Professional Documents

Culture Documents

Ijciet 08 05 019

Ijciet 08 05 019

Uploaded by

mooolkaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ijciet 08 05 019

Ijciet 08 05 019

Uploaded by

mooolkaCopyright:

Available Formats

International Journal of Civil Engineering and Technology (IJCIET)

Volume 8, Issue 5, May 2017, pp.160–167, Article ID: IJCIET_08_05_019

Available online at http://iaeme.com/Home/issue/IJCIET?Volume=8&Issue=5

ISSN Print: 0976-6308 and ISSN Online: 0976-6316

© IAEME Publication Scopus Indexed

RISK MANAGEMENT IN CONSTRUCTION

EQUIPMENT

Sai Teja N

Under Graduate student, Department of civil engineering,

KL University, Andhra Pradesh, India.

Surya Anil Ch

Under Graduate student, Department of civil engineering,

KL University, Andhra Pradesh, India.

Afshan Sheikh

Assistant Professor; Department of civil engineering,

KL University, Andhra Pradesh, India.

ABSTRACT

Risk is defined as an unforeseen occurrence of action that causes adverse effect on

the project. It is involved in each and every business and construction industry is no

special case. The interest in infrastructure projects is going to be incredibly increased

in the coming future. Use of modern construction equipment and technology has

accelerated the growth. As the construction industry expands the risks associated with

it are also increased. To mitigate different types of risks such as safety, financial,

equipment, labour etc. different risk management plans should be developed. The aim

of this paper is to identify the risks, assess them and to determine the risk control

factors for construction equipment. They are determined through substantial

literature review and a questionnaire survey to make a basis for future studies to

monitor and review risk control measures.

Key words: Risk Management, Risk Assessing, Construction Equipment.

Cite this Article: Sai Teja N , Surya Anil Ch and Afshan Sheikh Risk Management in

Construction Equipment. International Journal of Civil Engineering and Technology,

8(5), 2017, pp. 160–167.

http://iaeme.com/Home/issue/IJCIET?Volume=8&Issue=5

1. INTRODUCTION

All construction equipment has the potential to cause problems in the construction site. If

failed to identify the risks associated with the use of equipment, every individual using that

piece of equipment will be at risk. Everyone utilizes the equipment to a greater or lesser

http://iaeme.com/Home/journal/IJCIET 160 editor@iaeme.com

Risk Management in Construction Equipment

degree as a part of their work. Risk management plans should be developed with the use of

equipment. Construction equipment management is an important aspect of construction

project planning. The cost of this equipment may range from 30 to 40% of the total cost of a

construction project. As construction equipment contribute to the maximum percentage of the

work, the proper planning and selection of the equipment is essential to achieve construction

targets and to keep construction costs low. To make an effective and efficient risk

management it is necessary to have a proper and systematic methodology and, more

importantly, knowledge and experience of various types. For example, it requires knowledge

of the unexpected events that may occur during the execution of the project, on the actions

that work well or not when one of these events happens, on ways to assess a risk or estimate

the likelihood that it will occur, and so on. Equipment intensive projects are usually the very

ones that can prove great financial risks due to improper planning of costly equipment. Due to

these factors it is very essential for contractors to develop risk management plans and go

through effective planning of equipment.

2. OBJECTIVES AND SCOPE

The primary objective of this paper is to determine the risk control measures in construction

equipment. Initially the risks that are involved in the construction have been identified and

their extent is known through a questionnaire survey. Then primary risks that come up with

construction equipment have been identified through intensive literature survey. In this regard

the contribution of this paper relies on identifying and assessing the risks to determine the

risk control measures involved with equipment.

3. METHODOLOGY

This paper mainly deals with the ways to mitigate the risks in construction equipment. In

order to achieve this, a primary survey on various risks that contribute to construction and

their extent is known by preparing a questionnaire and having it surveyed in the major

construction sites by site engineers, supervisors, project engineers, executive engineers etc.

