Professional Documents

Culture Documents

Pat (Shaniyia) Catering Facility Checklist

Pat (Shaniyia) Catering Facility Checklist

Uploaded by

Lawrence adeleke Omisakin0 ratings0% found this document useful (0 votes)

2 views5 pagesCopyright

© © All Rights Reserved

Available Formats

DOC, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as DOC, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

2 views5 pagesPat (Shaniyia) Catering Facility Checklist

Pat (Shaniyia) Catering Facility Checklist

Uploaded by

Lawrence adeleke OmisakinCopyright:

© All Rights Reserved

Available Formats

Download as DOC, PDF, TXT or read online from Scribd

You are on page 1of 5

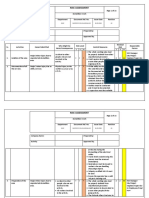

CAMP CATERING FACILITY CHECKLIST

Facility Location : __________________________________________ Date of Audit: __________________________

Facility In-charge :___________________________________________ Auditing Dept: _________________________

TYPE OF AUDIT: Regular Complaint Follow-up Survey

SN ITEM Y N REMARKS

1.0 GENERAL REQUIREMENTS

a. Facility is free of public health nuisances – objectionable

odours, smoke, dust, noise, and other harmful conditions

dangerous to human life or detrimental to health.

b. Entry limited to authorized personnel only. Signs posted.

c. Only articles necessary to the operation and maintenance

stored in the facility.

d. Independent Laundry building provided.

e. Facility not used as living/sleeping quarters.

f. Premises free from live animals, pests etc.

g. Entrances, exits, corridors, stairways etc. properly

illuminated. free of obstruction, licks, trips.

h. Building closed to avoid entrance of insects, etc. tolerable

opening is 0.8mm / 1/32”.

i. Smoking regulated in storage, preparation, handling,

processing, washing areas. No smoking signs posted. Smoking

area designated.

j. Floor slope maintained for easy draining.

k. All area easily cleanable surfaces.

l. Sufficient water taps for hand washing.

m. Hand wash area well maintained.

n. Food left over not dumped in was basins/toilets etc.

2.0 PERSONNEL

a. A responsible person designated on the compliance of sanitary

code.

b. All personnel possess valid medical health certificate. Food

handlers have authorization cards.

c. Medical examination scheduled every six (6) months. Or as

required by Saudi Laws.

d. Personnel physically fit and free from septic / chronic skin

conditions.

e. Personnel wearing clean uniform, mask, apron, gloves, caps

and safety shoes/boots.

f. Personnel have short and clean fingernails; short and clean

hair and no beards and (except for religious reason).

g. Personnel not allowed to wear jewellery when handling food /

equipment.

h. Management developed “on-the-job” food sanitation training

program.

i. Individual file of health records of employees readily available

in the office for ref.

j. Good hygienic practices established.

3.0 WATER SUPPLY

CAMP CATERING FACILITY CHECKLIST

a. Water obtained, conveyed, stored, or distributed in a closed

system. Open containers are not allowed.

b. Water obtained from an approved source.

c. Storage tanks enclosed from the filling to discharge outlet.

d. Storage tanks have vent overflows on downward termination

and screened; provided with a sample tap.

e. Water supply system free of defects.

f. Sufficient taps and hoses provided.

g. Tank trucks, tanks, containers intended to hold potable water

cleaned regularly including valves flexible connections. Records

of cleaning schedule available for inspection.

h. Water sampling for chemical or bacteriological analysis

conducted every month.

i. Records of lab. examination available showing data that water

free from organic, inorganic or other hazards.

4.0 FOOD STORAGE – DRY

a. Suitable space and adequate shelves, skids, racks or pallets

provided to accommodate orderly storage.

b. Stocks stored six (6”) inches off the floor.

c. Stocks stored at least 18” away from walls and with sufficient

space left between stocks to allow air circulation.

d. Temperature maintained at 30 C (86 F) or below.

e. Stocks rotations on a first-in-first out manner based on expiry

dates.

f. Stocks free form adulteration, pest infestation.

g. In bulk-storage, containers properly labelled.

h. Bulk ingredient storage provided with approved plastic or

stainless steel scoops.

i. Highly odorous food (i.e. spices) stored in suitable containers

and segregated from food liable to tainting.

j. Cleaning schedule posted and implemented.

