AgilePID User Manual A00 21

Sineng Electric Co., Ltd.

Chapter VI Product Maintenance

This chapter introduces the maintenance of PID products, including the maintenance cycle and maintenance methods of

PID products. Please read the instructions in this section carefully before maintaining PID products.

Danger

Professionals may maintain PID products, and others are not allowed to operate without authorization!

In order to ensure the safety of maintenance personnel, it is not allowed to touch any live parts of PID products when they are

running, and it is necessary to check whether the grounding points of the products are connected reliably.

Please use the qualified spare parts provided by our company. If the equipment is damaged due to the use of spare parts not

provided by our company, it has nothing to do with our company.

Unauthorized or licensed disassembly of PID products may cause equipment damage. This kind of equipment damage has

nothing to do with our company!

Periodic inspection and maintenance of PID products may confirm the status of PID products in time and improve the

working reliability of PID products. The periodic check list is shown in Table 6-1.

Table 6-1 Periodic Checklist

Inspection content Method Inspection cycle

Cable connection Check whether the AC/DC cables are connected Once every six months

reliably, damaged and whether the waterproof locks

are tightened;

Check whether the grounding wire is connected

reliably.

AgilePID User Manual A00 22

Sineng Electric Co., Ltd.

After-sales Service Information

Sineng Electric Co., Ltd. provides customers with all-round technical support. Users

may contact the nearest Sineng Electric Co., Ltd. office or customer service center, or

directly contact the company headquarters.

Sineng Electric Co., Ltd.

Address: No.6 Hehui Road, Huishan Economic Development Zone, Wuxi city, Jiangsu

province

Post Code: 214174

Customer Service Hotline: 0510-88888118

Fax: 0510-85161899

AgilePID User Manual A00 VI

Sineng Electric Co., Ltd.

Product Warranty Card

Thank you for choosing PID products produced by our company.

Project Model:

Factory No.:

Please refer to the instructions in the User Manual for the specifications, implementation

standards and technical conditions of this product.

This product is guaranteed for ___ year(s). During the warranty period, our company

will provide free component repair or replacement services for failures caused by

non-human causes and irresistible factors (including but not limited to earthquakes,

mudslides, floods, typhoons and wars).

User Name:

User Address:

Contact:

User Phone Number:

E-mail:

Sineng Electric Co., Ltd.

Address: No.6 Hehui Road, Huishan Economic Development Zone, Wuxi city, Jiangsu province

Post Code: 214174

Customer service Hotline: 0510-88888118

Fax: 0510-85161899

Website: www.si-neng.com

AgilePID User Manual A00 VII

You might also like

- Contractor Permit To WorkDocument2 pagesContractor Permit To WorkAndri Mujahidin75% (4)

- 02-7. MT (Modbus - TCP) - MOO-ARIOCMTU-V1.1-1905US - W (Modbus Add)Document29 pages02-7. MT (Modbus - TCP) - MOO-ARIOCMTU-V1.1-1905US - W (Modbus Add)kanasaiNo ratings yet

- DlmsDocument102 pagesDlmsRaj Ganesh100% (4)

- Euro StandardDocument21 pagesEuro Standardllauro2010No ratings yet

- Autonics CX Series - User ManualDocument87 pagesAutonics CX Series - User ManualEldglay da Silva DomingosNo ratings yet

- sdc10 PDFDocument38 pagessdc10 PDFjroyal692974100% (1)

- Dell 2209WA Service Manual Rev 1.0Document85 pagesDell 2209WA Service Manual Rev 1.01133523568585No ratings yet

- VG User en 190129 WDocument126 pagesVG User en 190129 WaluiziojoseNo ratings yet

- Manual - Autonics Vision Sensor VGDocument124 pagesManual - Autonics Vision Sensor VGMuhammad Imam MuthahharNo ratings yet

- User's Manual: Model ISC450G Inductive Conductivity Converter (Style: S2)Document81 pagesUser's Manual: Model ISC450G Inductive Conductivity Converter (Style: S2)Roger Molina GomezNo ratings yet

- Distributed Busbar Protection REB500: Commissioning ManualDocument26 pagesDistributed Busbar Protection REB500: Commissioning ManualaladiperumalNo ratings yet

- User Manual: PrefaceDocument92 pagesUser Manual: PrefaceJosé Gregorio González TorresNo ratings yet