The risks that are involved in construction equipment are identified through intensive

literature survey. Assessment of these factors and the extent of them are obtained through

Risk Matrix. Further, to determine the management of these risks a case study is done by

considering a construction project and the equipment they use. After looking up the risks in

that, ways to mitigate them are regulated.

http://iaeme.com/Home/journal/IJCIET 161 editor@iaeme.com

Sai Teja N , Surya Anil Ch and Afshan Sheikh

Identifying the risks

Questionnaire survey

Analyse through SPSS

software

Identifying risks in Construction

Equipment

Assessing risks through Risk Matrix

Case study

Results and conclusion

Figure 1 Flowchart representing research methodology

3.1. QUESTIONNAIRE SURVEY & ANALYSIS USING SPSS

Risks are a part of every field and construction field too has its effects. They can cause major

disasters, if risk management plans are not developed adequately. So to know the effect of

each risk in construction, a questionnaire is prepared which included various factors that

contribute to risk, like environmental, material, equipment, financial, scheduling, contracts

etc. Influence of each factor varied from very low to very high on likert scale and the options

are given as mentioned. On handing out the questionnaire in the construction sites, nearly 35

responses were obtained from construction managers, site engineers, contractors, architects.

These responses have been analysed using SPSS software. The pie-chart below represents the

impact of each factor that has on construction industry.

http://iaeme.com/Home/journal/IJCIET 162 editor@iaeme.com

Risk Management in Construction Equipment

Figure 2 Impact of each risk factor

The results show that financial risk and equipment risk have contributed the most with 28.2 %

and 18.8 % respectively. The other factors such as political, scheduling, environmental

factors, site location, labour, material, ownership, engineering and design contribute to 5.6%,

5.6%, 3.7%,7.5%, 3.7%,9.4%, 3.7%,13.2% respectively So this paper mainly deals with

equipment risk and financial risk that is involved in equipment.

3.2 RISKS IN CONSTRUCTION EQUIPMENT

Construction equipment risks are generally overlooked, but needless to say they are one of

the key components in construction. The equipment market is valued at Rs.1,05,000 crores

alone whereas rest of the materials such as cement, bitumen, steel, bricks etc. combined value

at Rs.1,92,000 crores. Therefore, the risks associated with equipment are also more. With

intensive literature survey the various risk factors have been identified as follows:

• Unavailability of Skilled labour

• Maintenance Risk

• Financial Risk

• Labour Accidents

• Faulty equipment Risk

• Availability of spare parts

3.3 ASSESSMENT USING RISK MATRIX

A Risk Matrix is used to assess the risk in contemplation of determining the harm probability

category and harm severity category. The probability ranges from Rare to Almost certain and

the severity ranging from Insignificant to catastrophic with catastrophic being the highest.

http://iaeme.com/Home/journal/IJCIET 163 editor@iaeme.com

Sai Teja N , Surya Anil Ch and Afshan Sheikh

Table 1 Risk Matrix

Insignificant Minor Moderate Major Catastrophic

Rare SP FE

Unlikely

Possible A

Likely L

Almost Certain M F

In the Risk MatricSP stands for Availability of spare parts risk, FE for Faulty Equipment

risk, A for Labour Accidents risks, L for Skilled labour risk, F for Financial Risk and M for

Maintenance risk.

Availability of spare parts, labour accidents and maintenance risks have moderate effect

when they occur. But the spare parts risk is rarely occurred, labour accidents have a

possibility of occurrence and maintenance risk is almost certain to happen. Skilled labour risk

can likely occur and will have a minor effect. Faulty equipment risk also rarely occurs but can

have major effect. Financial risk is very certain to happen and when it does, the effect is

catastrophic.

Table 2 Risk Mitigation Techniques

TYPE OF RISKS WAYS OF OCCURRENCE MITIGATING TECHNIQUES

• Improper intake of skilled labour Employment of skilled labour and

• Improper knowledge of handling imparting proper training to

Labour risk the equipment labour/operators.

• Wear and tear of the equipment Day to day check of the equipment

• Wrong usage of the equipment and maintaining a report, quality

Maintenance

• Improper servicing servicing and quality check after

servicing.

• Shocks, high pressure Safety precautions like helmets and

environment, heat, vehicle gloves etc., introducing safety

Accidents overturning department which looks over the

safety of labour and equipment.

