Professional Documents

Culture Documents

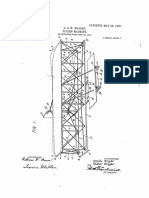

SAITO ENGINE DEL KELLET ESCALA 1 A 5 FA-100hp

SAITO ENGINE DEL KELLET ESCALA 1 A 5 FA-100hp

Uploaded by

Mariela Tissera0 ratings0% found this document useful (0 votes)

2 views6 pagesOriginal Title

SAITO ENGINE DEL KELLET ESCALA 1 A 5 FA-100hp

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

2 views6 pagesSAITO ENGINE DEL KELLET ESCALA 1 A 5 FA-100hp

SAITO ENGINE DEL KELLET ESCALA 1 A 5 FA-100hp

Uploaded by

Mariela TisseraCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 6

Instructions for

_SAITO FA-100/100GK (AAC) 4-St

‘We would like to expres our sincere thanks for your purchase of the SAITO FA

100/100GK engine, which i manafsctured by Saito Seisakusho, Lid. Please read our

instwcionscaeflly and teat your engine with care. Should there bea manufacturing,

defect, Saito Seiakusho, Lid will make necessary repairs at fee of ebarge. You will

notice letter (A, A, C ele) stamped on the top of the sight mounting Wu This

identifies the production version of your engine. If you ever need to order apart ox

hve a question about your engine, speci long withthe part uraber you

ced so We can beter handle your request

ith completely ign Silio FA'IOO/100GK engines have been

dssigned placing emphasis on the lightweight, high-pecfommance and excelent

+ finde nwnsTimns 1 the mons secre of cylinder Hed and

finer wih vet ned chm. pled Taner sree

Siitout sing cinder lines this engae” emplaszes

voy wile le ffs lightened terion oplaution of 4 Stroke Cycle Eugine

tre sue vith proved colng enc.

so: su gh isn cit lad tn Sethe ps se

onsrcton ile har s compreson ring ances ie

Seewo’s eines. m

“Crankstat: Made of slid chrome molybdenum ste, and spores | SAGQT| RE

by two ball bearings. 4

+ Cam gonna Our fiat outed com ear design cele n compat

engine oS) (

com _Feanres hgh ups type high com Y)

“Combustion chanberInceased combustion effieney with improved Ietmakestoke 2. Compression rks

‘endegtedenl shape 3. Expansion stoke 4. Exhaust stroke

+ Catan auHigh performance pe wih sow adusinent exhpped

ne "= . — ‘The four-stroke engine consists of four individual piston

rmovement eased above: “Sule” erm th he pion i

+ Dep nD at eg o preven al-f fr ety ‘ved fom he oper ead hte o hs lower esd ener ps

+ atm soe nRea pine exigent ound the fonrtste pian, as pte compat ere ere

1 Wightman Lightnt th aa

PAAOVAONGK Technical Data

Bow Pina da Sete 26mm

‘eke ate ‘wien Aeon 5 che nl (Apt: 0, w=

Prt

ee ‘Aprox. 2000~11,000 rm (Recommended highest seston he rod: 8 $00~10,000 rm)

=e ae Approx. 40ce/minute (at full throttle, approx. 9300 rpm)

ae a Fuel flow: ‘Fuel flow varies depends upon propeller load. More fucl flow

‘sit egerloe andl fel ow wih sole oe

inact ight feel fw sme incre

Fuel, ‘Synthetic oil with 10~20% nitromethane content f a »

Sates Approx 2.72. 919300 pm with ARC

Applian TRC Sn Aplne Se Aplus Sports Alla: of ye GO ar ad bey daw

Spene for pet astngeetnnnnannnLeach Main pestle eeasion bet lech

penmotea | Rrmtedelegscew ppemee (QI) ooscAeeh Mallen

| Hexagonal spanner (weeach)(1.5,2.022.5)....leach PS glow plug. bi co cock

Manufacturing cde (engine bed op)

ie

‘A. Fuel

$205 eset cer dn pa

Moe eee aN

er aaeteuee nn Memeeoeeniee

‘Saito Fuel Filter“F-2" exhibits highest performance.

