Professional Documents

Culture Documents

Applying Category Management in Procurement in Manufacturing Companies, Burlakova Et Al. 2019

Uploaded by

David MagalhaesCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Applying Category Management in Procurement in Manufacturing Companies, Burlakova Et Al. 2019

Uploaded by

David MagalhaesCopyright:

Available Formats

See discussions, stats, and author profiles for this publication at: https://www.researchgate.

net/publication/338508200

Applying category management in procurement in manufacturing companies

Article in Upravlenets · December 2019

DOI: 10.29141/2218-5003-2019-10-6-5

CITATION READS

1 5,491

3 authors:

Irina Burlakova Dmitry A. Karkh

Ural Federal University 27 PUBLICATIONS 51 CITATIONS

3 PUBLICATIONS 1 CITATION

SEE PROFILE

SEE PROFILE

Liudmila Ruzhanskaya

Ural Federal University

16 PUBLICATIONS 11 CITATIONS

SEE PROFILE

Some of the authors of this publication are also working on these related projects:

CEEMAN View project

Category management in purchasing View project

All content following this page was uploaded by Liudmila Ruzhanskaya on 02 July 2020.

The user has requested enhancement of the downloaded file.

International Journal of Advanced Science and Technology

Vol. 29, No. 8s, (2020), pp. 2099 - 2107

Category Management in manufacturing companies: new application of an

old retail practice

Irina V. Burlakova, Liudmila S. Ruzhanskaya

International Economy and Management Dept.

Ural Federal University named after the first President of Russia B.N. Yeltsin

19 Mira St., Ekaterinburg, 620002, Russia

Abstract

The topic of category management in manufacturing has been widely discussed in recent years, but not in

academic papers. The methodology of category management for manufacturing companies has not been

clearly defined yet. Traditional category management (CM) in retail involves effective management of the

margin of goods, which is achieved by concentrating control over purchase, pricing, promotion and

marketing in the hands of a category manager. It is obvious that the whole set of tools of traditional retail

category management is impossible to apply to the purchases of industrial companies due to a number of

specific restrictions: some of the goods purchased by the industrial enterprise are modified in the process

of production, and the others are acquired not for external, but for the needs of company internal

consumer. Therefore, it is necessary to make a number of clarifications in the methodology of category

management for industrial companies concerning the toolkit and implementation algorithm used. By

analyzing the theory of traditional CM and summarizing the experience of industrial companies we

outline the methodology of implementing CM in manufacturing companies that will become a basics for

further efficiency evaluation of this practice.

Keywords: Purchasing, procurement, supply management, category management, purchasing category

management.

1. INTRODUCTION

The major research directions for Purchasing and Supply management in recent years are known as green

procurement and sustainability. Category management in manufacturing is another topic that has been

widely discussed, but mostly between company management and business consultants. One will hardly

find many scientific articles systematizing literature on the subject or studying the practice itself.

Many consulting and analytical companies such as Nielsen Company (US), who used to study retail

category management practices, state than CM is equally applicable to manufacturing and assumes the

same fundamental steps:

Category definition,

Category role,

Category assessment,

Category scorecard,

Category strategy,

Category tactics,

Category implementation

Category review.(Nielsen, 2014)

In 2018 category management have been introduced to the procurement process in PCF, the most widely

used cross-industry process classification framework by American Productivity and Quality center

(APQC), which means its applicability to retail, wholesale and manufacturing business equally.

Compared with previous version (2017) the process “develop sourcing strategy” was replaced by

ISSN: 2005-4238 IJAST 2099

Copyright ⓒ 2020 SERSC

International Journal of Advanced Science and Technology

Vol. 29, No. 8s, (2020), pp. 2099 - 2107

“perform category management”, and a new process “Develop sourcing and category management

strategies” was introduced.

Figure 1. PCF framework for process group 4.2. “procure materials and services”(PCF, 2018)

But in academic literature most of the articles on CM are devoted to grocery, retail and not industry, as

the approach itself originated in retail.

Efficient Consumer Response (ECR), first introduced in academic literature in 1993, is a concept aligning

particular practices and activities to deliver better value to the consumer. The initiatives of ECR include

Category management (CM), which assumes a shift from the traditional brand management approach to

the product category management approach, which can be accomplished by defining the basic business

unit as a product category as opposed to a specific brand or product line (Reyes, 2005).

Since category management is a set of tools originally developed for retail, there is no scientifically sound

basis for its introduction in industry:

the set of CM tools applicable to the industrial enterprise is not defined;

There are no published guidelines for implementation;

There is no algorithm for introducing categorical management into the practice of industrial

enterprises.