• Inbuilt fault of the equipment Inspection of the equipment before

Faulty equipment • Improper calibration buying or renting, test drives with

the equipment

Availability of spare • Unavailability/in sufficient Maintaining spare parts.

parts availability of spare parts

http://iaeme.com/Home/journal/IJCIET 164 editor@iaeme.com

Risk Management in Construction Equipment

4. CASE STUDY

Among all the risks that are associated with construction equipment, financial risk is the most

troublesome one. It is almost certain to happen in every project and when it happens there

will be a huge loss to the firm. Financial risks can be subcategorized based on how they

occur. The type of procurement method adopted contributes significantly to financial risk.

The 3 basic procurement methods are

• Renting- Renting is a method of procurement in which the equipment can be

rented from a particular firm on a monthly or a weekly basis. Small scale

industries can be profited from this as the construction time can be less and the

cost of renting would be less. But in some cases the renting cost would be much

higher than leasing.

• Leasing- Leasing is another type of procurement method which is useful when the

equipment is used most of the time in a project. It has both the benefits of renting

and buying. Leasing is generally taken for a longer period of time. Sometimes

leasing can also bring losses if the equipment is not maintained properly as the

lessee is responsible for the equipment during the leasing period.

• Buying- An equipment is generally bought if the workload of the particular

equipment at the given site is more than 60%. It also depends on other factors such

as the due time of the next project for the firm, whether the firm is going to give

that equipment for a lease etc. but buying an equipment isn’t a bad option if the

money wasted on the lease is rather used to buy the equipment.

If the procurement method is not chosen carefully, serious loss can be occurred. To

cement this statement a case study of a medium scale construction project is carried out. The

details of the project were collected by consulting the project manager of the site. The firm

Sai Sudha Constructions has constructed a 6 storey residential building in Tadepalli area of

Guntur district, Andhra Pradesh. It took approximately 14 months for them to construct and

their next project is due in 3 months.

For this project the firm has used majorly four equipment.

• Excavators

• Concrete Mix truck

• Boom Cranes

• Tippers

The work load and the need of each equipment varied accordingly.

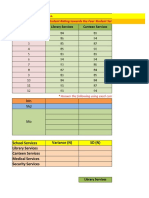

Table 3 Work load, need and procurement method of each equipment

Work Load Need Procurement type

Excavators (2) 12% Initial stage Rented

Concrete Mix truck(1) 80% Entire Project Leased

Boom Cranes(1) 25% Occasional Rented

Tippers(4) 60% Entire Project Leasing

http://iaeme.com/Home/journal/IJCIET 165 editor@iaeme.com

Sai Teja N , Surya Anil Ch and Afshan Sheikh

5. RESULTS AND DISCUSSION

Since excavators and boom cranes were rented, the firm incurred no loss since these are used

only for a portion of the project execution. These equipment were rented on a monthly basis

or weekly basis when required. Whereas concrete mix trucks which had work 80% of the

time were taken for lease which caused a loss for them as they could have bought the

equipment which could have been used for the next project as it was due in 3 months. Regular

leasing can lead to a loss if the next project is near and if the equipment is used more than

60% of the time. Tippers were taken for lease on a yearly basis, which remained idle most of

the times. They were used only when the material was to be transported, and the excavated

material was to be taken away. Thus, it is better to rent tipperson a monthly basis.

6. CONCLUSION

The outcome of analysis from the study can be said to be of great relevance to the

construction industry. The survey findings indicated that equipment risk and financial risk are

crucial factors that needed to be considered. There are many factors that induce the risk in

equipment. The risk matrix helped in determining the risk probability and impact of each

factor. Financial risk can have catastrophic effect on equipment. However in this study the

factors are determined and the ways of mitigating the risks are also determined. Risk

Management plans should be developed in every construction project in order to ensure that

there are no losses to the firm. By taking a case study, financial risk mitigation that is

involved in procurement of an equipment is determined. Different scales of industries can

profit from different procurement method depending on their work load, current needs and

the due time of next project. For example, in a small scale industry most equipment such as

Concrete mix, cranes etc. can be rented and equipment such as vibrators etc. can be bought.

As the construction time is less. In the same way, for large scale industries which are never in

short of Projects can purchase equipment accordingly.

REFERENCES

[1] Aven T(2012).“The risk concept-historical and recent development trends, Reliability

Engineering and System Safety” (99), 33–44.

[2] Veland H., AvenT(2013)., “Risk communication in the light of different risk perspectives,

Reliability Engineering and System Safety” (110) 34–40.