B.£ueltank

Pease select best fel tank avaiable fn the market referring to the data for the opacity: Sethe level of fel i the tank fo heb

that of alt nipple of eorburctor Also, pt weigh othe fuel alt ata distance of approximately Sma fom the rear wall of th

thet roughly the same wih

"

3H Check: Sor the cack inthe alminum pipe and silicon tube inthe tak. Since Sato engine employs muler presse, careful atention fs required for tbe

leakage, Also, be careful ot to make length piping icon tube unsecessrily long, (Web for possible crack)

C.Plug

Since ove explosion occurs every two rotons in 4 stroke agin, sclection of the plug is rica. Use of improper plus resus ina rouble of exgne Since

‘etorouce a he cagie varies eccovdig tothe matching wih the fe oft the season, we recommend testing Warous pes forthe tsi perforce

Haaecsne yg of he ober manafactrer extbis good match with Saito engine. Also, performance ofthe plug deeirses afer many ght hours even

tot broken reuent exchange ofthe plug with new one would be necessary)

ise of SALTO ["SAL GPO17GER) Clow Plag i recommended.

D.Propeller

varies according to the body of atplne, however, standard sive ranges from 13°M9"~13"x11" and 14°N6"~ 14°10" (asst guilin).

Pease selec the one avaible inthe nacket wih high reliability. (We recommend APC)

‘Thonough balancing must be earied out (Use balancing device is recommended) Use of unbalance proper creates excessive vl

and is nngerous Ifyou fnd Naw etc, replace it with new one, a itis dangerous

ing the cogine beyond 11,000 pen with ight load propeller on the ground and Below 8,500 rpm with lange load propeller ctherwisecranksal

necing rods cam gears ete. may be damaged,

ia, reduces performace

‘Use propeler tht tatches tothe airplane aad turns in good canton in the range of 8500-~10,000rpa on the ground i view ofthe characteristics of this

cesiee Of propel sae isnot inthe stndad, ifs OK long a the spe is within this range) Speed vases depending upon te manufacturer amd als, in

‘me Testaacr, i occurs with the propellers in the some size those manufactured by the same manufacturer, We recommend testing vious propellers

‘E.Engine Mounting

‘Your cngine canbe mounted in any direction requted. However, we recommend using the vertical or horizontal poston i possible An verted ensine may be

hmaged upon tuning and requires tht the glow plug be removed, withthe prop tured over several ies to remove any exces fue, afler each Nying session.

‘Use of Suto Engine Mount is recommended.

“Topreveet loose engine mousting, application of small qzamty of rubber adhesive o

he tp of Md cap sere is effective.

‘E.Proparation before Starting Engine.

Engine must e mous to the sturdy test Bench with correct paralelism oro the body of sip. (Engi

sot move?)

(For the break-in on the bench, tse fuel tak with wsupacty between 400 and SOc. Fr aiplate body, use the one lead

tbe firmly fie in lier ease so that does

et

(Foe the fue, se the one with sppreximately 15% nlte-content except ow ol conten.

DF te propel, prepare APC 14°" propeller (around 9,300~9 400 rpm at standard)

‘3eTo fix propeller, tar dive ange iw forward dtection (counterclockwise) and when pressure is fl place propeller in horizontal posiion and flly gen

doll nt to fix (Spine must also be attached 25 he starr wil be use)

wooden propel, Would he compressed

Catton:

@since4-stoke engine doesnot clearly exhibit peak coun like 2-sroke engine, use twehoweter to prevent oversqueeze or overheating.

@Attch silicon tube othe bree vpple to check the exhaust of breather (0 check ol Now).

(DMuffler presse must be wsed without ail, (Make sure that oo leakage fs occuring from the tak.)

BPrepare necessary materials and tools for plug bes

(Drrepare he starter and battery,

(Contin: Hany specitoris watching nash, please ask the one 19 move backward prior fo start the engine. Also, he arm iat holds sgplane must be Rept

_avay fom the prop. Whee ihe eagite is started, move tthe back of srplae. Any operation Ike needle adjusten! must be ceed ou from the

back of splane If airplane is oot ied, it x mafe task your assistat to old the irlane.

Following procedure describes the colton i which engine is mounted to the body of sirplane.

(A) Staring method witha starter (For your own safety, this method is recommended.)