Thus, the purpose of this study is to define the methodology of applying category management tools for

manufacturing companies.

ISSN: 2005-4238 IJAST 2100

Copyright ⓒ 2020 SERSC

International Journal of Advanced Science and Technology

Vol. 29, No. 8s, (2020), pp. 2099 - 2107

Category management in retail and its methodology.

Category management, as an approach to the management of purchased products range, originated in

Procter'Gamble in the 1990s (Holweg, 2009). Traditionally, categorical management has evolved as a

method of managing purchase in retail and wholesale trade.

According to ECR, CM can be defined as a distributor/supplier process of managing categories as

strategic business units producing enhanced business results by focusing on delivering consumer value

(Holweg, 2009).

One of the most comprehensive definitions of category management was given by S. Sysoeva and E.

Buzukova:

“Category management (product management) – is an approach to the management of product range,

which assumes the following rules:

1. The division of the entire product range into product categories not necessarily in accordance with

generally accepted groups and types of goods, but based primarily on the psychology and perception of

the consumer.

2. Responsibility of one employee of a trading company for the entire cycle of the category - from

purchase to sale.

3. Considering each product category as a mini-enterprise within a company with its own budget, pricing,

procurement policy, etc.

4. Approach to the assortment of a retail store as a single set of all categories, according to the buyer’

sperception” (Sysoeva, 2016).

The wide opportunities of applying CM outside of retail were mentioned by various authors: "Category

management is applicable for retailers and wholesale companies. It allows to identify their role, strategy,

tactics and thus to determine the points of growth. Category management allows you to assess the

effectiveness of sales of an unlimited number of items, identify the causes of low sales, plan and

implement measures to improve the performance of each individual category. This, in turn, will increase

the efficiency of sales and profitability of the company." (Ilyenkova 2018). The methodology of CM can

be structured as follows:

The first step of implementing category management is to divide the range into categories and allocate

subcategories in accordance with consumer perception. Then, based on the share in turnover and revenue

of the company, the roles of categories (basic, convenient, etc.) are determined. For each category it is

necessary to analyze its composition, internal structure, supplier market and strategies. Based on the

category development strategy, a plan of activities related to marketing, layout, pricing, etc. is being

developed. Before the project starts, it is necessary to clearly define the goals and formulate the indicators

to achieve.

ISSN: 2005-4238 IJAST 2101

Copyright ⓒ 2020 SERSC

International Journal of Advanced Science and Technology

Vol. 29, No. 8s, (2020), pp. 2099 - 2107

Category management

Defining categories and subcategories

Defining roles

Category analysis and defining strategies

Defining tactics

Setting objectives

Project implementation (using 4P marketing concept)

Assortment Merchandising Marketing activities Pricing

management

Theanalysisofstatisti

Competitor price

Market analysis Supplier analysis csonpreviouscampai

analysis

gns

Consumer analysis Consumer analysis Consumer analysis Consumer analysis

Supplier Supplier Supplier Supplier

cooperation cooperation cooperation cooperation

Result analysis

Implementation

Figure 2. Eight stages of the category management method. Source: Ilyenkova, 2018, p. 129

ISSN: 2005-4238 IJAST 2102

Copyright ⓒ 2020 SERSC

International Journal of Advanced Science and Technology

Vol. 29, No. 8s, (2020), pp. 2099 - 2107

CM at the project stage includes the following:

Managing the product range, managing suppliers;

Marketing activities aimed at increasing sales and customer loyalty;

Pricing. A pricing policy is developed for each category separately to maximize the profits of the

company;

Layout (merchandising) is a retail tool that allows to increase sales by effective location of goods

on the shelves.

When the project is finished the results are to be analyzed according to the specified indicators and

conclusions are to be made. These findings should form the basis of the next phase of work with

categories and be taken into account when setting goals and objectives. We will take these tools and

stages of CM project as a basis when analyzing the implementation CM in manufacturing plants.

Category management is based on the theory of marketing. Philippe Kotler defines values as the

relationship between the benefits that a consumer receives from the acquisition and use of a product and

the cost of purchasing and using it. When we talk about CM in manufacturing companies, the consumer is

not the end consumer, but the internal customer, the employee/division of an enterprise. Therefore, the

target function of CM is shifting from the customer's satisfaction to cost optimization. In developing a

category approach for a production organization, it is necessary to shift from the marketing concept

because the consumer is inside the enterprise itself. The theoretical basis for the development of a new

category approach will be the following:

TCO concept (total cost of ownership)

strategic planning

project management

The lack of literature on the methodology and practice of applying category management by

manufacturing companies was one of the factors that prompted the authors to write this article.