[3] KarimiAzari A., Mousavi N., Mousavi F., Hosseini S(2011)., “Risk assessment model

selection in construction industry, Expert Systems with Applications” (38), 9105–9111.

[4] K. Iyer, K. Jha(2006).,“Critical factors affecting schedule performance: evidence from

Indian construction project”132(8) , pp.871-881.

[5] A. Faridi, S. El-Sayegh(2006), “Significant factors causing delay in the UAE construction

industry”24 (11) , pp. 1167–117.

[6] S. M. Renuka, C. Umaraniet.al(2014), A Review on Critical “Risk Factors in the Life

Cycle of Construction Projects”, Journal for Civil Engineering Research, , Vol-4, PP 31-

36.

[7] Jacob Oluwoyeb, Lynn Crawford(2013), “Causes of delay and cost overruns in

construction of groundwater projects in a developing countries; Ghana as a case study

Yaw Frimponga” ,.International Journal of Project Management 21, 321–326.

[8] Owolabi James D, AmusanLekan M, Oloke C.O, Olusanya O, Tunji-Olayeni P,

OwolabiDele, PeterJoy (2014) “Causes and effects of delay on project construction

delivery time” International Journal of Education and Research Vol. 2 No. 4, 197- 208.

http://iaeme.com/Home/journal/IJCIET 166 editor@iaeme.com

Risk Management in Construction Equipment

[9] Seyed Hossein, AbedianKalkhoran, GholamaliLiravi, FereshteRezagholi(2014), “Risk

Management in Construction Projects” International Journal of Engineering Trends and

Technology (IJETT) –Volume 10 Number 3.

[10] Seyed Hossein, AbedianKalkhoran, GholamaliLiravi, FereshteRezagholi, “Risk

Management in Construction Projects” International Journal of Engineering Trends and

Technology (IJETT) –Volume 10 Number 3,2014.

http://iaeme.com/Home/journal/IJCIET 167 editor@iaeme.com

You might also like

- Solutions to Chapter 4 Problems: 1 2 1 2 1 2 1 2 1 2 1 2 jπt −jπtDocument10 pagesSolutions to Chapter 4 Problems: 1 2 1 2 1 2 1 2 1 2 1 2 jπt −jπtHarry Willsmith100% (3)

- Lab 1 ChemDocument6 pagesLab 1 ChemirfanNo ratings yet

- Risk Assessment in Construction ProjectsDocument5 pagesRisk Assessment in Construction ProjectsIJRASETPublicationsNo ratings yet

- Risk Assessment and Identifications The Pivot of Risk Management in An Organization.Document18 pagesRisk Assessment and Identifications The Pivot of Risk Management in An Organization.enbassey100% (1)

- HIRA in Construction Sector PDFDocument44 pagesHIRA in Construction Sector PDFE. Ricardo Ponce EspejoNo ratings yet

- Risk Management in Construction Projects As Per Indian ScenarioDocument10 pagesRisk Management in Construction Projects As Per Indian ScenarioIAEME PublicationNo ratings yet

- 153 155ncice 078Document4 pages153 155ncice 078Dewa Gede Soja PrabawaNo ratings yet

- A Review of Risk Management Techniques For Construction ProjectsDocument6 pagesA Review of Risk Management Techniques For Construction ProjectsIJRASETPublicationsNo ratings yet

- Risk Assessment Methods and Application in The Construction ProjectsDocument5 pagesRisk Assessment Methods and Application in The Construction ProjectsGladstone SamuelNo ratings yet

- Risk Assessment FaberDocument12 pagesRisk Assessment FaberghadasaudiNo ratings yet

- Enterprise Risk Management in The Airline IndustryDocument16 pagesEnterprise Risk Management in The Airline IndustryAbdurrhmanNo ratings yet

- Risk Assessment For Civil Engineering Facilities: Critical Overview and DiscussionDocument12 pagesRisk Assessment For Civil Engineering Facilities: Critical Overview and Discussionterror_ro533No ratings yet

- Implementation of Health and Safety Management System ToDocument10 pagesImplementation of Health and Safety Management System ToLesly GarciaNo ratings yet

