Professional Documents

Culture Documents

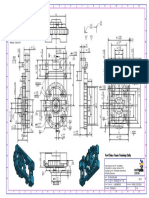

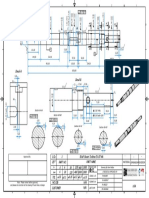

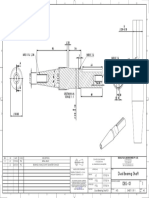

302 4 - 013288 - Z Parallel Pinion Gear DRAFT

Uploaded by

samyOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

302 4 - 013288 - Z Parallel Pinion Gear DRAFT

Uploaded by

samyCopyright:

Available Formats

1 2 3 4 5 6 7 8

1432 ±0.5

A

A

107.0 1138 ±0.1 187.0

85.0 300.0 505.0 248.0

0.02 A - B

X 0.02 A - B

3.2

3.2

0.02 A - B

R14.0

3.2

30.0 30° E R10.0

C

D

382.197

+0.079

240 p6 +0.050

+0.060

200 n6 +0.031

-0.036

170 p6 -0.061

423.0

182.0

280.0

H G

B

B

454.997

B

A

0.8

0.8

0.8

3.2

3.0 X 45° 2.0 X 45° 3.0 X 45° 3.2

R14.0

R14.0 E

13.0 0.02 A - B

SCALE 1 : 10

CASE HARDENING 6.3 +0.5

FT

Min Effective Depth = 1mm 276 0.0

0.02 A - B

C

C

N 3 M20 30 F 12

0.3 7.0 0° F

INVOLUTE CYLINDERICAL HELICAL GEAR R4.0 R3.0

5.0 0.3 0° N 3 M20 30

SYMBOL PARAMETER

VALUE

UNIT 12

°

PINION(1)

+0.060

200 n6 +0.031

15

15

RA

°

REFERENCE PROFILE DIN 3972/IIIP

+0.068

170 p6 +0.043

0.4

120°

ACCURACY CLASS ISO 328/6 8° 8°

120°

TEETH FINISHING TYPE GRINDING

0.5

m n NORMAL MODULE 16 mm

Z NUMBER OF TEETH 26 115.0

12

D

NORMAL PRESSURE ANGLE 20 deg 0° 115.0

D

αn °

β HELIX ANGLE 10 deg 120

UNDER CUT DETIAL F4x7 DIN 509 UNDER CUT DETIAL F3x5 DIN 509

HELIX DIRECTION LH F

DETAIL C DETAIL D F

dw

d

WORKING PITCH DIAMETER

REFERENCE PITCH DIAMETER

423.000

422.417

mm

mm

D

SCALE 2 : 1 SCALE 1 : 1 VIEW G VIEW H

da TIP DIAMETER 454.997 mm 240.0 H7/p6

df ROOT DIAMETER 382.197 mm

db BASE DIAMETER 396.223 mm 14.0

h TOOTH DEPTH 36.400 mm 1.5

56 P9

F FACE WIDTH 300.000 mm

E

a OPERATING CENTER DISTANCE 423.000 mm

E

120°

M30

31

3.2

60°

3.2

aref REFERENCE CENTER DISTANCE 422.417 mm DETAIL X

[ ] Unquoted Bevel

HOLES

mn R

ADDENDUM MODIFICATION 15° Machinings 12.5 0.8 3.2 6.3 Ch= 1*45° Unquoted Radius R= 0.5

X 0.0183 mm 2-3 0.5 3.0 54.0

COEFFICENT 3.5-6 1 R1.4

mn

k TIP-SHORTENING COEFFICIENT 0.000182922 mm 0.0

6.3

7-10 2

R

Y CENTER DISTANCE MODIFICATION 0.036408091 mm 11-15 3 220 -0.3

COEFFICIENT SECTION F-F

16-20 4

SCALE 1 : 2

MIN 0.26082

22-28

30-40

6

8

SECTION E-E 00 24/03/2022 ISSUED Amr M.Hegazy Amr M.Hegazy E.Ellakany

Jn NORMAL BACKLASH mm

MAX 0.38084 TEETH CHAMFER BEFORE HARDENING REV. Date Description: Drawn by: Revised By: Approved by:

Fp TOTAL PITCH ERROR 54 μm mn ch Target Section: HRM MAINTENANCE Plant: General Tolerances,

which are not stated are according to:

Fβ HELIX ERROR 25 μm Location: IIC

F

2-3 0.25 ISO 2768-1,Class: Medium

Chx45

F

Material 2:

Fa TOTAL PROFILE ERROR 27 μm 3.5-6 0.50

Material 1: 18CrNiMo7-6 EN10084

Assembly Name/Code:

GEAR UNIT FOR ESS 430/H RIGHT 8.030313.B

7-10 1.0 Material 1 Heat Treatment Material 1 Hardness

Scale:

1:5

Description: REV.

4.013287.Q 11-15 1.5 Description: Temp. Core Surface/Depth Format: A2

00

Z=26 16-20 2.0 CASE HARDENING 780-820 C

All rights reserved, The information, data and

PARALLEL PINION GEAR No. of Sheet:

MESH WITH 1 drawings embodied in this document are

Qty./ Set 1 of 1

4.013288.Z 302

strictly confidential and are supplied with the

4.015131.E 22-28 2.5 2 TEMPERING 150-200 C 280-300HB 55-60 HRC/1mm understanding that they will not be disclosed to Weight(Kg):

Z=22

third parties without consent of Egyptian Steel

30-40 3 3 ....-.... C Technical office 783.1

1 2 3 4 5 6 7 8

You might also like

- Sheet 04 Barrel VaultDocument1 pageSheet 04 Barrel VaultSoham SatamNo ratings yet

- Submersible Pumps GuidelinesDocument5 pagesSubmersible Pumps GuidelinesJanneth Herrera FloresNo ratings yet

- Construction Project Schedule Template G1 Residential BuildingDocument85 pagesConstruction Project Schedule Template G1 Residential BuildingMansi PatilNo ratings yet

- JIS-B0251-1975-Limit Gauges For Metric Coarse Screw ThreadsDocument65 pagesJIS-B0251-1975-Limit Gauges For Metric Coarse Screw Threadsfatimah83% (6)

- Method Statement Pipe JackingDocument7 pagesMethod Statement Pipe Jackingsinthian88% (8)

- Gravure Trouble-Shooting GuideDocument8 pagesGravure Trouble-Shooting GuideMULYADI100% (1)

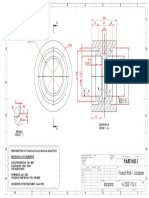

- 301 4 - 013287 - Q Parallel Pinion Gear DRAFTDocument1 page301 4 - 013287 - Q Parallel Pinion Gear DRAFTsamyNo ratings yet

- PA000008-Bearing PreloaderDocument1 pagePA000008-Bearing PreloaderYAGNA V YAGNA VNo ratings yet

- If in Doubt Ask... Do Not Scale The Drawing All Dimensions Are in MM Unless Otherwise Stated Remove All Burrs and Sharp EdgesDocument2 pagesIf in Doubt Ask... Do Not Scale The Drawing All Dimensions Are in MM Unless Otherwise Stated Remove All Burrs and Sharp EdgescparamesNo ratings yet

- 第46届世界技能大赛数控铣项目湖北省选拔赛样题2 091801Document1 page第46届世界技能大赛数控铣项目湖北省选拔赛样题2 091801omarNo ratings yet

- 72T 2.5M 22ha 30FW 20paDocument1 page72T 2.5M 22ha 30FW 20paaliNo ratings yet

- SF 30 e 10 64 Peek Bush SF 30Document1 pageSF 30 e 10 64 Peek Bush SF 30jituniNo ratings yet

