Professional Documents

Culture Documents

GO-007-LNG Norman Lady - Cargo Operating Manual

GO-007-LNG Norman Lady - Cargo Operating Manual

Uploaded by

Federico CasconCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

GO-007-LNG Norman Lady - Cargo Operating Manual

GO-007-LNG Norman Lady - Cargo Operating Manual

Uploaded by

Federico CasconCopyright:

Available Formats

Norman Lady Cargo Operating Manual

Cargo Operating Manual 2.1d Relative Density of Methane and Air 4.7.1 Inert Gas Generators

2.2.1a Flammability of Methane, Oxygen and Nitrogen Mixtures 4.7.2 Nitrogen Generator

List of Contents 2.2.2a Structural Steel: Ductile to Brittle Transition Curve 4.7.3 Void Space Dryers

Issue and Update

Cargo Symbols and Colour Scheme Part 3: Distributed Control System (DCS) 4.8 Custody Transfer System

Electrical and Instrument Symbols 4.8.1 Custody Transfer System (CTS)

3.1 Cargo Control Room (CCR) Arrangement 4.8.2 Float Level Gauges

Introduction

4.8.3 Loading Computer

3.2 Vessel Control System

Part 1: Design Concept of the Vessel 3.2.1 Damatic XD Distributed Control System (DCS) Overview 4.9 Gas Detection Systems

1.1 Principal Particulars 3.2.2 Operator Stations 4.9.1 Fixed Gas Detection Systems

1.1.1 Ship Principal Particulars 3.2.3 Screen Displays 4.9.2 Portable Gas Detection Instruments

1.1.2 Principal Particulars of Cargo Machinery 3.2.4 Operation

3.2.5 Mimics 4.10 Valve Remote Control and Emergency Shutdown System

1.1.3 General Arrangement

3.2.6 Cargo and Ballast Operations 4.10.1 Cargo Valve Remote Control System

1.1.4 Tanks and Capacity Plan

4.10.2 Emergency Shutdown System

1.2 Rules and Regulations Illustrations 4.10.3 Ship Shore Link

3.1a Cargo Control Room Layout

1.3 Cargo System Technology 3.1b Cargo Control Room Console 4.11 Relief Systems

1.3.1 Cargo Containment System Principle 3.2.1a Distributed Control System Overview 4.11.1 Cargo Tank Relief Valves

1.3.2 Kvaerner-Moss Cargo Containment 3.2.2a Operator Station Keyboard 4.11.2 Line Relief Valves

1.3.3 Failure of Containment 3.2.3a Screen Display 4.11.3 Void Space Relief Valves

1.3.4 Void Spaces 3.2.3b Operating Panel Display

3.2.4a Operation 4.12 Ballast System

1.4 Hazardous Areas and Zones 3.2.5a Mimics 4.12.1 Ballast Piping

3.2.6a Ballast Operating Display Screens 4.12.2 Ballast Control and Indicating System

Illustrations

1.1.3a General Arrangement Part 4: Cargo and Ballast Systems Illustrations

1.1.3b Compressor Room Layout 4.1.1a Leakage Pipes

1.1.4a Tank Capacity Plan 4.1 Cargo Containment and Monitoring Systems 4.1.2a Temperature and Pressure Monitoring System

1.3.2a Construction of Containment System - Equatorial Ring and 4.1.1 Liquid Leakage Detection 4.1.3a High Level and Overfill Alarm System

Wedge Space 4.1.2 Temperature and Pressure Monitoring System 4.2a Cargo Piping System

1.3.2b Construction of Containment System - Rupture Discs 4.1.3 High Level and Overfill Alarm System 4.2b Manifold Arrangement

1.3.2c Construction of Containment System - Dome and Tank Access 4.2.3a Spray Pipes in the Cargo Tanks

1.3.2d Construction of Containment System - Insulation 4.2 Cargo Piping System 4.3.1a Main Cargo Pump

1.3.2e Construction of Containment System - Piping Insulation 4.2.1 Liquid Line 4.3.1b Pump Arrangement in Cargo Tank

1.3.4a Void Spaces and Ventilation 4.2.2 Vapour Line 4.3.2a Spray Pump

1.3.4b Relationship between Corrosion and Relative Humidity 4.2.3 Spray Line 4.4.1a High Duty Compressor

1.4a Hazardous Areas and Gas Dangerous Zones 4.2.4 Fuel Gas Line 4.4.1b High Duty Compressor Performance Curves

4.2.5 Vent Masts 4.4.2a Low Duty Compressor

Part 2: Properties of LNG 4.2.6 Inerting/Aeration Line 4.4.2b Low Duty Compressor Performance Curves

4.5a Cargo Heater

2.1 Physical Properties and Composition of LNG 4.3 Cargo Pumps 4.6a LNG Main Vaporiser

4.3.1 Main Cargo Pumps 4.7.1a Inert Gas System

2.2 Characteristics of LNG 4.3.2 Stripping/Spray Pumps 4.7.2a Nitrogen Generator

2.2.1 Flammability of Methane, Oxygen and Nitrogen Mixtures 4.7.2b Nitrogen System

2.2.2 Supplementary Characteristics 4.4 Gas Compressors

4.7.3a Void Space Dryers

4.4.1 High Duty Compressors

4.8.1a CTS Printout

2.3 Health Hazards 4.4.2 Low Duty Compressor

4.8.2a Whessoe Float Level Gauge

4.5 Cargo Heaters 4.8.3a Loading Computer Screen

Illustrations

4.9.1a Ballast and Void Spaces Gas Sampling System

2.1a Vapour Pressure Diagram of Liquid Cargoes

4.6 LNG Vaporisers 4.9.1b Boil Off Gas Pipe Vent Duct Gas Sampling System

2.1b Physical Properties of LNG

4.9.1c Cargo Areas Gas Sampling System

2.1c Composition of LNG from Major Export Terminals (Mol%)

4.7 Void Space Systems 4.9.2a Portable Gas Detectors

Issue: 2 Front Matter - Page 1 of 9

Norman Lady Cargo Operating Manual

4.10.1a Cargo Valve Remote Control System 5.5.2b Fire Fighting Equipment Decks 3 and 4 6.4.3a Cargo Loading with Vapour Return to Shore via the High

4.10.1b Cargo Gate Valve 5.5.2c Fire Fighting Equipment Decks 5 and 6 Duty Compressors

4.10.2a Fibre Optic Ship-Shore Link System and Pneumatic ESD 5.5.2d Fire Fighting Equipment Upper Deck and Engine Room 6.4.3b Completing Loading

Circuit 5.5.3a Lifesaving Equipment Decks 1 and 2 6.4.4a Deballasting

4.10.2b Emergency Shutdown Logic 5.5.3b Lifesaving Equipment Decks 3 and 4 6.5.1a Loaded Voyage with Normal Boil-Off Gas Burning

4.11.1a Cargo Tank Relief Valves 5.5.3c Lifesaving Equipment Decks 5 and 6 6.6.1a Preparations for Discharging

4.11.3a Void Space Relief Valves 5.5.3d Lifesaving Equipment Upper Deck and Engine Room 6.6.2a Liquid Line Cooldown

4.11.3b Monitoring of Pressure Relatives (Tank-Void Space-Atmosphere) 6.6.3a Arm Cooldown Before Unloading

4.12.1a Ballast Piping System Part 6: Cargo Operations 6.6.4a Discharging Cargo

6.6.4b Discharging

Part 5: Cargo Auxiliary and Deck Systems 6.1 Operating Procedures Overview 6.6.5a Ballasting

6.7.1a Stripping and Line Draining

5.1 Fire Detection System 6.2 Post Dry Dock Operation 6.7.2a Tank Warm Up

6.2.1 Drying Cargo Tanks and Void Spaces 6.7.3a Inerting

5.2 Fire Fighting Systems

6.2.2 Inerting Cargo Tanks 6.7.4a Aerating

5.2.1 Fire and Deck Wash System

6.2.3 Gassing Up Cargo Tanks

5.2.2 Water Spray System

6.2.4 Cooling Down Cargo Tanks Part 7: Emergency Procedures

5.2.3 Forward Emergency Fire Pump System

5.2.4 Dry Powder Systems 6.3 Ballast Passage 7.1 LNG Vapour Leakage to Insulation Space

5.2.5 CO2 System 6.3.1 Cooling Down Cargo Tanks Prior to Arrival

5.2.6 Emergency Headquarters 7.2 LNG Liquid Leakage to Insulation and Void Space

6.4 Loading 7.2.1 Use of Eductors for LNG removal

5.3 Cargo Compressor Room Systems 6.4.1 Preparations for Loading

5.3.1 Cooling Water System 6.4.2 Cargo Lines Cooldown 7.3 Water Leakage to Void Spaces

5.3.2 Steam to Cargo Consumers 6.4.3 To Load Cargo with Vapour Return to Shore via the High 7.3.1 Use of Eductors for Water Removal

Duty Compressors

5.4 Deck Machinery and Systems 7.4 Failure of Cargo Pumps - Emergency Discharge

6.4.4 Deballasting

5.4.1 Mooring Winches Windlasses and Deck Steam System

5.4.2 Mooring Plan 6.5 Loaded Voyage With Boil-Off Gas Burning 7.5 Fire and Emergency Breakaway

5.4.3 Pilot and Accommodation Ladders 6.5.1 Loaded Voyage with Normal Boil-Off Gas Burning

5.4.4 Deck Cranes 7.6 One Tank Operation

6.6 Discharging with Gas Return to Shore 7.6.1 One Tank Warm Up

5.5 Safety Plan 6.6.1 Preparations for Discharging 7.6.2 One Tank Gas Freeing

6.6.2 Liquid Line Cooldown 7.6.3 One Tank Aerating

Illustrations

6.6.3 Arm Cooldown Before Unloading

5.1a Fire Detection System 7.7 Ship to Ship Transfer

6.6.4 Discharging Cargo

5.2.1a Fire and Deck Wash System 7.7.1 General Safety

6.6.5 Ballasting

5.2.2a Water Spray System 7.7.2 Pre-Mooring Preparations

5.2.3a Forward Fire Pump System 6.7 Pre Dry Dock Operations 7.7.3 Mooring

5.2.4a Dry Powder Systems 6.7.1 Stripping and Line Draining 7.7.4 Transfer Operations