Firs tua on the switch of transmit. Next, tut onthe switch ofreeiver Unit o check hot ation and then, st thle stick atthe position fully closed,

@open main needle by 440 5 tune (This sus guide)

|®open shot valve 1/4 to 13 from fll lose position with thro sick (Str wth excessively opens

@rum propeter in reverse diestion (clockwise) unl engine is compressed

Brower he pve.

ttle is dnogeroue a the spine jumps forward)

forward direction, sit is dangerous.

(8) Manual starting method (Forte safety, wear gloves and sey stick ete)

(DFirst tua onthe switch of transmitter. Next ur onthe switeh of reciver unit to check thot action and then, st trot stick af the position fll closed.

open visin needle by 41 S twas. (This isjust a gue)

@ser those valveat fall open with tht tick,

@ctose the est of the muller wil hand aad tra propeller 2 to tens

‘Caution, Excestive fel intake compresses fuel and may damage connecting rods ee. Crank 12 tums with hand sd eheck i 0 fuel compression bas

svcurre,

‘Balter vote valve ix fully closed ooce with thvoile stick, open throtle valve 1/4 to 1/3 with thre stick. (Sta with excessively opened thot is dangerous

asthe airplane jumps forward)

@Pum propeller ie forward aiection (countetclockwis) to feel compression (propeller i horizon),

(Dower the poe

@Alier th plug is powered, wot fora few seconde nd, when the propeller forcibly cranked in clockwise direction, engine starts in forward diretion bythe

explosion counteraction

(Caution, In case of itoke engine, donot ry fo Sart engine manually in forward direction fom the poi where rhe engine is in compressed condition like

in he case of? stoke engine, ae Your lager may be inured due o reverse action ofthe engine. Above staring method most be followed

‘wiht fi

‘As the break-in is

(Dantr fue tanks ill up start the engine a described ia tbe above.

Water opening of tote valve is set approximately 1/2 or less jus asa guide) with thre ck, adjust engine speed to stabilized condiion a approximately

‘6.000ep or less ich contin with main needle valve is opened § tras or more while carefully Watching tachometer and exhaust ol density an cischarge

‘densi from the beac un the engine in this condo for ‘also be employed [the case allows.

important procedure to pull out maximum performance ofthe engin, it must be cautiously implemented

Caution, Absolutly never sake fel mina ole condition in this stage Even if you d speed and rin the expe at lw speed,

‘Sizate would vecvcit the mintare is leat, Object ofthis breakin is initial alization Of connecting rods, gears moving pars aad so 08 the

‘sondtion mainly wih ich fuel miature

(Neat st vote vadve a fll epenand ran the engine in ich condition for fll tank (In this stage, exhaust il density and discharge density frm the breather

rust also be checked.)

@Mce, vn the engine at just before 9,000 rpm for hall tak.

Fall, run the engine at peak sped and less speed alternatively and ifthe engine runs at peak speed without unevenness, pound breakin bas completed for

the time being, Thea, after tappet clearace Is adjusted according to the procedure described in Arile J and carburetor is also adjusted according to the

following ariel, and alter around 10 Might alse speed, breakin wll be complete

F Caution forthe fight For cary igs fyaigplane inthe windward and keep high aitude and distance so tht the airplane is abe return to the irl

tvenf the engine hos sopped.f you fly amlane at low ate fom the begining, body of smplane sy be damaged at emergency

i Tanding diet engine rouble

Base steps forthe ajusiment of carburetor are fist obtaining peak speed (maximum speed) by adjusting main needle ad then, set idling. speed

{Glow speed) using htt valve and slow needle. (Vice vers is nt possible, however)

@DAMtr fot takes filed vp stat engine ws deseibed in Article G. Alte throne valve opening is set at fll open with thot

‘vith main nese while watching tachometer and listesing tothe exbavst nose

2, cautiously obtain peal speed

F Canin: Excessive chsing of min needle very dangerous, asthe propeller ni besomes loose. In such oceasion, immediately tua the sin ase in

counterclockwise to loosen

{®t slowly close thie valve and eauouly adjust the speed sing a screwdriver for slow needle and thet stick fr trot valve opening so thatthe

28

engine runs at aniling speed inthe ange of arousd 2,000~2,500 gpm in sabe condition. (See the gare Below)

(@onee ing speed is set, slowly open the thot valve to ful pes, If he speed! becomes irepsar or suddenly increases this process, carefully make fine

‘djustnent wiih low needle so thatthe peed changes linearly [om the iling othe peak speed

@W hen the above adjusiment has completed, quicky change he speed from idling to its peak. If the speed does nat reach at its peak sim

‘onaition of throttle valve fully pened, retura main needle by single knrl notch, Thea, quickly change the speed from idling to its peak again, Repeat this

procedure cautiously unl you cas obtain good response.