Category management practice in manufacturing companies

In 2009 Jonathan O'Brien, manager of the international procurement management consulting agency,

published a book named "Category Management in Procurement". This was the first book about the

application of category management to non-retailers. O'Brien uses the terms “marketing category

management” and "purchasing category management" The first refers to the traditional approach to the

management of product groups, depending on how the buyer sees and uses them. The author introduces

the concept of category management in purchasing: it is the practice of dividing the main areas of

expenditure for purchased goods and services into separate groups according to their functions and the

characteristics of the respective markets. (O'Brien, 2019).

Using the division of purchased goods into categories, employees work in cross-functional teams on each

category: study the cost of purchases, study the use of products category in the organization - Study the

markets and individual suppliers

The purpose of their work is to develop category strategies that can create added value for the

organization. (O'Brien, 2019). It is clear that we are not talking about the use of traditional category

management tools: pricing, marketing, merchandising.

ISSN: 2005-4238 IJAST 2103

Copyright ⓒ 2020 SERSC

International Journal of Advanced Science and Technology

Vol. 29, No. 8s, (2020), pp. 2099 - 2107

The use of terms "marketing category management" and "purchasing category management " seems

incorrect because, according to most authors, the classic "category management" in retail includes

marketing management activity, and this approach is most often implemented by managers of retail

procurement departments. Thus, category management can use marketing tools, and at the same time be

carried out by the employees responsible for procurement.

Hereafter we will explain the necessity to distinguish the notions of retail and wholesale CM (marketing

CM by O’Brian) and category approach to managing product range of manufacturing companies

(purchasing CM by O’Brian).

Raw materials Semiproduct Consumer goods Wholesaler Retailer

manufacturer manufacturer manufacturer

Figure 3. A classic supply chain centered on the consumer goods manufacturer.

Retail outlet is the final point of a supply chain, where the goods are sold to the consumer. A category

manager controls the profit from sales (determines purchase price, sale price, marketing activities to

stimulate sales, and decides on the assortment). It assumes total control over the profitability and

efficiency of a product category.

The tools of CM are mostly applicable to wholesale companies, as the goods are not modified or

transformed. The same manager may be responsible both for purchase and for sales of a product category

to retail stores or manufacturing plants. In this case the toolkit of CM that can be used will be narrower,

as in the B2B market there is no direct interaction with the end consumer. There is no contact with buyer

in retail store, which means that merchandising is not applicable.

Here a company will focus on pricing, margin, purchasing prices.

Regarding C Min manufacturing we will only study companies, manufacturing goods, because service

production is a very different phere and should be regarded separately.

Manufacturing companies in a supply chain can be classified as follows:

• Mining companies (raw materials);

• Processing plants (processing natural resources or producing semi-finished products from

several types of raw materials);

• Manufacturer of consumer goods (producers of the final product).

Goods purchased by a manufacturing plant can be divided into two main classes: direct and indirect

procurement. Direct procurement group includes products that are used directly in production and are

constituent parts of a finished product. Indirect procurement is related to products that are used to provide

production and non-production processes, but are not included in final product. The structure a

production company's range of purchased goods will depend on its place in the supply chain. Therefore,

the closer to the center of the supply chain, the greater the share of direct materials.

ISSN: 2005-4238 IJAST 2104

Copyright ⓒ 2020 SERSC

International Journal of Advanced Science and Technology

Vol. 29, No. 8s, (2020), pp. 2099 - 2107

Table 1 A production company purchase structure.

Firm type Purchase structure

Mining companies Mostly Indirect

Processing plants Direct+indirect

Manufacturer of consumer goods Direct + indirect. Direct exceed in terms of

purchasing budget.

Direct materials are purchased for manufacturing. Indirect materials are purchased not for manufacturing,

but also not for sale, but to satisfy inner demand of the company departments. Thus marketing, pricing,

merchandising is not applicable in both cases.

Category management is a value-oriented approach. However, the value as its founders understood lean

production (O'Brien, J. 2019. P.64-68 Womack, J., Jones, D. 2003. PP. 29-37), should be considered from

the point of view of perception of the end consumer, not to confuse with internal customer. The end

consumer is the buyer of the finished product of the company, not its employee, who ordered materials

for repair and maintenance. This makes it possible to standardize, optimize, manage purchased goods,

analyze total costs, i.e. developing category strategies and tactics.

Table 2 Potential to use category management tool sin enterprises occupying different position sina

supply chain.