- Socle Manal TahtahDocument1 pageSocle Manal TahtahManal TahtahNo ratings yet

- Yywwd: Usb Type-C Pin Assignments Signal NameDocument2 pagesYywwd: Usb Type-C Pin Assignments Signal NameDane MoslanNo ratings yet

- SEGUNDODocument1 pageSEGUNDOPercy Sucno TorreNo ratings yet

- RedactedDocument1 pageRedactedJose PerezNo ratings yet

- Slider - 01 - 422: Ozn Mrkpolje FLDDocument1 pageSlider - 01 - 422: Ozn Mrkpolje FLDStefan MilojevicNo ratings yet

- BaseDocument1 pageBaseAhmad عfiaNo ratings yet

- MC Spool 250X144X100X36X182Document1 pageMC Spool 250X144X100X36X182rajiv jainNo ratings yet

- 5 x4 Tehnicki Polirana Povrsina: Cavity - 0420Document2 pages5 x4 Tehnicki Polirana Povrsina: Cavity - 0420Stefan MilojevicNo ratings yet

- Casa Artesanos GeometriaDocument3 pagesCasa Artesanos GeometriaFernando Silva LeyvaNo ratings yet

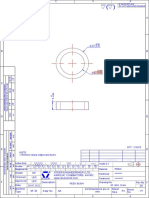

- Part No.1: 4.252115.X Fixed Roll - LooperDocument1 pagePart No.1: 4.252115.X Fixed Roll - Loopersameh mamdouhNo ratings yet

- BaseDocument1 pageBasepeyvastehNo ratings yet

- Dimensions Are in Millimeters Unless Specified Olerances: Linear 0.1mm Angular 0.5Document1 pageDimensions Are in Millimeters Unless Specified Olerances: Linear 0.1mm Angular 0.5Gundhi AsmoroNo ratings yet

- Pa000005-Motor Mounting SpacerDocument1 pagePa000005-Motor Mounting SpacerYAGNA V YAGNA VNo ratings yet

- National Qualifiers 2015Document1 pageNational Qualifiers 2015Gundhi AsmoroNo ratings yet

- STPRO1358510000-05 Cameron Double BOP 16 - 5 000 Psi - Type U - BodyDocument3 pagesSTPRO1358510000-05 Cameron Double BOP 16 - 5 000 Psi - Type U - BodyPaco RiberaNo ratings yet

- Bai 02Document1 pageBai 02Phú ThọNo ratings yet

- Pib22-064 - FGR (Gripper Finger R)Document1 pagePib22-064 - FGR (Gripper Finger R)fendri firstNo ratings yet

- Material - Cast Nylon (Mould) 1. Hardness - 90 Shore A 2.: IndiaDocument1 pageMaterial - Cast Nylon (Mould) 1. Hardness - 90 Shore A 2.: IndiaAbi ShekNo ratings yet

- Slid 01 Bar 422Document1 pageSlid 01 Bar 422Stefan MilojevicNo ratings yet

- TB-55-107 - Piston Hook FabricateDocument1 pageTB-55-107 - Piston Hook FabricateAnuj BhardwajNo ratings yet

- PDF Tipo3Document1 pagePDF Tipo3ana claudia avila cedeñoNo ratings yet

- CN18550 AMY-25-ZOOM 20220408 MechanicalDrawingDocument1 pageCN18550 AMY-25-ZOOM 20220408 MechanicalDrawingLuar ParraNo ratings yet

- Manufacturing Drawing: D:/Engineering/Ns Engineering/Cad Data/Angle Choke/Angle Disc Valve/Ea-1/Wear Sleeve Carrier Ea-1Document1 pageManufacturing Drawing: D:/Engineering/Ns Engineering/Cad Data/Angle Choke/Angle Disc Valve/Ea-1/Wear Sleeve Carrier Ea-1Tridi PrintingNo ratings yet