5.0 FOOD STORAGE – COLD

a. Food stored on pallets, shelves or racks and off-the-floor.

b. Temperature maintained at 5 C ( 41 F ) or below.

c. Temperature of frozen food maintained at – 18 C ( 0 F ) or

below.

d. Temperature of gauges of REF and FREEZERS in good

condition.

e. REF and FREEZERS not overstocked.

f. Free air circulation maintained in REF and FREEZERS.

g. FREEZERS defrosted regularly.

h. Prepared foods stored in suitable containers and segregated

from raw foods to avoid cross contamination.

i. Food not in contact with un-drained ice.

j. Storage facilities adequately locked.

6.0 FOOD PREPARATION

a. Food when received inspected for damage, discoloration,

mould, and insect attack/soiled.

b. All food, including fruits and vegetables thoroughly washed

with tap water.

c. No food stored or placed near washbasins.

d. All equipment/utensils/food contact surfaces cleaned &

CAMP CATERING FACILITY CHECKLIST

sanitized before & after use.

e. Prepared items segregated from unprepared items. A space in

storage container or refrigerator is designated for raw and

cooked/prepared food.

f. All items keep covered or kept in separately covered container.

g. Foods prepared for immediate consumption identified with a

date of batch code.

h. Pre-prepared food not stored longer than 24 hours.

i. Storage of pre-prepared food in a refrigerator capable of

maintaining the food at 5C (41 F) or below.

j. Frozen food, fruits, vegetables, meat etc. kept in freezers at 0

F(-18 C) below.

k. Thawing of frozen food done on chillers/not on warm water.

l. Canned foods immediately emptied in to cleaned/sanitized

container and never stored in opened cans.

m. Outdated/expired food products not used or served for

consumption.

7.0 FOOD SAMPLING

a. Each prepared food served in each meal has a 100 gr. samples

retained under refrigeration.

b. Food samples preserved for a minimum of 72 hours from the

time of sampling.

c. Food samples properly labelled, identified as to its food name,

date of serving and dining period, date and time prepared, and

location the food will be served.

d. Sampling done before the food are transported for

distribution/prior to serving in dining hall.

e. Sampling procedure supervised by a competent and

responsible person.

f. Equipment/utensils used in food sampling including the

specimen containers cleaned, sanitized/sterilized.

g. Necessary measures undertaken to avoid spoiling and

contamination of food samples until the required preservation

period.

h. In the event of an outbreak of food-borne illnesses will these

samples be required for laboratory examination.

8.0 FOOD TRANSPORTATION

a. Food protected by individually wrapped and approved

containers.

b. Vehicles used to transport food are cleaned and closed type,

and not used for any other purpose.

c. Vehicles are identified by displaying on both sides the

business name and address.

9.0 EQUIPMENT AND UTENSILS

a. Equipment/utensils are corrosion-resistant.

b. Equipment/utensils are cleaned to control cross

contamination.

c. Galvanized metal are not used as a food contact surface.

10.0 CLEANING AND SANITATION OF EQUIPMENT/UTENSILS

a. Clean and equipment sanitation are regularly scheduled.

b. Washed utensils are rinsed with potable water or solutions

c. Washed utensils are allowed to air-dry.

CAMP CATERING FACILITY CHECKLIST

d. Single-use disposable paper towels available for use in

cleaning food contact surface.

11.0 CLEANING AND MAINTENANCE OF PHYSICAL FACILITIES

a. Cleanliness of the facility is maintained.

b. Maintenance program and cleaning schedule developed and

implemented.

c. Cleaning period is scheduled of least amount of equipment,

ingredient and product exposed.

