Professional Documents

Culture Documents

Bellow Seal Globe Valve BLS1 (DN15-DN200)

Uploaded by

Peerasut ChaisrimaneepanCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Bellow Seal Globe Valve BLS1 (DN15-DN200)

Uploaded by

Peerasut ChaisrimaneepanCopyright:

Available Formats

BLS1-01

ARITA Revise 02

Bellow Seal Globe Valve

Model : BLS1

Body : Cast Steel

Flanged PN 16

Description

“ARITA” Bellow seal globe valve in line stop valve

for use on steam ,gas, liquid systems.

Size and pipe connections

DN15, 20, 25, 32, 40, 50, 65, 80, 100, 125, 150, 200

Flanged PN16

Limiting conditions

Body design condition PN40

Maximum design temperature 400 oC

Maximum operating pressure 16 bar

Designed for a maximum cold hydraulic 60 bar

test pressure.

Pressure / Temperature limits

400

Temperature C

o

300

200 Steam saturation curve

100

0

0 5 10 15 20 25 30 35 40

Pressure bar g 37

7

Materials

Parts Materials

1 Body Cast Steel GS-C25

2 Seat Cast Steel GS-C25+13CR 6

3 Disc Forged Steel A105+13CR 5

4 Bellows Stainless Steel SS 304 4

Graphite Laminated with

5 Body bonnet gasket 3

Stainless Steel Insert

2

6 Bonnet Cast Steel GS-C25

1

7 Stem Stainless Steel 2Cr13 / 420

Size DN15 DN20 DN25 DN32 DN40 DN50 DN65 DN80 DN100 DN125 DN150 DN200

Kv 4 7 12 19 30 47 77 120 193 288 410 725

For conversion : Cv (UK) = Kv x 0.97 Cv(US) = Kv x 1.17

BLS1-02

ARITA Bellow Seal Globe Valve Revise 02

Dimension (approximate) in mm and kg

Size DN15 DN20 DN25 DN32 DN40 DN50 DN65 DN80 DN100 DN125 DN150 DN200

L 130 150 160 180 200 230 290 310 350 400 480 600

D 95 105 115 140 150 165 185 200 220 250 285 340

D1 65 75 85 100 110 125 145 160 180 210 240 295

D2 45 58 68 78 88 102 122 138 158 188 212 268

b 16 18 18 18 18 20 20 20 20 22 22 24

f 2 2 2 2 3 3 3 3 3 3 3 3

H 195 195 207 218 225 230 272 290 355 410 425 540

W 140 140 160 160 160 200 220 250 300 350 350 445

4 4 4 4 4 4 4 8 8 8 8 8

Welght 4 4.5 5 7 9 12 18.5 23 38.5 56 75 113.5

H

DN

D1

D2

b f

L

Installation

Install the valve in the direction of flow given by the arrow on the body.

The preferred position is with the spindle vertical.

The valve can be installed from the vertical to the horizontal plane

Note : It is advisable that when work is being carried out downstream of a valve installation, double

isolation (block and bleed) should be fitted. In addition when installed as the final valve in

a pipeline, as a safety precaution, a blanking plate or blank flanged must be fitted at the outlet.

You might also like

- Diamec U6 PHC Hydraulic SystemDocument15 pagesDiamec U6 PHC Hydraulic SystemEmanuel Nicolas Villarruel100% (5)

- Plumbing Bank 2 PDFDocument14 pagesPlumbing Bank 2 PDFRichardPerezFabian100% (2)

- Materials Data for Cyclic Loading: Low-Alloy SteelsFrom EverandMaterials Data for Cyclic Loading: Low-Alloy SteelsRating: 5 out of 5 stars5/5 (2)

- Metering Pumps SpecDocument2 pagesMetering Pumps Spececsuperal100% (1)

- Lift Check Valve: Straight, Flanged EndsDocument1 pageLift Check Valve: Straight, Flanged Endsadvantage025No ratings yet

- CP-3513NO-EF-003 - 0G P&ID North - Automatic Well Test System SHT 4 of 4Document1 pageCP-3513NO-EF-003 - 0G P&ID North - Automatic Well Test System SHT 4 of 4aerfansNo ratings yet

- Turbine RollingDocument39 pagesTurbine RollingSarah Frazier100% (2)