@When al covdtions are st, erm the adjustment by 2 to 3 knuelnot

taneously withthe

1s (or about 300 pm slower).

300 rpm, seduce speed by 30 rpm to sett at 9,000 rpm, Its the Key for Tonge service lif 10 run the engine at &

2 When peak speed wih fll tank fuel

‘speed slower than speak by around 300 rpm and the bearings would huey get

‘ue standard values shown in the folowing figure asthe standard for carburetor needle opening ajusiment, hough light adjustment is equired according to

the engine mounting postion, propeler type ue ype plug, weather condition, and so feth

agioneeae Fuel nile Sedan aes

Jre_, Title er

Stow eee

(Fruthiome ever

(sew iver Forlani

orrchmiste

@o not openste your engine to lean at fll tote, a twill cause overheated engine, Adjust it silly slower than the peak (Teo Lean operation causes

knocking, Soppage and negative iniluence on the connecting rods and cam gear)

DTappet exp adjustment

‘Aller operating the engine fo one hour, you shoul! ages tappet gap (valve elearnce) because of inal wear. Adjustment of tppet sip mst be cari out

‘ve the engine is col.

Tor the adjectneat of appet exp femove plag and rocker arm cover and when the propellers slowly timed in forward direction with hand, ocker arm stops

IT ou tre the propeller fhe, pst reaches at ts top dead center of compression. Then, make adjusinent using attacked spanner and hexagonal wrench 30

Thos cates tatty closet aero while the compression exist atthe position, When the gap ts cheekeg, securly fasten (but not excessively) the locking

‘in cose of actual automobile eagige, small gp i provided by anticipating valve longaion. However, in the case of our engine, gap becomes lager daring

charton as elongtfon of einer (lamina) is larger than tat of the vale, therefore, the gop must be st indefinitely lose to zero while te engine is

ie

‘Alte his sdjstneat,appet gap mu be checked from time to time wit he above procedure. If attached gauge (limit gauge 1-0.) aa be inserted, 3p

tetonne tex rgecand adjutneht must be made-Tapret gap isthe most important factor inthe maintenance of 4stoke engine. fhe engin is operated with

exeesive gop it would esl rlormance

‘@ivien exhaust pipe i fixed tote cylinder and propeller uti fixed, apply sal quantity of silicon rubber (oot excessively onthe Head section and sew it

in I prevent leakage and loseeing.

@Asstiinal ighening of propeller nut and exhaust nt (hil is hos) mast be erred out fom tie i

@Atier the Hight, ubvieste entre engine with spray type preserve lubricant through the carburetor or breather

ir the esatac is aot operated for any Tonger period of tne, remove the plug, tear cover head cover ete. from the engine an clean them thorbuphy with

alcchol Alter lubication, reassemble them othe original condition and pata plastic cover oni

it the engine is stopped with mach mixture, bearings in the crankcase may get rus. Run your engine for about 10 seconds at maximum speed before itis

stopped and cut of the uel 10 op.

Bo prevem wear and sigue of rotating section and sliding surtce ofthe engine, necessary areas ae lubricated with back molybeoum ol. When the engine

isin openton, black waste oli preduced from breather apple, nil, et, however, you can continue your operation i is normal. I eerurs in break

sage

{@Pision bearings. cam gear, ee are lubricated by the ol tha comes int crankcase through the gop between cylinder

(Do discharge wast oil, connec silicon tube et. othe breather appl lested under the fon forthe dlscarge outside ofthe seplane

(DSafety is the most important element when operaing model engines. Be careful motto cause trouble to others,

‘Denne for mode! snplane is wt toy. Handle twit extreme cre

stow

‘K. Hints for Disassembly/Assembly Work

Dimssembling aod assembling of your engine are not recommended, however, fllow the following insretions when necessary

(DFor the dismmaitng, put beach marks on the parts by yourself (ase marking pen ete) while checking ereetion of pars in proper sequence. Als, clean cach

part

To putcular,carefl stein is required onthe valve ining, valve inet and exhaust, ston deetion, connecting od direction, aids forth

DT he eyliner serews should be lovened lite by lie in ersscross pattern. If hey are loosened improper, you may distort the eyinr

ag?

