Professional Documents

Culture Documents

SL101.24EC Series Programming Manual EN

SL101.24EC Series Programming Manual EN

Uploaded by

shasha4060 ratings0% found this document useful (0 votes)

3 views2 pagesOriginal Title

SL101.24EC-Series-Programming-Manual-EN

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

3 views2 pagesSL101.24EC Series Programming Manual EN

SL101.24EC Series Programming Manual EN

Uploaded by

shasha406Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 2

SL101 SERIES PUMP MODELS

SL101 pump elements ensure precise and

consistent lubricant delivery during operation.

Electrically operated SL101 Pumps are suitable to

use with SAE 140 oil up to NLGI 2 grade grease.

SL1O1.D models : D models are the direct

pumps that can be controlled externally by a

separate controller or the own PLC of the machine.

SL101. EC models : Pump running time and

pause time is controlled with in-built PCB, giving full

customization for all applications. Pump running

time can be adjusted between 1 - 99 min. ; pause

time varies between 0 - 24 hrs and 0 - 59 min.

SL101.EC/AL models: In addition to the

SL101.EC model pump functions, the distribution of

the grease to the bearings are controlled through

an inductive sensor fitted onto the distribution block

so that the alarm activates on the depletion of

lubricant in the reservoir or the clogging of

SL101.EC SERIES

distribution block. When the alarm activates, “AL”

warning starts to flash on the digital display and

audio warning alarm beeps at the same time. EC/AL

model pump provide one block control. Alarm

PROGRAMMING

output connection is available to enable conveying

alarm warning to a desired place.

INSTRUCTIONS

LUBRIMAC®

Malazgirt Cad. Vali Sok. 28/2

SL101.EC/AL3 models : In addition to the Gungoren – Istanbul - TURKIYE

SL101.EC/AL model pump functions, EC/AL3 models Tel: 0212 556 8308

provide control over 3 blocks. The pump will alarm F: 0212 556 0193

in the case that the grease runs out in the reservoir www.lubrimac.com

or a clogging occurs in the distribution block. In info@lubrimac.com

such cases the failed block is displayed on the

digital indicator as A1, A2 or A3 and the buzzer

activates automatically. Alarm outlet is available to

enable conveying alarm warning to a desired place.

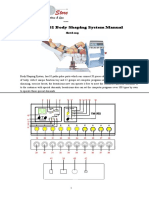

CONTROL PANEL OVERVIEW 16. Exit the programming screen by pressing the

1. Press the PROGRAM button for 3 secs. “P1” PROGRAM button one more time. If “ON”

“PROGRAM” button: starts programming will appear on the screen. function has been selected, the pump will start

process. 2. Press PROGRAM button. running, if “OFF” function has been selected,

“+/START” button: used to perform a

3. Enter the desired lubrication duration in the pump will activate after the pause duration

prelubrication or to switch to manual

operation. It is also used to increase the minutes using the +/START button. (2-3 min.s is completed.

numeric values during programming. may suffice) Note: Additional lubrication can be

4. Press the PROGRAM button. “P2” will appear performed when desired, simply by

PROGRAM FUNCTIONS on the screen. pressing “+/START” button.

5. Press the PROGRAM button.

P1. Determines the pump’s running duration. 6. Enter the pause duration in hours using

The entered values are indicated in minutes. the +/START button. (if the pause duration is ELECTRICAL SUPPLY: 12v/24vDC.

ie: When the P1 value is set to 2, the pump limited to minutes, enter “0”) Please see the voltage label on the pump. The

runs 2 minutes and then switches to pause 7. Press PROGRAM button. “P3” will appear on electric connection should be done as follows;

mode each time it is operated. the screen.

P2. Determines the pump pause duration in 8. Press PROGRAM button.

hours. ie: When the P2 value is set to “0”, the 9. Enter the holding duration in minutes

holding duration will be 0 hours. using the +/START button.