Firm type Retail Wholesale Manufacturer of Mining

consumer company

goods/processing

plant

Defining categories

Category analysis,

strategy, tactics

Project realization :

Managing categories

Marketing

Pricing

Merchandising

Our paper “Applying category management in procurement in manufacturing companies” (Burlakova,

2019) describes the practices of implementing CM in four Russian manufacturing companies, based on

open source information (articles industry and logistics magazines).

The managers outline 2 most common practices of CM implementation:

• development and application of the "category strategy". "Category strategy refers to a

document that includes supplier market analysis, cost analysis, analysis of overall costs, and

strategic decisions on how to purchase materials and the principles of supplier selection.

• creation of a category team - a cross-functional project team that solves the problem of supply

chain management for a specific product category.

ISSN: 2005-4238 IJAST 2105

Copyright ⓒ 2020 SERSC

International Journal of Advanced Science and Technology

Vol. 29, No. 8s, (2020), pp. 2099 - 2107

Another recent study “Purchasing Category Management: Providing Integration between Purchasing and

Other Business Functions” (Heikkilä, J, 2019), based on interviews with managers of manufacturing

companies using category approach, outlines the following common practices:

• Defining purchasing categories.

• Using cross-functional purchasing category teams.

The generalization of CM application experience in Russian and European manufacturing firms allowed

to formulate the main steps of applying the category approach:

1. Defining purchasing categories;

2. Creating cross-functional category teams;

3. Determining purchasing strategies for category;

4. Formalization of strategies in a form of a document.

It is fair to say that defining purchasing categories was mentioned by P. Kralich in 1983, when he

proposed to divide the range into several categories on the basis of risk and the possible economic

benefits (Kraljic, P, 1983)Kralichmatrix is often called by business consultants a CM tool for applying

CM production companies.

However, Phase 2,3,4 had not previously been clearly defined, and in practice the production facilities

often missed these important points.

It should also be noted that many of the tools that are attributed to category management (e.g. cost

analysis, overall cost analysis, inventory management calculations, supplier management) have long been

known as "Supply Chain Management" (Chopra S., Meindl P., 2006).

In the near future, the specifics of CM implementation for procurement management in manufacturing

plants will be refined, and that will allow to measure the key efficiency indicators of its application, that is

still a field of opportunities for further research.

References

[1] Category management – common language between retailers and manufacturers, Nielsen (2014).

Online: https://www.nielsen.com/wp-content/uploads/sites/3/2019/04/category-management-

2014en.pdf

[2] Cross Industry Process Classification Framework (PCF), version №7.2.1 generated on

17.09.2018. Online: https://www.apqc.org/resource-library/resource-listing/apqc-process-

classification-framework-pcf-cross-industry-pdf-8

[3] Reyes, P.M. and Bhutta, K.(2005) ‘Efficient consumer response: literature review’, Int. J.

IntegratedSupply Management, Vol. 1, No. 4, pp.346–386.

[4] Holweg C., Schnedlitz P., Teller C. (2009) The drivers of consumer value in the ECR Category

Management model, The International Review of Retail Distribution and Consumer Research.

Online:

https://www.academia.edu/18138219/The_drivers_of_consumer_value_in_the_ECR_Category_

Management_model

[5] Sysoeva S., Buzukova E. (2016). Category management: retail assortment management.

St.Petersburg: Peter.400 s.

[6] Ilyenkova K. M. (2018), Introduction of category management in traditional retail, Herald of

Moscow University, No 3, pp. 124-145.

[7] O'Brien, J. (2019) Category Management in Purchasing. Kogan Page. Kindle Edition. 497 p.

[8] omack, J. and Jones, D. (2003) Lean Thinking. L: Free Press, 2003.

ISSN: 2005-4238 IJAST 2106

Copyright ⓒ 2020 SERSC

International Journal of Advanced Science and Technology

Vol. 29, No. 8s, (2020), pp. 2099 - 2107

[9] Burlakova I.V., Karkh D.A., Ruzhanskaya L.S. (2019). Applying category management in

procurement in manufacturing companies. Upravlenets – The Manager, vol. 10, no. 6, pp. 54–66.

[10]Heikkilä, J; Kaipia R, Ojala M (2018) Purchasing Category Management: Providing Integration

between Purchasing and Other Business Functions, International Journal of Procurement

Management (IJPM), Vol. 11, No. 5, pp.533 – 550

[11]Chopra, S. and Meindl, P. (2001), Supply Chain Management, Pearson Prentice Hall, Upper

Saddle River, New Jersey.

