Professional Documents

Culture Documents

Lab Report 5 Setting Tolerances For Pipettes in The Laboratory 1

Lab Report 5 Setting Tolerances For Pipettes in The Laboratory 1

Uploaded by

Eugenia TonelottoOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Lab Report 5 Setting Tolerances For Pipettes in The Laboratory 1

Lab Report 5 Setting Tolerances For Pipettes in The Laboratory 1

Uploaded by

Eugenia TonelottoCopyright:

Available Formats

This publication provides technical information regarding the use, application, and metrology related to liquid handling instrumentation.

Setting Tolerances for

Pipettes in the Laboratory

The performance • Pipette performance is influenced • Statistical factors such as the

Fast is fine,

of mechanical significantly by environmental

factors such as temperature and

number of data points taken

impact the probability of

but accuracy action pipettes humidity.1 This means that a intermittent or false failures.

pipette calibrated at an For example, ten data points at

must be tested periodically to

is final ensure accurate liquid delivery.

environmentally controlled each volume are recommended

for testing to the tolerances in this

facility may deliver incorrectly

Kevin Costner The results of such testing then

on the benchtop.2 Artel therefore Lab Report. Use of fewer than ten

as Wyatt Earp may be compared with pre-estab-

recommends testing pipette data points will increase uncertainty,

lished tolerances, and out-of-

performance under working and decrease the reliability of the

tolerance conditions corrected.

conditions. test, which can be compensated

Tolerances that are too strict can

for by tightening tolerances. Please

cause a large number of so-called • The skill of the pipette see Lab Report 1 for a more

“false failures,” where a pipette in operator plays a very important

complete discussion.

good working order produces test role in the accuracy, precision

results that are out of tolerance. and trueness of the pipette.†

Tolerances that are too broad can The choice of pipetting technique Developing

degrade the quality of the

laboratory’s analytical work.

(e.g., reverse mode versus forward

mode) is also a source of

achievable

This Lab Report reviews the key

variability in pipetting results.3 tolerance limits

Proper training can help reduce

issues that should be considered Based on our experience with many

false failures by ensuring that

when establishing tolerance limits different makes and models of pipettes,

results are valid and can be

for the working laboratory, and including single and multi-channels.

reproduced across operators.

recommends a set of achievable Artel recommends the values in

Artel’s guide, 10 Tips to Improve

tolerance limits for single and Table 1 as a starting point for achiev-

Your Pipetting Technique 4, is

multi-channel pipettes of various able tolerance limits. These limits are

available for download at

sizes. based on a simple guideline: Two

www.artel-usa.com to help you percent of full scale at all volume

establish good pipetting settings.5 For example, the systematic

Beware of practices in your laboratory. error for a 100 μL variable-volume

manufacturers’ • Pipette tips also affect testing pipette is ±2.0 μL (2%) at the 100 μL

setting, and ±2.0 μL (4%) at the 50 μL

specifications results. Most manufacturers and

reputable calibration services

setting.

Users frequently find it difficult to carefully specify the type of tips This type of generalized tolerance

to be used when testing a limit has been employed successfully

reproduce a manufacturer’s per-

particular pipette. If the user in a number of other fields, such as

formance claims, for a number of

humidity measurement and syringe

reasons: chooses another type of tip (e.g.,

calibration, where a fixed percentage

a filter, elongated or gel loading

• There are no consistent standards tip), or a lower quality tip, the

of full scale reading is the customary

for how manufacturers set means for specifying performance.

pipette can easily test outside The ISO 8655-2 standard for pipette

their performance claims. of the manufacturer’s tolerances. testing1 also uses a percentage of full

These claims are often a tradeoff

scale approach.

between engineering judgment

and marketing necessities. † Definitions of accuracy, precision and trueness are detailed in Artel Lab Report 4

Lab Report 5 8_19_19.indd 1 9/16/19 9:22 AM

Table 1. Artel's suggested initial tolerance limits

Fine tuning tolerance limits Pipette Volume, μL Relative Error Absolute Error

The tolerance limits recommended here are based on what is typically Nominal Setting Systematic Random Systematic Random

achievable by a reasonably skilled operator. These recommendations do ±% ≤% ± μL ≤ μL