P3. Determines the pump pause duration in 10. Press PROGRAM button. “AL” will appear on

minutes. ie: When the P3 value is set to “30”, the screen.

pump holding duration will be 30 minutes. The 11. Press PROGRAM button. PIN1 12/24VDC +

pump runs as the amount of duration set for 12. Set AL to “A0” using the +/START button. PIN2 12/24VDC -

running time (P1 value) and then switches to 13. Press PROGRAM button.

the next 30-minute pause interval. 14. Either “ON” or “OFF” function will appear on

AL. AL value is the alarm function in the the screen. “ON” function refers to starting

sensor-controlled systems which activates the operation in running mode in the initial start-

alarm in case of failures due to lubrication. AL up (when the power comes to the pump).

value should be set to “A1” in EC/AL pump “OFF” function refers to starting operation with

series and “A0” in EC pump series. pause mode in the initial start-up. Function

PL. PL refers to the number of signals that will selection is done by using +/START button.

be sent from the sensor fitted to the ie: If it is intended to activate and run the

distribution block. Ex: When PL is set to 5, the pump in start-up, “ON” function should be

pump will adjust its running duration according selected. If it is intended to start the pump on

to the 5 signals transmitted from the pause mode, “OFF” function should be

distribution block. Following the 5 signals, the selected.

pump will switch to the holding mode. 15. Press PROGRAM button. “PC” will appear on

PROGRAMMING: the screen. (“PC” = Programming Completed)

You might also like

- Understanding Your PMC KilnDocument5 pagesUnderstanding Your PMC KilnMohammed Abdo100% (2)

- Manual TM-502Document4 pagesManual TM-502Casyana Nicolae86% (7)

- 92 8Document10 pages92 8Александр Коптяев100% (2)

- Manuale Operativo Touch Evolve - ng14 - r2b 08042013-Final - EngDocument74 pagesManuale Operativo Touch Evolve - ng14 - r2b 08042013-Final - EngTran Le100% (1)

- Details Trims Forecast A W 22 23Document19 pagesDetails Trims Forecast A W 22 23paula venancioNo ratings yet

- Strongbow InternationalizationDocument22 pagesStrongbow InternationalizationXuân NguyễnNo ratings yet

- s1 Thec11p5s ManualDocument23 pagess1 Thec11p5s Manualjuny sanchezNo ratings yet

- Tomahawk Car Alarm TW - 9010 English ManualDocument41 pagesTomahawk Car Alarm TW - 9010 English ManualGlenn86% (7)

- Easytronic Micro II 28 05 2010 08 35 20 Revision 05 Controller 1 PDFDocument10 pagesEasytronic Micro II 28 05 2010 08 35 20 Revision 05 Controller 1 PDFСергей Заика100% (1)

- POTTERTON EP2000 EP2002 EP3002 User ManualDocument4 pagesPOTTERTON EP2000 EP2002 EP3002 User Manualn6725055% (11)

- Audit of PpeDocument19 pagesAudit of PpeLiezel LaborteNo ratings yet

- SL101.24EC - AL Series Programming Manual EN 1Document2 pagesSL101.24EC - AL Series Programming Manual EN 1shasha406No ratings yet

- TM-619-series: General Information Programming The Timer #1Document2 pagesTM-619-series: General Information Programming The Timer #1rodrigo danielowskiNo ratings yet

- 155 17-O2 PDFDocument152 pages155 17-O2 PDFArshad MahmoodNo ratings yet

- 英文电气操作说明书Document8 pages英文电气操作说明书Kenneth Gerald RodriguezNo ratings yet

- MC12 902P+92 v1'00Document8 pagesMC12 902P+92 v1'00mr.giraudjulienNo ratings yet

- TCP3 - Manuale-Uso - UK - WDocument9 pagesTCP3 - Manuale-Uso - UK - WShuttle FireNo ratings yet

- Models - 290-Ah1 Amp Hour Totalizer 290-Ahp2 Strokecount Pump Controller (Models: P2-1/1, 1/2, 2/1, 2/2) ContentsDocument13 pagesModels - 290-Ah1 Amp Hour Totalizer 290-Ahp2 Strokecount Pump Controller (Models: P2-1/1, 1/2, 2/1, 2/2) ContentsHECTOR IBARRANo ratings yet