- PumpDocument9 pagesPumpNguyen ChuyenNo ratings yet

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- Troubleshooting Pumps: Pump Failure AnalysisDocument19 pagesTroubleshooting Pumps: Pump Failure Analysispankaj vermaNo ratings yet

- SM VOLVO L90C WHEEL LOADER Service Repair ManualDocument16 pagesSM VOLVO L90C WHEEL LOADER Service Repair ManualMarco Yarasca Romero100% (2)

- Spare Parts Catalogue: Purebilge SystemDocument101 pagesSpare Parts Catalogue: Purebilge SystemCentrifugal SeparatorNo ratings yet

- ROBINET SERTAR PANA CORP PLAT TECOFI Model V3200 - Fisa TehnicaDocument1 pageROBINET SERTAR PANA CORP PLAT TECOFI Model V3200 - Fisa TehnicaVasi ChiriacNo ratings yet

- 2309+QT04 - Gala-Motorized Butterfly ValveDocument4 pages2309+QT04 - Gala-Motorized Butterfly ValveNam Đỗ100% (1)

- Cast Iron Regulating Globe Valves PN 16Document3 pagesCast Iron Regulating Globe Valves PN 16Mohamed RaafatNo ratings yet

- Swing Check DrawDocument1 pageSwing Check DrawPriyanka rajpurohitNo ratings yet

- 05263G Sample ChapterDocument1 page05263G Sample ChapterBambangIrawan48No ratings yet

- Balancing Valve Honeywell MakeDocument8 pagesBalancing Valve Honeywell MakeNagendra EtikalaNo ratings yet

- IGV-D (Group) (V0418) - RevisedDocument1 pageIGV-D (Group) (V0418) - Revisedismi iqhwan ihsanNo ratings yet

- Swing Check Valve Rubber DiscDocument2 pagesSwing Check Valve Rubber DiscsathishNo ratings yet

- (S-11.12-00) 2019 Gala Butterfly Valve Wafer Type 16 Bar SUS 304 Disc ANSI 150 Fig 2302Document3 pages(S-11.12-00) 2019 Gala Butterfly Valve Wafer Type 16 Bar SUS 304 Disc ANSI 150 Fig 2302Bernard Bonnin CervantesNo ratings yet

- ValvesgaDocument1 pageValvesgaDado AliNo ratings yet

- En Ab Avdc PDFDocument8 pagesEn Ab Avdc PDFManuel ValenciaNo ratings yet

- MDT 2021 Bro Yfe 10K FCDocument1 pageMDT 2021 Bro Yfe 10K FCsuwono radukNo ratings yet

- Safety Relief Valve VSEODocument4 pagesSafety Relief Valve VSEOShashank HNo ratings yet

- DIN 2545 PN40 Plate Flange (Slip On Flange)Document2 pagesDIN 2545 PN40 Plate Flange (Slip On Flange)celiajudalineNo ratings yet

- 5104-Gala-Silent Check ValveDocument1 page5104-Gala-Silent Check ValveNam ĐỗNo ratings yet

- V5-Gan-Gp16 Series: Resilient Seated Gate Valve, Non Rising Stem (Hand Wheel)Document2 pagesV5-Gan-Gp16 Series: Resilient Seated Gate Valve, Non Rising Stem (Hand Wheel)Em Es WeNo ratings yet

- Valvula de Retencion A Clapeta Oscilante Din pn16 dn50 300Document2 pagesValvula de Retencion A Clapeta Oscilante Din pn16 dn50 300JOHNNY CALERONo ratings yet

- Swing Check Valve - Flanged: Technical FeaturesDocument1 pageSwing Check Valve - Flanged: Technical FeaturesAhmed El MorsyNo ratings yet

- Fig. 292 ® Gate Valve: Also Available in PN16Document2 pagesFig. 292 ® Gate Valve: Also Available in PN16TamNo ratings yet

- Comp PN16Document1 pageComp PN16Martin Augusto Torrau CayoNo ratings yet

- V4-CWD-A200: Double Door Check ValveDocument1 pageV4-CWD-A200: Double Door Check ValveArthur DeiparineNo ratings yet

- SY Rubber Disc Check ValveDocument2 pagesSY Rubber Disc Check ValvePhú Song LongNo ratings yet

