Professional Documents

Culture Documents

Oil Strainer

Uploaded by

Saleh Alomari0 ratings0% found this document useful (0 votes)

3 views1 pageCopyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

3 views1 pageOil Strainer

Uploaded by

Saleh AlomariCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

JG-JGA Maintenance & Repair Manual – Maintenance 01/27/2023

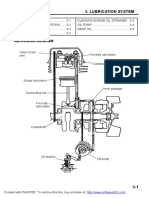

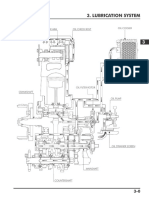

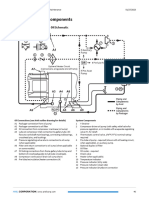

Oil Strainer Oil Pump & Regulating Valve

An oil strainer installed upstream of the pump The oil pump constantly supplies oil to all journal

prevents debris from entering the pump and bearings, bushings, and crosshead sliding

damaging it. Ariel supplies a 30 mesh (595 surfaces. The crankshaft drives it by a chain and

microns) or 40 mesh (400 microns) on all frames, sprocket to provide adequate oil flow to bearings

depending on frame size. It is located on the when the compressor operates at the minimum

auxiliary end of the crankcase below oil level. speed rating (typically half of maximum rated

Remove the strainer basket and wash it in an speed).

appropriate solvent whenever lubricating oil is

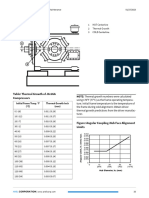

changed. Figure: Typical JG:JGA Lube Oil Pump

1 Discharge

2 Safety Relief Valve

3 Dust Cap

4 Suction

Smaller compressor models have

threaded suction/discharge connections.

JG:JGA compressors maintain oil pressure with a Oil Cooler

spring-loaded safety relief valve within the pump

head (see Figure: Typical Lube Oil Pump ). With An oil cooler is required to remove heat from the

the unit running at minimum operating speed frame lube oil. When sizing an oil cooler, consider

and the frame lube oil at operating temperature, temperature and flow rate of both cooling

170°F (77°C), remove the dust cap to expose the medium and lube oil. Insufficient cooling water

safety relief valve adjustment screw and set it so flow rate is the primary cause of high oil

the pressure gauge on the clean side of the oil temperatures. Mount cooler as close to the

filter reads 60 psig (4.1 barg). compressor as possible with piping of adequate

size to minimize pressure drop of both lube oil

When installing a new oil pump on a compressor and cooling medium.

or after maintenance on an existing oil pump,

Ariel recommends priming the pump (wetting The Application Manual lists required cooling

the gears with oil) before start-up to ensure water temperature and flow rate to properly cool

proper operation. Upon compressor start-up oil with Ariel supplied coolers. The Ariel

after oil pump replacement, oil pressure should Performance Program lists oil heat rejection data

immediately reach 50-60 psi. If oil pressure fails for each frame in the frame details section

to reach 50-60 psi immediately, shut down the (contact Ariel for details).

compressor and correct the problem. Dry oil

pump gears sometimes contribute to the

problem.

ARIEL CORPORATION | www.arielcorp.com 42

You might also like

- Heating and Air Conditioning: Compressor Overhaul For TaiwanDocument13 pagesHeating and Air Conditioning: Compressor Overhaul For TaiwanMarc MarcelleNo ratings yet

- Heating and Air Conditioning: Compressor Overhaul Except TaiwanDocument8 pagesHeating and Air Conditioning: Compressor Overhaul Except TaiwanMarc MarcelleNo ratings yet

- Er 56 06Document26 pagesEr 56 06Faisal Naeem100% (1)

- Lubricación Forzada Compresor ArielDocument26 pagesLubricación Forzada Compresor ArielAnonymous FH8OunZrXNo ratings yet

- A/C Compressor Oil CheckingDocument7 pagesA/C Compressor Oil CheckingRonald FernandezNo ratings yet