[12]Kraljic P (1983). Purchasing must become Supply management. Harvard Business Review, pp

109-117

ISSN: 2005-4238 IJAST 2107

Copyright ⓒ 2020 SERSC

View publication stats

You might also like

- Weekly Progress Report PDFDocument7 pagesWeekly Progress Report PDFHeak Hor50% (2)

- Modern Guide To Plo ExtractDocument24 pagesModern Guide To Plo ExtractSteve ToddNo ratings yet

- Aras Jung Curriculum IndividualDocument72 pagesAras Jung Curriculum IndividualdianavaleriaalvarezNo ratings yet

- Further MathematicsDocument44 pagesFurther MathematicsMohd Tirmizi100% (1)

- Sustainability Transition in Industry 4.0 and Smart Manufacturing With The Triple-Layered Business Model CanvasDocument19 pagesSustainability Transition in Industry 4.0 and Smart Manufacturing With The Triple-Layered Business Model CanvasadeNo ratings yet

- Segmenting Technology Markets Applying The NestedDocument16 pagesSegmenting Technology Markets Applying The NestedGHITA ARYANA PUTRI YULINONo ratings yet

- A Framework For Product DevelopmentDocument15 pagesA Framework For Product DevelopmentDorcus AnishaNo ratings yet

- Measuring The Maturity of Digitalization Transformation From Operational Excellence's PerspectiveDocument16 pagesMeasuring The Maturity of Digitalization Transformation From Operational Excellence's PerspectiveGlobal Research and Development ServicesNo ratings yet

- The Role of Economic Efficiency and Business Strategy To Achieve Competitive AdvantageDocument15 pagesThe Role of Economic Efficiency and Business Strategy To Achieve Competitive AdvantageGlobal Research and Development ServicesNo ratings yet

- Innovation Strategies in Retail Services: Solutions, Experiences and MeaningsDocument20 pagesInnovation Strategies in Retail Services: Solutions, Experiences and MeaningsJulieta Tiurma NapitupuluNo ratings yet

- Kerangka Kerja Perencanaan Pengembangan Produk Sebagai Peningkatan Daya Saing Industri Kecil MenengahDocument13 pagesKerangka Kerja Perencanaan Pengembangan Produk Sebagai Peningkatan Daya Saing Industri Kecil MenengahaminsuhadiNo ratings yet

- Kerangka Kerja Perencanaan Pengembangan Produk Sebagai Peningkatan Daya Saing Industri Kecil MenengahDocument13 pagesKerangka Kerja Perencanaan Pengembangan Produk Sebagai Peningkatan Daya Saing Industri Kecil MenengahAnnisa Rahma BerlianiNo ratings yet

- Supply Chain Improvement in Construction IndustryDocument8 pagesSupply Chain Improvement in Construction IndustryMade Adi WidyatmikaNo ratings yet

- Systematic ReviewDocument17 pagesSystematic Reviewhamza ghouriNo ratings yet

- A Framework For Product DevelopmentDocument15 pagesA Framework For Product DevelopmentWayn CahiligNo ratings yet

- Artificial Intelligence in Supply Chain Management: A Systematic Literature ReviewDocument17 pagesArtificial Intelligence in Supply Chain Management: A Systematic Literature ReviewVijay Singh ThakurNo ratings yet

- 20mbar0278 Kommu Hema Sip ReportDocument62 pages20mbar0278 Kommu Hema Sip ReportAthul BijuNo ratings yet

- Achieving Sustainable Development Goals Through Ident - 2020 - International JouDocument13 pagesAchieving Sustainable Development Goals Through Ident - 2020 - International JouBona Christanto SiahaanNo ratings yet

- Lean Manufacturing: Literature Review and Research IssuesDocument66 pagesLean Manufacturing: Literature Review and Research IssuesRahul KumarNo ratings yet

- Lean Manufacturing: Literature Review and Research IssuesDocument66 pagesLean Manufacturing: Literature Review and Research IssuesRahul KumarNo ratings yet

- Gerasimov - 2018 - The International Journal Entrepreneurship and Sustainability Issues Identification of The Factors of ComDocument15 pagesGerasimov - 2018 - The International Journal Entrepreneurship and Sustainability Issues Identification of The Factors of ComelvinsetanNo ratings yet

- Coca Cola India and Its Distribution Channel: A Selection by Analytic Hierarchy Process (AHP)Document16 pagesCoca Cola India and Its Distribution Channel: A Selection by Analytic Hierarchy Process (AHP)Laura Sofia Lopez BermudezNo ratings yet