- NVC DCP551B Um CP SP 1032e 18Document220 pagesNVC DCP551B Um CP SP 1032e 18johnductamNo ratings yet

- CITA 60-180 DC User Manual V1-1Document35 pagesCITA 60-180 DC User Manual V1-1ahmed banaNo ratings yet

- ELD5 User Manual Ver1.00Document81 pagesELD5 User Manual Ver1.00MechanicalEngineNo ratings yet

- Module Manual - MOO-ARIOMU-V1.1-2305US - 230519 - WDocument35 pagesModule Manual - MOO-ARIOMU-V1.1-2305US - 230519 - WMark BukerNo ratings yet

- 670/650 Series Version 2.2 ANSI: Quick Start GuideDocument48 pages670/650 Series Version 2.2 ANSI: Quick Start GuideDiego dos Santos AmaralNo ratings yet

- Im11g02q02 51en PDFDocument45 pagesIm11g02q02 51en PDFsagar_ovhalNo ratings yet

- ENC 4P H264 - InstallGuideDocument144 pagesENC 4P H264 - InstallGuideDaniel GarnicaNo ratings yet

- Tai Lieu Man Hinh HMI AutonicsDocument80 pagesTai Lieu Man Hinh HMI AutonicsViệnVuiVẻNo ratings yet

- ATV FB Manual V209 EN PDFDocument90 pagesATV FB Manual V209 EN PDFAlejandro Alberto Robalino MendezNo ratings yet

- RE - 620 - Engineering Maunal PDFDocument128 pagesRE - 620 - Engineering Maunal PDFUzair HussainNo ratings yet

- ASI7213Y-V3-T1 User ManualDocument80 pagesASI7213Y-V3-T1 User ManualXmi Note9No ratings yet

- Konica Minolta QMS Magicolor 61x0 Service ManualDocument446 pagesKonica Minolta QMS Magicolor 61x0 Service ManualHiram SoberanesNo ratings yet

- 02 8. MR (Modbus Rtu) - Moo Ariocmru v1.1 1905us - WDocument28 pages02 8. MR (Modbus Rtu) - Moo Ariocmru v1.1 1905us - Wjohanes kharismaNo ratings yet

- DMC8000 Video Wall Controller Quick Guide-V1.00Document23 pagesDMC8000 Video Wall Controller Quick Guide-V1.00Birthley RagasaNo ratings yet

- Instruction Manual: Frequency Response AnalyzerDocument145 pagesInstruction Manual: Frequency Response AnalyzerWuzekNo ratings yet

- SRA - 8601A 1 en 2Document36 pagesSRA - 8601A 1 en 2RobertNo ratings yet

- eVD4 - Breaker Integrated Protection RBX615 - Engineering Guide PDFDocument56 pageseVD4 - Breaker Integrated Protection RBX615 - Engineering Guide PDFHans MortenNo ratings yet

- m700 Serie PLC Interface Manual - Ib-1500001 (Eng) BDocument460 pagesm700 Serie PLC Interface Manual - Ib-1500001 (Eng) Bmyoppok8No ratings yet

- Digital Indicator Model DI25: Operating InstructionsDocument44 pagesDigital Indicator Model DI25: Operating InstructionsGoran NajdovskiNo ratings yet

- Autonics Ario Instruction ManualDocument31 pagesAutonics Ario Instruction ManualDiego F. GarnicaNo ratings yet

- GW - Lynx Home U Series (LV) User Manual-ENDocument34 pagesGW - Lynx Home U Series (LV) User Manual-ENJorge Garrido RedondoNo ratings yet

- Profibus-Dp Option Technical Manual: Models: CIMR-G5, F7, P7, G7 Document Number TM - AFD.12Document68 pagesProfibus-Dp Option Technical Manual: Models: CIMR-G5, F7, P7, G7 Document Number TM - AFD.12Luis Fernando Gomez SalasNo ratings yet

- RE 615ANSI Oper 050592 ENbDocument148 pagesRE 615ANSI Oper 050592 ENbPGNo ratings yet

- Autonics TK ManualDocument124 pagesAutonics TK ManualFathurrahman Yudhi NugrahaNo ratings yet

- Lantek2 Manual v1Document110 pagesLantek2 Manual v1Luciano BarbieratoNo ratings yet

- 615 Series Opertion ManualDocument140 pages615 Series Opertion Manualfiatraj1No ratings yet