12.0 POISONOUS OR TOXIC MATERIALS

a. Only those materials specifically approved for sanitizing, and

pest control are allowed to be present. Stored separately from

food.

b. Detergents, sanitizers, caustics, etc. shall not be stored or

mingled with food, equipment, or utensils.

c. Containers of poisonous or toxic materials labelled or

identified.

d. Poisonous or toxic materials stored in locked cabinet or rooms

used for no other purpose.

e. First-aid supplies or personnel medications kept away in

separate storage.

13.0 PEST CONTROL

a. Pest breading, harbouring spots under periodic control.

b. Severe / drain opening closed with a properly secured

perforated metal cover.

c. Pesticides dispensed and handled by trained and

knowledgeable personnel.

d. Pesticides not applied in areas where food handling, ware

washing are in progress.

e. Fly electrocution devices provided.

14.0 GARBAGE AND REFUSE FACILITIES

a. Sufficient number of containers provided to hold all the

garbage and the refuse.

b. Containers provided with tight fitting leads, doors or covers.

c. Covers, doors in closed position when not in immediate use.

d. Containers lined and do not contribute hazards.

e. Smaller containers lined with heavy duty plastic bags.

f. After being emptied, each container thoroughly washed inside

and outside.

g. Refuse disposed off proper way as often as required to prevent

development of odours and attraction of insects.

15.0 INSPECTIONS / RECORD

a. Food establishment management cooperates fully on the

audit/inspection.

b. Deficiencies sited corrected on time.

c. Food establishment management conduct sanitation

inspection on weekly basis.

d. Records of inspections, as well as follow up actions forwarded

to management’s information.

16.0 FIRE PROTECTION/EMERGENCY PREPAREDNESS

a. Adequate number of fire extinguishers installed in

conspicuous location, readily accessible, clearly marked. Fire

extinguisher is of ABC type.

CAMP CATERING FACILITY CHECKLIST

b. Fire alarm system in good condition (if any)

c. Personnel trained on fire fighting using the fire extinguisher.

d. Fire exits on building clearly marked with exit signs.

e. Emergency telephone numbers clearly displayed near

telephones for ready reference

17.0 FIRST-AID

a. First-aid kit provided with first-aid medicines

b. First-aid medicines are stored separately not to contaminate

food and ingredient.

Remarks (FURTHER INFORMATION)

OVERALL CONDITION: Excellent Satisfactory Unsatisfactory

Good Less satisfactory Hazardous

Name & Signature of the Inspector Date

Name & Signature of the Camp Manager Date

You might also like

- Disposal of Pest Control Waste Risk AssessmentDocument5 pagesDisposal of Pest Control Waste Risk AssessmentLawrence adeleke Omisakin100% (1)

- AHA Roofing SystemDocument8 pagesAHA Roofing SystemLawrence adeleke Omisakin100% (2)

- 360 Training Food Handlers Final Exam Answers PDF Latest PDFDownloadablesDocument12 pages360 Training Food Handlers Final Exam Answers PDF Latest PDFDownloadablesAkash100% (2)

- QHSEDOCS-Demolition Work Activities Risk AssessmentDocument14 pagesQHSEDOCS-Demolition Work Activities Risk AssessmentLawrence adeleke OmisakinNo ratings yet

- Electrical Safety PlanDocument53 pagesElectrical Safety PlanLawrence adeleke OmisakinNo ratings yet

- Daily Sanitation Inspection ChecklistDocument3 pagesDaily Sanitation Inspection ChecklistJames Christian Hermetanio LopezNo ratings yet

- The Code On Sanitation of The PhilippinesDocument66 pagesThe Code On Sanitation of The PhilippinesMark JamesNo ratings yet

- Backfilling and Compaction MVLDocument3 pagesBackfilling and Compaction MVLLawrence adeleke OmisakinNo ratings yet

- HSE Coporate Meeting No. 006 Dubia (AutoRecovered)Document5 pagesHSE Coporate Meeting No. 006 Dubia (AutoRecovered)Lawrence adeleke OmisakinNo ratings yet

