0% found this document useful (0 votes)

554 views3 pagesProximity Switch Installation

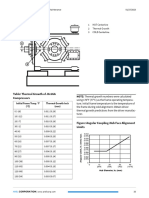

The document provides instructions for installing and troubleshooting proximity switches used to monitor lubrication systems. It describes how to install proximity switches on divider valves and adjust them so the switch changes state as the valve cycles. Potential problems like improperly adjusted switches, damaged magnets, or bent housings are explained.

Uploaded by

Saleh AlomariCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

554 views3 pagesProximity Switch Installation

The document provides instructions for installing and troubleshooting proximity switches used to monitor lubrication systems. It describes how to install proximity switches on divider valves and adjust them so the switch changes state as the valve cycles. Potential problems like improperly adjusted switches, damaged magnets, or bent housings are explained.

Uploaded by

Saleh AlomariCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd