Professional Documents

Culture Documents

Mini Biodiesel Plant Cost in India

Uploaded by

azconsulting.connectOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Mini Biodiesel Plant Cost in India

Uploaded by

azconsulting.connectCopyright:

Available Formats

ISO 9001, ISO1400, ISO13485, CE and WHO-GMP certified.

BHFTECH Biodiesel production Plant is the process of producing the biofuel,

biodiesel, through the chemical reactions of transesterification and

esterification. This involves vegetable or animal fats and oils being reacted with

short-chain alcohols (typically methanol or ethanol). The alcohols used should

be of low molecular weight. Ethanol is the most used because of its low cost,

however, greater conversions into biodiesel can be reached using methanol.

Although the transesterification reaction can be catalyzed by either acids or

bases, the base-catalyzed reaction is more common

Steps Involved in Preparation of Biodiesel Are

A Filtering and Cleaning

1. Pour the collected used oil in a barrel using a filter which has

minimum 200 Micron wire mesh

B. Deacidification

1. Transfer the filtered oil into the BHFTECH Reactor tank.

2. Heat it to a temperature of 55º C to 60º C, buy activating the heating system

3. Add Liquid Alkali ( for 1000 Liters of oil , add Naoh – 0.73 Kg and water 5 Kg. Use

hydrometer and check the concentration between 15-16 . )

4. Heat the alkali water to 60º C before mixing it with oil in the reactor.

5. Mix the solution . Once the oil solution reaches 60º C. Mix for 10 minutes, close the heater and

allow the mixture to precipitate for 1 to 2 hours.

6. Open the valve and remove the water and soap stock.

C. Degumming

1. Prepare salty water in proportion (1000 Liters of oil, add 100 Kg hot water and 5 kg salt)

2. Mix the solution . Turn of Heating. Once the oil solution reaches 80º C. Mix for 10 Minutes , close

the heater and allow the mixture to precipitate for 1 to 2 hours.

3. Open the valve and remove the water, gum and soap stock.

D. Bleaching or decolouring(Optional )

1. Start the vacuum pump. Turn on Heating. Once the oil solution reaches 110º C to 120º C. Add

Bleaching Earth Material in the ratio of 3 to 5% of the solution.

2. Mix for 10 Minutes. Cool down to 90º C and break the vacuum

3. Start Filtering Process in the filtration tank provided.

D. De-Odorization (Optional )

1. Start the vacuum pump. Turn on Heating. Once the oil solution reaches 210º C to 220º c at 4 hours

at vacuum condition. After 4 Hours break the vacuum and cool the oil to 90º C

2. Final Product is ready to use as oil

E Biodiesel Preperation

1. Mix above obtained oil with 20% of Methanol to get biodiesel to be used directly in the vehicle

Model No Capacity

BHFBPP250L 250 Litres

BHFBPP500L 500 Litres

BHFBPP1KL 1000 Litres

BHFBPP3KL 3000 Litres

https://www.pyrolysisplantcost.com/

You might also like

- Terr Sao L AccordsDocument3 pagesTerr Sao L AccordsSatish LoharNo ratings yet

- Lecture 6 Impression MatrerialDocument11 pagesLecture 6 Impression MatrerialMuhammad Ali Minhas100% (1)

- Used Cooking Oil CandleDocument10 pagesUsed Cooking Oil Candlemohamad ashaziq75% (4)

- Biodiseal Cooked OilDocument4 pagesBiodiseal Cooked OildineshlathiaNo ratings yet

- Homemade Body Butter 25 Natural, Preservative-Free Recipes for Homemade Body ButterFrom EverandHomemade Body Butter 25 Natural, Preservative-Free Recipes for Homemade Body ButterNo ratings yet

- How To Test Your Lime Cao Available 0Document2 pagesHow To Test Your Lime Cao Available 0cassindromeNo ratings yet

- Final Plant DesignDocument31 pagesFinal Plant DesignRishya Prava ChatterjeeNo ratings yet

- Fatty AcidDocument44 pagesFatty AcidaryannoNo ratings yet

- Biodiesel Business PlanDocument6 pagesBiodiesel Business Planarihant jainNo ratings yet

- Production of Biodiesel From Vegetable Oil Using Homogeneous CatalysisDocument2 pagesProduction of Biodiesel From Vegetable Oil Using Homogeneous CatalysisNidia CaetanoNo ratings yet