- Automate Your Network - Introducing The Modern Approach To Enterprise Network ManagementDocument244 pagesAutomate Your Network - Introducing The Modern Approach To Enterprise Network Managementnscinta100% (3)

- Diet Nabh GuidelinesDocument3 pagesDiet Nabh GuidelinesAruna Harikrishnan100% (1)

- Lesson1.2 Day3 Clean and Sanitize Kitchen PremisesDocument16 pagesLesson1.2 Day3 Clean and Sanitize Kitchen PremisesAliyah PlaceNo ratings yet

- Standard Operating Procedure - Employee Health & Personal HygieneDocument3 pagesStandard Operating Procedure - Employee Health & Personal HygienePrince Moni100% (4)

- Basic Hygiene & Food Safety Training ModuleDocument43 pagesBasic Hygiene & Food Safety Training ModuleRelianceHRNo ratings yet

- Clean, Sanitize Kitchen Tools 4Document4 pagesClean, Sanitize Kitchen Tools 4JaideHizoleSapulNo ratings yet

- 2-Chemicals Used in Cleaning and Sanitizing Kitchen Tools and EquipmentDocument35 pages2-Chemicals Used in Cleaning and Sanitizing Kitchen Tools and EquipmentMoonyeen Fontanilla Banagan100% (1)

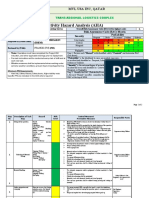

- Hazard Analysis and Critical Control Points (HACCP)Document5 pagesHazard Analysis and Critical Control Points (HACCP)gadmale100% (2)

- The Code On Sanitation of The PhilippinesDocument67 pagesThe Code On Sanitation of The Philippinessheena_rellorosa91% (11)

- Sanitation CodeDocument66 pagesSanitation CodeYsabel MacatangayNo ratings yet

- Crane Lifting Plan and Method StatementDocument5 pagesCrane Lifting Plan and Method StatementLawrence adeleke OmisakinNo ratings yet

- 024 - Competence Requirements For Drilling and Well Service PersonnelDocument16 pages024 - Competence Requirements For Drilling and Well Service PersonnelmashanghNo ratings yet

- Business PlanDocument7 pagesBusiness PlanISLAM ZINDABAD100% (2)

- KDI 1903M - KDI 2504M: Owner ManualDocument44 pagesKDI 1903M - KDI 2504M: Owner ManualJosko Prnjak100% (1)

- Emergency Response Procedures For Chemical SpillsDocument7 pagesEmergency Response Procedures For Chemical SpillsLawrence adeleke Omisakin100% (1)

- Vicarious Liability of StateDocument11 pagesVicarious Liability of StateZaheenKaur100% (1)

- Schedule FDocument64 pagesSchedule FZeel DholakiaNo ratings yet

- Honeywell UOP Gas Processing Brochure v2Document6 pagesHoneywell UOP Gas Processing Brochure v2Satria 'igin' Girindra Nugraha100% (1)

- Clean Milk ProductionDocument19 pagesClean Milk ProductionMohammad Ashraf Paul100% (3)

- Hsep-06 - Emergency Preparedness & ResponseDocument8 pagesHsep-06 - Emergency Preparedness & ResponseScha Affin100% (1)

- Gynecological ThesisDocument117 pagesGynecological ThesisSUPRIYA SINGHNo ratings yet

- SANITATION CODE OF THE PHILIPPINES Chapter III of P.D 856Document94 pagesSANITATION CODE OF THE PHILIPPINES Chapter III of P.D 856Ariell EmraduraNo ratings yet

- Electric Mining Shovels: Product OverviewDocument7 pagesElectric Mining Shovels: Product Overviewpaulocouceiro100% (1)

- The Code On Sanitation of The PhilippinesDocument66 pagesThe Code On Sanitation of The PhilippinesJhoanne DelloroNo ratings yet

- Food Facility Self Inspection ChecklistDocument2 pagesFood Facility Self Inspection Checklistmelisizwe2016No ratings yet

