Professional Documents

Culture Documents

Catalog DS

Catalog DS

Uploaded by

Nguyễn ĐứcCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Catalog DS

Catalog DS

Uploaded by

Nguyễn ĐứcCopyright:

Available Formats

BOGE DS-2 Refrigerant Dryers Outstanding efficiency meets top CO2 balance!

The new DS-2 series from BOGE has now raised the bar for refrigerant dryers: Thanks to

the fully integrated design of its highly efficient heat exchanger, the DS-2 upstages all other

refrigerant dryers in terms of energy efficiency – with significantly reduced refrigerant

consumption. The overall operating costs are indeed unbeatable, and the CO2 balance

isn’t to be sneezed at either. It is not by chance that the new

DS-2 models are designed for both

50 an 60 Hz (230 V) – there is no

problem with using them any-

where in the world.

ENERGY-

SAVING-

OPTION

Efficient Drying

The new DS-2 series features a high-efficiency aluminium heat exchanger,

which minimises performance losses in the refrigeration circuit while requiring

less refrigerant than comparable products. In conjunction with economical power

consumption this means that no other product can compete with the low

running costs.

Towards a sustainable future

All models use the environmentally friendly and future-proof R-513A refrigerant as

standard. With a GWP (Global Warming Potential) of 573, it fulfils the requirements of

f-gas regulation EU 517/2014 and ensures optimum service reliability. DS-2 models

are the best choice for protecting your investment, the climate and the environment.

Energy-saving option

Although all DS-2 models are extremely undemanding in terms of energy

consumption (in %)

Saving

Electrical power

consumption under partial load, the models with capacities of 2.6 m³/min and

above go one better: If required, they can reduce power consumption even further Flow capacity with

by cooling the compressed air entering the system by the mass of the heat energy-saving option

exchanger in partial load mode.

Flow capacity (in %)

BOGE DS-2 Refrigerant Dryers Outstanding efficiency meets top CO2 balance!

The operating principle

In the fully integrated high-performance aluminium heat exchanger the various parts

spring into action one after the other: an air/air section, an air/refrigerant section,

a high-efficiency demister condensate drain and a moisture collection container.

If required, the condensate produced is discharged from the system in a final step

via an electronically level-regulated condensate outlet.

To facilitate inspection and maintenance, the side panels can be removed, and the

dryer does not have to be opened to access the condensate drain.

All models in the new series come with digital control, including functions that were

previously subject to an extra charge in some cases. However, in everyday operation

they soon pay for themselves – such as the status display, the potential-free alarm

contact or the maintenance reminder.

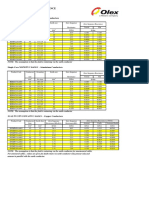

An overview of the new BOGE DS-2 refrigerant dryers

BOGE Flow capacity Max. Pressure Electric power Refrigerant R-513A Dimensions Weight Compressed air

type consumption* required refrigerant as connection

m3/min kW R 513 A CO2-equivalent

50 Hz 60 Hz bar 50 Hz 60 Hz kg t W x H x D (mm) kg BSPP-F acc.

DS 4-2 0.40 0.47 16 0.13 0.16 0.16 0.09 300 x 400 x 600 25 1/2"

DS 7-2 0.70 0.78 16 0.14 0.17 0.16 0.09 300 x 400 x 600 25 1/2"

DS 9-2 0.90 1.00 16 0.15 0.18 0.16 0.09 300 x 400 x 600 26 1/2"

DS 14-2 1.40 1.60 16 0.15 0.19 0.24 0.14 330 x 550 x 665 36 3/4"

DS 18-2 1.80 2.07 16 0.16 0.20 0.24 0.14 330 x 550 x 665 37 3/4"

DS 26-2 2.60 2.93 16 0.29 0.36 0.34 0.19 400 x 630 x 795 47 1"

DS 32-2 3.20 3.63 16 0.30 0.37 0.34 0.19 400 x 630 x 795 47 1"

DS 40-2 4.00 4.53 16 0.31 0.38 0.34 0.19 400 x 630 x 795 48 1"

DS 52-2 5.20 6.02 16 0.46 0.56 0.40 0.23 400 x 630 x 795 55 1 1/2"

DS 62-2 6.20 7.15 16 0.57 0.69 0.40 0.23 400 x 630 x 795 57 1 1/2"

DS 80-2 8.00 9.25 14 0.73 0.90 0.60 0.34 450 x 720 x 970 102 1 1/2"

DS 100-2 10.00 11.48 14 0.74 0.91 0.60 0.34 450 x 720 x 970 102 1 1/2"

All DS-2 models have a hermetically sealed refrigerant circuit in accordance with the f-gas regulation.

* all data refering to DIN ISO 7183. an ambient temperature of 20°C. inlet temperature of 35°C and 7 bar operating pressure

Correction factors f for varying operating pressures and temperatures

204-EN-BI-0-09.2021 · Technical changes and errors reserved.

Ambient/cooling water temperature °C 25 30 35 40 45 50 Inlet temperature °C 30 35 40 45 50 55 60 65

Correction factor f 1 1.00 0.93 0.88 0.82 0.75 0.69 Correction factor f 2 1.23 1.00 0.83 0.68 0.57 0.47 0.44 0.42

Operating pressure bar 3 4 5 6 7 8 9 10 11 12 13 14 15 16 Pressure dew point °C 3 5 7

Correction factor f 3 0.73 0.83 0.90 0.95 1.00 1.03 1.07 1.09 1.12 1.13 1.15 1.17 1.18 1.19 Correction factor f 4 1.00 1.11 1.24

Example for dew point 3 °C [f4 ]: Free air delivery [ V] : 90 m³/h

Ambient temperature [f1]: 35 °C = 0.88 V 90

= = = 131 DS 26-2

Inlet temperature [ f 2] : 45 °C = 0.68 f1 x f2 x f3 x f4 0.88 x 0.68 x 1.15 x 1

Pressure [ f 3 ] : 13 bar = 1.15

Pressure dew point [ f 4 ] : 3 °C = 1.00

BOGE Compressed Air Systems GmbH & Co. KG

Otto-Boge-Straße 1–7 · 33739 Bielefeld · Tel. +49 5206 601-0 · Fax +49 5206 601-200 · info@boge.com · boge.com

You might also like

- 2 Old Evaps LB and ELB Series PDFDocument28 pages2 Old Evaps LB and ELB Series PDFPreeti gulatiNo ratings yet

- Three Pillars of Central BankingDocument22 pagesThree Pillars of Central BankingJaden Christian67% (3)

- Samsung Galaxy S23 Series (Galaxy S23, S23 Plus and S23 Ultra) User Guide for Beginners and SeniorsFrom EverandSamsung Galaxy S23 Series (Galaxy S23, S23 Plus and S23 Ultra) User Guide for Beginners and SeniorsRating: 1 out of 5 stars1/5 (1)

- Green Series WC Screw Chillers IOMDocument73 pagesGreen Series WC Screw Chillers IOMBilal Khan0% (1)

- BS 7211 CableDocument22 pagesBS 7211 CablehanoiNo ratings yet

- TM-Block 14: P-OKITM07-10: P-OKITM07-10.EF - HO.SP2.001: Stock Preparation #2Document5 pagesTM-Block 14: P-OKITM07-10: P-OKITM07-10.EF - HO.SP2.001: Stock Preparation #2robby a. malikNo ratings yet

- RRLfor Gasoline StationDocument6 pagesRRLfor Gasoline StationWellan Joy Dela Fuerta100% (1)

- Zero Sequence1 - SummaryDocument4 pagesZero Sequence1 - SummaryTosikur Rahman100% (1)

- A Candle Trigger For Market BottomsDocument16 pagesA Candle Trigger For Market Bottomsemirav2100% (1)

- Critical Evaluation of "Best Practice" and "Best Fit" Practices in HRMDocument3 pagesCritical Evaluation of "Best Practice" and "Best Fit" Practices in HRMTUMMALAPENTA BHUVAN SAI KARTHIKNo ratings yet

- Practice MCQ (CH 6 To CH 9)Document7 pagesPractice MCQ (CH 6 To CH 9)rhlvajpayeeNo ratings yet

- Catalogue Fan Coil Unit DDBDocument36 pagesCatalogue Fan Coil Unit DDBLuqmanAssaffatG80% (5)

- Ethical CasesDocument32 pagesEthical CasesBianca Benj ZariNo ratings yet

- Gafco Carbon FilterDocument4 pagesGafco Carbon Filtermzmakba1No ratings yet

- Aluminum™ GafcoDocument4 pagesAluminum™ GafcoBoanerges MalazarteNo ratings yet

- Ingersoll Rand: Refrigerated Air DryersDocument12 pagesIngersoll Rand: Refrigerated Air DryersNhutNo ratings yet

- RU Catalogue-IRDocument11 pagesRU Catalogue-IRMeisam MomeniNo ratings yet

- K-ML-KT20: K-TRON Product Specification Twin Screw Loss-in-Weight FeederDocument2 pagesK-ML-KT20: K-TRON Product Specification Twin Screw Loss-in-Weight FeederselvaNo ratings yet

- LG Multi Split AC Catalogue 2019Document5 pagesLG Multi Split AC Catalogue 2019Ravi SankarNo ratings yet

- Dessicant Dryers: Benefits and FeaturesDocument2 pagesDessicant Dryers: Benefits and FeaturesJoost PostNo ratings yet

- DB Fravega Midwall Split R410aDocument2 pagesDB Fravega Midwall Split R410aStefan Pieter StromNo ratings yet

- Acu & Fcu Wiring DiagramDocument78 pagesAcu & Fcu Wiring DiagramSrinivas ChalumuriNo ratings yet

- 日立挂墙式空调1Document41 pages日立挂墙式空调13819706776No ratings yet

- Hotsec 03Document8 pagesHotsec 03Amservice 501No ratings yet

- 3 Core Cables: Ctrl+Shift+ADocument13 pages3 Core Cables: Ctrl+Shift+ASanthosh V RaajendiranNo ratings yet

- Sq. MM Ohm/Km MM MM MM MM MM KG/KM Metre 10% KGDocument1 pageSq. MM Ohm/Km MM MM MM MM MM KG/KM Metre 10% KGAshwini UdgaveNo ratings yet

- PCH Series: Btu/h Kcal/h Watt TR Btu/h Kcal/h Watt TR % Btu/h.WattDocument1 pagePCH Series: Btu/h Kcal/h Watt TR Btu/h Kcal/h Watt TR % Btu/h.WattrianartoNo ratings yet

- Katalog FCU DDB050BWDocument35 pagesKatalog FCU DDB050BWMICAH JEDAH0% (1)

- ENEOS SUSTINA Product Data Sheet 2016 PDFDocument1 pageENEOS SUSTINA Product Data Sheet 2016 PDFdan0410No ratings yet

- An 10005Document4 pagesAn 10005ClenaNo ratings yet

- CLC 17-12-2L: A 2%mo Containing 18 CR - 10 Ni Austenitic Stainless Steel (316L Grade)Document4 pagesCLC 17-12-2L: A 2%mo Containing 18 CR - 10 Ni Austenitic Stainless Steel (316L Grade)PeterWayNo ratings yet

- Amphenol 97 Series DTL 5015 Cable Clamps-1157722Document4 pagesAmphenol 97 Series DTL 5015 Cable Clamps-1157722Asep SaepudinNo ratings yet

- E-Finity Application and Product Brochure - CI - OneUp - 2018Document6 pagesE-Finity Application and Product Brochure - CI - OneUp - 2018jose favaNo ratings yet

- RO3000 Series BondplyData Sheet Processing GuidelinesDocument4 pagesRO3000 Series BondplyData Sheet Processing GuidelinesEricson NavasNo ratings yet

- Higher Density in A Smaller Body Displacement Range: 479cc N 898cc Output Range: 9.3 KW N 17.5 KW 12.5HPN23.5HPDocument12 pagesHigher Density in A Smaller Body Displacement Range: 479cc N 898cc Output Range: 9.3 KW N 17.5 KW 12.5HPN23.5HPNelson OsbornneNo ratings yet

- Super-Mini-Series Z482 Z602 D722 D902Document12 pagesSuper-Mini-Series Z482 Z602 D722 D902Anonymous 9xvU1F100% (1)

- Dimensions and Weight NEW TDRY FIAC S.p.A. Air CompressorsDocument3 pagesDimensions and Weight NEW TDRY FIAC S.p.A. Air CompressorsCECOEL GROUPNo ratings yet

- Ed Uccp 201501Document39 pagesEd Uccp 201501XUAN CUONG PHAN0% (1)

- EFFI Compare SEWDocument16 pagesEFFI Compare SEWApinat ChaisriNo ratings yet

- 07TD Series: Water Cooled Condensing UnitDocument4 pages07TD Series: Water Cooled Condensing UnitFelix YewNo ratings yet

- Boge TecData S10-D S15-DDocument1 pageBoge TecData S10-D S15-DAndy KershawNo ratings yet

- Katalog Bare PDFDocument41 pagesKatalog Bare PDFYuDiNo ratings yet

- (CARLA) Orcamento GilbertoDocument1 page(CARLA) Orcamento GilbertoPedro NiyamaNo ratings yet

- Data Sheet Material 2.4819Document3 pagesData Sheet Material 2.4819BoberNo ratings yet

- Spec. No. 7311-DE-041Document1 pageSpec. No. 7311-DE-041HEMANTNo ratings yet

- 61.-Freetox N2XHDocument2 pages61.-Freetox N2XHjoseNo ratings yet

- Dewatering Screen LiteratureDocument4 pagesDewatering Screen LiteratureKaiser CarloNo ratings yet

- 5.0 MM Dia Led Lamp 540R2GBC-CC: REV:A / 0Document8 pages5.0 MM Dia Led Lamp 540R2GBC-CC: REV:A / 0Nicholas RichardsonNo ratings yet

- TimberLogic Log Wall Estimator 8x8 D Log HALH 2014Document32 pagesTimberLogic Log Wall Estimator 8x8 D Log HALH 2014John BolgerNo ratings yet

- Technical Data Sheet G-10: General DescriptionDocument1 pageTechnical Data Sheet G-10: General Descriptionbahtiar affandyNo ratings yet

- WackerNeuson-Single-phase Submersible Pumps-EnDocument3 pagesWackerNeuson-Single-phase Submersible Pumps-EnPATRICK PEPINNo ratings yet

- High and Medium Voltage CableDocument25 pagesHigh and Medium Voltage CableVipuchit SirikhemapornNo ratings yet

- Lampade ITADocument4 pagesLampade ITAaldo serraNo ratings yet

- 60hz Medium Static Type Concealed Duct Unit Service Manual - Editado NewDocument26 pages60hz Medium Static Type Concealed Duct Unit Service Manual - Editado NewManuel Guardia AraujoNo ratings yet

- Na2xy-O/ (J) : Din Vde 0276-603 (5G-2)Document3 pagesNa2xy-O/ (J) : Din Vde 0276-603 (5G-2)Asad Ali100% (1)

- Eq DF2Document1 pageEq DF2SKYhabiaNo ratings yet

- Bostrig SC UnarmoredDocument3 pagesBostrig SC UnarmoredEnrique MartínezNo ratings yet

- Zero Sequence1 - Summary PDFDocument4 pagesZero Sequence1 - Summary PDFTosikur RahmanNo ratings yet

- GDD - Dryer Technical DataDocument1 pageGDD - Dryer Technical Dataharminder singh0% (1)

- 6491 B - Enhanced Fire Safety Wiring Cable: Standard: Voltage RatingDocument1 page6491 B - Enhanced Fire Safety Wiring Cable: Standard: Voltage Ratingkennethr24No ratings yet

- 8CR2Document1 page8CR2Ary KurniawanNo ratings yet

- Firetuf FTP 120 - Fire Resistant Armoured Power Cable: ConstructionDocument25 pagesFiretuf FTP 120 - Fire Resistant Armoured Power Cable: ConstructionBhagoo HatheyNo ratings yet

- SUPA75Document1 pageSUPA75Roxxana Roxxana1990No ratings yet

- British Commercial Computer Digest: Pergamon Computer Data SeriesFrom EverandBritish Commercial Computer Digest: Pergamon Computer Data SeriesNo ratings yet

- Anglo–American Microelectronics Data 1968–69: Manufacturers A–PFrom EverandAnglo–American Microelectronics Data 1968–69: Manufacturers A–PNo ratings yet

- Assignment-Decision TreeDocument12 pagesAssignment-Decision TreeThAnos nNo ratings yet

- Notification Dated 18 June 2014Document109 pagesNotification Dated 18 June 2014Bar & BenchNo ratings yet

- Presentation 1Document13 pagesPresentation 1Aye Hnin PhyuNo ratings yet

- Alok SinghDocument96 pagesAlok SinghAlok Singh100% (1)

- UNEB JANUARY 2023 PROGRESS REPORT-AdditionaLDocument6 pagesUNEB JANUARY 2023 PROGRESS REPORT-AdditionaLmpairwe cliffortNo ratings yet

- Moviegoers StatisticsDocument25 pagesMoviegoers StatisticsJose Angel Hernandez100% (1)

- Econ Finals QuizzesDocument12 pagesEcon Finals QuizzesMaimona SemaNo ratings yet

- The Power of CompoundingDocument5 pagesThe Power of CompoundingWaleed TariqNo ratings yet

- 44 Depreciation ScheduleDocument6 pages44 Depreciation SchedulezydusNo ratings yet

- Trustline Summer Training Report PresentationDocument27 pagesTrustline Summer Training Report Presentationatul kumar100% (1)

- Form VAT R2Document10 pagesForm VAT R2murarirahul80% (5)

- Texhong Textile GroupDocument23 pagesTexhong Textile GroupHatcafe HatcafeNo ratings yet

- Marketing Strategy of A Telecom Product in BangladeshDocument6 pagesMarketing Strategy of A Telecom Product in Bangladeshsauvik84inNo ratings yet

- QP 055 Accountancy Set 1Document40 pagesQP 055 Accountancy Set 1minisha.chawla09No ratings yet

- JICA 2013 Assessment Survey On Agriculture MyanmarDocument167 pagesJICA 2013 Assessment Survey On Agriculture MyanmarBenoit Ibv100% (1)

- Engagement State in UsDocument214 pagesEngagement State in UsfrenkybgdNo ratings yet

- Rate of ReturnDocument16 pagesRate of Returnsanjog kshetriNo ratings yet

- Accounting, Auditing & Accountability Journal: Article InformationDocument26 pagesAccounting, Auditing & Accountability Journal: Article InformationAnonymous yMOMM9bsNo ratings yet

- Environmental Product Declaration: Cement Based Tile AdhesivesDocument7 pagesEnvironmental Product Declaration: Cement Based Tile AdhesivesIoana CNo ratings yet

- ECN 211 QuestionsDocument84 pagesECN 211 QuestionsDaniel AdegboyeNo ratings yet

- Price List 2009 - MOSIL - MRP Only Rev 01 Issue 01Document16 pagesPrice List 2009 - MOSIL - MRP Only Rev 01 Issue 01pratikshah202100% (1)

- Sandia Homes Pricelist As of 09.25.20 Local OnlyDocument1 pageSandia Homes Pricelist As of 09.25.20 Local OnlyvicNo ratings yet

- Document #10B.1 - FY2018 Operating Budget Report - January 24, 2018 PDFDocument5 pagesDocument #10B.1 - FY2018 Operating Budget Report - January 24, 2018 PDFGary RomeroNo ratings yet