- UTStarcom B820 DSLAM Product DescriptionDocument116 pagesUTStarcom B820 DSLAM Product DescriptionSanjeev GargNo ratings yet

- ION8800 User GuideDocument222 pagesION8800 User GuidebansalrNo ratings yet

- Relion 615 Series - IEC 61850 Engineering GuideDocument60 pagesRelion 615 Series - IEC 61850 Engineering GuidepjaengjaikulNo ratings yet

- Programming Manual: Programmable ControllerDocument257 pagesProgramming Manual: Programmable ControllerCRISENTENANo ratings yet

- TK - EN - User ManualDocument125 pagesTK - EN - User ManualHector CamachoNo ratings yet

- PWC 600Document404 pagesPWC 600edynperuNo ratings yet

- Saitel DP: M562x0000y / AB - ACDocument71 pagesSaitel DP: M562x0000y / AB - ACMurilo GeambastianiNo ratings yet

- 三菱 M700系列 设定说明书Document551 pages三菱 M700系列 设定说明书Sơn Nhất HàNo ratings yet

- Network Video Recorder (Smart, Mini, Compact, 1U) Series - QSG - V1.0.1Document24 pagesNetwork Video Recorder (Smart, Mini, Compact, 1U) Series - QSG - V1.0.1Usama MehboobNo ratings yet

- Vital Signs Monitor PC-900 User Manual Shenzhen Creative Industry Co., Ltd.Document49 pagesVital Signs Monitor PC-900 User Manual Shenzhen Creative Industry Co., Ltd.أياام زمانNo ratings yet

- ABB Drives: User's ManualDocument26 pagesABB Drives: User's Manualramana3339No ratings yet

- User Manual: Panel PCDocument38 pagesUser Manual: Panel PCMarcos De AlmeidaNo ratings yet

- TK XGB (Rs485)Document24 pagesTK XGB (Rs485)Jahidul IslamNo ratings yet

- ELD2-RS Series DC Servo Drive User Manual V1.0Document221 pagesELD2-RS Series DC Servo Drive User Manual V1.0T FunnyNo ratings yet

- Face Recognition Access Controller: User's ManualDocument79 pagesFace Recognition Access Controller: User's ManualOmar BotiaNo ratings yet

- User's Manual: Model SC450G Conductivity Converter (Style: S2)Document85 pagesUser's Manual: Model SC450G Conductivity Converter (Style: S2)CarlosAbreuNo ratings yet

- SIFANG CSC-326 V1.00 Numerical Transformer Protection Equipment Manual 2010-08Document211 pagesSIFANG CSC-326 V1.00 Numerical Transformer Protection Equipment Manual 2010-08MarkusKunNo ratings yet

- User Manual 32845Document120 pagesUser Manual 32845jbsoundjb1No ratings yet

- DM3000 User ManualDocument103 pagesDM3000 User ManualSampath WeerakkodiNo ratings yet

- Data SheetDocument44 pagesData SheetElizabeth QuevedoNo ratings yet

- User Manual For Communication: PrefaceDocument36 pagesUser Manual For Communication: PrefaceŞafakSelçukNo ratings yet

- Switchsync™ PWC600 Version 1.0: User ManualDocument260 pagesSwitchsync™ PWC600 Version 1.0: User Manualshikin jamilNo ratings yet

- Temperature Sensor With Solar Shield HSSR-01Document2 pagesTemperature Sensor With Solar Shield HSSR-01Raj GaneshNo ratings yet

- Atrh 23042108Document2 pagesAtrh 23042108Raj GaneshNo ratings yet

- TSCL 9.6Mwp ArchitectureDocument1 pageTSCL 9.6Mwp ArchitectureRaj GaneshNo ratings yet

- DPM 4415 Series LED Type V0-0521Document2 pagesDPM 4415 Series LED Type V0-0521Raj GaneshNo ratings yet

- WS24Document2 pagesWS24Raj GaneshNo ratings yet

- R For BeginnersDocument76 pagesR For BeginnersChiucheng LiuNo ratings yet

- Spike 23Document3 pagesSpike 23Raj GaneshNo ratings yet

- Remote Monitoring System For Transformer SubstationDocument3 pagesRemote Monitoring System For Transformer SubstationscribdkkkNo ratings yet

- mdt9 3 enDocument2 pagesmdt9 3 enRaj GaneshNo ratings yet

- Novel Nine-Switch PWM Rectifier-Inverter Topology For Three-Phase UPS Applications AbstractDocument3 pagesNovel Nine-Switch PWM Rectifier-Inverter Topology For Three-Phase UPS Applications AbstractRaj GaneshNo ratings yet