- Good Manufacturing Practice in Food Industry PDFDocument5 pagesGood Manufacturing Practice in Food Industry PDFrakesh kumarNo ratings yet

- Sanitation & Fumigation - Inspection - AnswersDocument2 pagesSanitation & Fumigation - Inspection - AnswersKirtishbose ChowdhuryNo ratings yet

- Bell Ringers 1 - 20Document16 pagesBell Ringers 1 - 20Allan KaplanNo ratings yet

- Temporary Food FacilityDocument5 pagesTemporary Food Facilitykulargagneet27No ratings yet

- Sanitation Evaluation: ( Indicates No Partial Credit Available For That Item)Document4 pagesSanitation Evaluation: ( Indicates No Partial Credit Available For That Item)bam112190No ratings yet

- Hospital Kitchen ChecklistDocument3 pagesHospital Kitchen Checklisthossamali7272No ratings yet

- Food Safety RegulationsDocument12 pagesFood Safety Regulationssaisridhar99No ratings yet

- School Canteen GuidelinesDocument18 pagesSchool Canteen GuidelinesSeenivasagam CNo ratings yet

- Tle 9 - CookeryDocument38 pagesTle 9 - CookeryZilpa Ocreto100% (1)

- Hygiene RulesDocument7 pagesHygiene Rulesskylife1106No ratings yet

- SITXF002 Participate in Safe Food Handling PracticesDocument7 pagesSITXF002 Participate in Safe Food Handling Practicesgaganpreet kaurNo ratings yet

- Good Warehousing Practices 27 Sept 11Document3 pagesGood Warehousing Practices 27 Sept 11peterlimttkNo ratings yet

- AHS Closure OrderDocument9 pagesAHS Closure Orderedmontonjournal100% (1)

- 10 United States Public Health Services (Usphs) Golden RulesDocument2 pages10 United States Public Health Services (Usphs) Golden Ruleszoltan2014No ratings yet

- Guidelines Good Hygiene Practices For Small and Medium Scale Food Industries Towards HaccpDocument14 pagesGuidelines Good Hygiene Practices For Small and Medium Scale Food Industries Towards HaccpSally Salina FarahNo ratings yet

- Gap Analysis ChecklistDocument7 pagesGap Analysis ChecklistJulius MuhimboNo ratings yet

- Cookery PresentationDocument21 pagesCookery Presentationsalazarjustinmae652No ratings yet

- Code On Sanitation of The PhilippinesDocument29 pagesCode On Sanitation of The PhilippinesJas MadayagNo ratings yet

- Self-Inspection Checklist For RestaurantsDocument3 pagesSelf-Inspection Checklist For Restaurantsbouzit med es salihNo ratings yet

- Food Safet1Document2 pagesFood Safet1Jared TravillaNo ratings yet

- 1692087058Document2 pages1692087058Dewa AyuNo ratings yet

- Good Warehousing Practices 27 Sept 11Document3 pagesGood Warehousing Practices 27 Sept 11Khriztopher PhayNo ratings yet

- TLE 9 - Cookery - Week2Document6 pagesTLE 9 - Cookery - Week2Rix SuguitanNo ratings yet

- Food Safet2Document2 pagesFood Safet2Jared TravillaNo ratings yet

- Kitchen ChecklistDocument4 pagesKitchen ChecklistChandrasreeNo ratings yet

- Kitchen Session 24 Workplan AssessmentDocument37 pagesKitchen Session 24 Workplan AssessmentAsmita TimalsinaNo ratings yet

- The Good Manufacturing Practices ManualDocument2 pagesThe Good Manufacturing Practices ManualJared TravillaNo ratings yet

- Food SafetyDocument2 pagesFood SafetyJared TravillaNo ratings yet

- Infection Control Manual For Laundry and Linen ServiceDocument3 pagesInfection Control Manual For Laundry and Linen ServiceRosafe E. PeraltaNo ratings yet

- Laboratory Activity # 4 Decontamination & SterilizationDocument6 pagesLaboratory Activity # 4 Decontamination & Sterilizationleighzy lalaNo ratings yet