- SLD 02 Guide 430Document1 pageSLD 02 Guide 430Stefan MilojevicNo ratings yet

- SLD 02 Plate 430Document1 pageSLD 02 Plate 430Stefan MilojevicNo ratings yet

- MR3010Document1 pageMR3010mastermindizNo ratings yet

- Tipe 68Document49 pagesTipe 68naditransbojonegoroNo ratings yet

- Key Dimension Key Assy: ValvulasDocument1 pageKey Dimension Key Assy: Valvulassantha kumarNo ratings yet

- Gde01 03 039 ADocument1 pageGde01 03 039 Aluca.laniNo ratings yet

- Type CDocument2 pagesType CanilNo ratings yet

- Valve PDFDocument1 pageValve PDFJim TsikasNo ratings yet

- Jig Roof 4 v9Document1 pageJig Roof 4 v9Hamdan Rizqi PratamaNo ratings yet

- Wayra Dptos A3Document5 pagesWayra Dptos A3Nicolás GallegosNo ratings yet

- A01 ArquitecturaDocument1 pageA01 Arquitecturamarcelo.uculmana.rosasNo ratings yet

- 8 H7 Prolazno (x2) : SLD - 02 - Mid - Plate - 430Document1 page8 H7 Prolazno (x2) : SLD - 02 - Mid - Plate - 430Stefan MilojevicNo ratings yet

- Shaft Rotor ADocument1 pageShaft Rotor ADanil AdityaNo ratings yet

- Glue Disc RH (Pristin)Document1 pageGlue Disc RH (Pristin)arief yuliantoNo ratings yet

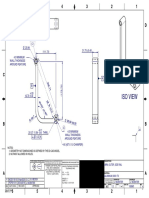

- Notes: - Max: 43.0kN Nom: 30.7kN Tooth ForceDocument2 pagesNotes: - Max: 43.0kN Nom: 30.7kN Tooth ForceWilderNo ratings yet

- E - Planos para Tesis Horacio - Arquitectura Horacion 2Document1 pageE - Planos para Tesis Horacio - Arquitectura Horacion 2frank.45jhonNo ratings yet

- Item: Dual Bearing Shaft 01 Material: 1045 SteelDocument1 pageItem: Dual Bearing Shaft 01 Material: 1045 Steelfsilassie8012No ratings yet

- Axial Fan PDFDocument1 pageAxial Fan PDFKhaled ELSaftawyNo ratings yet

- Ra3.2 Ra1.6: Napomena: Ostre Ivice Oboriti 0.5X45° Kolicina: 1 KomDocument1 pageRa3.2 Ra1.6: Napomena: Ostre Ivice Oboriti 0.5X45° Kolicina: 1 KomdbaNo ratings yet

- โครงสร้างหลังคาDocument13 pagesโครงสร้างหลังคาsarafan leewanNo ratings yet

- Plano Manejo de SoftwareDocument1 pagePlano Manejo de SoftwareCapi PaucarNo ratings yet

- Arquitectura 23Document1 pageArquitectura 23juan lunaNo ratings yet

- A3 - Plan TerasaDocument1 pageA3 - Plan TerasaRoxNo ratings yet

- 2D Technical DrawingDocument1 page2D Technical DrawingJuan Diego ZambranoNo ratings yet

- Sprue Bush M.659: 180 (145) Material MecavalDocument1 pageSprue Bush M.659: 180 (145) Material Mecavalryu prasetyaNo ratings yet

- Ex-20 55 HBDocument1 pageEx-20 55 HBCRUSTEK ENGINEERSNo ratings yet

- Gear Insert-3 Mix 9000 PDFDocument1 pageGear Insert-3 Mix 9000 PDFNathan KamNo ratings yet

- E E E E: Chamfer 0.3 X 45° Any Dimond Knurling Knurling Dia 7.2 Section E-EDocument1 pageE E E E: Chamfer 0.3 X 45° Any Dimond Knurling Knurling Dia 7.2 Section E-EAyush NarangNo ratings yet