5.2.4b Dry Powder Systems: Hose Boxes and Units 6.7.2 Tank Warm-Up 7.7.5 Unmooring

5.2.5a CO2 System 6.7.3 Inerting

5.3.1a Cargo Plant Water Cooling System 7.8 LNG Jettison

6.7.4 Aerating

5.3.2a Steam to Deck Consumers

5.4.1a Mooring Winches and Deck Steam System 7.9 General Emergency Procedures

Illustrations

5.4.1b Winch/Windlass 6.1a Operating Procedures Schedule Illustrations

5.4.2a Mooring Arrangement 6.2.1a Drying Cargo Tanks and Void Spaces 7.1a Vapour Leakage to Insulation Space

5.4.3a Required Boarding Arrangement for Pilot 6.2.2a Inerting Cargo Tanks 7.2.1a Use of Eductors for LNG Removal

5.4.3b Pilot and Accommodation Ladders 6.2.3a Gassing Up Cargo Tanks 7.3.1a Use of Eductors for Water Removal

5.4.4a Deck Cranes 6.2.4a Cargo Tanks Cooldown Rates 7.4a Emergency Discharge

5.5.1a Fire Detection and Alarms Decks 1 and 2 6.2.4b Cooling Down Cargo Tanks During Loading 7.6.1a One Tank Warm Up

5.5.1b Fire Detection and Alarms Decks 3 and 4 6.3.1a Cooling Down Cargo Tanks Prior to Arrival 7.6.2a One Tank Gas Freeing

5.5.1c Fire Detection and Alarms Decks 5 and 6 6.4.1a Preparations for Loading 7.6.3a One Tank Aerating

5.5.1d Fire Detection and Alarms Upper Deck and Engine Room 6.4.2a Cargo Lines Cool Down

5.5.2a Fire Fighting Equipment Decks 1 and 2

Issue: 2 Front Matter - Page 2 of 9

Norman Lady Cargo Operating Manual

Issue and Update Control This manual was produced by:

This manual is provided with a system of issue and update

control. Controlling documents ensures that: WORLDWIDE MARINE TECHNOLOGY LTD.

• Documents conform to a standard format;

For any new issue or update contact:

• Amendments are carried out by relevant personnel;

The Technical Director

• Each document or update to a document is approved

before issue; WMT Technical Office

The Court House

• A history of updates is maintained; 15 Glynne Way

Hawarden

• Updates are issued to all registered holders of Deeside, Flintshire

documents; CH5 3NS, UK

• Sections are removed from circulation when obsolete. E-Mail: admin@wmtmarine.com

Document control is achieved by the use of the footer

provided on every page and the issue and update table

below.

In the right hand corner of each footer are details of the

pages section number and title followed by the page

number of the section. In the left hand corner of each

footer is the issue number.

Details of each section are given in the first column of the

issue and update control table. The table thus forms a

matrix into which the dates of issue of the original

document and any subsequent updated sections are located.

The information and guidance contained herein is produced

for the assistance of certificated officers who by virtue of

such certification are deemed competent to operate the

vessel to which such information and guidance refers. Any

conflict arising between the information and guidance

provided herein and the professional judgement of such

competent officers must be immediately resolved by

reference to Höegh Fleet Shipping Co. Ltd Technical

Operations Office.