- Introduce LP&MP CompressorDocument61 pagesIntroduce LP&MP Compressorchuminh100% (1)

- Unit 5.oil System 16112019Document45 pagesUnit 5.oil System 16112019motores4297100% (1)

- Ac Compressor Oil CheckingDocument7 pagesAc Compressor Oil CheckingJeferson SilvaNo ratings yet

- 3 Lubrication SystemDocument7 pages3 Lubrication SystemedwinNo ratings yet

- Lubication Oil SystemDocument3 pagesLubication Oil SystemAustin UdofiaNo ratings yet

- 6M7 - Gr12 JMLDocument26 pages6M7 - Gr12 JMLPyae Win MaungNo ratings yet

- Section 3Document18 pagesSection 3Yurvis VasquezNo ratings yet

- 623-12 - Oil SystemDocument60 pages623-12 - Oil SystemA ENGENHARIA DAS COISASNo ratings yet

- Compressor Lubrication Best PracticesDocument22 pagesCompressor Lubrication Best Practicesengrsurif100% (1)

- SsangYong-Korando 2012 EN US Manual de Taller Sistema de Lubricacion 1b9b8b14fcDocument32 pagesSsangYong-Korando 2012 EN US Manual de Taller Sistema de Lubricacion 1b9b8b14fcRAMON LANDERO PEREZNo ratings yet

- WBHE ManualDocument3 pagesWBHE ManualBruno DelgadoNo ratings yet

- 3.hệ thống bôi trơnDocument7 pages3.hệ thống bôi trơnChu VuNo ratings yet

- Lubrication System: Lubrication System Diagram OIL Pressure Check Service Information Oil Pump Trouble ShootingDocument159 pagesLubrication System: Lubrication System Diagram OIL Pressure Check Service Information Oil Pump Trouble ShootingpoiufdsapuroiqNo ratings yet

- Sym 3. Lubrication System: Mechanism DiagramDocument7 pagesSym 3. Lubrication System: Mechanism DiagramLuis Carlos Barrera IdarragaNo ratings yet

- Triplex Pump Part 2Document20 pagesTriplex Pump Part 2Rodolfo Castro50% (4)

- Operating ManualDocument48 pagesOperating ManualHOSSAM FADELALLAH YASSiNNo ratings yet

- Compressor With Seal OilDocument7 pagesCompressor With Seal OilKamel NaimiNo ratings yet

- Group 12 LubricationDocument32 pagesGroup 12 LubricationLuisTocoraNo ratings yet

- Actual Sysem Setup Alpha LubricatorDocument7 pagesActual Sysem Setup Alpha LubricatorRanjan DiptanshuNo ratings yet

- Oil SepratorsDocument4 pagesOil SepratorsMohammad Amer0% (1)

- Odes 800cc1000cc - WorkshopDocument131 pagesOdes 800cc1000cc - WorkshopIvan RochfordNo ratings yet

- 5b - Lube System2Document22 pages5b - Lube System2agvassNo ratings yet

- PTR ManualDocument2 pagesPTR ManualvmrvdnvNo ratings yet

- 06 Lubrication SystemDocument55 pages06 Lubrication Systemramalingeswarao annamdevulaNo ratings yet

- Leroi Om Rotary Screw Manual PDFDocument40 pagesLeroi Om Rotary Screw Manual PDFscribdrazmNo ratings yet

- Leroi Om Rotary Screw Manual PDFDocument40 pagesLeroi Om Rotary Screw Manual PDFHerman Sandy100% (2)

- Oil Mist Lubrication System Working PrincipleDocument6 pagesOil Mist Lubrication System Working PrincipleYemaneDibetaNo ratings yet

- Leroi Gas Compressors: Installation - Operations Maintenance and Service GuideDocument36 pagesLeroi Gas Compressors: Installation - Operations Maintenance and Service Guidedavid lesmesNo ratings yet

- Lubrication System Diagram: CamshaftsDocument12 pagesLubrication System Diagram: CamshaftsgenuineswedeNo ratings yet