- Product Innovation Process Innovation and CompetitDocument6 pagesProduct Innovation Process Innovation and CompetitSardor JuraevNo ratings yet

- Servitization Implementation in Manufacturing Organizations - A Systematic Review To Identify Obstacles and Critical Success FactorsDocument17 pagesServitization Implementation in Manufacturing Organizations - A Systematic Review To Identify Obstacles and Critical Success FactorsIJRASETPublicationsNo ratings yet

- Improving The Method of Assessment of Strategic Management Efficiency On The Basis of Application of Modern Management Technologies in Textile EnterprisesDocument8 pagesImproving The Method of Assessment of Strategic Management Efficiency On The Basis of Application of Modern Management Technologies in Textile EnterprisesAcademic JournalNo ratings yet

- Industry and Competitive Landscape Analysis - Course OutlineDocument11 pagesIndustry and Competitive Landscape Analysis - Course OutlineSoundara VishalNo ratings yet

- Segmenting Technology MarketsDocument15 pagesSegmenting Technology MarketsGuillermo UribeNo ratings yet

- Lean Manufacturing in Fabrication Industry: Literature Review and Framework ProposalDocument33 pagesLean Manufacturing in Fabrication Industry: Literature Review and Framework ProposalGianfranco OrtizNo ratings yet

- A Two-Decade Literature Review On Challenges Faced by Smes in Technology AdoptionDocument13 pagesA Two-Decade Literature Review On Challenges Faced by Smes in Technology AdoptionYolita DelosreyesNo ratings yet

- Supply Chain - Innovation - Past, Present, and FutureDocument23 pagesSupply Chain - Innovation - Past, Present, and FutureŞemsettin ÇiğdemNo ratings yet

- Measurement of Company Performance As Part of Its Strategic ManagementDocument4 pagesMeasurement of Company Performance As Part of Its Strategic Managementravi shankarNo ratings yet

- WilliamsDocument28 pagesWilliamsTony DumfehNo ratings yet

- Lean Manufacturing Literature Review andDocument65 pagesLean Manufacturing Literature Review andHadi P.No ratings yet

- StudyofProduct LifeCycleandMarketingApplicationsDocument9 pagesStudyofProduct LifeCycleandMarketingApplicationsdevs1519964No ratings yet

- IJIMT, Sustainable Supply Chain Management, 2021Document6 pagesIJIMT, Sustainable Supply Chain Management, 2021parsadNo ratings yet

- Evaluation of Production Processes Performance, JencoDocument15 pagesEvaluation of Production Processes Performance, JencoDDCMNo ratings yet

- Lee Et Al. - 2021 - Model For Identifying Firm's Product Innovation DyDocument15 pagesLee Et Al. - 2021 - Model For Identifying Firm's Product Innovation Dymjobs247No ratings yet

- (Latest) Attribution Modelling in Marketing Literature Review and Research AgendaDocument22 pages(Latest) Attribution Modelling in Marketing Literature Review and Research AgendaNguyen Le Ngoc AnhNo ratings yet

- Assignment of Advanced Research MethodologyDocument6 pagesAssignment of Advanced Research MethodologyJunaid AhmedNo ratings yet

- Applicationof ADLMatrixin Developed Industrial CompaniesDocument3 pagesApplicationof ADLMatrixin Developed Industrial CompaniesnouiNo ratings yet

- 13 Crear Un Cluster InnovadorDocument5 pages13 Crear Un Cluster InnovadorJUAN CARLOS JERONIMO NINIZNo ratings yet

- The State of Inventory Accounting: An Analysis and Directions For ImprovementDocument9 pagesThe State of Inventory Accounting: An Analysis and Directions For ImprovementAcademic JournalNo ratings yet

- A Study On The Relationship Between Innovation and Corporate Performance: in The Context of China's Fitness Service IndustryDocument14 pagesA Study On The Relationship Between Innovation and Corporate Performance: in The Context of China's Fitness Service Industryijsab.comNo ratings yet

- Innovative Development Models and Principles of Service EnterprisesDocument8 pagesInnovative Development Models and Principles of Service EnterprisesAcademic JournalNo ratings yet

- A Literature Review On Circular Economy AdoptionDocument32 pagesA Literature Review On Circular Economy AdoptionRabia HassanNo ratings yet

- 4 PDFDocument15 pages4 PDFtanvir ahmedNo ratings yet

- Theoretical and Methodological Fundamentals of Creation and Development of Free Tourist ZonesDocument7 pagesTheoretical and Methodological Fundamentals of Creation and Development of Free Tourist ZonesCentral Asian StudiesNo ratings yet