Issue: 2 Front Matter - Page 3 of 9

Norman Lady Cargo Operating Manual

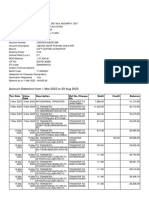

Issue 1 Issue 2 Issue 3 Issue 4 Issue 1 Issue 2 Issue 3 Issue 4

List of Contents February 2004 April 2005

Text

Cargo Symbols and Colour Scheme February 2004 February 2004

3.1

Electrical and Instrumentation Symbols February 2004 February 2004

April 2005 3.2

Introduction February 2004 February 2004

3.2.1

3.2.2 February 2004

Text February 2004

3.2.3

1.1 February 2004 February 2004

3.2.4

1.1.1 February 2004 February 2004

3.2.5

1.1.2 February 2004

3.2.6

1.1.3 February 2004

1.1.4 February 2004

Illustrations

1.2 February 2004 April 2005 February 2004

3.1a

1.3 February 2004 February 2004

3.1b

1.3.1 February 2004 February 2004

3.2.1a

1.3.2 February 2004 February 2004

3.2.2a

1.3.4 February 2004 February 2004

3.2.3a

1.4 February 2004 February 2004

3.2.3b

3.2.4a February 2004

Illustrations February 2004

3.2.5a

1.1.3a February 2004 February 2004

3.2.6a

1.1.3b February 2004

1.1.4a February 2004

Text

1.3.2a February 2004 February 2004

4.1

1.3.2b February 2004 February 2004

4.1.1

1.3.2c February 2004 Sept. 2005 February 2004

4.1.2

1.3.2d February 2004 Sept. 2005 February 2004

4.1.3

1.3.2e February 2004 February 2004

4.2

1.3.4a February 2004 Sept. 2005 February 2004

4.2.1

1.3.4b February 2004 February 2004

4.2.2

1.4a February 2004 February 2004

4.2.3 April 2005

4.2.4 February 2004 Sept. 2005

Text February 2004

4.2.5

2.1 February 2004 February 2004

4.2.6

2.2 February 2004 February 2004

4.3

2.2.1 February 2004 February 2004

4.3.1

2.2.2 February 2004 February 2004

4.3.2

2.3 February 2004 February 2004

4.4

4.4.1 February 2004

Illustrations February 2004

4.4.2

2.1a February 2004 February 2004

4.5

2.1b February 2004 February 2004

4.6

2.1c February 2004 February 2004

4.7

2.1d February 2004 February 2004

4.7.1

2.2.1a February 2004 February 2004

4.7.2

2.2.2a February 2004 February 2004

4.7.3

4.8 February 2004

4.8.1 February 2004

Issue: 2 Front Matter - Page 4 of 9

Norman Lady Cargo Operating Manual

Issue 1 Issue 2 Issue 3 Issue 4 Issue 1 Issue 2 Issue 3 Issue 4

4.8.2 February 2004 4.10.1b February 2004

4.8.3 February 2004 4.10.2a February 2004

4.9 February 2004 4.10.2b February 2004

4.9.1 February 2004 4.11.1a February 2004

4.9.2 February 2004 4.11.3a February 2004

4.10 February 2004 4.11.3b February 2004

4.10.1 February 2004 4.12.1a February 2004

4.10.2 February 2004

4.10.3 February 2004 Text

4.11 February 2004 5.1 February 2004

4.11.1 February 2004 5.2 February 2004

4.11.2 February 2004 5.2.1 February 2004

4.11.3 February 2004 5.2.2 February 2004

4.12 February 2004 5.2.3 February 2004

4.12.1 February 2004 5.2.4 February 2004

4.12.2 February 2004 5.2.5 February 2004

5.2.6 February 2004

Illustrations 5.3 February 2004

4.1.1a 5.3.1 February 2004

4.1.2a February 2004 5.3.2 February 2004

4.1.3a February 2004 5.4 February 2004

4.2a February 2004 5.4.1 February 2004

4.2b February 2004 5.4.2 February 2004

4.2.3a February 2004 5.4.3 February 2004

4.3.1a February 2004 5.4.4 February 2004

4.3.1b February 2004 5.5 February 2004

4.3.2a February 2004

4.4.1a February 2004 Illustrations

4.4.1b February 2004 5.1a February 2004

4.4.2a February 2004 5.2.1a February 2004

4.4.2b February 2004 5.2.2a February 2004

4.5a February 2004 5.2.3a February 2004

4.6a February 2004 5.2.4a February 2004

4.7.1a February 2004 5.2.4b February 2004

4.7.2a February 2004 5.2.5a February 2004

4.7.2b February 2004 5.3.1a February 2004

4.7.3a February 2004 5.3.2a February 2004

4.8.1a February 2004 5.4.1a February 2004

4.8.2a February 2004 5.4.1b February 2004

4.8.3a February 2004 5.4.2a February 2004

4.9.1a February 2004 5.4.3a February 2004

4.9.1b February 2004 5.4.3b February 2004

4.9.1c February 2004 5.4.4a February 2004

4.9.2a February 2004 5.5.1a February 2004

4.10.1a February 2004 5.5.1b February 2004

Issue: 2 Front Matter - Page 5 of 9

Norman Lady Cargo Operating Manual

Issue 1 Issue 2 Issue 3 Issue 4 Issue 1 Issue 2 Issue 3 Issue 4

5.5.1c February 2004 6.3.1a February 2004

5.5.1d February 2004 6.4.1a February 2004 April 2005

5.5.2a February 2004 6.4.2a February 2004 April 2005

5.5.2b February 2004 6.4.3a February 2004

5.5.2c February 2004 6.4.3b February 2004

5.5.2d February 2004 6.4.4a February 2004

5.5.3a February 2004 6.5.1a February 2004

5.5.3b February 2004 6.6.1a February 2004

5.5.3c February 2004 6.6.2a February 2004

5.5.3d February 2004 6.6.3a February 2004

6.6.4a February 2004

Text 6.6.4b February 2004

6.1 February 2004 April 2005 6.6.5a February 2004

6.2 February 2004 6.7.1a February 2004

6.2.1 February 2004 April 2005 6.7.2a February 2004

6.2.2 February 2004 April 2005 6.7.3a February 2004

6.2.3 February 2004 April 2005 6.7.4a February 2004 April 2005

6.2.4 February 2004 April 2005

6.3 February 2004 April 2005 Text

6.3.1 February 2004 7.1 February 2004 April 2005

6.4 February 2004 7.2 February 2004

6.4.1 February 2004 April 2005 7.2.1 February 2004 April 2005

6.4.2 February 2004 April 2005 7.3 February 2004

6.4.3 February 2004 7.3.1 February 2004

6.4.4 February 2004 April 2005 7.4 February 2004

6.5 February 2004 7.5 February 2004

6.5.1 February 2004 April 2005 7.6 February 2004

6.6 February 2004 7.6.1 February 2004 April 2005

6.6.1 February 2004 7.6.2 February 2004 April 2005

6.6.2 February 2004 April 2005 7.6.3 February 2004 April 2005

6.6.3 February 2004 April 2005 7.7 February 2004

6.6.4 February 2004 April 2005 7.7.1 February 2004

6.6.5 February 2004 April 2005 7.7.2 February 2004

6.7 February 2004 7.7.3 February 2004

6.7.1 February 2004 April 2005 7.7.4 February 2004

6.7.2 February 2004 April 2005 7.7.5 February 2004

6.7.3 February 2004 April 2005 7.8 February 2004

6.7.4 February 2004 April 2005 7.9 April 2005

Illustrations Illustrations

6.1a February 2004 April 2005 7.1a September 2004 Sept. 2005

6.2.1a February 2004 7.2.1a February 2004 Sept. 2005

6.2.2a February 2004 7.3.1a February 2004 Sept. 2005

6.2.3a February 2004 7.4a February 2004

6.2.4a February 2004 7.6.1a February 2004

6.2.4b February 2004 April 2005 7.6.2a February 2004

Issue: 2 Front Matter - Page 6 of 9

Norman Lady Cargo Operating Manual

Cargo Symbols and Colour Scheme

H P Intermediate Position Mud Box

Stop Valve Air Horn Tank Penetration

Control

Thermostatic Temp. Simplex Strainer

Gate Valve HB Fire Hose Box Air Regulating Valve

Regulating Valve

Colour Scheme

P

Butterfly Valve P Pneumatic Y-Type Strainer FB Foam Box FM Flow Meter

Quick-Closing Valve

Steam

Screw Down Non-Return H

H Hydraulic Steam Trap With Strainer Condensate

Accumulator Flame Arrester

Valve Quick-Closing Valve and Drain Cock

Inert Gas

Normally Open

Lift Check Non-Return S Sounding Head with Not Connected or

Solenoid Actuator N.O or N.C Dry Air

Valve Filling Cap Crossing Pipe Normally Closed

Moist Air

Swing Check Valve Cylinder Piston Actuator Hopper Without Cover Connected Crossing Pipe Drain Trap

LNG Liquid

Hose Valve Spring Vent Pipe T Pipe LNG Vapour

LNG Vapour (Warm)

Vent Pipe with

3-Way Valve Weight Blind (Blank) Flange Level Gauge Level Gauge Ballast/Sea Water

Flame Screen

(Cylindrical Type) (Float Type)

Nitrogen

Spectacle Flange

Self-Closing Valve Float Flow Meter

( Open, Shut)

Fresh Water

Wire Quick-Closing Valve Centrifugal Type Pump Observation Glass Lubricating Oil

Orifice

Auto Filter Compressed Air

Safety / Relief Valve Gear Type Pump Deck Stand (Manual) Overboard Discharge

Bilge Water/Steam Exhaust

Fire Main/Wash/Spray Water

P1 P2

Pressure Reducing Valve Screw Pump H Deck Stand (Hydraulic) Flexible Hose Joint

CO2 Smothering

2-Way Cock (S-Type) Mono Pump Angled Screw Down Storm Valve Diesel Oil

Non-Return Valve

3-Way Swing Valves Electrical Signal

3-Way Cock Magnetic Valve Spool Piece

Reciprocating Type Pump Instrumentation

(L-Type / T-Type)

4-Way Cock Hand Pump Flow Control, Diaphragm Filter

Type Valve

Hand Operated Eductor (Ejector) Non-Return Ball Valve Discharge/Drain

Hydraulic Operated Filter Regulating Valve

Suction Bellmouth Relief Valve

(Open/Shut) With Strainer

P Pneumatic Operated

Rose Box Surface Valve Restrictor

(Open/Shut)

Issue: 1 Front Matter - Page 7 of 9

Norman Lady Cargo Operating Manual

Electrical and Instrument Symbols

CP Compound Gauge

Transformer DPI Differential Pressure Indicator

DPS Differential Pressure Switch

DPT Differential Pressure Transmitter

I Current to Press FD Flow Detector

P Converter FS Flow Switch

FT Flow Transmitter

P Press to Current IL Indication Lamp

I Converter LAH Level Alarm High

LAL Level Alarm Low

LI Level Indicator

Making Contact LIC Level Indicating Controller

LS Level Switch

LT Level Transmitter

Breaking PAH Pressure Alarm High

PAL Pressure Alarm Low

PI Pressure Indicator

Disconnection Switch PIC Pressure Indicating Controller

PIAH Pressure Indicator Alarm High

PIAL Pressure Indicator Alarm Low

Snap Switch PIAHL Pressure Indicator Alarm High Low

PS Pressure Switch

PT Pressure Transmitter

Earth SAH Salinity Alarm High

TAH Temperature Alarm High

TAL Temperature Alarm Low

TI Temperature Indicator

Shield Wire

TIC Temperature Indicating Controller

TIAH Temperature Indicator Alarm High

TIAL Temperature Indicator Alarm Low

Battery TIAHL Temperature Indicator Alarm High Low

TS Temperature Switch

TT Temperature Transmitter

GM Governor Motor VAH Viscosity Alarm High

VAL Viscosity Alarm Low

VCA Vacuum Alarm

DG Diesel Generator VCI Vacuum Indicator

VCT Vacuum Transmitter

VI Viscosity Indicator

VT Viscosity Transmitter

M AC Induction Motor XS Auxiliary Unspecified Switch

ZI Position Indicator

ZS Limit Switch

Zener Diode

Locally Mounted

XXX

Instrument

XXX Remotely Mounted

XXXX Instrument

Issue: 1 Front Matter - Page 8 of 9

Norman Lady Cargo Operating Manual

Introduction In the design of equipment and machinery, devices are included to ensure that, Illustrations

as far as possible, in the event of a fault occurring, whether on the part of the All illustrations are referred to in the text and are located either in-text where

General equipment or the operator, the equipment concerned will cease to function sufficiently small or above the text, so that both the text and illustration are

Although the ship is supplied with shipbuilder’s plans and manufacturer’s without danger to personnel or damage to the machine. If these safety devices accessible when the manual is laid face up. When text concerning an

instruction books, there is no single handbook which gives guidance on are neglected, the operation of any machine is potentially dangerous. illustration covers several pages the illustration is duplicated above each page

operating complete systems, as distinct from individual items of machinery. of text.

Description

The purpose of this manual is to fill some of the gaps and to provide the ship’s The concept of this Operating Manual is based on the presentation of operating Where flows are detailed in an illustration these are shown in colour. A key of

officers with additional information not otherwise available on board. It is procedures in the form of one general sequential chart (algorithm) which gives all colours and line styles used in an illustration is provided on the illustration.

intended to be used in conjunction with the other plans and instruction books a step-by-step procedure for performing operations. Details of colour coding used in the illustrations are given in the colour

already on board and in no way replaces or supersedes them. scheme.

The manual consists of introductory sections which describe the systems and

In addition to containing detailed information of the cargo equipment and equipment fitted and their method of operation related to a schematic diagram Symbols given in the manual adhere to international standards and keys to the

related systems, the CARGO SYSTEM and OPERATING MANUAL contains where applicable. This is then followed where required by detailed operating symbols used throughout the manual are given on the following pages.

safety procedures and procedures to be observed in emergencies and after procedures for the system or equipment involved.

accidents. Quick reference to the relevant information is assisted by division Notices

of the manual into parts and sections, detailed in the general list of contents on The overview of machinery operations, as detailed in Section 1, consists of a The following notices occur throughout this manual:

the preceding pages. Reference is made in this book to appropriate plans or basic operating algorithm which sets out the procedure for operations from pre-

instruction books. paring the plant for operation from dead ship condition, to shutting down the WARNING

plant in readiness for dry dock. The relevant illustration and operation section Warnings are given to draw reader’s attention to operation where

In many cases the best operating practice can only be learned by experience. number is located on the right hand side of each box. DANGER TO LIFE OR LIMB MAY OCCUR.

Where the information in this manual is found to be inadequate or incorrect,

details should be sent to the Hoegh Fleet Services AS LNG Operations Office Each machinery operation consists of a detailed introductory section which CAUTION

so that revisions may be made to the manuals. describes the objectives and methods of performing the operation related to the Cautions are given to draw reader’s attention to operations where

appropriate flow sheet which shows pipelines in use and directions of flow DAMAGE TO EQUIPMENT MAY OCCUR.

Safe Operation within the pipelines.

The safety of the ship depends on the care and attention of all on board. Most

(Note: Notes are given to draw reader’s attention to points of interest or to

safety precautions are a matter of common sense and good housekeeping and Details of valves which are OPEN during the different operations are provided supply supplementary information.)

are detailed in the various manuals available onboard. However, records show in-text for reference.

that even experienced operators sometimes neglect safety precautions through

over-familiarity and the following basic rules must be remembered at all times. The valves and fittings identifications used in this manual are the same as those

used by Höegh Fleet Services AS.

1 Never continue to operate any machine or equipment which

appears to be potentially unsafe or dangerous and always report

such a condition immediately.