- Plan Interventii 11Document1 pagePlan Interventii 11Taka TomoNo ratings yet

- Piston of A Petrol Engine: Aluminium Alloy HCS ChlorineDocument1 pagePiston of A Petrol Engine: Aluminium Alloy HCS ChlorineMiki BaneNo ratings yet

- LRFD Live Load Distribution Factors: Bridge DivisionDocument13 pagesLRFD Live Load Distribution Factors: Bridge DivisionKamran AhmedNo ratings yet

- Operating Principles of Narkomed Anaesthesia Systems - DrägerDocument189 pagesOperating Principles of Narkomed Anaesthesia Systems - DrägerSergio MontesNo ratings yet

- Other Buildings - Major Pending Work Orders To Be SubcontractedDocument10 pagesOther Buildings - Major Pending Work Orders To Be SubcontractedHmNo ratings yet

- Civ100-All Assignment Questions-RevisedDocument22 pagesCiv100-All Assignment Questions-RevisedgpacebonelloNo ratings yet

- Design of Footing 1 (ISOLATED FOOTING)Document32 pagesDesign of Footing 1 (ISOLATED FOOTING)John Paul Hilary EspejoNo ratings yet

- Elring CatalogDocument8 pagesElring Catalogsasha-kozak02No ratings yet

- NPT Sop Pde 004 f08 Bom Globe ValveDocument18 pagesNPT Sop Pde 004 f08 Bom Globe ValveMohamed SelimNo ratings yet

- Metalworking: Reporters: Casselle Madel Pable Ronie DagaleaDocument15 pagesMetalworking: Reporters: Casselle Madel Pable Ronie DagaleaRonie DagaleaNo ratings yet

- Types of Cutting DiesDocument4 pagesTypes of Cutting DiesrheahabyennNo ratings yet

- S110-10, S1110-10 SchematicDocument1 pageS110-10, S1110-10 SchematicWattsNo ratings yet

- Alco Lite Ladder Catalog PDFDocument20 pagesAlco Lite Ladder Catalog PDFIlhamHidayatNo ratings yet

- NO / NC Contacts: Program in LAD Program in STLDocument3 pagesNO / NC Contacts: Program in LAD Program in STLNurunNo ratings yet

- Carrier Air Cooled ChillerDocument48 pagesCarrier Air Cooled Chillernagmeldeen180% (5)

- Sumas y SaldosDocument46 pagesSumas y SaldosYhordu Ruiz LoveraNo ratings yet

- High Torque Timing Pulleys - S5MDocument1 pageHigh Torque Timing Pulleys - S5MdangmiuNo ratings yet

- HPM 770 PDFDocument2 pagesHPM 770 PDFTrev64No ratings yet

- Resume Zeeshan DalviDocument2 pagesResume Zeeshan DalviSyed AbuthahirNo ratings yet

- 300-02 # ST 1220, Four Leg Wire Rope SlingDocument3 pages300-02 # ST 1220, Four Leg Wire Rope SlingAgeng LaksitoNo ratings yet

- Test Results of Safety Devices " Aux. Boiler " Alarms and Shut Down TestsDocument1 pageTest Results of Safety Devices " Aux. Boiler " Alarms and Shut Down TestsPranay SomaniNo ratings yet

- Status Document Spec, RFQ, DatasheetDocument12 pagesStatus Document Spec, RFQ, DatasheetBoy AlfredoNo ratings yet

- Check Valve CV1 08: UcsonDocument2 pagesCheck Valve CV1 08: UcsonpavankumarNo ratings yet

- Pt. Tripatra Engineering: Calculation SheetDocument41 pagesPt. Tripatra Engineering: Calculation SheetriandiNo ratings yet

- LG - GC 151 ManualDocument13 pagesLG - GC 151 ManualadijayptNo ratings yet

- md1 StressesDocument3 pagesmd1 StressesJB_0929No ratings yet