Professional Documents

Culture Documents

Sulphuric Acid Production-Installation 3-5

Sulphuric Acid Production-Installation 3-5

Uploaded by

samehmo.abdoCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Sulphuric Acid Production-Installation 3-5

Sulphuric Acid Production-Installation 3-5

Uploaded by

samehmo.abdoCopyright:

Available Formats

SULPHURIC ACID PRODUCTION

1 GENERAL INFORMATION

Sulphuric acid is an important basic inorganic chemical, due to its various indus-

trial applications. Most of the sulphuric acid is consumed by the fertiliser indus-

try. Other important applications are the oil refining industry, the production of

pigments, and the steel industry and extraction processes of the non-ferrous

metal industry.

Sulphuric acid is furthermore used by the reference installation for the produc-

tion of viscose fibre.

The reference installation is operating three sulphuric acid production lines us-

ing different technologies for the production. All three production plants work af-

ter the principle that sulphur or sulphur containing waste gases are burned.

Sulphur-containing gases generated during the spinning process are collected

and recovered as the chemicals carbon disulphide and sulphuric acid. The co-

product sodium sulphate is produced from the input chemicals sulfuric acid and

sodium hydroxide solution. (Source: Operator information 2016).

2 INDUSTRIAL PROCESSES USED

The production of viscose fibres includes the treatment of pulp in several pro-

cess steps with carbon sulphide and a subsequent spinning step in sulphuric

acid baths. The waste gases contain CS2 and H2S (strong odorous gases and

weak odorous gases) and are combusted to avoid odour emissions. The thereof

obtained H2SO4 is reused in the production process.

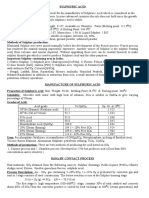

Table 1: Information of the three sulphuric acid production lines 2015. (Source: Operator information 2016)

Technology Output H2SO4 Output steam Input Input Input Conversion

Liquid Strong gas Weak gas

sulphur

t/d GJ/d t/h m³/h m³/h %

Sulphuric acid dry contact 300 964 (45 bar) 4.1 - - 99.9

production line 1 process

Sulphuric acid wet/dry con- 72 203 (45 bar) 0.68 80 6,560 99.8

production line 2 tact process

Sulphuric acid TOPSOE 151 924 (45 bar) 0.69 850 24,600 99.9

production line 3

Umweltbundesamt Vienna, 2017 1

Sulphuric acid production – Industrial Processes used

Another process used to produce sulphuric acid is the combustion of elemental

sulphur. The resulting sulphur dioxide is converted in sulphur trioxide in a dou-

ble contact process and finally absorbed in water for the formation of H2SO4.

Elemental sulphur is also added to strong odour gases if the sulphur concentra-

tion is not high enough.

The reference installation operates three sulphuric acid production lines as

shown in Table 1.

Description sulphuric acid production line 1 – dry contact process

In production line 1 elemental sulphur is combusted for the formation of SO 2,

which is subsequently oxidised to SO3 in a 4 layer double contact process with

intermediate absorption after layer 3.

Sulphur handling Liquid sulphur is pumped to the burner of the furnace from the sulphur storage

systems tank. All pipes and filters are double-walled and heated in order to avoid the so-

lidification of liquid sulphur before it is burned.

Sulphur furnace The liquid sulphur (ca. 4,000 kg/h) is injected into the sulphur furnace with a

pressurised atomiser burner. The combustion air is dried in a drying tower with

concentrated H2SO4 in counter-flow.

The gas after the furnace contains approx. 10 – 11 vol% SO2, the temperature

in the furnace is approx. 1,070 °C. After the furnace the gas is cooled to approx.

460 °C in the waste heat boiler.

Contact tower – dry The conversion of SO2 to SO3 is carried out in the contact tower in 4 layers ap-

contact process plying a vanadium pentoxide catalyst.

Since the conversion is an exothermic process, the gas temperature rises from

approx. 460 °C to 600 C (layer 1). For shifting the process to the product side,

the temperature is lowered after each layer by a heat exchanger to approx.