- Artificial Intelligence Techniques in Power SystemsDocument17 pagesArtificial Intelligence Techniques in Power SystemsRaj GaneshNo ratings yet

- Critical Risk Booklet - 3Document2 pagesCritical Risk Booklet - 3Sreejith SreekumarNo ratings yet

- Background of The StudyDocument3 pagesBackground of The Studyarnistina malbasNo ratings yet

- Occupational Safety and HealthDocument582 pagesOccupational Safety and HealthEliza_Sinta_2891100% (5)

- Safety Manual For LaboratoryDocument35 pagesSafety Manual For Laboratoryeuds100% (2)

- Nicosulfuron SDS, Safety Data SheetsDocument5 pagesNicosulfuron SDS, Safety Data Sheetsyanri cahyoNo ratings yet

- Htl4014 4017 Operator Manual - CompressedDocument232 pagesHtl4014 4017 Operator Manual - CompressedLhsan Rajawi100% (2)

- RPSG-IMS-HS-F - 01 - Hazard Observation CardDocument2 pagesRPSG-IMS-HS-F - 01 - Hazard Observation CardRocky BisNo ratings yet

- OHS-07 Personal Protective EquipmentDocument15 pagesOHS-07 Personal Protective EquipmentAshok PatelNo ratings yet

- Material Safety Data Sheet Zinc CarbonateDocument4 pagesMaterial Safety Data Sheet Zinc Carbonatefs1640No ratings yet

- Pocket Guide VibrationsDocument23 pagesPocket Guide VibrationsMani Rathinam RajamaniNo ratings yet

- Method Statement For Installation of PA SystemDocument2 pagesMethod Statement For Installation of PA SystemmujtiobamaliblNo ratings yet

- Indradrive MPX - 1xDocument90 pagesIndradrive MPX - 1xJonathan JonesNo ratings yet

- Nitobond HP EngDocument3 pagesNitobond HP EngthoufiqNo ratings yet

- Smi100406174 - 2.388 SDS 10115 Kopr-Kote® - SDS - Us - en - 2021-2-2Document8 pagesSmi100406174 - 2.388 SDS 10115 Kopr-Kote® - SDS - Us - en - 2021-2-2Luis Manuel Montoya RiveraNo ratings yet

- HBM ManualDocument132 pagesHBM ManualRiaz MuftiNo ratings yet

- Deif Parameter ListDocument132 pagesDeif Parameter Listfede_fab2009No ratings yet

- AluminumStearate30MSDS PDFDocument7 pagesAluminumStearate30MSDS PDFdr.tabitaNo ratings yet

- Chapter 2 Controls NewDocument46 pagesChapter 2 Controls NewNor Amirah RosliNo ratings yet

- A General Safety en 1Document67 pagesA General Safety en 1miguelNo ratings yet

- PTO - BrickworkDocument2 pagesPTO - BrickworkgrantNo ratings yet

- Coal Mining Risk Identification Flow ChartDocument1 pageCoal Mining Risk Identification Flow ChartZ Babar Khan100% (1)

- M Op. - SR14MADocument128 pagesM Op. - SR14MAFranco SartoriNo ratings yet

- Construction Safety in Design ProcessDocument8 pagesConstruction Safety in Design ProcessShahab HosseinianNo ratings yet

- KCC DATASHEET Technical Data Sheet Thinner-024 EngDocument2 pagesKCC DATASHEET Technical Data Sheet Thinner-024 EngIsabelo AbaoNo ratings yet

- خطة تطبيق برنامج سلامة الغذاء ايزو ٢٢٠٠٠ - ٢٠١٨-1Document8 pagesخطة تطبيق برنامج سلامة الغذاء ايزو ٢٢٠٠٠ - ٢٠١٨-1Hany Mohamed Abd ElwahabNo ratings yet

- Failure Mode, Effects, and Criticality AnalysisDocument8 pagesFailure Mode, Effects, and Criticality AnalysisFederico VillagránNo ratings yet

- Kaiser AS 36.8Document73 pagesKaiser AS 36.8mailomilena75% (4)

- BOSH-Safety Inspection PPT LectureDocument46 pagesBOSH-Safety Inspection PPT LectureReinier Harvey PabustanNo ratings yet