2 Make a point of testing all safety equipment and devices regularly.

Always test safety trips before starting any equipment. In

particular, overspeed trips on auxiliary turbines must be tested

before putting the unit into operation.

3 Never ignore any unusual or suspicious circumstances, no matter

how trivial. Small symptoms often appear before a major failure

occurs.

4 Never underestimate the fire hazard of petroleum products,

whether fuel oil or cargo vapour.

Issue: 2 Front Matter - Page 9 of 9

Part 1

Design Concept of the Vessel

Norman Lady Cargo Operating Manual

Part 1 Design Concept of the Vessel Length overall: 249.555m Cargo Tanks

Length between perpendiculars: 237.0m Maker: Kvaerner Brug AS

1.1 Principal Particulars Breadth moulded: 40.0m Type: Spherical tank: equator suspension

Depth moulded: 23.0m by continuous skirt

1.1.1 Ship Principal Particulars Service draught: 10.2m Material: 9% nickel steel

Summer draught: 10.641m Design: Moss Rosenborg Verft

Shipbuilder: Rosenberg Verft a.s. Cargo tank capacity: 87,603m3 Tanks 1 and 5: 31.0 metres diameter

Stavanger Fuel oil tank capacity: 6,0677m3 Tanks 2, 3 and 4: 33.1 metres diameter

Norway Gas oil tank capacity: 194m3 Tanks 1 and 5 capacity: 15,490m3

Yard number: 196 Service speed: 17.5 knots Tanks 2, 3 and 4 capacity: 18,860m3

Ship name: Norman Lady Fuel oil consumption per day: 160 tonnes per day without boil-off Safety valve setting: 0.25kg/cm2

Year built: 1973 gas burning Maximum specific gravity: 0.6 tonnes/m3

Flag: Norwegian Maximum working pressure: 0.25 bar

IMO number: 7320344 Endurance/range at 17.5 knots: 13,200 nautical miles without Maximum test pressure: 2.15 bar

MMSI: 259 903 000 boil-off gas burning Minimum tank pressure: -0.05 bar

Port of registration: Oslo Maximum specific weight LNG: 500kg/m3

Call sign: LAGX5 Manning design complement: 30 ship personnel

Others: 10 Cargo Tank Safety Valves

Type of ship: Steam driven LNG carrier Total: 40 Maker: Luceat

Type of cargo: LNG/LPG Type: R2101-HP

Cargo tanks: 5 Moss type independent spherical Main Machinery Capacity: 92,000Nm3/h

Stem: Bulbous bow and raked soft-nosed stem Heat cycle: Regenerative cycle No. of sets: 15 (3 sets each tank)

Stern: Transom Setting: 0.25 bar

Boilers

Classification: Det Norske Veritas Maker: Foster Wheeler Cargo Shore Connections:

1A.1, Tanker for LNG, Type: ESD III top fired water tube 2 x 16’ Liquid

(-163°C, 600 kg/m3, 0.25 bar) dat (-10ºC), Capacity: 44 tonnes/hour Liquid crossover ND 400ASA 150

EO, ICE C (maximum 57 tonnes/hour) Raised face

513ºC 62.2 bar

Regulation: SOLAS 1974 and Protocol 1978, 1981 and 1983 1 x 12’ Gas

Amendments to SOLAS Main Turbine ND 350ASA 150

1974/Protocol 1978 as existing ship Maker: General Electric Raised face

MARPOL 1973 and Protocol 1978 IMO code for Type: MST 141 cross compound

existing ships carrying liquefied gases in bulk Impulse steam turbine

USCG (foreign ship) Suez Canal Maximum continuous output: 22,370kW

Deadweight at 10.64m draught: 50,746t Main Electrical Power Generation

Gross tonnage: 71,822t Maker: Stal Laval

Net tonnage: 21,546t Type: VKI OF5HP turbine driven generator

Capacity: 1,690kW

No. of sets: 1

Maker: Nohab

Type: Polar SF 112 VS-F diesel-generators

Capacity: 1,500kW

No. of sets: 2

Issue: 1 Section 1.1.1 - Page 1 of 1

Norman Lady Cargo Operating Manual

1.1.2 Principal Particulars of Cargo Machinery Void Space Vent Fan Inert Gas Generator

Maker: Nyborg Maker: Moss Verft

Main Cargo Pumps Capacity: 2,000m3/h Type: LPU 2500-0.2

Maker: JC Carter No. of sets: 2 Capacity: Inert Gas Gas oil burner: 2,500m3/h

Type: 60190-3450-32 Motor maker: Newman Dryer 1 x refrigeration/absorption

Capacity: Rated at 750m3/h x 120 mth Type: E250 MD No. of sets: 2

No. of sets: 10 (2 per cargo tank) Output: 60kW

Ballast Pumps

Spray/Stripping Pumps Vent Fan for Gas Double Pipe Maker: Worthington

Maker: JC Carter Maker: Nyborg Type: 10-LNCV-12

Type: 6337-2113-3 Capacity: 600m3/h Capacity: 1,200m3/h

Capacity: Rated at 20m3/h x 60 mth No. of sets: 2 No. of sets: 2

No. of sets: 2 (No.3 and 4 tanks) Motor maker: Newman

Type: E100 LD/X LPG Reliquification Plant

High Duty Compressor Output: 1kW Maker: Kvaerner Brugs

Maker: Airco Cryogenics Type: Cascade

Type: Steam turbine driven Nitrogen Generator

Capacity: 10,750m3/h Maker: Kvaerner Moss

No. of sets: 2 Type: ‘Prism’ nitrogen system

Capacity: 21m3/h at 97% N2

Low Duty Compressor

Maker: Airco Cryogenics Nitrogen Recirculating Fan

Type: Steam turbine driven Maker: Nyborg

Capacity: 3,000m3/h Capacity: 2,000m3/h

No. of sets: 1 No. of sets: 2

Motor maker: Newman

LNG Vaporiser Type: E112 MD/X

Maker: Moss Verft Output: 2kW

Capacity: 597,000m3/h

Heating: Steam at 10 bar Nitrogen Generator Air Feed Compressor

No. of sets: 1 Maker: Kaeser

Type: FW cooled screw compressor

Gas Heater Capacity: 50Nm3/h at 10 bar

Maker: Moss Verft No. of sets: 1

Type: Shell and tube

Capacity: 329,000kcal/h Nitrogen Storage Tanks

Heating: Steam at 10 bar Maker: Linde

No. of sets: 2 Capacity: 25m3 and 15m3

No. of sets: 2

Void Space Dryer

Maker: Rosenberg Verft Nitrogen Dehumidifier

Type: Contardo Maker; Moss Verft

Capacity: 75,000kcal/h Capacity: 66,400Kcal/h

No. of sets: 2

Inert Gas Dehumidifier Dryers

Maker: Alfsen og Gunderson AS

Type: AG-SR-122E and AG-SR-122S

Capacity: 2,500m3/h

Issue: 1 Section 1.1.2 - Page 1 of 1

Norman Lady Cargo Operating Manual

Illustration 1.1.3a General Arrangement

Elevation Cross Section

Rope Fresh Chain

Store Water Locker

No.5 No.4 No.3 No.2 No.1

Cargo Tank Cargo Tank Cargo Tank Cargo Tank Cargo Tank

Deep

Tank

Fuel Oil Fore Peak

Tank Dry

Steering No.5 Lower Cross No.4 No.3 No.3 No.2 No.2 No.1 No.1 Side Pipe Pipe

Compartment Double Tank Involved in No.3 Double Lower Cross Double Lower Cross Double Lower Cross Double Water Ballast Duct Duct

Bottom Double Bottom Bottom Water Ballast Tank Bottom Water Ballast Tank Bottom Water Ballast Tank Bottom Bottom

Tank Fuel Oil Double Bottom Water Ballast

Spare Water Ballast

Plan

Accommodation Liquid LNG Compressor Manifold Cargo Control

Nitrogen Room Room

Principal Dimensions

Length (Overall) 249.5m

Liquid Electric Motor LPG Compressor Length (Between Perpendiculars) 237.0m

Nitrogen Room Room

Breadth (Moulded) 40.0m

Depth (Moulded) 23.0m

Height from bottom/top of radio mast 48.4m

Issue: 1 Section 1.1.3 - Page 1 of 2

Norman Lady Cargo Operating Manual

Illustration 1.1.3b Compressor Room Layout

Escape

Hatch

Entrance Door

Vapour Heater Vapour Heater

Vaporiser

HD

Compressor

Vaporiser

Controllers

HD

Compressor

LD

Compressor

Cargo

Instrument

Air Receiver

Void Space Dryer/

Heat Exchangers

Issue: 1 Section 1.1.3 - Page 2 of 2

Norman Lady Cargo Operating Manual

1.1.4 Tanks and Capacity Plan

CARGO TANKS WATER BALLAST TANKS

( 100% Full, +20ºC)

Centres of Gravity Centres of Gravity

Compartment Metres3 Feet3 US Barrels US Gallons Compartment Frame Side Metres3 Feet3 Tonnes

Forward of Ap Ab Base Forward of Ap Ab Base

Port/

Cargo Tank No.1 15,556 543,355 97843.49 4,107,428 193.31 19.75 No.1 Side Tank 88 - 95 Starboard 1,294 45,697 1,326 198.33 15.40

No.2 Side Tank Port/

Cargo Tank No.2 18,953 669,320 119,209.80 5,006,813 158.73 18.75 79 - 88 Starboard 1,704 60,176 1,747 167.76 16.51

No.3 Side Tank Port/ 2,775

Cargo Tank No.3 18,980 670,272 119,379.63 5,013,946 123.27 18.75 66 - 79 Starboard 97,998 2,844 123.27 16.63

Cargo Tank No.4 Port/

18,950 669,214 119,190.34 5,006,020 87.81 18.75 No.4 Side Tank 57 - 66 Starboard 1,762 62,225 1,806 78.41 16.31