460 °C.

Acid unit After layer 3, the gas is cooled with boiler feed water to 225 °C and enters the

intermediate absorber. SO3 is removed from the gas stream resulting in concen-

trated sulphuric acid.

The gas which does not contain SO3 anymore is heated to 420 °C with steam

and conducted to the fourth layer. The remaining SO2 is oxidised to SO3 and,

after heat exchange, conducted to the final absorber. In the final absorber, SO 3

is removed via concentrated, trickled H2SO4 in counter flow. The resulting sul-

phuric acid is stored in a 2,000 t tank or is pumped to the viscose production

unit.

The exhaust gas is cleaned by cartridge filters to avoid sulphuric acid mist. The

waste gas stream is 22,500 Nm³/h (source: operator information 2015).

Description sulphuric acid production line 2 – LURA 1

This H2SO4 production unit was built in order to eliminate H2S and CS2 from the

strong odour gases which occur during the production of viscose. The strong

gases contain 40 – 45 Vol% H2S and 15 – 25 Vol% CS2. Dependent on the

2 Umweltbundesamt Vienna, 2017

Sulphuric acid production – Industrial Processes used

availability of strong gases from the production process elemental sulphur is fed

into the line to ensure a steady SO2 concentration in the combustion gas. The

conversion to sulphuric acid is carried out in a combined wet/dry contact process

(Source: Operator information 2016).

Before entering the furnace, condensate in strong odour gases is separated. Sulphur furnace

The strong gases and liquid sulphur are combusted at 1,100 °C to ensure a

steady SO2 concentration of 7 – 8 Vol%. After passing the heat recovery boiler

the gas is fed into the contact tower.

The conversion of SO2 to SO3 is carried out in a 4 layer contact tower applying Contact tower

a vanadium pentoxide catalyst.

Excess heat due to the chemical reaction is discharged after each layer with a

heat exchanger.

The wet contact process is necessary as the gases contain water (if H2S is

burned H2O is generated) and so H2SO4 is formed during the catalytic oxidation

of SO2 to SO3. Therefore, the gas enters the intermediate absorber after layer 3

with approx. 360 °C to avoid corrosion due to condensation of H2SO4.

H2SO4 mist formed in the intermediate absorber is separated by mist filter.

The remaining SO2 is oxidised to SO3 in layer 4 by a dry contact process and

removed as H2SO4 in the final absorber.

Both absorption towers (intermediate absorber after level 3 and final absorber Absorption towers

after level 4) are filled with packing material. The gas stream is channelled in

counter current to H2SO4.

The formed H2SO4 is conducted continuously to tanks. It is reused in the spin-

ning process.

H2SO4 mist in the exhaust gas (6,500 Nm³/h) is abated by cartridge filters

(Source: Operator information 2016).

Description sulphuric acid production line 3 – TOPSOE

The production line 3 is utilized, as production line 2, to abate H2S and CS2

generated in the production of viscose.

Therefore, strong odour gases from the spinning process and weak odour gas- Sulphur furnace

es from the spinning vats (serves also as combustion air supply) are combusted

in a furnace for the formation of SO2. Before the weak gas enters the furnace, it

is cleaned via a gas scrubber to remove remaining substances and solids from

the spinning baths.

To ensure constant operating conditions (SO2 and temperature), liquid sulphur

is dosed. If necessary to reach the required reaction temperature, fuel oil extra

light is co-combusted. The ignition burner uses natural gas.

The combustion gas is cooled in the waste heat boiler and the energy is used

for the steam production.

The gas is conducted with 400 °C in the converter, which has 2 catalyst layers SO2-converter

for oxidising SO2 to SO3. After layer 1, the gas is cooled down by an intermedi-

ate cooler. Both layers are filled with TOPSOE-H2SO4-catalyst.

Umweltbundesamt Vienna, 2017 3

Sulphuric acid production – Current Emissioin and Consumption Levels

Subsequently the gas is cooled to approx. 290 °C in a process gas cooler. Wa-

ter is dosed adequately for the formation of acid in terms of steam after the

cooler. Condensation nuclei are added and the gas is conducted to the WSA-

condenser.