- Risk Management in Construction Projects As Per Indian ScenarioDocument11 pagesRisk Management in Construction Projects As Per Indian ScenarioLithin rajuNo ratings yet

- Risk-Based Maintenance (RBM) A Quantitative Approach ForDocument13 pagesRisk-Based Maintenance (RBM) A Quantitative Approach ForJuan Carlos RiveraNo ratings yet

- Safety, Responsibilities and Rights: Unit - IVDocument37 pagesSafety, Responsibilities and Rights: Unit - IVJohn andre MarianoNo ratings yet

- An Approach To Risk Quantification in Construction Projects Using EMV AnalysisDocument9 pagesAn Approach To Risk Quantification in Construction Projects Using EMV AnalysisdramacrackNo ratings yet

- Critical Risk Consideration For Cost EstimatingDocument18 pagesCritical Risk Consideration For Cost EstimatingJuan Camilo Aldana BarreraNo ratings yet

- 423165ijsetr4701 457Document3 pages423165ijsetr4701 457patelparva833No ratings yet

- Risk Management of Housing ProjectDocument4 pagesRisk Management of Housing ProjectIJSTENo ratings yet

- A Risk Mapping Tool For Construction Projects: A.E. Yildiz & I. Dikmen & M.T. BirgonulDocument8 pagesA Risk Mapping Tool For Construction Projects: A.E. Yildiz & I. Dikmen & M.T. BirgonulFrederic PutrantoNo ratings yet

- Moanassar,+8499 25077 1 LEDocument27 pagesMoanassar,+8499 25077 1 LEBrajendraNo ratings yet

- Penerbit, 039Document11 pagesPenerbit, 039Harshini Silva KumarNo ratings yet

- Enterprise Risk Management in The Airline IndustryDocument16 pagesEnterprise Risk Management in The Airline IndustryAbdurrhmanNo ratings yet

- Investigation of Risk Management Perception in Albanian Construction IndustryDocument12 pagesInvestigation of Risk Management Perception in Albanian Construction IndustryTaqwa HadidiNo ratings yet

- Risk Scenario Generation Based On Importance Measure AnalysisDocument18 pagesRisk Scenario Generation Based On Importance Measure AnalysisFaisalNo ratings yet

- Analisa Risiko Kecelakaan Kerja Pada Proyek Konstruksi Jembatan Musi Vi PalembangDocument6 pagesAnalisa Risiko Kecelakaan Kerja Pada Proyek Konstruksi Jembatan Musi Vi PalembangRoraNo ratings yet

- Risk Mapping in Construction WorksDocument13 pagesRisk Mapping in Construction WorksAhmed AboulielaNo ratings yet

- Work at HeightDocument10 pagesWork at HeightShoaib RazzaqNo ratings yet

- Application of Formal Concept AnalysisDocument6 pagesApplication of Formal Concept AnalysisJayaletchumi MoorthyNo ratings yet

- Tipili and YakubuDocument13 pagesTipili and YakubudramacrackNo ratings yet

- Inter 2Document16 pagesInter 2MelyaaNo ratings yet

- Risk Assessment and Risk MappingDocument7 pagesRisk Assessment and Risk MappingAJER JOURNALNo ratings yet

- Risk Assessment For Building ConstructioDocument7 pagesRisk Assessment For Building ConstructioLei Angielin Romulo DurwinNo ratings yet

- Risk Assessment For Building ConstructioDocument7 pagesRisk Assessment For Building ConstructioLei Angielin Romulo DurwinNo ratings yet

- Manufacturing Risk Identification in The Steel Industry: Dharu Dewi Imam Bastori Arnold SoetrisnantoDocument11 pagesManufacturing Risk Identification in The Steel Industry: Dharu Dewi Imam Bastori Arnold SoetrisnantoWaqas KhanNo ratings yet

- Construction Project Risk ManagementDocument14 pagesConstruction Project Risk ManagementAdriano ZvNo ratings yet

- IISITv6p595 615nikolic673 PDFDocument21 pagesIISITv6p595 615nikolic673 PDFJack MisterouffeNo ratings yet

- Risk Assessment of Construction Projects: Edmundas Kazimieras Zavadskas, Zenonas Turskis, Jolanta TamošaitienėDocument14 pagesRisk Assessment of Construction Projects: Edmundas Kazimieras Zavadskas, Zenonas Turskis, Jolanta TamošaitienėAbid IqbalNo ratings yet