- NAF-Navalsteam Ball Valves FK 25.76 (2) GB: Primary CharacteristicsDocument2 pagesNAF-Navalsteam Ball Valves FK 25.76 (2) GB: Primary CharacteristicsNguyen KhaNo ratings yet

- Diaphragm Valve: G2K Rising HW Type, Flanged EndsDocument1 pageDiaphragm Valve: G2K Rising HW Type, Flanged EndsHARSHANo ratings yet

- 3521 Gala Gate Valve CatalogDocument1 page3521 Gala Gate Valve CatalogChhomNo ratings yet

- Ghibson GB015Document2 pagesGhibson GB015Jessicalba LouNo ratings yet

- LIFECO Model 3299 300 FLF OSY Resilient Seated Gate ValveDocument1 pageLIFECO Model 3299 300 FLF OSY Resilient Seated Gate ValveEng.Ibrahim OthmanNo ratings yet

- Temp. Control ValveDocument7 pagesTemp. Control Valvesaurabh kumarNo ratings yet

- OSY Flanged Ends 3299 300 FLF 3 1Document1 pageOSY Flanged Ends 3299 300 FLF 3 1melashry2023No ratings yet

- Ca 3241Document1 pageCa 3241Tien LamNo ratings yet

- OS&Y Gate Valves - Flanged Ends: Schematic DrawingDocument1 pageOS&Y Gate Valves - Flanged Ends: Schematic Drawingbhima irabattiNo ratings yet

- CFV Foot ValveDocument1 pageCFV Foot ValveAgung YudistiraNo ratings yet

- KSB Psa KHG-WDocument4 pagesKSB Psa KHG-WRicardo BarrosNo ratings yet

- Econ Ball Valves PN 16 Bronze Fig. 1943: Full Bore 1 or 2 Piece Body Blow-Out Proof StemDocument1 pageEcon Ball Valves PN 16 Bronze Fig. 1943: Full Bore 1 or 2 Piece Body Blow-Out Proof StemChristianGuerreroNo ratings yet

- Technical Data Sheet: OS&Y Resilient Seated Gate Valve - Flanged Ends-300PSIDocument1 pageTechnical Data Sheet: OS&Y Resilient Seated Gate Valve - Flanged Ends-300PSIshoaibmahmood312No ratings yet

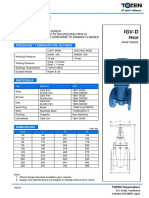

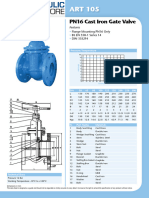

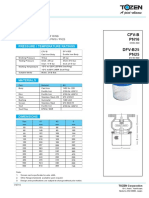

- Tozen Valve CatalogueDocument45 pagesTozen Valve CatalogueMyo Kyaw Kyaw100% (1)

- QuotationDocument1 pageQuotationNhật Quang PhạmNo ratings yet

- NPT Sop Pde 004 f08 Bom Globe ValveDocument18 pagesNPT Sop Pde 004 f08 Bom Globe ValveMohamed SelimNo ratings yet

- 11.8a Ghibson GB015Document2 pages11.8a Ghibson GB015Shah Rizal AbidNo ratings yet

- Armas-Strainer-Y TypeDocument2 pagesArmas-Strainer-Y TypeAnnie De WildeNo ratings yet

- Circular Sightglas e Malux Din28120Document2 pagesCircular Sightglas e Malux Din28120ivanoliveira3261No ratings yet

- AP014Document1 pageAP014Bibene MakitaNo ratings yet

- Econ Ball Valves Carbon Steel Stainless Steel 3 Way Port: Full Bore Blow-Out Proof StemDocument1 pageEcon Ball Valves Carbon Steel Stainless Steel 3 Way Port: Full Bore Blow-Out Proof StemChristianGuerreroNo ratings yet

- Fig. 315 / 330 G Fig. 415 / 430: Ball Valves PN 20/50 (Class 150/300) AIT & IIT ConstructionDocument5 pagesFig. 315 / 330 G Fig. 415 / 430: Ball Valves PN 20/50 (Class 150/300) AIT & IIT ConstructionBureau VeritasNo ratings yet

- Spirax Sarco Piston Valve RP31Document2 pagesSpirax Sarco Piston Valve RP31PaulNo ratings yet