WSA condenser The WSA condenser is a vertical tube falling film condenser/concentrator with

tubes made of borosilicate, acid and shock resistant glass. The process gas

flows up the tubes and is cooled by ambient air circulating on the outside of the

tubes. Sulphuric acid condenses in the tubes and flows downward counter-

current to the process gas. This contact with the hot process gas concentrates

the acid to the desired concentration. The acid is collected (260 °C) cooled by

adding already cooled down acid and delivered to the storage tanks with 35 °C.

(http://www.sulphuric-acid.com/techmanual/Technology/wsa.htm)

The condenser is cooled with air. The generated hot air (230 °C) is used to pre-

heat the boiler feed water.

To reduce the remaining SO2 contamination in the exhaust air, a peroxide

scrubber is installed. The total efficiency is about 99.9%. The exhaust gas vol-

ume is 21,000 Nm³/h.

3 CURRENT EMISSIOIN AND CONSUMPTION

LEVELS

3.1 Air

SO2 and SO3 (H2SO4 aerosols) are the major air emissions in the production of

sulphuric acid.

SO2 emissions are emitted due to an incomplete reaction of SO2 into SO3 on

the catalyst. SO2, which is not converted into SO3, is hardly absorbed in water.

SO2 emissions are dependent on SO2 content of the raw gases, the oxygen

concentration, the reaction parameters (temperature) and the resulting conver-

sion rate of the contact process.

In Table 2 emission limit values (ELV) are presented. Line 1 and line 2 have

similar ELVS of 700 mg/Nm³ and 625 mg/Nm³ respectively. Line 3 has an emis-

sion limit value of 200 mg/Nm³.

The emissions have to be monitored continuously according to the figures pre-

sented in Table 2.

1), 2), 3)

Table 2: Emission limit values monitoring

Emission limit values for 700 mg/Nm³

line 1 continuous

SO2 of sulphuric acid dry contact process recorded as daily average

production lines 1-3. line 2 625 mg/Nm³ continuous

(Source: Operator wet/dry contact process recorded as daily average

information 2016) line 3 200 mg/Nm³ continuous,

TOPSOE recorded as daily average

1)

Ge20-13-01-310-2010, Ge20-13-01-372-2010

2)

Ge20-13-01-158-2010, Ge20-13-01-372-2010

3)

Ge20-13-01-315-2003

4 Umweltbundesamt Vienna, 2017

Sulphuric acid production – Current Emissioin and Consumption Levels

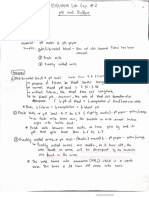

The distributions of the daily average values of SO2 emissions for the 3 lines

are presented in Table 3 and Figure 2. The daily averages were recorded dur-

ing April and July 2016. According to the emission limit values the lowest emis-

sions were obtained for line 3 (TOPSOE process with subsequent H 2O2 scrub-

3

ber) were the values were in the range of 120 – 160 mg/Nm . For line 1 and 2

the majority of daily averages in the reference period were between 500 –

3

700 mg/Nm .

Some measured values are higher than the emission limit values because the

plant is operated at the upper capacity limit. For the emission limit value compli-

ance, validated values (measured values minus the measurement uncertainty)

are used. All validated values are below the emission limit value.

[mg/Nm³] Line 1 [mg/Nm³] Line 2 [mg/Nm³] Line 3 Table 3:

No. of values No. of values No. of values Daily averages of SO2

emissions to air.

500 – 600 18 16% 400 – 500 3 2% 75 – 100 0 0%

(Source: Operator

600 – 700 60 52% 500 – 600 8 7% 100 – 125 2 2%

information 2016)

700 – 800 37 32% 600 – 625 8 7% 125 – 150 119 98%

Total 115 100% 625 – 650 38 31% 150 – 175 0 0%

650 – 700 64 53% 175 – 200 0 0%

Total 121 100% Total 121 100%

Figure 1:

SO2 emissions to air

Daily averages of SO2

800 emissions to air.