- Risk Analysis Techniques in Construction Engineering ProjectsDocument9 pagesRisk Analysis Techniques in Construction Engineering ProjectsOm PrakashNo ratings yet

- Risk Assessment of Construction Projects Using Network Based Adaptive Fuzzy SystemDocument7 pagesRisk Assessment of Construction Projects Using Network Based Adaptive Fuzzy SystemKarthi KeyanNo ratings yet

- Hazard Identification, Risk Analysis and Risk Assessment On High-Rise Building Construction ProjectDocument10 pagesHazard Identification, Risk Analysis and Risk Assessment On High-Rise Building Construction ProjectIqlima Nuril AminiNo ratings yet

- Risk ManagementDocument6 pagesRisk ManagementAkhileshkumar PandeyNo ratings yet

- MPRA Paper 112055Document16 pagesMPRA Paper 112055Elisha WankogereNo ratings yet

- Risk Determination Prioritization and ClassifyingDocument11 pagesRisk Determination Prioritization and Classifyingtiket murah adinNo ratings yet

- An Assessment of Factors Affecting Risk Management in The South African Construction IndustryDocument9 pagesAn Assessment of Factors Affecting Risk Management in The South African Construction Industrycontrax8No ratings yet

- Group 1 RMFD SynopsisDocument7 pagesGroup 1 RMFD SynopsisguptadivyeNo ratings yet

- Stochastic Methods in Risk AnalysisDocument7 pagesStochastic Methods in Risk Analysisn0188741wNo ratings yet

- IT Risk Assessment: Quantitative and Qualitative Approach: Artur RotDocument6 pagesIT Risk Assessment: Quantitative and Qualitative Approach: Artur RotwvqhjdvwjqNo ratings yet

- IRJET-Maturity Model V5I5466 PDFDocument10 pagesIRJET-Maturity Model V5I5466 PDFMeddy harjantoNo ratings yet

- Risk Assessment Modeling in Aviation Safety ManagementDocument7 pagesRisk Assessment Modeling in Aviation Safety ManagementAnnisa RakhmawatiNo ratings yet

- 1 PBDocument11 pages1 PBAkun M naibahoNo ratings yet

- Ejnupt180162-Mkts V23N2 2017Document83 pagesEjnupt180162-Mkts V23N2 2017Herlinda DasrilNo ratings yet

- 1 PBDocument11 pages1 PBayodya jayaNo ratings yet

- Risk Assessment Process For Construction Projects in AfghanistanDocument7 pagesRisk Assessment Process For Construction Projects in AfghanistanIJAERS JOURNALNo ratings yet

- Identification and Management of Risks in Construction ProjectsDocument8 pagesIdentification and Management of Risks in Construction ProjectsPrasanthi KoneruNo ratings yet

- 284-Article Text-672-1-10-20180301 PDFDocument8 pages284-Article Text-672-1-10-20180301 PDFDyeri FloresNo ratings yet

- Risk Assesment N Allocation in UAE Construction IndustryDocument8 pagesRisk Assesment N Allocation in UAE Construction IndustrysimaksinanNo ratings yet

- Business Continuity Management: Building an Effective Incident Management PlanFrom EverandBusiness Continuity Management: Building an Effective Incident Management PlanNo ratings yet

- Reliability and Probabilistic Safety Assessment in Multi-Unit Nuclear Power PlantsFrom EverandReliability and Probabilistic Safety Assessment in Multi-Unit Nuclear Power PlantsRating: 5 out of 5 stars5/5 (1)

- Disaster Risk Assessment for Project Preparation: A Practical GuideFrom EverandDisaster Risk Assessment for Project Preparation: A Practical GuideNo ratings yet

- 2019 05 RAILHOW Project Delivery Methods V1a 1Document35 pages2019 05 RAILHOW Project Delivery Methods V1a 1mooolkaNo ratings yet

- 9781000646795 (1)Document297 pages9781000646795 (1)mooolkaNo ratings yet

- Shallow Foundations: Chapter ThreeDocument30 pagesShallow Foundations: Chapter ThreemooolkaNo ratings yet