- Control Panel Sequence DayungDocument12 pagesControl Panel Sequence DayungMohamad IwanNo ratings yet

- Digital Timer Modulator With Diagnostic Readout: Operating Instructions (701 10 Series)Document4 pagesDigital Timer Modulator With Diagnostic Readout: Operating Instructions (701 10 Series)Alex ConstantinescuNo ratings yet

- Logixpro Traffic Control Lab Utilizing Word ComparisonDocument22 pagesLogixpro Traffic Control Lab Utilizing Word ComparisonLuis Angel Medina MejiaNo ratings yet

- Manual Daewoo TVDocument28 pagesManual Daewoo TVcobanelNo ratings yet

- K112 GeigerPal MANDocument6 pagesK112 GeigerPal MANDavid KasaiNo ratings yet

- HBT100 GBDocument12 pagesHBT100 GBtechnus5No ratings yet

- KCR1 HandbookDocument12 pagesKCR1 Handbooksales38No ratings yet

- Programming ManualDocument53 pagesProgramming ManualValeri ArsovNo ratings yet

- Innovair Mini Split Remote Control User Manual English 4Document11 pagesInnovair Mini Split Remote Control User Manual English 4Christtian MontoyaNo ratings yet

- Nabertherm Manuale B150Document20 pagesNabertherm Manuale B150So Nic0% (2)

- Service Manual Vts254 Vts256 Vts 258 Vonmarcken.Document40 pagesService Manual Vts254 Vts256 Vts 258 Vonmarcken.Mostafa MahmoudNo ratings yet

- Power On Off FadalDocument8 pagesPower On Off FadalDSunte WilsonNo ratings yet

- APT-9S Timer QuickStartDocument6 pagesAPT-9S Timer QuickStartYufferi MuhammadNo ratings yet

- ULTRA User Manual With ICONSDocument2 pagesULTRA User Manual With ICONSfasolăiNo ratings yet

- Sistema de Engrase CentralizadoDocument76 pagesSistema de Engrase CentralizadoJose NeiraNo ratings yet

- Gripper Instructions 1Document10 pagesGripper Instructions 1rubenNo ratings yet

- 6 RE IntellisysDocument98 pages6 RE IntellisysNikolay VelchevNo ratings yet

- LG Cf-21d30x Chassis Mc64b SMDocument35 pagesLG Cf-21d30x Chassis Mc64b SMConstantin Topirceanu100% (1)

- Lab 4Document15 pagesLab 4Jose PedoroNo ratings yet

- Digital Timer Modulator With Diagnostic Readout: Operating Instructions (701 10 Series)Document4 pagesDigital Timer Modulator With Diagnostic Readout: Operating Instructions (701 10 Series)Terence ActonNo ratings yet

- Agitador Vortex Scientific IndutriesDocument3 pagesAgitador Vortex Scientific IndutriesLUIS MIGUEL PUERTA CARVAJALNo ratings yet

- AirMaster P1ÄÜÆ® Ñ (¿ ®) PDFDocument10 pagesAirMaster P1ÄÜÆ® Ñ (¿ ®) PDFkaduz800% (1)

- Logixpro The Batch Mix Lab Utilizing PLC CountersDocument5 pagesLogixpro The Batch Mix Lab Utilizing PLC CountersMatthew AdeyinkaNo ratings yet

- Service Bulletin: Troubleshooting DTC P1456 and P1457Document4 pagesService Bulletin: Troubleshooting DTC P1456 and P1457Vic3501No ratings yet

- Quick Start TutorDocument3 pagesQuick Start TutorLucaNo ratings yet

- IV Pump Flo-Gard 6301Document48 pagesIV Pump Flo-Gard 6301Dba BiomedtechNo ratings yet

- Generator ControllerDocument21 pagesGenerator ControllerBrianHazeNo ratings yet