- Instruction ManualDocument36 pagesInstruction ManualJoséNo ratings yet

- CompressorsDocument8 pagesCompressorsShariq Ali0% (1)

- Manual Motor WC30D Tier-3 SM PDFDocument105 pagesManual Motor WC30D Tier-3 SM PDFAndres Abril100% (1)

- Module 6 Lube SystemDocument22 pagesModule 6 Lube Systembenitez1No ratings yet

- Section 13C - Engine Oil System PDFDocument4 pagesSection 13C - Engine Oil System PDFrobbertmdNo ratings yet

- SM 03 BDocument34 pagesSM 03 BMark OreschnickNo ratings yet

- Manual HGDocument36 pagesManual HGF Sisniegas GCNo ratings yet

- Fuller Heavy Duty Transmissions TRSM0917: Service ManualDocument21 pagesFuller Heavy Duty Transmissions TRSM0917: Service Manualubaldo caraballoNo ratings yet

- Leroi Om Rotary Screw Manual1Document49 pagesLeroi Om Rotary Screw Manual1cesosqui0% (1)

- Selection and Setup of Backpressure Regulators To Optimize Performance in Lubrication Oil ServiceDocument3 pagesSelection and Setup of Backpressure Regulators To Optimize Performance in Lubrication Oil ServiceShambhu MehtaNo ratings yet

- C200 - Lubrication SystemDocument5 pagesC200 - Lubrication SystemKada Ben youcefNo ratings yet

- 03 Lubrication System AbwtDocument12 pages03 Lubrication System Abwtcarlos melendez morenoNo ratings yet

- Engine Lubrication: Section 6GDocument8 pagesEngine Lubrication: Section 6GRichard Wilson Mera JaimeNo ratings yet

- Ac OilDocument1 pageAc OilJason ClarkNo ratings yet

- Lub Oil System FinalDocument44 pagesLub Oil System FinalNitish Kumar100% (2)

- BMW Engine Lubrication: Key To Reliability: Reprinted From Butler & Smith BMW Motorcycle Journal Spring 1979 Page 1 of 2Document2 pagesBMW Engine Lubrication: Key To Reliability: Reprinted From Butler & Smith BMW Motorcycle Journal Spring 1979 Page 1 of 2Serkan DilverNo ratings yet

- Main Turbine Lub. Oil System: Prepared byDocument44 pagesMain Turbine Lub. Oil System: Prepared byNitish Kumar100% (1)

- SECTION 5.30: Lubrication SystemDocument54 pagesSECTION 5.30: Lubrication SystemLUISA FERNANDA TORRES MANOSALVANo ratings yet

- LubricationsDocument9 pagesLubricationsSamarth SNo ratings yet

- Kbu KBZ8Document9 pagesKbu KBZ8Andrew VNo ratings yet

- Oil Grease PumpDocument68 pagesOil Grease PumpedgarNo ratings yet

- Seal Oil SysDocument32 pagesSeal Oil SysASHIT KUMAR100% (1)

- LubricationDocument29 pagesLubricationMarco CalderonNo ratings yet

- Geareducer Model 32.2: UsermanualDocument8 pagesGeareducer Model 32.2: UsermanualR BhattacharyaNo ratings yet

- Frame Oil System ComponentsDocument1 pageFrame Oil System ComponentsSaleh AlomariNo ratings yet

- Thermal GrowthDocument1 pageThermal GrowthSaleh AlomariNo ratings yet

- Proximity Switch InstallationDocument3 pagesProximity Switch InstallationSaleh AlomariNo ratings yet

- JA-JGA Repair ToolsDocument2 pagesJA-JGA Repair ToolsSaleh AlomariNo ratings yet

- Solutions: Please Direct Any Questions To The Forum On The Openedx Courseware PageDocument3 pagesSolutions: Please Direct Any Questions To The Forum On The Openedx Courseware PageMazen A. TaherNo ratings yet

- Brand IndexDocument44 pagesBrand IndexAhmed Zakareya Emam100% (2)