- RBRCO21CPB100-Tapping Saddle Flanged Outlet For DI and Steel PipesDocument3 pagesRBRCO21CPB100-Tapping Saddle Flanged Outlet For DI and Steel PipesALESSANDRONo ratings yet

- En bf880 PDFDocument1 pageEn bf880 PDFshaonaaNo ratings yet

- CI Wafer / DI Lug Butterfly Valves: Series 0160Document2 pagesCI Wafer / DI Lug Butterfly Valves: Series 0160Vignesh NadimuthuNo ratings yet

- MDT 2021 Bro Gtfe 10K FCDocument1 pageMDT 2021 Bro Gtfe 10K FCsuwono radukNo ratings yet

- CFV-B: Foot ValveDocument1 pageCFV-B: Foot Valveimmanuel izaniNo ratings yet

- Iron Wafer Type Check Valve: Kitz Cast Iron ValvesDocument1 pageIron Wafer Type Check Valve: Kitz Cast Iron ValvesAndy SetyawanNo ratings yet

- 447 - en - CAAV - DAAV (CAAV0620S)Document1 page447 - en - CAAV - DAAV (CAAV0620S)Mohammed NiqrisNo ratings yet

- Visilume Standard Sightglass: (Also Available Complete With Wiper Assembly)Document2 pagesVisilume Standard Sightglass: (Also Available Complete With Wiper Assembly)Dương HoàngNo ratings yet

- Cast Steel Gate Valves: Class 150 - Outside Screw & Yoke - Flexible Wedge DiscDocument3 pagesCast Steel Gate Valves: Class 150 - Outside Screw & Yoke - Flexible Wedge DiscMina MagdyNo ratings yet

- 200 - Series TI S03 03 ENDocument5 pages200 - Series TI S03 03 ENMalik DaniyalNo ratings yet

- Gala ValveDocument2 pagesGala ValveThomas JohnNo ratings yet

- PN25 Rating Valves: Cast Iron Gate Valve/Cast Iron Swing Check Valve/ Ductile Iron Y-Pattern StrainerDocument2 pagesPN25 Rating Valves: Cast Iron Gate Valve/Cast Iron Swing Check Valve/ Ductile Iron Y-Pattern StrainerSenoPati KudusNo ratings yet

- Li 2019 IOP Conf. Ser. Earth Environ. Sci. 237 042020Document6 pagesLi 2019 IOP Conf. Ser. Earth Environ. Sci. 237 042020Peerasut ChaisrimaneepanNo ratings yet

- 2019 NEBB - Ninth Edition - TAB Procedure Standard CommissioningDocument84 pages2019 NEBB - Ninth Edition - TAB Procedure Standard CommissioningPeerasut ChaisrimaneepanNo ratings yet

- HumG-HQ-21 r2 210616 For GeneralDocument26 pagesHumG-HQ-21 r2 210616 For GeneralPeerasut ChaisrimaneepanNo ratings yet

- AI195986432891en 000101Document2 pagesAI195986432891en 000101Peerasut ChaisrimaneepanNo ratings yet

- Ahstco Product CatalogDocument79 pagesAhstco Product CatalogPeerasut ChaisrimaneepanNo ratings yet

- LID - 281201 - EN - Testing Procedures For Valve Repair ShopsDocument9 pagesLID - 281201 - EN - Testing Procedures For Valve Repair ShopsPeerasut ChaisrimaneepanNo ratings yet

- คำนวณอาคาร LIONDocument2 pagesคำนวณอาคาร LIONPeerasut ChaisrimaneepanNo ratings yet

- Chap12 SummerDocument29 pagesChap12 SummerPeerasut ChaisrimaneepanNo ratings yet

- เงื่อนไขในการใช้บริการสอบเทียบDocument1 pageเงื่อนไขในการใช้บริการสอบเทียบPeerasut ChaisrimaneepanNo ratings yet

- สติ๊กเกอร์ พวงลาลัยDocument1 pageสติ๊กเกอร์ พวงลาลัยPeerasut ChaisrimaneepanNo ratings yet

- LCT-M-100 Water Pipe Layout Rev.ADocument4 pagesLCT-M-100 Water Pipe Layout Rev.APeerasut ChaisrimaneepanNo ratings yet