(@Assennble it with te some crisscross method applying engi ul tthe ips af the eerews

you tighten the screws without el, you may cause dunage tothe threaded areas.

@assenbe the eum gear ising up the necessary marks perth digram. The crams! shoul be p

‘am gear should be positioned below.

one atte op dead center, Then he eoneidence ofthe

(Position the piston, connecting rod, rocker arm, pias, push rod, appel, ete in thee original position. Engine pris are mated afer vusing and they must be

returned to heir origiaal positions. When you de assemble your engine, apply engine oi to cach past and reassemble them i proper sequence while cttuly

‘checking marks and directions without applying excessive frce when igen

1-1) Pot mars onail ports

Thee pincplesofdisussenbly: _} 2) Make sure dizecions are core %

3) Loosen sorews evenly and digo

1) Keepall pats clean,

| Thee principles of wssembiy: + 2) Labricate each part with engine ol.

C5 Fasten sre fly ond evenly and do aot ove lighten,

Marking atthe bation,

Crest of gear eoth

(@ovange in mounting direction of carburetor (See

1) Remove mouating cap screws so tbat the

surburtorsan be moved

2) Tueathe carburetor about 90 degrees as

showa in Fig. 2 using the section where

Jotake pipe is inserted into epinder ae

{bleram without removing carburetor

and ace pipe

3) Turathe carbretorin opposite ditetion

previous postion,

4) Return carburetor tothe mounsiog

postion and mount i with mounting sap

Sesevis. Corel stienton is required for

‘he Hightening torque of exp screws a8

excessive torque results ia poor

‘movement of thotle valve (rot)

®

All specifications and modes ate subject ochange without notice

SAITO SEISAKUSHO, CO. , LTD.

22-7, 3-chome, ‘Tokagi, Ichikawa, Chiba 272-002

Phone 047-378-4156

Fox 047-378-4155

SAITO FA—~100, 100GK Peres List

m0 Deseription we) [ae Deseription wy

ot | eviinaee 1] [a2 [Recker orm scrow Wut (42-1, 42-2) tea

06 [Piston 1] [Tas [Recker are sin z

ot_| Piston pin 1] [Tas [ave set in w Ba) 61 15-2) Taet

8 | Piston pin retainer 2] [#1 [alve spring & Keeper & Re zea,

03 | Piston ring 1 AT-1, 47-2, 48

10 | Connecting Fed 1] [at [ave retainer (otter [2

14 [Cylinder serow oot T1162) Tet] [Tao [Rocker ora cover 2

15 | Crankoase 1 02_| Intake manifold (Intake pipe) to

TT Rear caver 1] [re [uettter Gen sipoie) 1

T0_[ Breather nipple 1] [Las [etter manifold set TET, 80. 160 inet

20_[ Front bearing 1] [Tao etter nut (to avttien 7

22 | Rear bearing 1] [Beet | corburetor complete inet

75_| Crankehefe 1] [68-1 [Corburetor body assenbly tae

faper collet & Drive flange(i-1, 21-2 [iee. BAT egsTo2G2a|-Q.Og Tee TTB |

zr Tap so aD) BETslathatse eal g ee

26 [Prop washer & Nut (281, 28-2) Te) EE -

[[1_[[crankease seven sot (21-1, 31-2,31-3) Taet a a

aT [Throttle barrel assenbly

SP | Enotne sesket set + 2-1-5, 62-1-6, 621-8, 88, 89 ka

301, 30-0 92-3, 0-4, 1-5, TE 2 ae ;

SES | [at Linrettte Taver(@,s0-1 ja

aa 83 | Idle needle 1

35 D

— 1) [er [Garburetor soron & sprive eet re

: 2-1-6, 2-1-1, 82-1-8, 82-113, 90-1 ve

a Test

TT [Carburetor gasket set

38_| Tappet 2 Tet

50-4, 92-5, 80-6, 6221-3, TTA

38_| Pustred z

TI Asti Tassening nuk 1

4G | Foshrod cover & Rubber oval WOn1, 40-2, 40-3) [ee.) Para Veseening me

[Ta [Rocker arm z See eee

FA=100

I

|

Carburetor Complete

(2006.