- S690ql ThyssenkruppDocument7 pagesS690ql ThyssenkruppSivabalan100% (1)

- Aisle Master 20 & 44 - Service ManualDocument51 pagesAisle Master 20 & 44 - Service ManualJose Pereira100% (1)

- Astm A139Document6 pagesAstm A139banglvhNo ratings yet

- XX X XXXX XX XXXX - Tank Foundation 45m Dia X 25m High On Earthen Bund FoundationDocument30 pagesXX X XXXX XX XXXX - Tank Foundation 45m Dia X 25m High On Earthen Bund FoundationKhairul JaggerNo ratings yet

- Aerio 2005Document225 pagesAerio 2005Oscar Andres Berrocal ROjasNo ratings yet

- BS Hinges 2Document22 pagesBS Hinges 2Peter MohabNo ratings yet

- A Master's Guide To Ship's Piping 2nd EditionDocument42 pagesA Master's Guide To Ship's Piping 2nd Editiondassi99100% (1)

- Additional Tutorial 2 Temperature Heat Part 2Document6 pagesAdditional Tutorial 2 Temperature Heat Part 2TeeWenSengNo ratings yet

- Know MoreDocument6 pagesKnow MoreramkumarNo ratings yet

- 4328224R1 - N9 and N10 Engine Operation and Maintenance ManualDocument102 pages4328224R1 - N9 and N10 Engine Operation and Maintenance ManualJonathan Luiz PolezaNo ratings yet

- Estandard FireDocument76 pagesEstandard FireAlireza KhodabandehNo ratings yet

- Vacuum Breaker Valve: DN50-DN500 PN10-16-25Document2 pagesVacuum Breaker Valve: DN50-DN500 PN10-16-25Cirilo SousaNo ratings yet

- Vent Master Cam C InjeccionDocument2 pagesVent Master Cam C InjeccionFreddy VeraNo ratings yet

- Construction and Building Materials: Ali N. AL-Gemeel, Yan ZhugeDocument9 pagesConstruction and Building Materials: Ali N. AL-Gemeel, Yan ZhugeManisha ShewaleNo ratings yet

- Ansys Asas 12.1Document4 pagesAnsys Asas 12.1Faizan HabibNo ratings yet

- Impulse and Momentum Problem Set October 21, 2014Document2 pagesImpulse and Momentum Problem Set October 21, 2014Nikko Angelo V MolinaNo ratings yet

- Plastic Molding TutorialDocument32 pagesPlastic Molding TutorialSergio RodriguezNo ratings yet

- According To DTS: "Name of The Plant" "XXX-000-V-00-A"Document6 pagesAccording To DTS: "Name of The Plant" "XXX-000-V-00-A"Adnan NawazNo ratings yet

- NR467 - C1 - 2018-07 BV RulesDocument568 pagesNR467 - C1 - 2018-07 BV Rulesmlaouhi majedNo ratings yet

- SWL 25 MT Padeye at Crosby G-2130 - Extg - MS - 9mm (Hole - Gap - 7mm) (Side - Gap - 9mm) (For 500T GC & AHII)Document2 pagesSWL 25 MT Padeye at Crosby G-2130 - Extg - MS - 9mm (Hole - Gap - 7mm) (Side - Gap - 9mm) (For 500T GC & AHII)Paulo MoreiraNo ratings yet

- 5 60 Lecture23Document4 pages5 60 Lecture23sgybleeNo ratings yet

- Format - CISDocument8 pagesFormat - CISgopichandallakaNo ratings yet

- Twin Steel Helix Fiber Reinforced Concrete: P. Alekhya, R. Prashanth Kumar, N. Murali KrishnaDocument8 pagesTwin Steel Helix Fiber Reinforced Concrete: P. Alekhya, R. Prashanth Kumar, N. Murali KrishnaSumair LoneNo ratings yet

- A Review of Flow and Heat TransferDocument28 pagesA Review of Flow and Heat TransferOssama Bohamd100% (1)