Cargo Tank No.5 15,555 549,320 97,837.20 4,109,163 53.34 19.75 Port/

No.5 Side Tank 39 - 57 Starboard 1,628 57,492 1,669 42.39 17.39

Total 87,994 3,107,482 553,461.06 23,245,370 No.1 Lower Cross Tank 84 - 88 1141 40,294 1,170 176.28 4.92

No.2 Lower Cross Tank 75 - 79 1,499 52,937 1,537 141.00 4.37

NITROGEN BUFFER TANKS No.3 Lower Cross Tank 66 - 70 1,499 52,937 1,537 109.54 4.37

Centres of Gravity Port/

Compartment Frame Side Metres3 Feet3 Tonnes No.1 Bottom Wing Tank 79 - 88 Starboard 1,733 61,200 1,776 164.74 3.56

Forward of Ap Ab Base

No.2 Bottom Wing Tank Port/

Nitrogen (N2) 59 Port 25 883 20.3 70.47 25.42 70 - 79 Starboard 2,083 73,561 2,135 131.14 3.41

No.3 Bottom Wing Tank Port/ 2,836

Nitrogen (N2) 59 Starboard 15 530 12.2 69.30 24.93 57 - 70 Starboard 100,153 2,907 88.90 3.50

Total 40 1413 32.5 Aft Peak -7 - 17 262 9,253 269 5.49 12.41

No.2 D.B. Tank 61 - 88 3,187 112,548 3,262 134.32 1.07

39,218 1,384,972 40,200

HEAVY FUEL OIL TANKS

Centres of Gravity

Compartment Frame Side Metres3 Feet3 Tonnes

Forward of Ap Ab Base

GAS OIL TANKS

Deep Tank Forward 95 - 111 3382 119,434 3215 215.21 11.06

Centres of Gravity

No.3 D.B. Tank 53 - 61 2522 89,063 2324 66.13 2.98 Compartment Frame Side Metres3 Feet3 Tonnes

Forward of Ap Ab Base

No.6 Side Tank Port/ 335 24.57 19.01 No.7 Side Tank 27 - 30 Starboard 76 2,684 64 19.42 20.08

30 - 39 Starboard 11,830 309

Total 6,574/6,534 No.8 D.B. Tank 18 - 30 154 5,438 130 16.63 1.66

232,157 6,057

Total 230 8,122 194

Issue: 1 Section 1.1.4 - Page 1 of 2

Norman Lady Cargo Operating Manual

Illustration 1.1.4a Tank Capacity Plan

No.6 No.5 Ballast No.4 Ballast No.3 Ballast No.2 Ballast No.1 Ballast

H.F.O. Side Tank Side Tank Side Tank Side Tank Side Tank

Tank

Deep

Tank

Fuel Oil Fore Peak

Aft Peak No.7 D.B. No.5 D.B. Tank Dry

Tank No.3 Bottom No.3 Lower No.2 Bottom No.2 Lower No.1 Bottom No.1 Lower

Tank Tank

Wing Tank Cross Tank Wing Tank Cross Tank Wing Tank Cross Tank

No.8 D.B. No.6 D.B. No.4 D.B. No.3 D.B. Tank No.2 D.B. Tank No.1 D.B. Tank

Tank Tank Tank

0 5 10 15 20 25 30 35 40 45 50 51 52 53 54 55 56 57 58 59 60 61 62 63 64 65 66 67 68 69 70 71 72 73 74 75 76 77 78 79 80 81 82 83 84 85 86 87 88 89 90 91 92 93 94 95 100 105 110 115 120 125 130135 140145 150

No.5 Ballast

No.7 No.4 Ballast Side Tank (Port) No.3 Ballast Side Tank (Port) No.2 Ballast Side Tank (Port) No.1 Ballast Side Tank Side Tank

Lubricating No.5 Ballast Side (Port)

Oil Side Tank Tank (Port) No.4 Double

I, II & III (Port)

Bottom Tank

No. 10 No.6 Side Tank

Fuel Oil (Port) No.3 Double

Feed Water Bottom Tank

Tank

No.8 Fresh Water Tank (Port)

Deep

No.9 Distilled Water Tank (Port) Fore Peak

Tank Frame 53

Tank

Fuel Oil

Aft Peak

Water Ballast No.6 Side Tank

Tank Fuel Oil (Stbd)

No.7 Gas Oil No.4 Ballast

No.5 Ballast Side Side Tank

Side Tank Tank (Stbd) (Stbd)

(Starboard) No.4 Ballast Side Tank (Stbd) No.3 Ballast Side Tank (Stbd) No.2 Ballast Side Tank (Stbd) No.1 Ballast Side Tank

No.3 Double

Bottom Tank

No.3 Bottom No.2 Bottom No.1 Bottom

No.3 Bottom

Wing Ballast Tank (Port) Wing Ballast Tank (Port) Wing Ballast Tank (Port)

Wing Tank

Frame 60

No.4 D.B. No.3 Lower No.3 Lower No.2 Lower No.1 Lower No.1 Double Bottom

Dry Tank Cross Tank Cross Tank Cross Tank Cross Tank Dry Tank

Fuel Oil Water Ballast Water Ballast Water Ballast

No.3 Ballast Pipe

Side Tank Duct No.2 Lower

Cross Tank

No.2 Double

Bottom Tank

No.3 Bottom No.2 Bottom No.1 Bottom

Wing Ballast Tank (Stbd) Wing Ballast Tank (Stbd) Wing Ballast Tank (Stbd) No.2 Bottom

Wing Tank

Frame 77

Gas No.5 D.B. Sea No.3 Bottom No.2 Bottom

Wing Ballast Tank (Port) Wing Ballast Tank (Port) No.1 Bottom

Oil Tank Fuel Oil Chest Wing Ballast Tank (Port)

Tank

Pipe Duct No.1 Ballast

Atm. Side Tank

Drain Tank

No.3 Double Bottom No.2 Double Bottom Spare No.1 Double Bottom

Fore Peak

No.4 Double Fuel Oil Tank Water Ballast Tank Dry Tank

Dry Tank

Bottom No.1 Double

Dry Tank Bottom Tank

Pipe Duct

Sea No.6 D.B. Sea No.1 Bottom

No.3 Bottom No.2 Bottom Wing Ballast Tank (Stbd) Frame 94

Chest Storage Chest

Tank Wing Ballast Tank (Stbd) Wing Ballast Tank (Stbd)

Issue: 1 Section 1.1.4 - Page 2 of 2

Norman Lady Cargo Operating Manual

1.2 Rules and Regulations The existing ship code was completed in 1976 and remains as an IMO The change in the Reid vapour pressure includes the ‘certain other substances’

recommendation for all gas carriers in this fleet of ships. referred to in paragraph 1.2 of the Code, but does not include any product in

Since the introduction of liquefied gas carriers into the shipping field, it was IMO’s Chemical Code except ethylene, which is presently listed in the Code

recognised that there was a need for an international code for the carriage of The IGC code requires that a certificate (International Certificate of Fitness for and the Chemical Code. The change in the Reid vapour pressure was proposed

liquefied gases in bulk. the Carriage of Liquefied Gases in Bulk) must be issued to all new gas carriers. by the U.S. delegation to the IMO but the change was not adopted, although

The certificate should comply to a pro-forma, as set out in ‘Model Form’ there was apparently no objection to it. The change, however, does not affect

At the beginning of the 1970’s, the Marine Safety Committee (MSC) of the attached as an appendix to the code and should be available on board all new the list of regulated cargoes.

International Maritime Organisation (IMO), known then as the International gas carriers.

Consultative Maritime Organisation (IMCO), started work on a gas carrier The rate of air change between the air lock door is not specified in the Code

code with the participation of the major country delegations representing gas The basic philosophy behind the code is summarised in the International Code (para 3.6.1) but is proposed at 12 changes per hour.

carrier owners, the International Association of Classification Societies, the for the Construction and Equipment of ships Carrying Liquefied Gases in Bulk

United States Coast Guard and several other international associations. which is readily available on board in the ship’s library. Chapter 4 of the Code includes a provision for the evaluation of the insulation

and hull steel assuming, for the purpose of design calculations, that the cargo

The result of this work was the ‘Code for the Construction and Equipment of Preamble tanks are at the design temperature and the ambient outside air and sea design

Ships Carrying Liquefied Gases in Bulk’ introduced under assembly resolution temperatures as follows:

A328 (IX) in November 1975. Most of the provisions in the IMO code are covered by the Classification

Society’s rules and regulations, however, attention must be drawn to the fact General Worldwide

This was the first code developed by IMO having direct applicability to gas that it contains requirements that are not within the scope of classification as

carriers. defined in the society’s rules, for example, chapter II Ship Survival Capability, Still Air: +5°C (41°F)

chapter XIV Personnel Protection and chapter XVII Operating Requirements. Sea Water: 0°C (32°F)

The intention was to provide ‘a standard for the safe bulk carriage of liquefied

gases (and certain other substances) by sea by prescribing design and Chapter 4 also provides that each administration may set higher or lower

However, where the societies are authorised to issue the International

constructional features of ships and their equipment, so as to minimise risks to ambient design temperatures. This document proposed the following

Certificate of fitness, these requirements, together with any amendments or

ships, their crew and the environment’. temperatures:

interpretations adopted by the appropriate national authority, will be applied

where applicable.

The GC code has been adopted by most countries interested by the transport of Any Waters in the World, Except Alaskan Waters

liquefied gases by sea, as well as all classification societies, and is now part of

Since the IMO recommendations defer some matters to the discretion of each

SOLAS. Air (at 5 knots): -18°C (0°F)

administration, and in other matters are not specific enough for Coast Guard

Still sea water: 0°C (32°F)

regulatory purpose, several major changes have been introduced from the code

The USCG have added some extra requirements to the GC code for ships

in the proposed Coast Guard rules. These changes are discussed in the

trading in the USA’s waters. Alaskan Waters

following paragraphs.