(Inaccuracy) (CV) (Inaccuracy) (Std. Dev.)

not take into account the more stringent data quality requirements of a

particularly demanding analytical method. In such circumstances, 2.0 2.0 1.0

2 1.0 4.0 2.0 0.04 0.02

laboratories should evaluate the results of past testing to fine-tune the

0.2 20.0 10.0

initial tolerance limits relative to the requirements of the method. 2.5 2.0 1.0

The following examples illustrate solutions for common problems 2.5 1.0 5.0 2.5 0.05 0.025

encountered when establishing pipette tolerances. 0.2 25.0 12.5

10 2.0 1.0

10 5 4.0 2.0 0.20 0.10

Example 1: An analytical method requires dispensing a 100 μL sample 1 20.0 10.0

with ±3% systematic error. The laboratory has been using a 200 μL pipette 20 2.0 1.0

20 10 4.0 2.0 0.4 0.2

set to 100 μL for this purpose. Table 1 shows the recommended tolerance

2 20.0 10.0

to be 4%, which is too liberal for the method. The simplest and most

50 2.0 1.0

reliable solution is to replace the 200 μL pipette with a 100 μL pipette. 50 25 4.0 2.0 1.0 0.5

This pipette, when used at its full scale setting, can be tested against a 5 20.0 10.0

2% tolerance. 100 2.0 1.0

100 50 4.0 2.0 2.0 1.0

10 20.0 10.0

Example 2: An analytical method requires ±1% systematic error at a 200 2.0 1.0

volume of 1,000 μL. This is greater trueness than for any pipette in 200 100 4.0 2.0 4.0 2.0

20 20.0 10.0

Table 1. Pipette performance data are examined to determine whether

500 2.0 1.0

this degree of trueness can be attained. It is found that two particular 500 250 4.0 2.0 10.0 5.0

operators are regularly attaining the desired level of performance when 50 20.0 10.0

using a particular make and model of pipette, while other operators are 1000 2.0 1.0

1000 500 4.0 2.0 20.0 10.0

not. The superior pipette is specified in the procedure, and the highly

100 20.0 10.0

skilled operators are used as benchmarks against which others may 2000 2.0 1.0

be trained. The tolerance limit for this pipette can then be tightened 2000 1000 4.0 2.0 40.0 20.0

to ±1% without causing a large number of false failures. 200 20.0 10.0

2500 2.0 1.0

2500 1000 5.0 2.5 50.0 25.0

Using Table 1 500 10.0 5.0

5000 2.0 1.0

Begin by choosing either the “Relative Error” or “Absolute Error” 2500 4.0 2.0 100.0 50.0

5000

tolerance limit values. These tolerance limits reflect what is reasonably 500 20.0 10.0

achievable in a working laboratory. They presume that the pipette is

calibrated and functioning properly, is used with good quality tips, and Notes

is tested by a reasonably skilled operator. When these criteria are met, a) Systematic error (sometimes referred to as inaccuracy) is expressed as

most makes and models of pipettes should test within these tolerance the deviation of the mean of ten samples from the set point volume.

Systematic error can be expressed in either absolute units such as microliters, or

limits unless they are mechanically defective. relative units such as percent. Random error is expressed in units of microliters as

the standard deviation (Std. Dev.) of ten samples, or as the coefficient of variation

For fixed-volume pipettes, the nominal value is the fixed volume. (CV) of ten samples.