- Research Article: Supply Chain Integration in The Manufacturing Firms in Developing Country: An Ethiopian Case StudyDocument13 pagesResearch Article: Supply Chain Integration in The Manufacturing Firms in Developing Country: An Ethiopian Case StudyDame TolossaNo ratings yet

- Market Share Model Analysis Determiningparameterseffecton Market ShareDocument10 pagesMarket Share Model Analysis Determiningparameterseffecton Market ShareGERSON DENNYS MUÑIZ SANCHEZNo ratings yet

- Dibb 1994Document9 pagesDibb 1994karatas71No ratings yet

- Organizational Performance and Indicators: Trends and OpportunitiesDocument8 pagesOrganizational Performance and Indicators: Trends and OpportunitiesBenzon Agojo OndovillaNo ratings yet

- C. 2020 Industry Engagement With Control Research Prespective and MessagesDocument14 pagesC. 2020 Industry Engagement With Control Research Prespective and MessagesLeonardo Bohorquez MaldonadoNo ratings yet

- The Role of Market Analysis in Developing Efficient Marketing AuditDocument9 pagesThe Role of Market Analysis in Developing Efficient Marketing Auditbrainhub50No ratings yet

- Disrupting Fast Fashion A Case Study of Sheins inDocument14 pagesDisrupting Fast Fashion A Case Study of Sheins inziani_manel9418No ratings yet

- The Impact of Digitalization On Supply Chain Integration and Performance - A Comparison Between Large Enterprises and SMEsDocument21 pagesThe Impact of Digitalization On Supply Chain Integration and Performance - A Comparison Between Large Enterprises and SMEsAsmae El JazouliNo ratings yet

- Exaptation Dynamics and Entrepreneurial Performance: Evidence From The Internet Video IndustryDocument18 pagesExaptation Dynamics and Entrepreneurial Performance: Evidence From The Internet Video IndustryKenny ChingNo ratings yet

- Essence of Quality Control in Small ManufacturingDocument7 pagesEssence of Quality Control in Small ManufacturingtetianapribylievaNo ratings yet

- Brand Positioning Strategy in The Competitive AspeDocument9 pagesBrand Positioning Strategy in The Competitive AspeLisnawati LimbongNo ratings yet

- Five Forces Framework: January 2016Document8 pagesFive Forces Framework: January 2016engasmaaNo ratings yet

- Demand Chain Management + Response Management Increased Customer SatisfactionDocument27 pagesDemand Chain Management + Response Management Increased Customer SatisfactionKnowledge ExchangeNo ratings yet

- Assessing The Value of Product/Service Systems Alternatives: A Conceptual FrameworkDocument10 pagesAssessing The Value of Product/Service Systems Alternatives: A Conceptual FrameworkShreshtha MalhotraNo ratings yet

- Key Characteristics Management in Product Lifecycle Management: A Survey of Methodologies and PracticesDocument21 pagesKey Characteristics Management in Product Lifecycle Management: A Survey of Methodologies and PracticesMouadNo ratings yet

- InvsCUANTI. Gestión de La Empresa, Competitividad y Éxito en El MercadoDocument12 pagesInvsCUANTI. Gestión de La Empresa, Competitividad y Éxito en El MercadoDiego OlarteNo ratings yet

- The Management of Additive Manufacturing: Enhancing Business ValueFrom EverandThe Management of Additive Manufacturing: Enhancing Business ValueNo ratings yet

- The Effects of Strategic Sourcing On Supply Chain Strategies (2019)Document20 pagesThe Effects of Strategic Sourcing On Supply Chain Strategies (2019)David MagalhaesNo ratings yet

- Strategic Purchasing Participation, Supplier Selection, Supplier Evaluation and Purchasing Performance, Nair Et Al. 2015Document17 pagesStrategic Purchasing Participation, Supplier Selection, Supplier Evaluation and Purchasing Performance, Nair Et Al. 2015David MagalhaesNo ratings yet

- Achieving Purchasing Competence Through Purchasing Performance Measurement System Design A Multiple Case Studya Nalysis, Pohl (2010)Document15 pagesAchieving Purchasing Competence Through Purchasing Performance Measurement System Design A Multiple Case Studya Nalysis, Pohl (2010)David MagalhaesNo ratings yet

- A Process-Based Analysis of E-Procurement Adoption, Abu-ELSamen (2010)Document18 pagesA Process-Based Analysis of E-Procurement Adoption, Abu-ELSamen (2010)David MagalhaesNo ratings yet