- User Manual of WINVIEW Controller (TK8070-SERIES)Document16 pagesUser Manual of WINVIEW Controller (TK8070-SERIES)Duong PhạmNo ratings yet

- Handleiding WA7 Stulz CCD-U 61Document39 pagesHandleiding WA7 Stulz CCD-U 61pxcontact1gmailcom100% (1)

- Manuel PRO V2 enDocument11 pagesManuel PRO V2 enjohnknight000No ratings yet

- Rover PDFDocument15 pagesRover PDFJorge Antonio Guillen100% (1)

- Op3 Demo GuideDocument3 pagesOp3 Demo Guide4wocker4No ratings yet

- Universal Remote: Keys and FunctionsDocument7 pagesUniversal Remote: Keys and FunctionsBren Rogers GlasnerNo ratings yet

- Manual Programare Kikko Ry Espresso - Instant - 220 Volt - 50 HZDocument53 pagesManual Programare Kikko Ry Espresso - Instant - 220 Volt - 50 HZRadoi RaduNo ratings yet

- Baum Operators Control Panel Inst For 2020 18 15 tp10386Document12 pagesBaum Operators Control Panel Inst For 2020 18 15 tp10386Guido RamosNo ratings yet

- LG Cf-20e40x Chassis Mc64a SMDocument0 pagesLG Cf-20e40x Chassis Mc64a SMAnonymous RCPxaonfvNo ratings yet

- Primus 96 Advanced®/ Primus 96 Advanced® Gradient: Innovative PCR-TechnologyDocument11 pagesPrimus 96 Advanced®/ Primus 96 Advanced® Gradient: Innovative PCR-TechnologyAnonymous C6laqkPAAKNo ratings yet

- Operating Specification Steam GeneratorDocument2 pagesOperating Specification Steam GeneratorAltin SkenduliNo ratings yet

- Alimentador Nexus ProgrammingDocument6 pagesAlimentador Nexus ProgrammingRafaColemaNo ratings yet

- Uputstvo Advan. 3000 Rev 1.8pDocument9 pagesUputstvo Advan. 3000 Rev 1.8pIvan DulicNo ratings yet

- L7 Ing PDF PDFDocument6 pagesL7 Ing PDF PDFIgorNo ratings yet

- Digiflo OP91052CDocument25 pagesDigiflo OP91052Crichard_vannevelNo ratings yet

- Apple Watch Series 9/Ultra 2 & the iPhone 15 Pro Max: A Comprehensive Practical Guide With Tips, Tricks and Pictures For Beginners and Experts in Mastering the Watch OS 10 FeaturesFrom EverandApple Watch Series 9/Ultra 2 & the iPhone 15 Pro Max: A Comprehensive Practical Guide With Tips, Tricks and Pictures For Beginners and Experts in Mastering the Watch OS 10 FeaturesNo ratings yet

- The Complete Guide to Olympus' E-m1 - Firmware 2.0 ChangesFrom EverandThe Complete Guide to Olympus' E-m1 - Firmware 2.0 ChangesNo ratings yet

- SPPE000065 WDocument1 pageSPPE000065 Wshasha406No ratings yet

- Lubrimac SL101 Range Pumps enDocument15 pagesLubrimac SL101 Range Pumps enshasha406No ratings yet

- SL101.24EC - AL Series Programming Manual EN 1Document2 pagesSL101.24EC - AL Series Programming Manual EN 1shasha406No ratings yet

- Brochure PlumbingDocument2 pagesBrochure Plumbingshasha406No ratings yet

- 1297 GB Extruder PartsDocument2 pages1297 GB Extruder Partsshasha406No ratings yet

- TBLMy Dust CollectorDocument33 pagesTBLMy Dust Collectorshasha406No ratings yet

- Xavier University-Ateneo de Cagayan College of Nursing: in Partial Fulfillment of The Requirements in NCM 112 (RLE)Document3 pagesXavier University-Ateneo de Cagayan College of Nursing: in Partial Fulfillment of The Requirements in NCM 112 (RLE)Ashley Jane MacapayadNo ratings yet