700

600

SO2 [mg/Nm³]

500

400

300

200

100

0

Apr 2016 May 2016 Jun 2016 Jul 2016 Aug 2016

Plant 1 Plant 2 Plant 3

Source: Operator information (2016)

Month line 1 line 2 line 3 line 1 line 2 line 3 Table 4:

[mg/Nm³] [kg/h] Monthly averages of

SO2 emissions to air

Jan 2013 441 708 135 10.01 4.45 3.02

2013 and 2014. (Source:

Feb 2013 453 697 161 10.11 4.30 2.82

Operator information

Mar 2013 455 688 153 10.09 4.17 2.96 2016)

Apr 2013 520 694 170 11.33 4.10 2.98

May 2013 609 694 165 13.14 4.00 2.99

Jun 2013 492 558 155 11.04 3.66 2.99

Jul 2013 481 730 158 10.87 5.25 2.87

Umweltbundesamt Vienna, 2017 5

Sulphuric acid production – Current Emissioin and Consumption Levels

Month line 1 line 2 line 3 line 1 line 2 line 3

[mg/Nm³] [kg/h]

Aug 2013 481 708 159 10.82 5.08 2.98

Sep 2013 476 711 173 10.93 5.16 3.05

Oct 2013 508 722 165 11.37 5.40 2.96

Nov 2013 384 719 152 8.51 5.41 2.98

Dec 2013 360 728 157 8.31 5.50 2.96

Jan 2014 375 725 147 8.73 5.45 2.98

Feb 2014 381 716 140 8.91 5.34 2.99

Mar 2014 336 716 164 7.91 5.35 2.98

Apr 2014 262 713 144 6.25 5.14 2.98

May 2014 305 649 166 7.05 4.93 1.45

Jun 2014 293 708 143 6.78 5.16 3.03

Jul 2014 336 708 145 7.64 5.17 3.04

Aug 2014 336 702 159 7.08 5.15 3.02

Sep 2014 392 711 157 7.70 5.18 3.07

Oct 2014 290 716 147 6.31 5.19 3.00

Nov 2014 288 716 160 5.87 5.25 2.88

Dec 2014 279 716 132 5.89 5.28 2.97

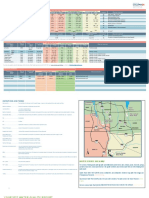

In Table 4 and Figure 2 monthly averages of SO2 emissions for the three pro-

duction lines over a period of two years (January 2013 – December 2014) are

displayed. The monthly averages (MA) of line 1 (double contact dry process)

3

are mostly in the range of 200 – 500 mg/Nm with only one value above 500

3

mg/Nm . The range of monthly averages for line 2 (wet/dry contact process) for

3

the two year period (2013 – 2014) is 600 – 700 mg/Nm . The lowest monthly

3

averages within the range of 100 – 200 mg/Nm were obtained for line 3

(TOPSOE process with subsequent H2O2 scrubber).

Figure 2:

SO2 emissions

Monthly averages of

SO2 emissions to air. 800 14

700 12

SO2 [mg/Nm³]

600 10

SO2 [kg/h]

500

8

400

6

300

200 4

100 2

0 0

Feb 2013

Mar 2013

Apr 2013

Oct 2013

Feb 2014

Mar 2014

May 2013

Apr 2014

Oct 2014

May 2014

Jul 2013

Jul 2014

Jan 2013

Jun 2013

Jan 2014

Jun 2014

Aug 2013

Sep 2013

Nov 2013

Dec 2013

Aug 2014

Sep 2014

Nov 2014

Dec 2014

Line 1 [mg/Nm³] Line 2 [mg/Nm³]

Line 3 [mg/Nm³] Line 1 [kg/h]

Line 2 [kg/h] Line 3 [kg/h]

Source: Operator information (2016)

6 Umweltbundesamt Vienna, 2017

Sulphuric acid production – Current Emissioin and Consumption Levels

The formation of SO3 emissions takes place due to incomplete absorption. SO3

emissions are monitored periodically 4 times a year for line 1 as well as line 2

and monthly for line 3. No measures are taken to reduce SO3 emissions to air

and no emission limit value is permitted.

SO3 Minimum Yearly Maximum Table 5:

[mg/Nm³] Average SO3 emissions to air for

Line 1 9.1 16.5 22.4 production lines 1,2

Line 2 12.2 21.2 26.3 and 3. (Source:

Operator information

Line 3 7.6 20.3 50.6

2016)

Minimum and Maximum emission values represent averages over four hours. All emission values

were obtained during 1 year (June 2015 – July 2016) and refer to standard conditions (0°C and

1,013 mbar) and dry gas.

Emission values for SO3 are presented in Table 5 and range from 9.1 –

3 3

22.4 mg/Nm for line 1. Line 2 has a similar range from 12.2 – 26.3 mg/Nm .

Minimum values and yearly average for line 3 are also similar compared to the

3

other production lines. The maximum value is 50.6 mg/Nm and therefore high-

er in relation to line 1 and 2.

Including the maximum averages, all SO3 emission values are within the range

3

of ≤50 mg/Nm .

The sulphuric acid production lines are fully enclosed, therefore no fugitive Fugitive emissions

emissions SO2 and SO3 occur.

3.2 Water

No waste water arises from the sulphuric acid production.

3.3 Waste

The first catalyst layers are exchanged every 5 to 10 years, the other layers

every 10 to 15 years. The decision to exchange the catalyst is made depending

on the catalysts reaction rate. In between the catalyst exchanges the catalyst

beads are sieved to remove dust.

Used catalyst material is recycled in the metal industry.

3.4 Energy

The sulphuric acid production is an exothermic process. Excess heat is used to

produce steam.

Umweltbundesamt Vienna, 2017 7

Sulphuric acid production – References

4 REFERENCES

UMWELTBUNDESAMT (2001): Wiesenberger, H.; Kircher, J.: Stand der Technik in der

Schwefelsäureerzeugung im Hinblick auf die IPPC-Richtlinie. Monographien,

Bd. M-137. Umweltbundesamt, Wien.

UMWELTINSPEKTION (2015): Schwefelsäureproduktionsanlagen.

8 Umweltbundesamt Vienna, 2017

You might also like

- Sulfuric Acid Manufacture: Analysis, Control and OptimizationFrom EverandSulfuric Acid Manufacture: Analysis, Control and OptimizationRating: 3.5 out of 5 stars3.5/5 (3)

- Contact ProcessDocument16 pagesContact ProcessOmar Almonte100% (1)

- Lead Chamber Process For H2so4Document11 pagesLead Chamber Process For H2so4Zamir Khan100% (3)

- Sulfur - Sulfuric Acid IndustryDocument18 pagesSulfur - Sulfuric Acid IndustryS S S REDDY100% (1)

- NotesDocument50 pagesNotesShashwat SrivastavaNo ratings yet

- Chemistry Depth StudyDocument11 pagesChemistry Depth StudyAdyasree AlluruNo ratings yet

- Sulphuric Acid (H SO4)Document44 pagesSulphuric Acid (H SO4)Faisal Azis RamadhanNo ratings yet

- Chapter 19: Sulfur and Sulfuric AcidDocument5 pagesChapter 19: Sulfur and Sulfuric AcidJoaquin LumactodNo ratings yet

- Module-Ii: Chemical Technology-V SemDocument149 pagesModule-Ii: Chemical Technology-V SemPrashant Giri100% (1)

- Lecture 2 Inorganic Industries 2019Document41 pagesLecture 2 Inorganic Industries 2019Mohamed AbdelaalNo ratings yet

- 7 - Sulfur & Sulfuric Acid TaughtDocument58 pages7 - Sulfur & Sulfuric Acid TaughtsahibjotNo ratings yet

- Unit II - Final-1Document40 pagesUnit II - Final-1S kabileshNo ratings yet

- Sulfuric Acid Production PDFDocument66 pagesSulfuric Acid Production PDFTrần Kiên100% (3)

- Sulphuric Acid ManufactureDocument5 pagesSulphuric Acid ManufactureLeonardo ColmenaresNo ratings yet

- Chapter 2: Sulfur & Sulfuric Acid Chapter 2: Sulfur & Sulfuric AcidDocument20 pagesChapter 2: Sulfur & Sulfuric Acid Chapter 2: Sulfur & Sulfuric AcidabichedNo ratings yet

- Heavy Chemical IndustryDocument20 pagesHeavy Chemical IndustryUsman AliNo ratings yet

- Wa0003Document15 pagesWa0003Muavha MadembeNo ratings yet

- Chapter Two Feasibility Study 2.0 Methods of Producing Ammonium Sulphate, ( (NH) SO)Document9 pagesChapter Two Feasibility Study 2.0 Methods of Producing Ammonium Sulphate, ( (NH) SO)Adeyoju RebeccaNo ratings yet

- 4-sulphuric-acid...... NaseerDocument22 pages4-sulphuric-acid...... Naseermaliknaseer1214721No ratings yet

- Sulfuric AcidDocument29 pagesSulfuric AcidDanish BaigNo ratings yet

- Air Polluition ControlDocument37 pagesAir Polluition ControlGendewa Tunas RancakNo ratings yet

- Chapter 2sulphuric Acid Manufacture Sept 2014Document5 pagesChapter 2sulphuric Acid Manufacture Sept 2014kvk326No ratings yet

- Group 01Document34 pagesGroup 01Muhammad MugheeraNo ratings yet

- Overview of The ProcessDocument10 pagesOverview of The ProcessChaitanya PottiNo ratings yet

- Basic Raw Material For Sulphur Acid ProductionDocument13 pagesBasic Raw Material For Sulphur Acid ProductionGrace Oluchi0% (1)

- Stage 1: Preparation of Sulphur DioxideDocument2 pagesStage 1: Preparation of Sulphur Dioxidenajwasyafiqah_1No ratings yet

- Sulfuric Acid Manufacturing PlantDocument6 pagesSulfuric Acid Manufacturing PlantmichsantosNo ratings yet

- Sulfur and Sulfuric Acid HCl-1Document57 pagesSulfur and Sulfuric Acid HCl-1Vijay SethupathiNo ratings yet

- Carbon Disulphide PlantDocument8 pagesCarbon Disulphide PlantDipanjanSarkarNo ratings yet

- SULPHURIC ACID PLANT PROCESSoDocument33 pagesSULPHURIC ACID PLANT PROCESSojagadeesh100% (2)

- Contact ProcessDocument12 pagesContact ProcessAdil Yaqub - 74665/TCHR/CNTBNo ratings yet

- Unit 3 Chemical Process Technology II Lesson 1 Nitrogen Industries (M)Document22 pagesUnit 3 Chemical Process Technology II Lesson 1 Nitrogen Industries (M)Green JeskNo ratings yet

- Inthe1 Converter Occurs Twice A Gas Cooling Through The Two Heat Exchanger Interbed Cooler and Process Gas CoolerDocument2 pagesInthe1 Converter Occurs Twice A Gas Cooling Through The Two Heat Exchanger Interbed Cooler and Process Gas Coolerrudy_423522658No ratings yet

- Sulfuric Acid Manufacturing ProcessDocument5 pagesSulfuric Acid Manufacturing ProcessamirahabidinNo ratings yet

- Sulfuric AcidDocument40 pagesSulfuric AcidrenitadyahNo ratings yet

- Modern Chemical ManufacturerDocument8 pagesModern Chemical ManufacturerUltra Gamer (sishant)No ratings yet

- Sulfur and Sulfuric AcidDocument20 pagesSulfur and Sulfuric AcidZakia LuthfianaNo ratings yet

- Materi Sesi 2 - 25 - Hugot - SulphitationDocument8 pagesMateri Sesi 2 - 25 - Hugot - SulphitationAngella LalaNo ratings yet

- CPT Unit 3 InorganicDocument86 pagesCPT Unit 3 InorganicMicrosoft GamingNo ratings yet