The applicability of the code is as follows : Air (at 5 knots): -29°C (–20°F)

‘Liquefied gas’ is changed from the codes definition of ‘a product having a

Still sea water: - 2°C (28°F)

vapour pressure of 2.8 bar abs at 37.8°C’ to the proposed definition of ‘a

Gas carriers built after June 1986 (the IGC code)

product having a vapour pressure of 1.76 bar abs at 37.8°C’. This is a change

The code which applies to new gas carriers (built after June 1986) is the in the definition from a Reid vapour pressure of 40 psi abs. to 25 psi abs.

“International Code for the Construction and Equipment of Ships carrying

Liquefied Gases in Bulk” known as the IGC code.

At a meeting of the MSC in 1983 approving the second set of amendments to

SOLAS, the requirements of the IGC Code become mandatory with almost

immediate effect.

Gas Carriers built before 1977 (the Existing Ship Code)

The regulations covering gas carriers built before 1977 are contained in the

‘Code for Existing Ships Carrying Liquefied Gases in Bulk’ first advertised

under assembly resolution A 329 (IX). Its content is similar to the GC code,

though less extensive.

Issue: 2 Section 1.2 - Page 1 of 2

Norman Lady Cargo Operating Manual

The proposed regulations specify enhanced grades of steel for crack arresting The latest version of the following regulations and recommendations n) SOLAS 1994 Chapter V, Emergency Towing Arrangements for Tankers.

purposes in the deck stringer, sheer strake and bilge strake. The minimum incorporating all subsequent additions and amendments currently in force, or

acceptable grade for the deck stringer and the sheer strake is Grade E or an agreed between the owner and the builder, but awaiting ratification, enactment o) SOLAS Draft Resolution II-1/14-1, corrosion prevention of dedicated

equivalent steel that is specially approved by the Commandant (G-MMT). The or implementation at the time of signing of the contract shall be applied. ballast tanks.

minimum acceptable grades for the bilge strake are Grade D, or Grade E or an

equivalent steel that is specially approved by the Commandant (G-MMT). a) Maritime Rules and Regulations of Korea, Indonesia, Malaysia, Oman and p) OCIMF Recommendations on Equipment for the Towing of Disabled

Qatar for entry into those ports. Tankers, September 1981.

The Code allows pressure and temperature control of cargoes by venting cargo

vapours to the atmosphere when the vessel is at sea and in port if accepted by b) International Convention on Loadlines, 1966, amendments 1971,1975, 1979 q) OCIMF Standardisation of Manifold for Refrigerated Liquefied Gas

receiving administration. It is proposed to prohibit normal venting of cargo and 1983 and Protocol of 1988 as amended by Resolution A513(XIII) / Carriers (LNG).

into the atmosphere in many ports. A514(XIII).

r) OCIMF Guidelines and Recommendations for the Safe Mooring of Large

The Code requires the cargo system to be designed to withstand the full vapour c) International Convention for the Safety of Life at Sea, 1974 with Protocol Ships’ at Piers and Sea Islands (except special conditions of the intended

pressure of the cargo under conditions of the upper ambient design of 1978 and Amendments of 1981, 1983, 1989, 1990, 1991, 1992 and 1994 and terminal).

temperature, or have other means to maintain the cargo tank pressure below the 1988. GMDSS amendments including International Code for the Construction

maximum allowable relief valve setting (MARVS) of the tank. These and Equipment of Ships Carrying Liquefied Gases in Bulk (IGC-code) (herein s) OCIMF Ship to Ship Transfer Guide (Liquefied Gases).

regulations propose that when the cargo carried is a liquefied gas, the cargo called ‘SOLAS’).

tank pressure must be maintained below the design vapour pressure t) SIGTTO Recommendations for Emergency Shut Down Systems.

indefinitely, the pressure on the LNG tank would be maintained below the d) International Convention for the Prevention of Pollution from Ships, 1973

design pressure for a period of not less than 21 days. Cargo tank pressure may (Annex I, IV &V), as modified by the Protocol 1978 relating thereto (herein u) SIGTTO Recommendations for the Installation of Cargo Strainers.

be maintained below the design pressure by several methods including called MARPOL 73/78) and amendment 1987, 1989, 1991 and 1992.

refrigeration systems, burning boil-off in waste heat or catalytic furnaces, v) IMO Resolution A708(17) Navigation Bridge Visibility and Function.

using boil-off as fuel, or a combination of these methods. Using the boil-off as e) Convention on the International Regulations for Preventing Collisions at

a fuel for propulsion is limited to a vessel carrying LNG. Sea, 1972 with Amendments of 1981, 1987 and 1989 as amended by resolution w) International Electro-technical Commission (IEC).

A493(XII) and A494(XII).

The proposed regulations also include the following: x) IMO Publication No.978 Performance Standards for Navigational

f) International Convention on Tonnage Measurement of Ships, 1969, as Equipment (1988 edition).

1) Transfer requirements for vinyl chloride. amended by IMO Resolution A493(XII) and A494(XII).

y) ISO 8309-1991 Refrigeration Light Hydrocarbon Fluids. Measurement of

2) Loading requirements for methyl acetylene propadiene mixture. g) International Telecommunication Union (ITU) Radio Regulation A343 with liquid levels in tanks containing liquefied gases electric capacitance gauges.

annex and revisions (1983 and 1987).

3) Additional operating requirements. z) IMO Resolution A601(15) Provision and display of manoeuvring

h) IMO Resolution A468(IX) Recommendation on method of measuring noise information on board ships.

4) Requirements for inspection or re-inspection of US flag vessels at intervals levels at listening posts.

that are the same as for vessels inspected under Sub-chapter D. Inspection for

certification would be required every 2 years and re-inspection would be i) IMO Resolution A468(XII) Code on Noise Levels Onboard Ships.

required between the 10th and 14th month following the issue of a Certificate

of Inspection. j) USCG for foreign flag vessels operating in the navigable waters of the

United States except Alaskan waters (CFR Title 33-Navigation and Navigable

5) Requirements for the initial and periodic inspections and tests of the cargo Waters, Part 155, 156, 159 and 164 and CFR Title 46-Shipping, Part 154) and

containment system, cargo and process piping, and hull heating and cold spots. Public Law 95-474, 1978 ‘Port and Tanker Safety Act 1979’.

The proposed Coast Guard regulations and the Classification Society’s rules k) ISO draft proposal No.6954 ‘Guidelines for Overall Evaluation of Vibration

have cross references showing the corresponding IMO code numbers to allow in Merchant Ships, 1984’.

identification of the required paragraph.

l) ILO convention concerning crew accommodation on board ships, No.92 and

133.

m) ILO Guide to Safety and Health in Dock Work, 1977 and 1979.

Issue: 1 Section 1.2 - Page 2 of 2

Norman Lady Cargo Operating Manual

Illustration 1.3.2a Construction of Containment System - Equatorial Ring and Wedge Space

Tank Dome

Rubber Seal

Dome Shell

Void Upper Hemisphere

Space

Equatorial

Forged Ring

Weld

Wedge

Space

Skirt Wedge Space

Dome Shell

Skirt

Lower Hemisphere

Insulation

Issue: 1 Section 1.3 - Page 1 of 10

Norman Lady Cargo Operating Manual

1.3 Cargo System Technology The tower is fitted with guides at the lower end to restrict movement but allow These areas are all protected with stainless steel sheet covers.

for expansion.

1.3.1 Cargo Containment System Principle Cargo Operations

The insulation thickness of 215mm means that the boil-off rate is

approximately 0.22% of cargo weight per day. This corresponds to a heat Before any cargo operation is started, the pipelines and equipment must be

The cargo containment system consists of five insulated independent spherical

leakage from the five tanks of 460kcal/h at 0.22%. cooled to avoid thermal shock and to reduce the rate of boil-off generated at

cargo tanks encased within void spaces and situated in-line from forward to aft

the start of the operation.

within the hull. The containment tank system is patented by the builders, Moss

Leak Detection

Rosenberg Verft.

The cargo is loaded and discharged through the same manifold, located

The construction of gas carriers is currently governed by Volume III of the between No.3 and 4 cargo tanks. The pressures are equalised between all the

The containment system serves two purposes:

SOLAS International Code for the Construction and Equipment of Ships cargo tanks by an interconnecting forward and aft vapour header. This header

To contain LNG cargo at cryogenic temperatures (-160°C). Carrying Liquefied Gases in Bulk; usually referred to as ‘The Gas Code’. is connected to the shore vapour lines via vapour crossover lines when loading

or unloading.

To insulate the cargo from the hull structure. The basis of the ‘Type B’ philosophy is the ‘leak before failure’ concept. This

presumes that the primary barrier will fail progressively, not suddenly and When the ship is on loaded and ballast voyages, the boil-off gas is normally

The materials used for the hull structure are designed to withstand varying

catastrophically. In order to meet these requirements certain conditions have to utilised as fuel for the boilers.

degrees of temperature. At temperatures below their specified limits, these

be met. These include:

steels will crystallise and become brittle. The materials used for the

The cargo handling operations are controlled from the Cargo Control Room

containment system are required to reduce the heat transfer from the hull

1) Stress levels, fatigue life and crack propagation characteristics of (CCR), located aft of the navigation bridge on Deck 6. This control centre

structure to minimise the boil-off gas from the cargo, as well as to protect the

the tanks must be determined using finite element model tests and contains the DCS system control stations providing monitoring and control for

hull structure from the effects of cryogenic temperature.

refined analysis methods. the cargo storage and handling system.