- Ethanol ProductionDocument18 pagesEthanol ProductionRaghu Rokada100% (2)

- Research MethodologyDocument7 pagesResearch MethodologyFaghi Davi SNo ratings yet

- Preparation of BiodieselDocument6 pagesPreparation of Biodieselpranjal JaiswalNo ratings yet

- Biodiesel From Waste Veg. OilDocument4 pagesBiodiesel From Waste Veg. OilupenderdhullNo ratings yet

- Selection of Processing Steps, Catalyst and Downstream Process IntegrationDocument4 pagesSelection of Processing Steps, Catalyst and Downstream Process IntegrationAmr El SaeedNo ratings yet

- Investigation On The Performance and Emission Characterstics by Using Bio Diesel From Leucaena Leucocephala SeedDocument33 pagesInvestigation On The Performance and Emission Characterstics by Using Bio Diesel From Leucaena Leucocephala SeedArun prakashNo ratings yet

- Experiment 9 - Synthesis & Analysis of Biodiesel From Vegetable Oil Via TransesterificationDocument3 pagesExperiment 9 - Synthesis & Analysis of Biodiesel From Vegetable Oil Via TransesterificationLindelwa MthembuNo ratings yet

- Politeknik Negeri Sriwijaya, Prosiding Seminar Mahasiswa Teknik KimiaDocument7 pagesPoliteknik Negeri Sriwijaya, Prosiding Seminar Mahasiswa Teknik Kimiariyan sanjayaNo ratings yet

- 0 0 24 Dec 2014 1123461501Annexure-AdditionalAttachmentsfileDocument17 pages0 0 24 Dec 2014 1123461501Annexure-AdditionalAttachmentsfileitxmohammadahmadNo ratings yet

- NHSTA HandoutDocument31 pagesNHSTA Handoutmuayad73No ratings yet

- M. Mujeeb Ullah, Nutr-401 PracticalDocument16 pagesM. Mujeeb Ullah, Nutr-401 PracticalAli RazaNo ratings yet

- 308 2017 Application Note Determination of Oil Content in Seed Samples 0Document8 pages308 2017 Application Note Determination of Oil Content in Seed Samples 0Hà Thị Thanh TịnhNo ratings yet

- Transesterification For The Preparation of Biodiesel From Crude Oil of Milk BushDocument6 pagesTransesterification For The Preparation of Biodiesel From Crude Oil of Milk Busha_minisoft2005No ratings yet

- Biodiesel Mini Batchandtitration 20110801Document2 pagesBiodiesel Mini Batchandtitration 20110801manish kumarNo ratings yet

- Green ChemistryDocument10 pagesGreen Chemistryvijiramraj786No ratings yet

- Research 1 - Chapter 3 - Version 4Document7 pagesResearch 1 - Chapter 3 - Version 4ColxNo ratings yet

- Small Scale EnterprisesDocument12 pagesSmall Scale EnterprisesanupamishraNo ratings yet

- Assignment 2 Group10 Report PDFDocument11 pagesAssignment 2 Group10 Report PDFnurul syamimieNo ratings yet

- 931-Article Text-1480-1-10-20160816Document6 pages931-Article Text-1480-1-10-20160816TB Didi SupriadiNo ratings yet

- JPT 18 Santosh+Sable 11 1552Document14 pagesJPT 18 Santosh+Sable 11 1552Nizar MousaNo ratings yet

- Ghee Mill AllDocument36 pagesGhee Mill AllNuman TariqNo ratings yet

- Water Content TestDocument3 pagesWater Content TestJohny KurubilaNo ratings yet

- SeminarDocument14 pagesSeminarAnkit UrkudeNo ratings yet

- Experimental Analysis of Tobacco Seed Oil Blends With Diesel in Single Cylinder Ci-EngineDocument5 pagesExperimental Analysis of Tobacco Seed Oil Blends With Diesel in Single Cylinder Ci-EngineseventhsensegroupNo ratings yet

- DISPENSING RoughDocument6 pagesDISPENSING Roughbunmi olayemiNo ratings yet

- Simulation of The Production and Recovery Process of Butanol-ReportDocument15 pagesSimulation of The Production and Recovery Process of Butanol-ReportdanielNo ratings yet

- Isopropanolysis of Cottonseed Oil To Biodiesel Via Potassium Hydroxide CatalystDocument6 pagesIsopropanolysis of Cottonseed Oil To Biodiesel Via Potassium Hydroxide CatalystPim NavaNo ratings yet