- LRFDPaperDocument12 pagesLRFDPapermooolkaNo ratings yet

- Commercial Buildings Requirements: Levels, Heights and Number of FloorDocument4 pagesCommercial Buildings Requirements: Levels, Heights and Number of FloormooolkaNo ratings yet

- Soil Definitions (Sec 1)Document7 pagesSoil Definitions (Sec 1)mooolkaNo ratings yet

- Shallow FoundationDocument38 pagesShallow FoundationmooolkaNo ratings yet

- Theater Working Drawings: Ziad AhmedDocument35 pagesTheater Working Drawings: Ziad AhmedmooolkaNo ratings yet

- Delivery Method Comparison ChartDocument1 pageDelivery Method Comparison ChartmooolkaNo ratings yet

- Banff Centre Campus Photos 3of3Document6 pagesBanff Centre Campus Photos 3of3mooolkaNo ratings yet

- VianadaFonseca JGGE ASCE 2001Document16 pagesVianadaFonseca JGGE ASCE 2001mooolkaNo ratings yet

- Slums As Expressions of Social Exclusion: Explaining The Prevalence of Slums in African CountriesDocument26 pagesSlums As Expressions of Social Exclusion: Explaining The Prevalence of Slums in African CountriesmooolkaNo ratings yet

- Efdwedrtrtj ModelDocument1 pageEfdwedrtrtj ModelmooolkaNo ratings yet

- Various Types of FoundationDocument4 pagesVarious Types of FoundationmooolkaNo ratings yet

- Ground Improvement Technique - A View of Stone Column Method With The Case StudyDocument6 pagesGround Improvement Technique - A View of Stone Column Method With The Case StudymooolkaNo ratings yet

- Slums Issues in Egypt: An Approach To The Application of Green Building ConceptsDocument20 pagesSlums Issues in Egypt: An Approach To The Application of Green Building ConceptsmooolkaNo ratings yet

- Iii I: DC D"-DDocument1 pageIii I: DC D"-DmooolkaNo ratings yet

- Applied Sciences: Numerical Analysis of The Settlement Behavior of Soft Soil Improved With Stone ColumnsDocument22 pagesApplied Sciences: Numerical Analysis of The Settlement Behavior of Soft Soil Improved With Stone ColumnsmooolkaNo ratings yet

- A Guide To Better Public Toilet Design and Maintenance: Illustration 2: Off-Set Entrance Maze Without DoorsDocument1 pageA Guide To Better Public Toilet Design and Maintenance: Illustration 2: Off-Set Entrance Maze Without DoorsmooolkaNo ratings yet

- Between Modernism and Postmodernism-A Comprehensive Study On The Works of Louis I. KahnDocument9 pagesBetween Modernism and Postmodernism-A Comprehensive Study On The Works of Louis I. KahnmooolkaNo ratings yet

- Pavers: Unilock Boston, New York, Cleveland, Buffalo, Detroit, Chicago, Milwaukee & Toronto TOLL FREE: 1-800-864-5625Document1 pagePavers: Unilock Boston, New York, Cleveland, Buffalo, Detroit, Chicago, Milwaukee & Toronto TOLL FREE: 1-800-864-5625mooolkaNo ratings yet

- UntitledDocument1 pageUntitledmooolkaNo ratings yet

- Dealing With Slums in Egypt - Learning From The Success Factors of - 230321 - 122532Document96 pagesDealing With Slums in Egypt - Learning From The Success Factors of - 230321 - 122532mooolkaNo ratings yet

- 698Document1 page698mooolkaNo ratings yet

- Newly Planted Tree / Road Median ApplicationDocument1 pageNewly Planted Tree / Road Median ApplicationmooolkaNo ratings yet

- 541Document1 page541mooolkaNo ratings yet

- HouseOfRepresentatives2014-46 enDocument19 pagesHouseOfRepresentatives2014-46 enmooolkaNo ratings yet

- Time-Saver Standards For Building TypesDocument28 pagesTime-Saver Standards For Building Typesmooolka100% (1)

- 5500 082Document1 page5500 082mooolkaNo ratings yet

- New Pile Foundation Structures For Swelling Clay Soils: Journal of Physics: Conference SeriesDocument7 pagesNew Pile Foundation Structures For Swelling Clay Soils: Journal of Physics: Conference SeriesmooolkaNo ratings yet