1.3.2 Kvaerner-Moss Cargo Containment 2) A partial ‘secondary barrier’ must be fitted which must be capable A local cargo control room is located centrally on the main deck between No.3

of containing any envisioned leakage from the ‘primary barrier’ and 4 cargo tanks. This control room contains a control station for the DCS

The five tanks carry LNG at cryogenic temperatures and at a pressure close to (the tank plating itself) for a period of 15 days and must prevent system concerned primarily with cargo loading.

atmospheric pressure. There is no secondary barrier as the tanks, primarily due the temperature of the ship’s structure falling to an unsafe level.

to their spherical construction, have a high degree of safety against fracture or The failure of the primary barrier must not cause the failure of the Cargo Equipment

failure. The tanks are heavily insulated with approximately 215mm of secondary barrier and vice versa.

polystyrene foam to reduce natural boil-off to a minimum. The LNG compressor room, situated on the port side of the main deck between

3) A ‘spray shield’ must be provided to deflect any leakage down No.4 and 5 cargo tanks contains the following major items of equipment:

The tanks are constructed of 9% nickel steel. Each tank is covered by a into the secondary barrier and away from the hull structure.

The Low Duty (LD) gas compressor, used to:

spherical steel tank cover which is mainly for tank and insulation protection.

The cover also permits control of the hold space atmosphere.The lower edge In the exceptional case of a crack occurring in the tank nickel-steel material, a Send boil-off gas to the ship’s boilers

of each cover is welded to the deck, forming a watertight seal. A flexible rubber small leakage of LNG within the insulation will be detected at an early stage

seal is used at the point where the tank dome protrudes out from the cover. The by the gas detection system fitted at the equatorial ring area and at the drip pan. The High Duty (HD) gas compressors, used to:

tanks are each supported by a metal skirt from the equatorial ring, which The drip pan, installed directly below each cargo tank, is fitted with

transmits the weight of the tank and the cargo to the lower hull. The skirt is temperature sensors to detect the presence of LNG and an eductor system to Return LNG vapour ashore during loading operations

stiffened in the upper part by horizontal rings and the lower part by vertical allow for removal of the liquid. Return gas/vapour ashore during gassing-up and

corrugated stiffeners.

initial cooldown operations

The spray shield is formed by the aluminium foil surface of the tank insulation.

A special casting joint is fitted between the skirt and the tank’s equatorial ring The foil also protects the insulation as well as directing any leakage away. Any Circulate heated cargo vapour through the cargo tank

to provide the necessary strength at this point and to reduce heat conduction LNG liquid leakage drains by gravity from between the tank plating and the system during warm-up operations.

into the tank and a corresponding conduction of low temperature to the skirt insulation to the drip pan via a drain tube at the bottom. The drain at the bottom

and hull. of the insulation space is sealed in normal service by a bursting disc which is The two steam heated horizontal shell and tube type gas heaters, used to:

designed to fail at cryogenic temperatures.

The tanks contain a central pipe tower, fitted in the domes for the purpose of Supply warm gas to the boilers for burning and to supply gas

access into the tank and for the support of pipes and cables running to and from Liquid flow from the northern hemisphere collects in the drain channel which to the cargo tanks during warm-up operations prior to inerting,

the cargo pumps, spray pump (if fitted), discharge and filling lines, CTS is formed by the upper skirt ring stiffener and is directed to the leakage pipes aeration and entry.

(Custody Transfer System) capacitance level gauge, Whessoe float gauge located forward, aft, port and starboard of the tank. These pipes direct the

system, spray lines and a gas sampling pipe. liquid on to the void space deck and then to the drip pan.

Issue: 1 Section 1.3 - Page 2 of 10

Norman Lady Cargo Operating Manual

Illustration 1.3.2b Construction of Containment System - Rupture Discs

Rupture Disc

Cross Section

Pressure Insulation

Nitrogen

Blank Flange

Bleed

Rupture Disc

Removed for

Gas Sampling

Rupture Disc

Rupture Disc

Skirt

Leakage Pipes

Polystyrene Insulation with

Rupture Catch Basin Stainless Steel Cover

Disc

Issue: 1 Section 1.3 - Page 3 of 10

Norman Lady Cargo Operating Manual

The two LNG steam heated horizontal shell and tube vaporisers, used to: Loaded Voyage Operating Precautions

Produce gas to purge the inert gas from the cargo tanks prior During normal operation, the boil-off gas from the tanks is compressed using The LNG transfer system valves and pumps are normally operated from the

to cooldown the LD compressor and used as fuel for the boilers. The boil-off gas fuel supply CCR. The local valve controls are only used if the normal controls fail or

system is controlled so that the tank pressure is maintained at its predetermined emergency conditions arise.

Produce gas to maintain tank pressure when unloading, if the

value. Two methods are available to control the vapour pressure in the cargo

shore return gas is not available

tank: All the cargo pumps will be started in sequence and operated simultaneously

under bulk discharge conditions.

In each cargo tank are two vertical, submerged, electric motor driven cargo

1) Disposal of excess vapour via the boil-off gas system and

pumps. When all ten cargo pumps are in simultaneous operation, a full cargo

subsequently the steam dump system (if required). (Note: The ship must never start cargo pumps until asked to do so by the shore

can be unloaded in approximately 15 hours.

terminal control room.)

2) The venting of excessive vapour through the remotely operated

A vertical, submerged, electric motor driven spray pump is fitted in tanks 3 and

vent valve at vent mast No.4, via the heater. All liquid valves, except those on spray lines, should be kept closed when the

4, discharging to a spray header. Branches are led from the header to spray

transfer system is not in use. Under normal operational conditions, valves in

nozzles inside each tank. Liquid is sprayed into the tanks on the ballast voyage,

Unloading use should be fully open. However, loading valves are partially closed when

to maintain them at a temperature low enough to prevent excessive stress on

topping-off and pump discharge valves are automatically controlled within the

each tank structure, especially the equatorial ring, during loading.

Normally, as the cargo pumps in each tank pump out the cargo, cargo vapour permissible range to prevent overload or cavitation and to control the flow to

is returned from the shore and the pressure is monitored to ensure that the the shore. Any cavitation is indicated by fluctuations in pump current and

An Inert Gas (IG) plant is provided for inerting cargo tanks before and after

pressure in the cargo tanks remains within the acceptable range. In the event of discharge pressure. The vapour line valves at the tank domes are locked open

aeration and entry, and for inerting the void spaces if required. Dry air is also

the shore terminal being unable to return vapour, make-up vapour must be under normal circumstances. The blank flanges fitted to the manifolds must be

supplied from the plant for drying cargo tanks and hold spaces following any

generated by feeding LNG to the ship’s vaporiser. kept in place at all times except when connecting to either load or unload.

inspections and maintenance.

A small amount of cargo is left in all the tanks (called the heel), with an extra Pipework expansion bellows and welded joints should be inspected regularly

Two nitrogen generators are located in the aft storage room on the starboard

reserve being left in tanks 3 and 4 (the tanks fitted with spray pumps) for where possible and manifold flange joints are to be checked under nitrogen

side, to provide nitrogen for the following purposes:

cooling the cargo tanks and for fuel during the ballast voyage. During the pressure with a soap solution prior to loading or unloading. Special care must

Cargo compressor gland sealing ballast voyage, the cargo tanks are spray-cooled utilising the spray pumps and be taken to avoid LNG leaks, as the temperature of the liquid can cause steel

the extra cargo left on board for this purpose. decks to fracture.

Cargo tank wedge and insulation space inerting/purging

Cargo line purging The presence of water or other contaminants in the cargo system can be

eliminated by taking great care during refit and maintenance operations.

Boiler gas line purging

Inerting and purging procedures are to be strictly followed. Cargo manifold

A Custody Transfer System (CTS) is provided to enable accurate cargo strainers are fitted at the unloading port to prevent the possibility of shore

quantity measurement. The system includes the equipment to measure liquid contamination. At the loading port, the ship is protected against contamination

level, liquid and vapour temperatures and also the vapour pressure within each by a strainer fitted in the shore liquid line in addition to the ship supply

cargo tank. This data, together with the tank calibration data tables, is used to manifold strainers fitted at each loading.

perform cargo quantity calculations. A secondary float actuated mechanical

system (the Whessoe system) is also provided. The calibration of all the CTS

and tank equipment, is carried out by an independent firm of sworn measurers

who act jointly for buyers, sellers and customs.

There is an Emergency Shutdown System (ESDS) which is provided to protect

the cargo systems on the ship and on the shore during loading and unloading

operations. The system incorporates ship/shore links so that a shutdown may

be initiated either manually or automatically from the ship or from the shore.