- P - P CU-012 Hygiene StandardsDocument11 pagesP - P CU-012 Hygiene Standardsdinh huy truongNo ratings yet

- Good ManufacturingDocument2 pagesGood ManufacturingJared TravillaNo ratings yet

- Lesson 1 Teacher: Mr. Arman D. Orlanda Level: Grade 12 - TVL Allotted Time: 4 HrsDocument9 pagesLesson 1 Teacher: Mr. Arman D. Orlanda Level: Grade 12 - TVL Allotted Time: 4 HrsDayrille Althea Liwag YalungNo ratings yet

- Guideline No.: FH/001 Issue Date: 29/04/2010: Title: Food Supplier GuidelineDocument6 pagesGuideline No.: FH/001 Issue Date: 29/04/2010: Title: Food Supplier GuidelineAnonymous 1gbsuaafddNo ratings yet

- Maldives Food RegulationsDocument8 pagesMaldives Food RegulationssarahnsureNo ratings yet

- Sanitary Deficiencies Compliance Advisory, 2017Document7 pagesSanitary Deficiencies Compliance Advisory, 2017Bao TranNo ratings yet

- Good Manufacturing ManualDocument2 pagesGood Manufacturing ManualJared TravillaNo ratings yet

- Major SubjectDocument7 pagesMajor SubjectJames SachznaNo ratings yet

- Module 2Document14 pagesModule 2Angeline MusniNo ratings yet

- Current Practices Being Used in Their Manufacturing ProcessDocument5 pagesCurrent Practices Being Used in Their Manufacturing ProcessjaredjoeNo ratings yet

- Cascades Kitchens Q. Daily ChecklistDocument3 pagesCascades Kitchens Q. Daily Checklistمحمد عبد الحميدNo ratings yet

- AHA Flushing & Disinfection of Water SupplyDocument5 pagesAHA Flushing & Disinfection of Water SupplyLawrence adeleke OmisakinNo ratings yet

- Earth WorksDocument4 pagesEarth WorksLawrence adeleke OmisakinNo ratings yet

- Qhse Documents-Heat Stress - A Summertime Hazard Toolbox TalksDocument3 pagesQhse Documents-Heat Stress - A Summertime Hazard Toolbox TalksLawrence adeleke OmisakinNo ratings yet

- Concrete Works AHADocument9 pagesConcrete Works AHALawrence adeleke OmisakinNo ratings yet

- Above Ground Chilled Water Pipe InsulationDocument3 pagesAbove Ground Chilled Water Pipe InsulationLawrence adeleke OmisakinNo ratings yet

- Daily Attendance 05Document1 pageDaily Attendance 05Lawrence adeleke OmisakinNo ratings yet

- Water FilterDocument1 pageWater FilterLawrence adeleke OmisakinNo ratings yet

- Testing, Adjustment and Balancing (TAB)Document4 pagesTesting, Adjustment and Balancing (TAB)Lawrence adeleke OmisakinNo ratings yet

- Risk Assessment For Testing and Commissioning For Mechanica BMS Systems and PlumbingDocument6 pagesRisk Assessment For Testing and Commissioning For Mechanica BMS Systems and PlumbingLawrence adeleke OmisakinNo ratings yet

- Emergency Response Procedures For Natural DisastersDocument6 pagesEmergency Response Procedures For Natural DisastersLawrence adeleke OmisakinNo ratings yet

- Progress Meeting 4th May, 2023Document2 pagesProgress Meeting 4th May, 2023Lawrence adeleke OmisakinNo ratings yet

- Safety Toolbox Meeting 87Document3 pagesSafety Toolbox Meeting 87Lawrence adeleke OmisakinNo ratings yet

- MVL Daily Permt To WorkDocument2 pagesMVL Daily Permt To WorkLawrence adeleke OmisakinNo ratings yet

- Testing and Commissioning of Fire Protection Systems AHADocument4 pagesTesting and Commissioning of Fire Protection Systems AHALawrence adeleke OmisakinNo ratings yet