For variable-volume pipettes, the nominal value is the largest b) For single and multi-channel pipettes with nominal volumes between those

user-selectable volume setting; e.g., a 10-100 μL pipette has a provided in this table, systematic error limits are equal to ±2.0% of the pipette’s

nominal volume, and the tolerance limit for random error is 1% of the pipette’s

nominal volume of 100 μL. nominal volume.

c) Relative error tolerance limits at other volume settings can be calculated

The absolute error for the nominal volume applies to every selectable by dividing the absolute tolerance limit (see Table 1 or Note b) by the set point

pipette volume; e.g., a 100 μL nominal volume yields limits of ±2.0 μL volume. Multiply the result by 100 to convert it to a percentage.

systematic error (mean value) and less than 1.0 μL random error References:

(measured as a standard deviation) for all volumes. The relative error 1. Piston-Operated Volumetric Apparatus—Part 2: Piston Pipettes. ISO 8655-2:2002.

varies throughout the pipette range; e.g., for a 10-100 μL pipette at 2. Bias, Uncertainty and Transferability in Standard Methods of Pipette Calibration.

100 μL the relative systematic error is ±2.0%. However, at 10 μL the Artel white paper, 2003.

relative systematic error is ±20.0%. 3. Carle, et. al. Best Practices for the Use of Micropipets

www.artel-usa.com/resource-library/best-practices-use-micropipets/

4. 10 Tips To Improve Your Pipetting Technique: www.artel-usa.com/resource-library/

10-tips-to-improve-your-pipetting-technique/

19A323OH

5. Clinical and Laboratory Standards Institute, General Laboratory Equipment

Performance Qualification, Use and Maintenance, 2019 : clsi.org/standards/products/

quality-management-systems/documents/qms23/

25 Bradley Drive, Westbrook, Maine 04092 USA

888-406-3463 | info@artel.co | © 2019 Artel®, Inc.

Lab Report 5 8_19_19.indd 2 9/16/19 9:22 AM

You might also like

- Astm D4718Document5 pagesAstm D4718Pier Arriaga100% (1)

- Oxo Machm 07va A000 Xxaann PDFDocument3 pagesOxo Machm 07va A000 Xxaann PDFChristopher JohnNo ratings yet

- Astm E300-03 PDFDocument24 pagesAstm E300-03 PDFCeciliagorra100% (1)

- Total Evaporable Moisture Content of Aggregate by Drying: Standard Test Method ForDocument3 pagesTotal Evaporable Moisture Content of Aggregate by Drying: Standard Test Method ForYarisel Shosha MuñozNo ratings yet

- ASTM D4718 D4718M 15 - Correccion Por SobretamañoDocument5 pagesASTM D4718 D4718M 15 - Correccion Por SobretamañoHector AnccotaNo ratings yet

- E2111 20868 PDFDocument10 pagesE2111 20868 PDFAnderson CarvalhoNo ratings yet

- A Method For Assessing Membrane Fouling in Pilot-And Full-Scale SystemsDocument7 pagesA Method For Assessing Membrane Fouling in Pilot-And Full-Scale SystemsShakeel ur Rehman LashariNo ratings yet

- Astm E691Document23 pagesAstm E691AlbertoNo ratings yet

- ASTM E 691 Standard Practice For Conducting An Interlaboratory Study To Determine The Precision of A Test Method (Replaced by ISO 5725-2)Document23 pagesASTM E 691 Standard Practice For Conducting An Interlaboratory Study To Determine The Precision of A Test Method (Replaced by ISO 5725-2)ILSEN N. DAETNo ratings yet

- C702M-11 (Reducing Sample To Testing Size)Document5 pagesC702M-11 (Reducing Sample To Testing Size)Riceth Honeylet CancinoNo ratings yet

- VerificationDocument24 pagesVerificationNguyênNguyễnPhùngNo ratings yet

- BioPharm - Scale Down - Downstream PDFDocument10 pagesBioPharm - Scale Down - Downstream PDFGeetanjali HubliNo ratings yet

- ASTM F2129: When The FDA Requires A Detailed Corrosion Test: Beyond A Simple Trial ReportDocument1 pageASTM F2129: When The FDA Requires A Detailed Corrosion Test: Beyond A Simple Trial ReportNgọc Minh LêNo ratings yet

- Astm B117Document12 pagesAstm B117Tushar RanpiseNo ratings yet

- Combinatorial Coverageasan Aspectof Test QualityDocument5 pagesCombinatorial Coverageasan Aspectof Test QualityYang FengNo ratings yet