- Sulfuric Acid (H SO) IndustryDocument27 pagesSulfuric Acid (H SO) IndustryAqsa chNo ratings yet

- The Technology of Sulphuric Acid ProductionDocument58 pagesThe Technology of Sulphuric Acid ProductionGabriel AyauNo ratings yet

- Chemical Technology Sulphuric Acid Industry: Dr. Abhi Mukherjee Department of Chemical Engineering Contai PolytechnicDocument3 pagesChemical Technology Sulphuric Acid Industry: Dr. Abhi Mukherjee Department of Chemical Engineering Contai PolytechnicSk jahidul IslamNo ratings yet

- Chapter-17 Modern Chemical ManufacturersDocument10 pagesChapter-17 Modern Chemical Manufacturersraeesandip10No ratings yet

- SAPDocument16 pagesSAPsourav84No ratings yet

- 45766Document4 pages45766EmuskNo ratings yet

- Sulphuric AcidDocument6 pagesSulphuric AcidVishal ThakareNo ratings yet

- Sulfuric AcidDocument14 pagesSulfuric AcidAkh KreshnaNo ratings yet

- Manufacturing of Sulfuric Acid by Lead Chamber Process and Contact ProcessDocument14 pagesManufacturing of Sulfuric Acid by Lead Chamber Process and Contact ProcessDian Eka FajriyantoNo ratings yet

- Manufacture Nitric AcidDocument9 pagesManufacture Nitric AcidDjayustinus Heri HermawanNo ratings yet

- 13.2 Sulphur CompoundsDocument18 pages13.2 Sulphur CompoundsTrevor TatendaNo ratings yet

- Production of Sulfuric Acid Through Contact Process: Dusting Chamber Sulfur Reaction FurnaceDocument6 pagesProduction of Sulfuric Acid Through Contact Process: Dusting Chamber Sulfur Reaction FurnaceMinjdeDiosNo ratings yet

- Sulphur RecoveryDocument5 pagesSulphur RecoveryputrialdrianaNo ratings yet

- Topsoe Wet Gas Sulphuric Acid (WSA) TechnologyDocument8 pagesTopsoe Wet Gas Sulphuric Acid (WSA) Technologytsaleh100% (1)

- Unit Ii: Sulfur and Silicates IndustriesDocument35 pagesUnit Ii: Sulfur and Silicates IndustriesANSH SHUKLANo ratings yet

- S-Zorb (Conophillips) : Prepared By: Sadia Urooj Submitted To: Sir Zeeshan ZakiDocument4 pagesS-Zorb (Conophillips) : Prepared By: Sadia Urooj Submitted To: Sir Zeeshan ZakiSadia UroojNo ratings yet

- control of gaseous pollutantsDocument7 pagescontrol of gaseous pollutantssherincbabychempariyilNo ratings yet

- Kamar TimbalDocument6 pagesKamar TimbalAl Akil100% (1)

- Sulphuric AcidDocument2 pagesSulphuric Acidapi-239546340No ratings yet

- Chapter 21 - Sulfuric AcidDocument12 pagesChapter 21 - Sulfuric AcidargoniodideNo ratings yet

- Electrochimica Acta: Abrar Khan, Raja Arumugam Senthil, Junqing Pan, Sedahmed Osman, Yanzhi Sun, Xin ShuDocument10 pagesElectrochimica Acta: Abrar Khan, Raja Arumugam Senthil, Junqing Pan, Sedahmed Osman, Yanzhi Sun, Xin Shusalsa bilaNo ratings yet

- Periodic TableDocument1 pagePeriodic TableStefan GuiuanNo ratings yet

- Topic 04 Defect in Solid - Compatibility ModeDocument26 pagesTopic 04 Defect in Solid - Compatibility ModeSelviya AvaurumNo ratings yet

- The Cellular Level of Organization - AnaphyDocument12 pagesThe Cellular Level of Organization - AnaphyJean Rose SalahayNo ratings yet

- Concentration of SolutionsDocument42 pagesConcentration of SolutionsAien RonquilloNo ratings yet