- ADALUMO WEEEKLY REPORT WeekDocument7 pagesADALUMO WEEEKLY REPORT WeekLawrence adeleke OmisakinNo ratings yet

- Monthly Roster Plan-2023Document1 pageMonthly Roster Plan-2023Lawrence adeleke OmisakinNo ratings yet

- Waterline Tie-In With Existing Service AHADocument2 pagesWaterline Tie-In With Existing Service AHALawrence adeleke OmisakinNo ratings yet

- Al-Bazilt Weekly Report 18th - 23rd March 2023Document11 pagesAl-Bazilt Weekly Report 18th - 23rd March 2023Lawrence adeleke OmisakinNo ratings yet

- Howard 2012Document5 pagesHoward 20121alexandra12No ratings yet

- (Asce) 0733 9445 (1990) 116:10 (2671) PDFDocument20 pages(Asce) 0733 9445 (1990) 116:10 (2671) PDFS LNo ratings yet

- Taxable Income and Tax DueDocument13 pagesTaxable Income and Tax DueSheena Gane Esteves100% (1)

- Exfoliative Cytology PDFDocument2 pagesExfoliative Cytology PDFStaceyNo ratings yet

- PL + FH 150 FixDocument1 pagePL + FH 150 FixDedyBrianEricsonNainggolanNo ratings yet

- Pixma Ip4200 Reset AbsorberDocument4 pagesPixma Ip4200 Reset AbsorberBisce VaccaroNo ratings yet

- Design of An In-Vehicle Network (Using Lin, Can and Flexray), Gateway and Its Diagnostics Using Vector CanoeDocument6 pagesDesign of An In-Vehicle Network (Using Lin, Can and Flexray), Gateway and Its Diagnostics Using Vector Canoesarah bejaouiNo ratings yet

- Using The Computer and Managing Files (Windows XP)Document96 pagesUsing The Computer and Managing Files (Windows XP)Mohammed Sumaila Sawadugu Action-90No ratings yet

- MP 001 - 22 - PP - Esp - 00 - MP WT20X-WT30X-WT40X (3qyg06130) (SPN)Document242 pagesMP 001 - 22 - PP - Esp - 00 - MP WT20X-WT30X-WT40X (3qyg06130) (SPN)Honda almagrorepuestosNo ratings yet

- Informatica Logs ExplanationDocument16 pagesInformatica Logs ExplanationSenthil KumarNo ratings yet

- MOF Bimetalicos Producción BiodieselDocument9 pagesMOF Bimetalicos Producción BiodieselHilson ValdezNo ratings yet

- An Interdisciplinary Environmental EducationDocument10 pagesAn Interdisciplinary Environmental EducationCarolNo ratings yet

- Jurnal Prosedur SEM-EDXDocument105 pagesJurnal Prosedur SEM-EDXRiskaNo ratings yet

- The New Companies Act (Chapter 24 - 31) Impact On Corporate Governance - Honey and BlanckenbergDocument5 pagesThe New Companies Act (Chapter 24 - 31) Impact On Corporate Governance - Honey and BlanckenbergLuke MadzikotoNo ratings yet

- Review QuestionsDocument5 pagesReview QuestionsAR EddingNo ratings yet

- كتاب العملي باطنه وجراحهDocument103 pagesكتاب العملي باطنه وجراحهnoranhassanshams0No ratings yet

- Your Cookbook For Gaining Keratinized Tissue: Geistlich Mucograft in Open HealingDocument4 pagesYour Cookbook For Gaining Keratinized Tissue: Geistlich Mucograft in Open HealingErdeli StefaniaNo ratings yet

- MQC PDFDocument25 pagesMQC PDFVK DNo ratings yet

- Katishoola LumbagoDocument4 pagesKatishoola LumbagoRajiv SharmaNo ratings yet

- The Growth Story of Mineral Water Industry in IndiaDocument2 pagesThe Growth Story of Mineral Water Industry in IndiaSNo ratings yet

- Music Mood and MarketingDocument12 pagesMusic Mood and Marketingagnesmalk100% (1)