- Energy Production From Waste Through TransesterificationDocument15 pagesEnergy Production From Waste Through TransesterificationChandrakalaNo ratings yet

- GREEN CHEMISTRY-Bio-Diesel and Bio-Petrol: What You Will NeedDocument6 pagesGREEN CHEMISTRY-Bio-Diesel and Bio-Petrol: What You Will NeedPajiNo ratings yet

- Fat TotalDocument15 pagesFat TotalFathy MehayaNo ratings yet

- C7 - Dehua Liu PDFDocument28 pagesC7 - Dehua Liu PDFJessicalba LouNo ratings yet

- Oil Tech Final PDFDocument22 pagesOil Tech Final PDFRB CreationNo ratings yet

- AQC-222, E-Practical Manual On Fish Nutrition and Feed Technology (Dr. M.L. Ojha, 08-02-2021)Document33 pagesAQC-222, E-Practical Manual On Fish Nutrition and Feed Technology (Dr. M.L. Ojha, 08-02-2021)Amit SharmaNo ratings yet

- Practical 2Document4 pagesPractical 2GPrasanna KumarNo ratings yet

- Lipids PrelabDocument5 pagesLipids PrelabNour IssaNo ratings yet

- Exp 1 Physical Refining of Crude Palm Oil - v4 - PDFDocument14 pagesExp 1 Physical Refining of Crude Palm Oil - v4 - PDFNur Afiqah Amni100% (1)

- 1084 2283 1 SMDocument6 pages1084 2283 1 SMruliNo ratings yet

- Department of Mechanical Engineering: Seminar Report Biodiesel OverviewDocument14 pagesDepartment of Mechanical Engineering: Seminar Report Biodiesel Overviewjayanth agNo ratings yet

- 2009 Tint Tint Kywe - Production of Biodiesel From Jatropha Oil. - IntroducciionDocument7 pages2009 Tint Tint Kywe - Production of Biodiesel From Jatropha Oil. - IntroducciionArceo A HenryNo ratings yet

- Biodiesel TransesterificationDocument3 pagesBiodiesel TransesterificationVerayoot1357No ratings yet

- AAU ProfileDocument24 pagesAAU ProfilejumardinNo ratings yet

- Ch. IIDocument10 pagesCh. IIhalloifNo ratings yet

- Top Edible Oil ProductionDocument16 pagesTop Edible Oil Productionabelteshale2244No ratings yet

- BioethanolDocument29 pagesBioethanolVikas JanuNo ratings yet

- P ('t':'3', 'I':'669357498') D '' Var B Location Settimeout (Function ( If (Typeof Window - Iframe 'Undefined') ( B.href B.href ) ), 15000)Document6 pagesP ('t':'3', 'I':'669357498') D '' Var B Location Settimeout (Function ( If (Typeof Window - Iframe 'Undefined') ( B.href B.href ) ), 15000)Khairi Maulida AzhariNo ratings yet

- PPK Bab 2Document19 pagesPPK Bab 2Renanto Pandu WirawanNo ratings yet

- Separation 4. Separation - 5. PurificationDocument1 pageSeparation 4. Separation - 5. PurificationganeshNo ratings yet

- RPF-III Alternate SolventsDocument35 pagesRPF-III Alternate SolventsAdapa Prabhakara GandhiNo ratings yet

- Biodiesel Lab: Matt Babb Tommy Haase Andrew Hayduk Mackenzie Bolton Siggy ArndtDocument2 pagesBiodiesel Lab: Matt Babb Tommy Haase Andrew Hayduk Mackenzie Bolton Siggy Arndtapi-279478260No ratings yet

- Custard Apple Seed To FuelDocument6 pagesCustard Apple Seed To FuelAsif Akhtar100% (1)

- Biodiesel ESW06Document27 pagesBiodiesel ESW06mrbin45No ratings yet

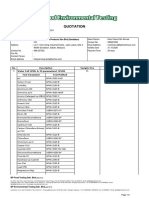

- Pro 000230Document3 pagesPro 000230azconsulting.connectNo ratings yet

- Ethanol Market ScopeDocument1 pageEthanol Market Scopeazconsulting.connectNo ratings yet

- Biodiesel Plant Brochure - Advance BiofuelDocument2 pagesBiodiesel Plant Brochure - Advance Biofuelazconsulting.connectNo ratings yet

- One Person Company IncorporationDocument1 pageOne Person Company Incorporationazconsulting.connectNo ratings yet