- 1974 Axelrod-NEUROTRANSMITTERSDocument15 pages1974 Axelrod-NEUROTRANSMITTERScortizmenNo ratings yet

- Emulsogen LCN 070 (TDS)Document1 pageEmulsogen LCN 070 (TDS)Joyce yychongNo ratings yet

- SECTION 23 01 30.51 Hvac Air Duct Cleaning: Based On DFD Master Specification Dated 10/1/12Document4 pagesSECTION 23 01 30.51 Hvac Air Duct Cleaning: Based On DFD Master Specification Dated 10/1/12htanhNo ratings yet

- Final ReportDocument31 pagesFinal ReportShriramNo ratings yet

- Biodegradable Polymers For Biomedical ApDocument61 pagesBiodegradable Polymers For Biomedical ApPedro HenriqueNo ratings yet

- Student Exploration: Stoichiometry 75 Pts (Class Code DXF7RX)Document5 pagesStudent Exploration: Stoichiometry 75 Pts (Class Code DXF7RX)Garnet Lee0% (1)

- Eng1467 5367Document4 pagesEng1467 5367joey FajardoNo ratings yet

- Pinch AnalysisDocument6 pagesPinch AnalysisShooeibNo ratings yet

- Comparação Entre Métodos Magistrais de Homogeneização para A Preparação de Cápsulas e Alendronato de Sódio: Saco Plástico X AlmofarizDocument8 pagesComparação Entre Métodos Magistrais de Homogeneização para A Preparação de Cápsulas e Alendronato de Sódio: Saco Plástico X AlmofarizZilmar OliveiraNo ratings yet

- BS 1414-1975 PDFDocument27 pagesBS 1414-1975 PDF윤규섭No ratings yet

- Dna Extraction: Kitchen ScienceDocument2 pagesDna Extraction: Kitchen Scienceya wenNo ratings yet

- Journal of Medicinal Chemistry and Drug DiscoveryDocument24 pagesJournal of Medicinal Chemistry and Drug DiscoveryDr. Ramadevi DevarakondaNo ratings yet

- Hastelloy Vs 316LDocument4 pagesHastelloy Vs 316LGoran RadonicNo ratings yet

- 7 Language of ChemistryDocument13 pages7 Language of ChemistryMaaz WaseemNo ratings yet

- Electrogravimetry: Electrogravimetric Analysis V Semester Inorganic ChemistryDocument2 pagesElectrogravimetry: Electrogravimetric Analysis V Semester Inorganic Chemistryvandv printsNo ratings yet

- 5070 s20 QP 12 PDFDocument20 pages5070 s20 QP 12 PDFtechno gamerNo ratings yet

- Design of Machine Elements (DOME) MENG 375: Instructor Dr. Riaz MuhammadDocument61 pagesDesign of Machine Elements (DOME) MENG 375: Instructor Dr. Riaz MuhammadLoay MohammedNo ratings yet

- Module-5 - Application Environmental Protection and ManagementDocument23 pagesModule-5 - Application Environmental Protection and Managementanand pujariNo ratings yet

- Xii Neet FRGT-02 - Key and Solutions (09.04.23)Document8 pagesXii Neet FRGT-02 - Key and Solutions (09.04.23)Elamparithi ANo ratings yet

- 16.0 Grade Wise Chemical CompositionDocument29 pages16.0 Grade Wise Chemical CompositionrohitNo ratings yet

- Shs Integrated Science NotesDocument234 pagesShs Integrated Science NotesMark NyamesemNo ratings yet

- Composite MaterialsDocument30 pagesComposite Materialsarvindvsk23No ratings yet

- Biochem CombinedDocument14 pagesBiochem CombinedAmber De la CernaNo ratings yet

- NCERT Exemplar Solutions Class 10 Science Chemical Reactions and EquationsDocument12 pagesNCERT Exemplar Solutions Class 10 Science Chemical Reactions and EquationsLushila MinjNo ratings yet

- 2022 Columbus Drinking Water ReportDocument8 pages2022 Columbus Drinking Water ReportMatt ThomasNo ratings yet