Professional Documents

Culture Documents

CBN Epsr

Uploaded by

RJAP85Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

CBN Epsr

Uploaded by

RJAP85Copyright:

Available Formats

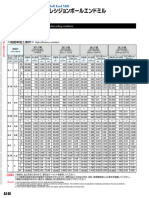

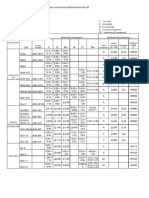

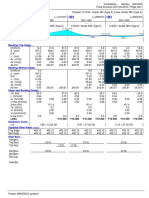

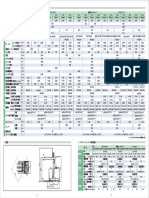

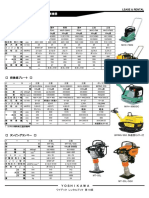

Epoch CBN Super Radius End Mill

エポックCBNスーパーラジアスエンドミル

標準切削条件表 Recommended cutting conditions CBN-EPSR

Carbide End Mills

<仕上げ加工条件> Finishing condition

1 2 3 4

被削材 焼入れ鋼 焼入れ鋼 焼入れ鋼 焼入れ鋼

Hardened steels Hardened steels Hardened steels Hardened steels

Work material (∼55HRC) (55∼65HRC) (65∼68HRC) (68∼72HRC)

HPM1,SKD61,SKT4 SKD11,SKH51 SKH,溶製ハイス HAP,粉末ハイス

Radius End Mills

切込み比率 Ratio to standard depth of cut 100% 90% 80% 70%

外径Dc コーナ半径r 首下長R2 切り込み量 Depth of cut(㎜) 回転数 n 送り速度 v f 回転数 n 送り速度 v f 回転数 n 送り速度 v f 回転数 n 送り速度 v f