5.

You might also like

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5807)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (346)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (842)

- Approximate Solution For Streamlines About A Lifting Rotor Having Uniform Loading and Operating in Hovering Naca-Tn-3921Document42 pagesApproximate Solution For Streamlines About A Lifting Rotor Having Uniform Loading and Operating in Hovering Naca-Tn-3921Mariela TisseraNo ratings yet

- Wrigth Flying Machine 1906 Patent Us821393Document10 pagesWrigth Flying Machine 1906 Patent Us821393Mariela TisseraNo ratings yet

- LANDING CHARACTERISTICS OF AN AUTOGIRO FECK 1934 19930081285Document22 pagesLANDING CHARACTERISTICS OF AN AUTOGIRO FECK 1934 19930081285Mariela TisseraNo ratings yet

- 1402 EMERGENCE OF COMPUTATIONAL FLUID DYNAMICS AT IMPERIAL COLLEGE 1965-1975 A PERSONAL RECOLLECTION 2013 RUNCHALDocument10 pages1402 EMERGENCE OF COMPUTATIONAL FLUID DYNAMICS AT IMPERIAL COLLEGE 1965-1975 A PERSONAL RECOLLECTION 2013 RUNCHALMariela TisseraNo ratings yet

- 458 Application_of_the_Craig-Bampton_method_to_blade_rotation LEORODocument10 pages458 Application_of_the_Craig-Bampton_method_to_blade_rotation LEOROMariela TisseraNo ratings yet

- 412 Improved Modal Dynamics of Wind Turbines to Avoid Stall induced Vibrations (2003) HANSENDocument17 pages412 Improved Modal Dynamics of Wind Turbines to Avoid Stall induced Vibrations (2003) HANSENMariela TisseraNo ratings yet

- Evaluation of The Induced Velocity Field of An Idealized Helicopter Rotor Coleman Feingold Stempin 1945 Filete 19930093086Document27 pagesEvaluation of The Induced Velocity Field of An Idealized Helicopter Rotor Coleman Feingold Stempin 1945 Filete 19930093086Mariela TisseraNo ratings yet

- ANALYISIS AND MODEL TEST OF AUTOPGIRO JU, P TAKE OFF WHEATLEY BIOLETTI 1937 JUMP TAKE OFF Naca-Tn-582 FILETE FILETE FILETEDocument31 pagesANALYISIS AND MODEL TEST OF AUTOPGIRO JU, P TAKE OFF WHEATLEY BIOLETTI 1937 JUMP TAKE OFF Naca-Tn-582 FILETE FILETE FILETEMariela TisseraNo ratings yet

- Frequency and Vibration Problems of Rotors Prewitt, R. H. - (1940)Document7 pagesFrequency and Vibration Problems of Rotors Prewitt, R. H. - (1940)Mariela TisseraNo ratings yet

- Wind Turbine Brake Fayette US4715782Document9 pagesWind Turbine Brake Fayette US4715782Mariela TisseraNo ratings yet

- MTO Autogyro Rotor Blade Inspection AG-SIL-2019-03-B-EN-Rotor-Blade-InspectionDocument6 pagesMTO Autogyro Rotor Blade Inspection AG-SIL-2019-03-B-EN-Rotor-Blade-InspectionMariela TisseraNo ratings yet

- Aeroelastic Model Helicopter Rotor Testing in The Langley TDT Wayne Yeager 1985 19860002056Document19 pagesAeroelastic Model Helicopter Rotor Testing in The Langley TDT Wayne Yeager 1985 19860002056Mariela TisseraNo ratings yet

- Underslung Rotor DesignDocument4 pagesUnderslung Rotor DesignMariela TisseraNo ratings yet

- Notes On Derivation of Empirical Charts For Calculation of Rotor Blades Nikolsky 1959 Ada952031Document16 pagesNotes On Derivation of Empirical Charts For Calculation of Rotor Blades Nikolsky 1959 Ada952031Mariela TisseraNo ratings yet