- Jar TestingDocument4 pagesJar TestingAlaa SalemNo ratings yet

- ASTM - D4212-99 Viscosity Zahn CupDocument6 pagesASTM - D4212-99 Viscosity Zahn Cupleonardo ariefNo ratings yet

- Conducting An Interlaboratory Study To Determine The Precision of A Test MethodDocument23 pagesConducting An Interlaboratory Study To Determine The Precision of A Test MethodServando LozanoNo ratings yet

- Astm B117-03Document11 pagesAstm B117-03Cesar RamirezNo ratings yet

- Practice ASTM E691Document22 pagesPractice ASTM E691Les Nataly Hernando JaqueNo ratings yet

- A. E. Fincham, Elf Exploration UK PLC., and B. Ferreol, Elf Exploration ProductionDocument7 pagesA. E. Fincham, Elf Exploration UK PLC., and B. Ferreol, Elf Exploration ProductionJavier E. Guerrero ArrietaNo ratings yet

- D7997-15 Standard Practice For Polyurethane Raw Materials Gel Tests For Polyurethane Non-Foam FormulationsDocument7 pagesD7997-15 Standard Practice For Polyurethane Raw Materials Gel Tests For Polyurethane Non-Foam FormulationsMohamedNo ratings yet

- SrealisticDocument2 pagesSrealisticZelda Diez EspinosaNo ratings yet

- Reducing Samples of Aggregate To Testing Size: Standard Practice ForDocument5 pagesReducing Samples of Aggregate To Testing Size: Standard Practice FormickyfelixNo ratings yet

- D4724 11 PDFDocument6 pagesD4724 11 PDFakbarNo ratings yet

- E925 09 2014Document7 pagesE925 09 2014Indra Aditama100% (1)

- Astm C702 C702M 11Document12 pagesAstm C702 C702M 11Jhaiiler ZlatanNo ratings yet

- E925 14 PDFDocument7 pagesE925 14 PDFTrầnXuânSơnNo ratings yet

- 3526280b Fcal 4 Steps App Note WDocument4 pages3526280b Fcal 4 Steps App Note WebyjoyNo ratings yet

- Norma E691 InglesDocument21 pagesNorma E691 InglesBrandon Flores VillanuevaNo ratings yet

- ASTM Chapter E2111Document9 pagesASTM Chapter E2111Chetalee Naik100% (1)

- D4543 08Document9 pagesD4543 08Bayron Parra100% (1)

- The - Dark - Side - of - Misreading - The - Relevance - of - Coating - Testing PDFDocument17 pagesThe - Dark - Side - of - Misreading - The - Relevance - of - Coating - Testing PDFrajiv_quantumNo ratings yet

- GeoConvention 2013 - True Residual Oil SaturationDocument22 pagesGeoConvention 2013 - True Residual Oil SaturationPaul ReedNo ratings yet

- 3 DOE & SQC Basic Workshop Course MaterialDocument18 pages3 DOE & SQC Basic Workshop Course Materialbuvana1980No ratings yet

- Sampling, Sample Preparation, Packaging, and Marking of Lime and Limestone ProductsDocument8 pagesSampling, Sample Preparation, Packaging, and Marking of Lime and Limestone ProductsjenserNo ratings yet

- 12 05 14 WhitePaper As Found OOT PDFDocument9 pages12 05 14 WhitePaper As Found OOT PDFrobertNo ratings yet

- D13 - Pauls MESURING BIASDocument36 pagesD13 - Pauls MESURING BIASmanuelNo ratings yet

- D6207-03 Fabric Stability ADimention Stability STMDocument6 pagesD6207-03 Fabric Stability ADimention Stability STMOfir LidorNo ratings yet

- Conducting A Repeatability and Reproducibility Study On Test Equipment For Nondestructive TestingDocument5 pagesConducting A Repeatability and Reproducibility Study On Test Equipment For Nondestructive TestingkrutikNo ratings yet

- Sampling, Sample Preparation, Packaging, and Marking of Lime and Limestone ProductsDocument9 pagesSampling, Sample Preparation, Packaging, and Marking of Lime and Limestone Productsasemamaw damtieNo ratings yet