Tool dia. Corner radius Under neck length

(mm) (mm) (mm) ap ae min-1 mm/min min-1 mm/min min-1 mm/min min-1 mm/min

0.5 0.004 0.05 50,000 400 48,000 350 45,000 290 43,000 240

0.2 0.05

1 0.003 0.05 45,000 340 43,000 290 41,000 250 38,000 200

0.5 0.006 0.1 50,000 600 48,000 520 45,000 430 43,000 360

0.75 0.006 0.1 50,000 600 48,000 520 45,000 430 43,000 360

0.3 0.05

1.5 0.005 0.1 45,000 510 43,000 440 41,000 370 38,000 300

2 0.003 0.1 40,000 430 38,000 370 36,000 310 34,000 260

0.5 0.008 0.15 46,000 740 44,000 630 41,000 520 39,000 440

0.4 0.05 1 0.008 0.15 46,000 740 44,000 630 41,000 520 39,000 440

2 0.006 0.15 41,000 620 39,000 530 37,000 450 35,000 370

0.5 0.01 0.2 46,000 920 44,000 790 41,000 660 39,000 550

0.05 1.5 0.01 0.2 46,000 920 44,000 790 41,000 660 39,000 550

3 0.005 0.2 37,000 670 35,000 570 33,000 480 31,000 390

0.5

0.5 0.01 0.15 46,000 920 44,000 790 41,000 660 39,000 550

0.1 1.5 0.01 0.15 46,000 920 44,000 790 41,000 660 39,000 550

3 0.005 0.15 37,000 670 35,000 570 33,000 480 31,000 390

1.5 0.012 0.2 42,000 1,010 40,000 860 38,000 730 36,000 600

0.6 0.1

3 0.009 0.2 38,000 870 36,000 740 34,000 620 32,000 510

2.5 0.012 0.3 42,000 1,280 40,000 1,090 38,000 920 36,000 770

0.8 0.1

5 0.008 0.3 38,000 1,090 36,000 930 34,000 780 32,000 650

1 0.02 0.45 38,000 1,520 36,000 1,300 34,000 1,090 32,000 900

0.05 2.5 0.02 0.45 38,000 1,520 36,000 1,300 34,000 1,090 32,000 900

5 0.015 0.45 34,000 1,290 32,000 1,090 31,000 940 29,000 770

1 0.02 0.4 38,000 1,520 36,000 1,300 34,000 1,090 32,000 900

1 0.1 2.5 0.02 0.4 38,000 1,520 36,000 1,300 34,000 1,090 32,000 900

5 0.015 0.4 34,000 1,290 32,000 1,090 31,000 940 29,000 770

2.5 0.02 0.3 38,000 1,520 36,000 1,300 34,000 1,090 32,000 900

0.2 5 0.015 0.3 34,000 1,290 32,000 1,090 31,000 940 29,000 770

10 0.005 0.3 27,000 920 26,000 800 24,000 650 23,000 550

2 0.02 0.7 32,000 1,920 30,000 1,620 29,000 1,390 27,000 1,130

0.05

5 0.02 0.7 29,000 1,650 28,000 1,440 26,000 1,190 25,000 1,000

2 0.02 0.65 32,000 1,920 30,000 1,620 29,000 1,390 27,000 1,130

1.5 0.1

5 0.02 0.65 29,000 1,650 28,000 1,440 26,000 1,190 25,000 1,000

5 0.02 0.55 29,000 1,650 28,000 1,440 26,000 1,190 25,000 1,000

0.2

10 0.015 0.55 26,000 1,400 25,000 1,220 23,000 990 22,000 830

3 0.02 0.95 28,000 2,240 27,000 1,940 25,000 1,600 24,000 1,340

0.05 5 0.02 0.95 28,000 2,240 27,000 1,940 25,000 1,600 24,000 1,340

10 0.02 0.95 25,000 1,900 24,000 1,640 23,000 1,400 21,000 1,120

3 0.02 0.9 28,000 2,240 27,000 1,940 25,000 1,600 24,000 1,340

2 0.1 5 0.02 0.9 28,000 2,240 27,000 1,940 25,000 1,600 24,000 1,340

10 0.02 0.9 25,000 1,900 24,000 1,640 23,000 1,400 21,000 1,120

5 0.02 0.8 28,000 2,240 27,000 1,940 25,000 1,600 24,000 1,340

0.2 10 0.02 0.8 25,000 1,900 24,000 1,640 23,000 1,400 21,000 1,120

20 0.01 0.8 20,000 1,360 19,000 1,160 18,000 980 17,000 810

0.05 6 0.02 1.45 24,000 2,450 23,000 2,110 22,000 1,800 20,000 1,430

3 0.1 6 0.02 1.4 24,000 2,450 23,000 2,110 22,000 1,800 20,000 1,430

0.5 6 0.02 1 24,000 2,450 23,000 2,110 22,000 1,800 20,000 1,430

※基本切り込みは被削材グループ1での目安を示しています。その他のグループの場合は、上表の切り込み比率を目安に調整してください。

本切削条件における切り込み量は、底面加工時を想定して算出しております。勾配面などの仕上げ加工においては、理論面粗さ

(カスプハイト量)

から設定してください。

The indicated standard cutting depth is a reference value for Group 1 work materials. For materials in other groups, the cutting depth should be adjusted using the reference ratio shown

in the above table.

The depth of cut stated in these cutting conditions are calculated assuming bottom surface machining. For finishing machining such as slope machining, it should be set according to the

theoretical surface roughness (cusp height).

【注意】①被削材、加工形状に合わせて、適切なクーラントを使用してください。

②この標準切削条件表は切削条件の目安を示すものです。実際の加工では加工形状、目的、使用機械等により条件を調整してください。

③機械の回転数が足りない場合は、回転数と送り速度を同じ比率で下げてください。

【Note】 1) Use the appropriate coolant for the work material and machining shape.

2) This standard cutting condition table is intended as reference cutting conditions. The conditions should be adjusted as necessary according to the actual conditions

of machined shape, purpose, machine used, etc.

3) If the machine rotation speed is insufficient, reduce the rotation speed and feed rate by the same ratio.

A247

You might also like

- JIS, JPI FlangesDocument7 pagesJIS, JPI FlangesLavzNo ratings yet

- CBN Epsb FDocument1 pageCBN Epsb FRJAP85No ratings yet

- CBN EhbDocument3 pagesCBN EhbRJAP85No ratings yet

- CalculpvcDocument7 pagesCalculpvcchorfi khemissiNo ratings yet

- AA7000 - Cook Book N°4Document47 pagesAA7000 - Cook Book N°4Kevin JosueNo ratings yet

- P10-19 S45CDocument10 pagesP10-19 S45CHeat treatment GTGNo ratings yet

- Viscositychart1a PDFDocument1 pageViscositychart1a PDFAnonymous PxySJR3HNo ratings yet

- Steel SpecificationDocument11 pagesSteel SpecificationKing KazmaNo ratings yet

- JIS G3522 1991 Piano Wire (SWPX) CHNDocument5 pagesJIS G3522 1991 Piano Wire (SWPX) CHNRicky ZengNo ratings yet

- Sanyo Special AlloysDocument12 pagesSanyo Special Alloysj08041632133No ratings yet

- ML RPS 500WSMDDocument2 pagesML RPS 500WSMDRoberto Eduardo Salvador MonteroNo ratings yet

- BT KHDLDocument11 pagesBT KHDLHuệ ĐặngNo ratings yet

- Neturen ITW WireDocument10 pagesNeturen ITW WiredemirilkNo ratings yet

- Bridas 150LBDocument1 pageBridas 150LBLuis ChiñasNo ratings yet

- E Ring PDFDocument3 pagesE Ring PDFsyuepiNo ratings yet

- Transporte ProyectoDocument7 pagesTransporte Proyectomercedes mudarraNo ratings yet