- 9 13 353 0Document6 pages9 13 353 0Peerasut ChaisrimaneepanNo ratings yet

- 8.ANSI-AMCA 210-07 ANSI-ASHRAE 51-07 Laboratory Methods of Testing Fans For Certified Aerodynamic Performance RatingDocument78 pages8.ANSI-AMCA 210-07 ANSI-ASHRAE 51-07 Laboratory Methods of Testing Fans For Certified Aerodynamic Performance RatingPeerasut ChaisrimaneepanNo ratings yet

- Pan 341Document42 pagesPan 341Peerasut ChaisrimaneepanNo ratings yet

- Thailand Outside Design ConditionsDocument59 pagesThailand Outside Design ConditionsPeerasut ChaisrimaneepanNo ratings yet

- HPG-PYW-S-06.1 - r2 Info To ME-62Document1 pageHPG-PYW-S-06.1 - r2 Info To ME-62Peerasut ChaisrimaneepanNo ratings yet

- TM044 TG - : CLARK TC C8602-146 REV.1 Assesment SheetDocument5 pagesTM044 TG - : CLARK TC C8602-146 REV.1 Assesment SheetXG WNo ratings yet

- Solenoid - Controlled - Pilot - Operated - Relief - Valve - SRF SeriesDocument6 pagesSolenoid - Controlled - Pilot - Operated - Relief - Valve - SRF SeriesEvandro Amaral RodriguesNo ratings yet

- Boiler Lab Safety Precaution 1Document12 pagesBoiler Lab Safety Precaution 1Muhammad UsmanNo ratings yet

- Pipierack PlanDocument1 pagePipierack PlanpouyaNo ratings yet

- SS316 Hose FittingsDocument79 pagesSS316 Hose FittingsRasheshNo ratings yet

- Catalogo AnchorDocument60 pagesCatalogo AnchorFlores BrayanNo ratings yet

- Waterjet 2008 CondensedDocument12 pagesWaterjet 2008 Condensedkaniappan sakthivelNo ratings yet

- DPV 50 HZ Vertical Pumps Technical DataDocument92 pagesDPV 50 HZ Vertical Pumps Technical DataEugenia BondarenkoNo ratings yet

- Catalogue Galtech enDocument36 pagesCatalogue Galtech endifevasanzNo ratings yet

- AR05.00-B-5521C.fm Remove and Install The Rocker Arms Mechanism 14.08.00Document4 pagesAR05.00-B-5521C.fm Remove and Install The Rocker Arms Mechanism 14.08.00LUKASNo ratings yet

- H405 Pipe Surge DatasheetDocument5 pagesH405 Pipe Surge DatasheetAdakole ObekaNo ratings yet

- Datasheet Test Pumps P40 P60Document2 pagesDatasheet Test Pumps P40 P60Михаил УльяновNo ratings yet

- Taiko ProductsDocument7 pagesTaiko ProductsAntonio AvilesNo ratings yet

- Cash Flow Requirement - QAP128Document9 pagesCash Flow Requirement - QAP128OmkarNo ratings yet

- Centrifugal Pump Basics: Terms Commonly Used in The Pumping IndustryDocument18 pagesCentrifugal Pump Basics: Terms Commonly Used in The Pumping Industrykomed diNo ratings yet

- Steel PIPE CHART PDFDocument1 pageSteel PIPE CHART PDFSatria 'igin' Girindra NugrahaNo ratings yet

- Lunch Box Session Series-And-Parallel PDFDocument6 pagesLunch Box Session Series-And-Parallel PDFmohamed adel ElreedyNo ratings yet

- Grout Pumps & System PDFDocument13 pagesGrout Pumps & System PDFImran AlamNo ratings yet

- Stock ListDocument6 pagesStock ListRajiv RanjanNo ratings yet

- J.1.1 - Gazpro-003-Ds-Inst-001-01 - PLC Input Output ListDocument10 pagesJ.1.1 - Gazpro-003-Ds-Inst-001-01 - PLC Input Output ListLanreSKNo ratings yet

- 104 13479 Mob02918 DSH 420 M 0008 - 2Document2 pages104 13479 Mob02918 DSH 420 M 0008 - 2Luis Orlando Gil BancallanNo ratings yet