- SOP 49 Standard Operating Procedure For Calibration of Environmental Monitoring Standards by Direct ComparisonDocument8 pagesSOP 49 Standard Operating Procedure For Calibration of Environmental Monitoring Standards by Direct ComparisonchrisNo ratings yet

- SPE 23612 Multi-Rate Test Evaluation Using Field Cases: Pacheco and G. Oa Prat, Halliburton Reservoir ServicesDocument10 pagesSPE 23612 Multi-Rate Test Evaluation Using Field Cases: Pacheco and G. Oa Prat, Halliburton Reservoir Servicespandu ariefNo ratings yet

- Astm E1135Document5 pagesAstm E1135David Francisco Plata DuranNo ratings yet

- Astm e 1135Document5 pagesAstm e 1135KEN KNo ratings yet

- D1883-2014 CBRDocument9 pagesD1883-2014 CBREddy Moron PinedoNo ratings yet

- Astm D4718 - 2015Document5 pagesAstm D4718 - 2015Qazeem IsmailNo ratings yet

- Astm D5463 - 13Document6 pagesAstm D5463 - 13Ali Saleh Saad AL-isawiNo ratings yet

- 2017 - Formulation & Adjuvant Technology 13Document1 page2017 - Formulation & Adjuvant Technology 13Catherine TangNo ratings yet

- Foam Testing ProcedureDocument2 pagesFoam Testing ProcedureAbdallah SaberNo ratings yet

- Determination of A Pooled Limit of Quantitation: Standard Practice ForDocument3 pagesDetermination of A Pooled Limit of Quantitation: Standard Practice ForahmedNo ratings yet

- Lit Nijenstein - Moisture Committee Meeting - STI126Oct2003Document1 pageLit Nijenstein - Moisture Committee Meeting - STI126Oct2003harry.nijensteinNo ratings yet

- Astm b117 PDFDocument15 pagesAstm b117 PDFMohamed MahfouzNo ratings yet

- A230 Accuracy Validity and ReliabilityDocument4 pagesA230 Accuracy Validity and Reliabilityramloghun veerNo ratings yet

- Evaluating Hygrothermal Corrosion Resistance of Permanent Magnet AlloysDocument5 pagesEvaluating Hygrothermal Corrosion Resistance of Permanent Magnet AlloysDanZel DanNo ratings yet

- ASTM C-50. Obsoleta13 (2019)Document9 pagesASTM C-50. Obsoleta13 (2019)JAIME CARDONA DIAZ DIAZNo ratings yet

- C 50 - C 50M - 13 PDFDocument9 pagesC 50 - C 50M - 13 PDFPedro Jose Cardenas PyastolovNo ratings yet

- Syringe Filter Brochure2Document6 pagesSyringe Filter Brochure2DanielNo ratings yet

- Water Resistance: Impact Penetration TestDocument4 pagesWater Resistance: Impact Penetration TestristaNo ratings yet

- 4MA0 3H Que 20130111Document20 pages4MA0 3H Que 20130111Amro BoudyNo ratings yet

- Motion of An Object Thrown or Projected Into The Air Acceleration As A Result of GravityDocument13 pagesMotion of An Object Thrown or Projected Into The Air Acceleration As A Result of GravityDiane Joy Fojas PanganibanNo ratings yet

- Beam Calculator Online (Calculate The Reactions - Draws Bending Moment - Shear Force - Axial Force) - 8Document2 pagesBeam Calculator Online (Calculate The Reactions - Draws Bending Moment - Shear Force - Axial Force) - 8abrahamrv44No ratings yet

- ElectromagneticradiationDocument4 pagesElectromagneticradiationapi-281187166No ratings yet

- Turbine Start UpDocument15 pagesTurbine Start UprobiansahNo ratings yet

- Optibelt Installation and Maintenance InstructionsDocument24 pagesOptibelt Installation and Maintenance InstructionsFabian BaezaNo ratings yet

- Current and ResistanceDocument21 pagesCurrent and Resistancebabacan14No ratings yet