- W7USP2 Nov13 RelNotesDocument8 pagesW7USP2 Nov13 RelNotesKazakos HaralambosNo ratings yet

- EF's Booking Conditions: What's Included On Your TourDocument6 pagesEF's Booking Conditions: What's Included On Your Tournmoultrie200No ratings yet

- Review Article The Use of Racial, Ethnic, and Ancestral Categories in Human Genetics ResearchDocument14 pagesReview Article The Use of Racial, Ethnic, and Ancestral Categories in Human Genetics ResearchBoda Andrea BeátaNo ratings yet

- Test Bank Ch1 36 For Economics 13th Edition by ArnoldDocument35 pagesTest Bank Ch1 36 For Economics 13th Edition by Arnoldbeastlyfulberj6gkg100% (45)

- The Concept of Romanticism IDocument24 pagesThe Concept of Romanticism ISiddhartha PratapaNo ratings yet

- C. Ayyappan and V.C. Harris Spectral SpeechDocument6 pagesC. Ayyappan and V.C. Harris Spectral SpeechNasrullah Mambrol100% (1)

- Flash MCQDocument7 pagesFlash MCQSilver MistNo ratings yet

- Acid Related DisordersDocument56 pagesAcid Related DisordersDr-Firas Nayf Al-ThawabiaNo ratings yet

- Marcos Jazz WaxDocument26 pagesMarcos Jazz WaxMarcos Valle ArchivesNo ratings yet

- PublishedDocument21 pagesPublishedScribd Government DocsNo ratings yet

- Sacred Groves of Tamilnadu PDFDocument172 pagesSacred Groves of Tamilnadu PDFasdfasdfNo ratings yet

- BUS835M Group 5 Apple Inc.Document17 pagesBUS835M Group 5 Apple Inc.Chamuel Michael Joseph SantiagoNo ratings yet

- Fernando V ST ScholasticaDocument2 pagesFernando V ST ScholasticaChristine Joy PamaNo ratings yet

- Departmental Store Management SystemDocument5 pagesDepartmental Store Management Systemgold bellNo ratings yet

- Perspectives On Competitive Intelligence Within Business: A Tactical Tool For Sales-People To Gain A Competitive AdvantageDocument3 pagesPerspectives On Competitive Intelligence Within Business: A Tactical Tool For Sales-People To Gain A Competitive AdvantageAbdessamad BenzNo ratings yet

- Pre-Trial Brief A. Possibility of Amicable SettlementDocument3 pagesPre-Trial Brief A. Possibility of Amicable SettlementgiovanniNo ratings yet

- Donner CompanyDocument6 pagesDonner CompanySanket Kale100% (1)

- Meaning Into WordsDocument3 pagesMeaning Into WordsFor spaceNo ratings yet

- MEX Special ShippandOffshore 6 2010Document14 pagesMEX Special ShippandOffshore 6 2010hany mohamedNo ratings yet

- Law N Eco RP 3Document12 pagesLaw N Eco RP 3Apoorva KudariNo ratings yet

- Thang Long High School English 10 Consolidation Test 2 - Unit 2. Your Body and You Name: . Class: .Document3 pagesThang Long High School English 10 Consolidation Test 2 - Unit 2. Your Body and You Name: . Class: .Đặng Tiến ĐạtNo ratings yet

- Thez ELKS Magazine 1956-08CDocument60 pagesThez ELKS Magazine 1956-08CocigranNo ratings yet

- Second Semester 2016/2017 (February 13, 2017 - September 10, 2017)Document1 pageSecond Semester 2016/2017 (February 13, 2017 - September 10, 2017)Ridzwan NurunnainNo ratings yet

- Financial Times Magazine - April 2017Document45 pagesFinancial Times Magazine - April 2017jwestmisterNo ratings yet

- Assignment Module-9 Coefficient of CorrelationDocument4 pagesAssignment Module-9 Coefficient of CorrelationFranchesca CuraNo ratings yet

- Blue Jay Private LimitedDocument2 pagesBlue Jay Private LimitedanuNo ratings yet