- 4.3 StatDocument2 pages4.3 StatArt CarlNo ratings yet

- Industrial Air ControlsDocument195 pagesIndustrial Air ControlsJShearer100% (1)

- Kall Et Al - 2022-From Good Intentions To Unexpected Results - Indonesian BSCDocument21 pagesKall Et Al - 2022-From Good Intentions To Unexpected Results - Indonesian BSCTita NopitawatiNo ratings yet

- Location: Method Statement TitleDocument32 pagesLocation: Method Statement TitleShanuNo ratings yet

- Jurnal AriantiDocument11 pagesJurnal AriantiMunadis SidqiNo ratings yet

- Offshore Field Development PlanDocument14 pagesOffshore Field Development Planvarsha dNo ratings yet

- First Draft - Mocko - Certificate of Secondary Education Examination Form Iv, 2021 - TimetableDocument1 pageFirst Draft - Mocko - Certificate of Secondary Education Examination Form Iv, 2021 - TimetableBakhresa alwatanNo ratings yet

- A Cycle of Celestial Objects For The Use of Naval Military and Private Astronomers 1844Document548 pagesA Cycle of Celestial Objects For The Use of Naval Military and Private Astronomers 1844firemanswife100% (1)

- Gulliver's Travels. - Homework. Muntean NapoleonDocument4 pagesGulliver's Travels. - Homework. Muntean NapoleonMunteanDoliSiAtatNo ratings yet

- Renisance Quiz 2Document4 pagesRenisance Quiz 2lincoln26102012No ratings yet

- Acoustics - Module 1Document40 pagesAcoustics - Module 1Ashna AshrafNo ratings yet

- Special TabelloutDocument56 pagesSpecial TabelloutWachama j SwanaNo ratings yet

- MATH 1300 Limit Worksheet 1/23/15Document3 pagesMATH 1300 Limit Worksheet 1/23/15Kiesha AltheaNo ratings yet

- Mkt. Strategies of BisleriDocument97 pagesMkt. Strategies of BisleriAnkit KumarNo ratings yet

- Signs of Low Self-EsteemDocument8 pagesSigns of Low Self-EsteemPriyankkaaNo ratings yet

- LECTURE - Descriptive Statistics - MAFCFS-CDocument13 pagesLECTURE - Descriptive Statistics - MAFCFS-Cpauline faclarinNo ratings yet

- Development Shobhit NirwanDocument30 pagesDevelopment Shobhit NirwanHONEYGAIN100% (3)

- DLA Testing: Relationship Between Power Factor and Dissipation FactorDocument3 pagesDLA Testing: Relationship Between Power Factor and Dissipation FactormshahidshaukatNo ratings yet

- Journal Review CognitiveDocument8 pagesJournal Review CognitiveSiti Najwa ZainalNo ratings yet

- Experimental Investigation of Mustard Oil Based Nano Cutting Fluid On CNC Turning OperationDocument13 pagesExperimental Investigation of Mustard Oil Based Nano Cutting Fluid On CNC Turning OperationIJRASETPublicationsNo ratings yet

- Maf651 Seminar 2 Sustainability Development & Environmental ManagementDocument33 pagesMaf651 Seminar 2 Sustainability Development & Environmental ManagementAISHAH HUDA AHMAD DAUDNo ratings yet

- JA, SOFAR and DGridDocument5 pagesJA, SOFAR and DGridAlmu'tasem Al-SaryrehNo ratings yet

- Etapas de Los ProcesosDocument2 pagesEtapas de Los ProcesosHECTOR VIDALÓN JORGENo ratings yet

- HasselblauDocument28 pagesHasselblauJovan MartinovicNo ratings yet

- Centre For Distance Education: AssignmentDocument3 pagesCentre For Distance Education: AssignmentCompany BrandNo ratings yet

- Types of ClaimsDocument19 pagesTypes of ClaimsKristina Angelina ReyesNo ratings yet

- Gotco Operation ManualDocument251 pagesGotco Operation ManualBrett KingNo ratings yet

- Maharaja Sawai Man Singh Vidyalaya: Holiday Assignment Class IXDocument6 pagesMaharaja Sawai Man Singh Vidyalaya: Holiday Assignment Class IXdevanshNo ratings yet