- Wallis Pag2 1966 - 0900Document1 pageWallis Pag2 1966 - 0900Mariela TisseraNo ratings yet

- Karl Ludvigsen - Juan Manuel Fangio - Motor Racing's Grand MasterDocument98 pagesKarl Ludvigsen - Juan Manuel Fangio - Motor Racing's Grand MasterMariela TisseraNo ratings yet

- Wallis Pag1 1966 - 0899Document1 pageWallis Pag1 1966 - 0899Mariela TisseraNo ratings yet

- The Influence of Wing Setting On The Wing Load and Rotor Speed of Pca-2 Autogiro NACA-report-523Document4 pagesThe Influence of Wing Setting On The Wing Load and Rotor Speed of Pca-2 Autogiro NACA-report-523Mariela TisseraNo ratings yet

- Study of Feasibility and Exactness For The Mathematical "Semirigid" Nonlinear Model of I. Nikolaev, E. N. Antoshkina 2012 PDFDocument9 pagesStudy of Feasibility and Exactness For The Mathematical "Semirigid" Nonlinear Model of I. Nikolaev, E. N. Antoshkina 2012 PDFMariela TisseraNo ratings yet

- Wallis Pag3 1966 - 0901Document1 pageWallis Pag3 1966 - 0901Mariela TisseraNo ratings yet

- Carlos Gardel - Su Vida, Su Música, Su Época Simon Collier, Carlos Gardini - (1999, Editorial Sudamericana S.a.)Document348 pagesCarlos Gardel - Su Vida, Su Música, Su Época Simon Collier, Carlos Gardini - (1999, Editorial Sudamericana S.a.)Mariela TisseraNo ratings yet

- Patente Aircraft With Rotative Wings Cierva 1928 Us1692081Document3 pagesPatente Aircraft With Rotative Wings Cierva 1928 Us1692081Mariela TisseraNo ratings yet

- (Aircraft Engineering and Aerospace Technology 1934-Jan Vol. 6 Iss. 1) - The Direct Control Autogiro (1934) (10.1108 - Eb029765) - Libgen - LiDocument2 pages(Aircraft Engineering and Aerospace Technology 1934-Jan Vol. 6 Iss. 1) - The Direct Control Autogiro (1934) (10.1108 - Eb029765) - Libgen - LiMariela TisseraNo ratings yet

- STANDARD SPECIFICATION FOR DESIGN AND PERFORMANCE OF LIGHT SPORT GYROPLANE AIRCRAFT 1 - 2020122309300880c75Document17 pagesSTANDARD SPECIFICATION FOR DESIGN AND PERFORMANCE OF LIGHT SPORT GYROPLANE AIRCRAFT 1 - 2020122309300880c75Mariela TisseraNo ratings yet

- The Odes of Horace (1900)Document204 pagesThe Odes of Horace (1900)Mariela TisseraNo ratings yet

- 103 User S Guide For The Nrel Force and Loads Analysis Program (Flap) Version 2 - 2 1992 Con Listado 4674Document238 pages103 User S Guide For The Nrel Force and Loads Analysis Program (Flap) Version 2 - 2 1992 Con Listado 4674Mariela TisseraNo ratings yet

- Visualizing The History of Energy TransitionsDocument9 pagesVisualizing The History of Energy TransitionsMariela TisseraNo ratings yet

- LIBRO Modifying - Production.cylinder - Heads.-.Clive - Trickey (Porting, FILETE FILETEDocument27 pagesLIBRO Modifying - Production.cylinder - Heads.-.Clive - Trickey (Porting, FILETE FILETEMariela TisseraNo ratings yet

- Aristarchus of Samos - On The Sizes and Distances of The Sun and Moon - Greek Text, Translation, Analysis Christián C. Carman, Rodolfo P. BuzónDocument326 pagesAristarchus of Samos - On The Sizes and Distances of The Sun and Moon - Greek Text, Translation, Analysis Christián C. Carman, Rodolfo P. BuzónMariela TisseraNo ratings yet

- 114 Bladed Software Theory Manual 2003 Garrad HassanDocument88 pages114 Bladed Software Theory Manual 2003 Garrad HassanMariela TisseraNo ratings yet