- Calc MacbarsDocument2 pagesCalc MacbarsSze Mian KuehNo ratings yet

- High-Quality Few Layer Graphene Produced by Electrochemical Intercalation and Microwave-Assisted Expansion of GraphiteDocument8 pagesHigh-Quality Few Layer Graphene Produced by Electrochemical Intercalation and Microwave-Assisted Expansion of Graphitemartha SevillaNo ratings yet

- Calculation Design Beam Jib CraneDocument25 pagesCalculation Design Beam Jib CraneAyena BrianNo ratings yet

- Centrífuga Alfa-Laval BREW2000Document2 pagesCentrífuga Alfa-Laval BREW2000Douglas TondelloNo ratings yet

- Centrifugal FanDocument25 pagesCentrifugal FanJohn Kris San LuisNo ratings yet

- Window Louver Structure Calculation SheetDocument67 pagesWindow Louver Structure Calculation SheetTONY HANNo ratings yet

- 22851-Article Text-65183-1-10-20210826Document11 pages22851-Article Text-65183-1-10-20210826MUHAMMAD KHOLIDNo ratings yet

- مذكرة شرح Physics - فيزياء لغات للصف الاول الثانوى لمدارس اللغات-الامتحان التعليمىDocument20 pagesمذكرة شرح Physics - فيزياء لغات للصف الاول الثانوى لمدارس اللغات-الامتحان التعليمىRania Gamal Fouad100% (1)

- Sylvester and SchurDocument7 pagesSylvester and SchurLouis JamesNo ratings yet

- Monitoring Centrifugal Pump Performance With VibrationDocument32 pagesMonitoring Centrifugal Pump Performance With VibrationMuhtiar100% (1)

- An Investigation Into The Distinctive Properties of LiAuS A - 2023 - Results inDocument7 pagesAn Investigation Into The Distinctive Properties of LiAuS A - 2023 - Results inronaldquezada038No ratings yet

- Rectilinear Kinetics: Engineering MechanicsDocument15 pagesRectilinear Kinetics: Engineering MechanicsFatima MohamadNo ratings yet

- Steel 40nicrmov15 Clarmhb7 - GBDocument2 pagesSteel 40nicrmov15 Clarmhb7 - GBAdnan ColoNo ratings yet

- Thermal Effects On Breakthrough Curves of Pressure Swing Adsorption For Hydrogen Puri CationDocument10 pagesThermal Effects On Breakthrough Curves of Pressure Swing Adsorption For Hydrogen Puri CationEvminidaNo ratings yet

- Physical Ageing in Amorphous Polymers and Other MaterialsDocument249 pagesPhysical Ageing in Amorphous Polymers and Other Materialswc_11111No ratings yet

- Parc de Villette, Paris: AREA - 55 Hectares YEAR - 1982-1983Document11 pagesParc de Villette, Paris: AREA - 55 Hectares YEAR - 1982-1983rudra pandyaNo ratings yet

- 3.2: Causality and Invertibility: Example: Mean and ACVF of An AR (1) Process 3.2.1Document5 pages3.2: Causality and Invertibility: Example: Mean and ACVF of An AR (1) Process 3.2.1Ana ScaletNo ratings yet

- One Dimensional ConsolidationDocument2 pagesOne Dimensional ConsolidationPaschal MazikuNo ratings yet

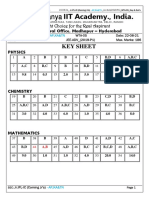

- Sri Chaitanya IIT Academy., India.: KEY SheetDocument6 pagesSri Chaitanya IIT Academy., India.: KEY SheetO SNo ratings yet

- Boğaziçi University Department of Civil EngineeringDocument2 pagesBoğaziçi University Department of Civil EngineeringIşık Ateş KıralNo ratings yet

- Flawtech Catalogue Website v6 Combined SmallDocument37 pagesFlawtech Catalogue Website v6 Combined SmallAnonymous AlhzFE9EVNNo ratings yet

- Refreshers (96 BRD 1) T1Document3 pagesRefreshers (96 BRD 1) T1Marcial Jr. MilitanteNo ratings yet