- Harga Borong Fit Up and WeldingDocument4 pagesHarga Borong Fit Up and Weldingsetya100% (3)

- BS EN746!3!1997 Industrial Thermoprocessing EquipmentDocument34 pagesBS EN746!3!1997 Industrial Thermoprocessing EquipmentThaiminh Vo100% (1)

- Parker IPS Catalog 1816-3Document256 pagesParker IPS Catalog 1816-3Mario DuranNo ratings yet

- Module V - Blow and Transfer Molding ProcessesDocument17 pagesModule V - Blow and Transfer Molding ProcessesAntonius PrakosaNo ratings yet

- Advanced Production Decline Analysis and ApplicationFrom EverandAdvanced Production Decline Analysis and ApplicationRating: 3.5 out of 5 stars3.5/5 (4)

- Well Control for Completions and InterventionsFrom EverandWell Control for Completions and InterventionsRating: 4 out of 5 stars4/5 (10)

- Well Integrity for Workovers and RecompletionsFrom EverandWell Integrity for Workovers and RecompletionsRating: 5 out of 5 stars5/5 (3)

- Machinery Lubrication Technician (MLT) I and II Certification Exam GuideFrom EverandMachinery Lubrication Technician (MLT) I and II Certification Exam GuideRating: 2 out of 5 stars2/5 (1)

- Casing and Liners for Drilling and Completion: Design and ApplicationFrom EverandCasing and Liners for Drilling and Completion: Design and ApplicationRating: 5 out of 5 stars5/5 (3)

- Internal Combustion: How Corporations and Governments Addicted the World to Oil and Subverted the AlternativesFrom EverandInternal Combustion: How Corporations and Governments Addicted the World to Oil and Subverted the AlternativesRating: 4 out of 5 stars4/5 (2)

- Oil: An Overview of the Petroleum IndustryFrom EverandOil: An Overview of the Petroleum IndustryRating: 4.5 out of 5 stars4.5/5 (3)

- Asset Integrity Management for Offshore and Onshore StructuresFrom EverandAsset Integrity Management for Offshore and Onshore StructuresNo ratings yet

- Asphaltene Deposition Control by Chemical Inhibitors: Theoretical and Practical ProspectsFrom EverandAsphaltene Deposition Control by Chemical Inhibitors: Theoretical and Practical ProspectsNo ratings yet

- A Practical Guide to Piping and Valves for the Oil and Gas IndustryFrom EverandA Practical Guide to Piping and Valves for the Oil and Gas IndustryRating: 5 out of 5 stars5/5 (3)

- An Operations Guide to Safety and Environmental Management Systems (SEMS): Making Sense of BSEE SEMS RegulationsFrom EverandAn Operations Guide to Safety and Environmental Management Systems (SEMS): Making Sense of BSEE SEMS RegulationsNo ratings yet

- Hydrocarbon Fluid Inclusions in Petroliferous BasinsFrom EverandHydrocarbon Fluid Inclusions in Petroliferous BasinsNo ratings yet

- Deepwater Drilling: Well Planning, Design, Engineering, Operations, and Technology ApplicationFrom EverandDeepwater Drilling: Well Planning, Design, Engineering, Operations, and Technology ApplicationRating: 4.5 out of 5 stars4.5/5 (2)

- 100 AI Use Cases in the Upstream Industry: A Comprehensive Guide for Professionals and Researchers to Overcome Industry Challenges Using AI and PythonFrom Everand100 AI Use Cases in the Upstream Industry: A Comprehensive Guide for Professionals and Researchers to Overcome Industry Challenges Using AI and PythonNo ratings yet

- Industrial Piping and Equipment Estimating ManualFrom EverandIndustrial Piping and Equipment Estimating ManualRating: 5 out of 5 stars5/5 (7)

- Pocket Guide to Flanges, Fittings, and Piping DataFrom EverandPocket Guide to Flanges, Fittings, and Piping DataRating: 3.5 out of 5 stars3.5/5 (22)