- SCR12BG-2612-12 52tetDocument1 pageSCR12BG-2612-12 52tetOruc MusayevNo ratings yet

- Cookbook 04Document39 pagesCookbook 04Absheen ZamanNo ratings yet

- thành phần hóa học Nguyên liệuDocument60 pagesthành phần hóa học Nguyên liệuanhthoNo ratings yet

- JPP PPDocument2 pagesJPP PP李万福No ratings yet

- P24-30 SCM440Document7 pagesP24-30 SCM440tsaipeterNo ratings yet

- Lapping Powder FujimiDocument2 pagesLapping Powder Fujimidoan lucNo ratings yet

- JIS B 2407 G番Document1 pageJIS B 2407 G番Kudanthai SenthilkumarNo ratings yet

- nsr10 Espectro SONSON 3 NIVELESDocument2 pagesnsr10 Espectro SONSON 3 NIVELESwilliamNo ratings yet

- 09 PDFDocument7 pages09 PDFAnonymous wUv02fNo ratings yet

- b1j 005Document20 pagesb1j 005Lê Đức Mạnh 4A7No ratings yet

- Atuden v1Document7 pagesAtuden v1sajjad_naghdi241No ratings yet

- Macf - Allrisk Mitsubishi April 2024Document1 pageMacf - Allrisk Mitsubishi April 2024fathurmitsubishiNo ratings yet

- Paket Passanger & Pick Up SuzukiDocument1 pagePaket Passanger & Pick Up Suzukimuhamad ilhamNo ratings yet

- Kamahara Sk40-3aDocument1 pageKamahara Sk40-3aPeto AlamNo ratings yet

- BorutoDocument2 pagesBorutogiangtakemuraNo ratings yet

- Olympic TradeDocument3 pagesOlympic TradeLofyysaNo ratings yet

- SMP 50Document23 pagesSMP 50adrian suicaNo ratings yet

- Taller FisixoDocument5 pagesTaller FisixoKaren Paola Morales AragonNo ratings yet

- 2178 OsakakoritudaiDocument20 pages2178 Osakakoritudait tNo ratings yet

- JIS B 2407 P番Document2 pagesJIS B 2407 P番Kudanthai SenthilkumarNo ratings yet

- 38 Dimensional Tolerances of CastingsDocument1 page38 Dimensional Tolerances of CastingsNguyễn KiệtNo ratings yet

- DN 600m Amirabad 4Document5 pagesDN 600m Amirabad 4anirbanpwd76No ratings yet

- Tercer Pacial TallerDocument4 pagesTercer Pacial TallerNicaury PimentelNo ratings yet

- 1330 Kobe DaiDocument16 pages1330 Kobe Dai岸本昂大No ratings yet

- 鋼材の規格Document2 pages鋼材の規格giangNo ratings yet

- TALLERDocument23 pagesTALLERLuz AlonsoNo ratings yet

- PDF ListDocument23 pagesPDF ListTim WalkdenNo ratings yet

- L 17 PMDocument2 pagesL 17 PMjidul16No ratings yet

- Material Equation S45CDocument3 pagesMaterial Equation S45CaiindustriyahoocoidNo ratings yet

- Beam CalDocument107 pagesBeam CalAbdulqudusNo ratings yet

- 収支計画テンプレートDocument1 page収支計画テンプレートKohsuke Matsumoto100% (6)

- Fet Mosfet IgbtDocument62 pagesFet Mosfet IgbtServis SonicesNo ratings yet

- Geneo R 01Document3 pagesGeneo R 01TRMNo ratings yet

- Catalog Power 02Document24 pagesCatalog Power 02Derek LeeNo ratings yet

- Instruction Manual Zoje ZJ-5821 PDFDocument112 pagesInstruction Manual Zoje ZJ-5821 PDFMaskusyaniNo ratings yet

- Cable 600V MLFC 80SQ, 50M X 2 HitachiDocument1 pageCable 600V MLFC 80SQ, 50M X 2 Hitachi6lackdoneNo ratings yet

- Tabel Z ScoreeeeDocument4 pagesTabel Z Scoreeeealiqa108No ratings yet

- Analisis Financiero Ratios Financieros - Caso VolcanDocument86 pagesAnalisis Financiero Ratios Financieros - Caso VolcanJulio CesarNo ratings yet

- Hitachi Sample DrawingsDocument4 pagesHitachi Sample DrawingsJocelyne LiNo ratings yet

- Legends 1Document2 pagesLegends 1BojanIveticNo ratings yet

- Ydt 05Document6 pagesYdt 05Ôtô Chuyên Dùng GreenNo ratings yet

- Ydec Rentalbook 09034Document1 pageYdec Rentalbook 09034Ôtô Chuyên Dùng GreenNo ratings yet

- Block IndustryDocument20 pagesBlock IndustryGbemisola FasuyiNo ratings yet