- A Methodology For Strategic Sourcing, Talluri (2002)Document15 pagesA Methodology For Strategic Sourcing, Talluri (2002)David MagalhaesNo ratings yet

- APPLICATION of 6 SIGMA METHOD in PURCHASING PROCESSDocument93 pagesAPPLICATION of 6 SIGMA METHOD in PURCHASING PROCESSDavid MagalhaesNo ratings yet

- Procurement - April 2023Document96 pagesProcurement - April 2023David MagalhaesNo ratings yet

- Lean and Digitize E-Procurement, 2014Document17 pagesLean and Digitize E-Procurement, 2014David MagalhaesNo ratings yet

- 6 Tips To Improve Your Indirect Spend ManagementDocument12 pages6 Tips To Improve Your Indirect Spend ManagementDavid MagalhaesNo ratings yet

- Ericsson - Cell PlanningDocument5 pagesEricsson - Cell PlanningBassem AbouamerNo ratings yet

- The Awakening Study Guide AnswersDocument24 pagesThe Awakening Study Guide AnswersAli RidhaNo ratings yet

- Electronic Transformer For 12 V Halogen LampDocument15 pagesElectronic Transformer For 12 V Halogen LampWin KyiNo ratings yet

- British Cost Accounting 1887-1952 PreviewDocument27 pagesBritish Cost Accounting 1887-1952 PreviewJessica JessNo ratings yet

- 01 Fir TheoryDocument2 pages01 Fir TheoryTrịnh Minh KhoaNo ratings yet

- Suzanne Cardenas Uesj Thesis 2020Document92 pagesSuzanne Cardenas Uesj Thesis 2020api-262960549No ratings yet

- Assignment FormatDocument3 pagesAssignment Formatfhsn84No ratings yet

- Ind As 108Document6 pagesInd As 108Khushi SoniNo ratings yet

- Apartments? Not in My Backyard. Stouffville & Affordable Housing. Presentation To Public HearingDocument14 pagesApartments? Not in My Backyard. Stouffville & Affordable Housing. Presentation To Public HearingArnold Neufeldt-FastNo ratings yet

- Syncronex Single Copy 3.1 Users GuideDocument208 pagesSyncronex Single Copy 3.1 Users GuideTony BoscoNo ratings yet

- Numerical Study of Depressurization Rate During Blowdown Based On Lumped Model AnalysisDocument11 pagesNumerical Study of Depressurization Rate During Blowdown Based On Lumped Model AnalysisamitNo ratings yet

- Henning ResumeDocument1 pageHenning Resumeapi-341110928No ratings yet

- Workshop Practical Attendance SheetDocument2 pagesWorkshop Practical Attendance SheetSachidhanandam MNo ratings yet

- 32 KV High Voltage Power Transmission Line and Stress On Brassica JunceaDocument4 pages32 KV High Voltage Power Transmission Line and Stress On Brassica Junceamuhammad mushofahNo ratings yet

- Mud Motor DV826Document1 pageMud Motor DV826CAMILO ALFONSO VIVEROS BRICEÑONo ratings yet

- Pugh ChartDocument1 pagePugh Chartapi-92134725No ratings yet

- Term SymbolDocument20 pagesTerm SymbolRirin Zarlina100% (1)

- Weforma WBZ ENDocument18 pagesWeforma WBZ ENRuben PauwelsNo ratings yet

- Middle East Product Booklet 5078 NOV18Document56 pagesMiddle East Product Booklet 5078 NOV18Mohamed987No ratings yet

- An Isolated Bridge Boost Converter With Active Soft SwitchingDocument8 pagesAn Isolated Bridge Boost Converter With Active Soft SwitchingJie99No ratings yet

- PDF Kajaria Report Final - CompressDocument40 pagesPDF Kajaria Report Final - CompressMd Borhan Uddin 2035097660No ratings yet

- Activity 4.analytic RubricDocument2 pagesActivity 4.analytic RubricAbby PolvorizaNo ratings yet

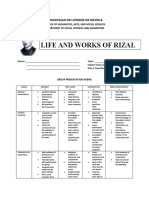

- Rubrics - Reporting - RizalDocument2 pagesRubrics - Reporting - RizaljakeNo ratings yet

- Physics Notes AJk 9th Class Chap6Document3 pagesPhysics Notes AJk 9th Class Chap6Khizer Tariq QureshiNo ratings yet

- Final CDP MuzaffarpurDocument224 pagesFinal CDP MuzaffarpurVivek Kumar YadavNo ratings yet

- 71 SubmissionDocument4 pages71 Submissionmohamed aliNo ratings yet