Issue: 1 Section 1.3 - Page 4 of 10

Norman Lady Cargo Operating Manual

Illustration 1.3.2c Construction of Containment System - Dome and Tank Access

Whessoe Gauge

Elevation

Level Alarm

8 9

Key

10

7 29

6 11 Cargo Tank Dome Arrangement

5

4 1 Discharge Pipe 15 Whessoe Level Indicator

Plan

2 Discharge Pipe 16 Omicron Level Alarm

17

3 Loading Pipe 17 DCS Connection

15

16

2 4 Spray Pipe 19 Access

25 Cable For Spray Pump

5 Spray Pipe 20 (Tanks 3 & 4 only)

28

12 6 Spray Pipe 21 Cable For Discharge Pump

3 26 Spray Pipe

7 22 Cable For Discharge Pump

(Tanks 3 & 4 only)

14 24

8 Ejector Pipe 23 Spare

30

1 9 Vapour Suction 24 Tank Safety Valve

23 13

Spray Pump Pipe

10 25 Spray Line Safety Valve

(Tanks 3 & 4 only)

11 Hot Gas Pipe 26 Pressure Gauge Connections

12 Tank Safety Valve 27 Tank Pressure Gauge Pipe

19

20 22 13 Tank Safety Valve 28 Safety Valve Between Throttle and Loading/Discharge Valve

21

14 Blank 29 Blank

Cargo Tank Dome Arrangement 30 Snap-On Connections

Issue: 2 Section 1.3 - Page 5 of 10

Norman Lady Cargo Operating Manual

Illustration 1.3.2d Construction of Containment System - Insulation

Stainless Steel

Support Straps

From Equator Skirt

Aluminium Foil

(Spray Shield)

Stainless Steel

Support Straps

Tank Wall

(Primary)

Void Space

Ventilation

Trunking TANK HOLD SPACE

Incremental

Contraction Slot

Cargo Tank Lower Hemisphere Showing Support Straps

Cold Side

Reinforcement

Spinning Weld

Crack

Barrier

Issue: 2 Section 1.3 - Page 6 of 10

Norman Lady Cargo Operating Manual

Illustration 1.3.2e Construction of Containment System - Piping Insulation

Fibreglass Reinforcement (1 Layer)

No Adhesives Stainless Steel Polystyrene Bitumas (2 Layers) Stainless Steel

Weld

Band Polyurethane Glue Elastified Polystyrene Galvanised Steel Polyurethane Foam

Fixed Clamp

Issue: 1 Section 1.3 - Page 7 of 10

Norman Lady Cargo Operating Manual

1.3.3 Failure of Containment A bilge ejector is installed in the catch basin to empty the area when required.

If the basin has to be emptied of water, water supplied from the ejector feed

A failure of the cargo containment would most probably be due to a crack in a pump has to be used as the driving force. The exhausted water is delivered

tank weld. In order to discover any leakages, the ship is equipped with overboard. After use, the flexible hoses must be disconnected and the pipe ends

comprehensive gas monitoring and leakage detection systems. The main blind-flanged. A needle valve, V1429, is located at each flange. Pressurised air

component in this system is the gas analyser which has four sample points in from the working air system on deck is introduced to the ejector pipe through

each cargo tank hold. Gas and leakage detection is described in section 4.1. these valves by means of quick connecting couplings and the air will empty the

ejector pipe of water through the drainpipe.

In the case of a crack in the tank shell, the cargo is able to flow between the

tank and the insulation. From the top of the tank upper hemisphere, a pressure When cargo has to be removed, cargo is also used as the eductor driving force.

equalising pipe leads to the insulated space between the tank and the skirt (the The procedure is fully explained in section 7.2.

wedge space). Gas leakage due to a crack in the lower hemisphere is led to the

wedge space. There is a suction point for the gas detection system located in

this wedge space. There are also suction points in one of the drain pipes from

the upper insulation space, the top of the void space and the bilge well

(sometimes called the drip pan or catch basin).

The leak protection system also includes a method of collecting and

accumulating small leaks of liquid cargo. This liquid is collected in the catch

basin on the double bottom. The catch basin is lined with polystyrene which is

coated with a protective cover of stainless steel, as shown in illustration 7.2.1a.

The liquid cargo leakage collects in this basin, where the monitoring

equipment is installed. The equipment consists of a sample point for the gas

detector, a liquid indicator and a temperature indicator to raise alarms in the

CCR via the DCS system.

Any liquid flow from the upper hemisphere will be collected in the drain

channel formed by the upper ring stiffener of the skirt. There are four drain

pipes, port, starboard, forward and aft of the tanks, which lead any cargo

leakage to the catch basin. Any liquid flow in the lower hemisphere will be led

to the catch basin by a drain pipe at the south pole.

Any liquid collecting in the catch basin will raise a liquid alarm via the DCS

system. Whether the liquid is LNG cargo due to a tank leakage, or water due

to leakage from the water ballast tanks, can be determined by observing the gas

detector and the temperature indicators. A low temperature (-163ºC for LNG)

indicates cargo leakage, while temperatures above 0ºC indicate water leakage.

Issue: 1 Section 1.3 - Page 8 of 10

Norman Lady Cargo Operating Manual

Illustration 1.3.4a Void Spaces and Ventilation

Moist Air Drawn Off

to Recirculation Fans V2306

Dried/Heated

Air

LNG

Compressor Cargo Tank Nitrogen

Room Cross-Section Bleed

LNG

V2303 V2209

Compressors

V2314 V2314

Void Space

Dryers View of Void Space Showing

Leakage Pipe and Cargo Tank

Key

V2135

Nitrogen V2313 V2313

Dry Air Dried/Heated

Air Ducts

Moist Air

V2311 V2311

Recirculation

Fans 2000m3/h

No.5 No.4 V2311 V2311 No.3 No.2 No.1

Cargo Tank Cargo Tank Cargo Tank Cargo Tank Cargo Tank

V2306 V2306 V2306 V2306 V2306

Purging

V2216 V2216 V2216 V2216 V2216 Outlets

at Dome

Boiler Purging V2213 V2303 V2303 V2303 V2303 V2303

V2209 V2209 V2209 V2209

/Compressor V2209

Sealing

Starboard IG Connection at Starboard Manifold Port

Nitrogen Nitrogen

Buffer Buffer

From Tank 15m3 Tank 25m3

Nitrogen

Generator

System

Issue: 2 Section 1.3 - Page 9 of 10

Norman Lady Cargo Operating Manual

1.3.4 Void Spaces

The areas between the water ballast tanks, the double bottom tanks, underneath Illustration 1.3.4b Relationship between Corrosion and Relative Humidity

the cargo tank weather covers and the cargo tank are called void spaces. This

space around the tank and inside the tank skirt area is kept as dry as possible.

The atmosphere in this space is controlled and monitored. It is especially

important that the void spaces are monitored during cargo operations.

The pressure in the void spaces over that of the cargo tanks should not rise over 120

0.05kg/cm2. This value has been determined by the builders to avoid any

possible chance of the tank buckling when empty. There are two void space

relief valves for each void space which will open to atmosphere if this value is

exceeded.

Before LNG is loaded into the tanks, the void spaces should be thoroughly dry 100

to avoid any moisture penetration into the tank insulation.

The void spaces must also be free of carbon dioxide as CO2 gas will solidify at

a temperature of -78.5ºC.

80

The operation to dry or inert the void spaces is dealt with in section 4.7. There

is a void space heating and drying system to dry out these spaces, thereby

removing moisture and preventing any dew forming. This also has the added RATE OF

benefit of preventing corrosion. It can be seen from the graph in illustration CORROSION

1.3.4b that if the relative humidity is kept below 50/60%, the corrosion rate is

kept extremely low.

60

The void spaces are fitted with gas detection and leakage detection. These

systems indicate/alarm in the CCR, via the DCS system.

The void spaces are accessed via air lock chambers to assist in maintaining the

atmosphere. 40

The air in the void spaces is continuously recirculated via the recirculation fans

which are fitted on the outside deck above the LNG compressor room. The fans

supply dried and heated air from the void space atmospheric steam heater and

void space dryers to the vent outlets situated at the bottom of each void space

directly underneath the cargo tank lowest point. The air is exhausted from an 20

outlet situated adjacent to the cargo tank dome. In this way, the air is drawn

from bottom to the top, across the entire void space.

The void spaces may be inerted, if required, using the IG connection located at

the starboard manifold. There is normally a spoon blank fitted at this

0

connection. 0 20 40 60 80 100%

RELATIVE HUMIDITY

Issue: 1 Section 1.3 - Page 10 of 10

Norman Lady Cargo Operating Manual

Illustration 1.4a Hazardous Areas and Gas Dangerous Zones

9m Radius 9m Radius 9m Radius 9m Radius 9m Radius Cross Section

No.5 No.4 No.3 No.2 No.1 NORMAN LADY

Cargo Tank Cargo Tank Cargo Tank Cargo Tank Cargo Tank

Elevation

Plan

Issue: 1 Section 1.4 - Page 1 of 2

Norman Lady Cargo Operating Manual

1.4 Hazardous Areas and Zones

(See illustration 1.4a)

Under the IMO code for the Construction and Equipment of Ships Carrying

Gases in Bulk, the following are regarded as hazardous areas:

Gas dangerous spaces or zones, are zones on the open deck within 3 metres of

any cargo tank outlet, gas or vapour outlet, cargo pipe flange, cargo valve and

entrances and ventilation openings to the LNG compressor house. They also

include the open deck over the cargo area and 3m forward and aft of the cargo

area on the open deck up to a height of 2.4m above the tank weather covers.

The entire cargo piping system and cargo tanks are also considered gas-

dangerous.

In addition to the above zones, the code defines other gas-dangerous spaces.

The area around the air swept trunking, in which the gas fuel line to the engine

room is situated, is not considered a gas dangerous zone under the above code.

All electrical equipment used in these zones, whether a fixed installation or

portable, is certified ‘safe type equipment’. This includes intrinsically safe

electrical equipment, flame-proof type equipment and pressurised enclosure

type equipment. Exceptions to this requirement apply when the zones have

been certified gas free, e.g. during refit.

Issue: 1 Section 1.4 - Page 2 of 2

Part 2

Properties of LNG

Norman Lady Cargo Operating Manual

Illustration 2.1a Vapour Pressure Diagram of Liquid Cargoes

TEMPERATURE (OC)

-165 -160 -155 -150 -145 -140 -135 -130 -125 -120 -115 -110 -105 -100 -95 -90 -85 -80 -75 -70 -65 -60 -55 -50 -40 -30 -20 -10 0 25 50 75 100

60

50

40

30

20

Propane

2mol % Ethane

10

9

8

7

Methane Ethylene Ethane Propylene Propane bar

6

5

Butadrene N. Butan

1.3

4

ata

3

1

0.9

0.8

0.7

0.6

-165 -160 -155 -150 -145 -140 -135 -130 -125 -120 -115 -110 -105 -100 -95 -90 -85 -80 -75 -70 -65 -60 -55 -50 -40 -30 -20 -10 0 25 50 75 100

TEMPERATURE (OC)

Issue: 1 Section 2.1 - Page 1 of 3