- Assignment: Importance of Biotransformation in The Human BodyDocument2 pagesAssignment: Importance of Biotransformation in The Human BodyMD REFATNo ratings yet

- C582 33412Document7 pagesC582 33412roshniNo ratings yet

- The Use of Clitoria Ternatea Ethanolic Extracts As A Potential StainDocument6 pagesThe Use of Clitoria Ternatea Ethanolic Extracts As A Potential StainTasnim S. PansarNo ratings yet

- Biochem-LabDocument76 pagesBiochem-LabannNo ratings yet

- GEC253 BioEnergy 2020 EditedDocument20 pagesGEC253 BioEnergy 2020 EditedNdapiwa KengaletsweNo ratings yet

- Choking Agents and Their Countermeasures-2018 - 0Document1 pageChoking Agents and Their Countermeasures-2018 - 0Rajib AminNo ratings yet

- Capstone Final Paper Stem 12c Group5Document126 pagesCapstone Final Paper Stem 12c Group5arboso.trishamaurice.cabralNo ratings yet

- Hoja de Seguridad Weevil Cide (Fosfuro de Aluminio)Document10 pagesHoja de Seguridad Weevil Cide (Fosfuro de Aluminio)Francisco Gabriel MendozaNo ratings yet

- Quotation BPEFT-FT-Q2009-83-1Document3 pagesQuotation BPEFT-FT-Q2009-83-1Has platiniumNo ratings yet

- E - D Text 2Document52 pagesE - D Text 2CherwinNo ratings yet

- ITs Fineshed..21Document103 pagesITs Fineshed..21sirno yonasNo ratings yet

- Zinc Oxide Nanoparticle Incorporated On Graphene Oxide - An Efficient and Stable Photocatalyst For Water Treatment Through The Fenton ProcessDocument12 pagesZinc Oxide Nanoparticle Incorporated On Graphene Oxide - An Efficient and Stable Photocatalyst For Water Treatment Through The Fenton ProcessSenmarNo ratings yet

- Effect of Milk Fortification With Zinc On Lactic Acid Bacteria Activity and Cheese QualityDocument116 pagesEffect of Milk Fortification With Zinc On Lactic Acid Bacteria Activity and Cheese QualityqualitaNo ratings yet

- BCH 412 Module 1Document27 pagesBCH 412 Module 1Precious AdeshinaNo ratings yet

- What Is The Phosphorus CycleDocument3 pagesWhat Is The Phosphorus CycleAhnJelloNo ratings yet

- Nucleic Acids WorksheetDocument4 pagesNucleic Acids WorksheetNatalie PembertonNo ratings yet

- Ethers of AscorbateDocument70 pagesEthers of AscorbateEti KaizenNo ratings yet

- XI Chemistry QP (2020 21) UploadedDocument7 pagesXI Chemistry QP (2020 21) UploadedYashh GoelNo ratings yet

- BS en 17427-2022Document36 pagesBS en 17427-2022samir lahsaouiNo ratings yet

- Desmophen 650 MPADocument3 pagesDesmophen 650 MPAさいとはちこNo ratings yet

- Department of Chemistry Annual Review 2013Document78 pagesDepartment of Chemistry Annual Review 2013tohunabohunNo ratings yet

- Chemical Methods of ImobilizationDocument5 pagesChemical Methods of ImobilizationJyotishna SinghNo ratings yet

- JEE (Main+Advanced) 2023: Chem. Worksheet-5 IupacDocument2 pagesJEE (Main+Advanced) 2023: Chem. Worksheet-5 IupacSoham X ANo ratings yet

- Phan Tich Bang Cong Cu PTBCC Chapter 10 Gas Chromatography (Cuuduongthancong - Com)Document86 pagesPhan Tich Bang Cong Cu PTBCC Chapter 10 Gas Chromatography (Cuuduongthancong - Com)Phong VõNo ratings yet

- MSDS HCLDocument11 pagesMSDS HCLLemuel GulliverNo ratings yet

- Factors Affecting Stability of ComplexesDocument5 pagesFactors Affecting Stability of ComplexesABDUL HANANNo ratings yet

- True Terpenes Sensory BookletDocument11 pagesTrue Terpenes Sensory BookletYing SuvannachiveNo ratings yet

- Diversas Formulaciones de SimeticonaDocument29 pagesDiversas Formulaciones de SimeticonaMariano_Arisme_1941No ratings yet