Professional Documents

Culture Documents

1 Chapter 5 a Spoilage, Rework & Scrap

1 Chapter 5 a Spoilage, Rework & Scrap

Uploaded by

Minaw BelayCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

1 Chapter 5 a Spoilage, Rework & Scrap

1 Chapter 5 a Spoilage, Rework & Scrap

Uploaded by

Minaw BelayCopyright:

Available Formats

Chapter 5

Spoilage, Rework Units and Scrap

Spoilage (Defective): are units of production whether fully or partially complete that don’t meet

the standard required by customers for good units and that are discounted or sold for reduced

price. Example: defective shirts, shoes, electronic devices.

Reworks: are units of production that don’t meet the standard required by customers for finished

units that are subsequently repaired and sold as acceptable finished unit.

Scrap (By product): are materials left over when making a product. They have low sale value

compared with the sale value of the main products.

Example: short lengths from wood working operations, frayed cloth etc.

Types of Spoilage

Normal spoilage: is spoilage inherent in a particular production process that arises even under

efficient operating condition. Depending on the production process, management decides the

spoilage it considers normal.

Cost of normal spoilage is typically included as a component of cost of good unit’s manufactured

because good units can be made without also making some units that are spoiled. Normal

spoilage is inventor able costs. The managements are tolerating small amount of spoilage as

normal.

Abnormal spoilage: is spoilage that would not arise under efficient operation condition. It is not

inherent in a particular production process. It arises because of machine breakdown and

operator’s error. Abnormal spoilage is usually avoidable or controllable. Abnormal spoilage cost

is recorded separately and treated as loss of the current year. Costs of abnormal spoilage are not

considered as inventor able costs and are written off as costs of the period in which detection

occurs.

Two Approaches of Treating Normal Spoilage

Approach A: counting spoiled units when computing out put in equivalent units

Approach B: not counting spoiled units when computing output in equivalent unit Approach

A better than approach B because

In approach B, WIP ending is changed for spoilage twice

Approach A high lights cost of normal spoilage, this will help management take action to

minimize normal spoilage

Example 1: Counting and not Counting Spoiled Unit

Chipmakers, incorporation manufactures computer chip for TV set, all direct material is added

at the beginning of the production process. In May 2003, $270,000 direct material was

introduced in to the production process. Production data for may indicate 10,000 units were

started, 5,000 units were completed and 1,000 units were spoiled (all normal spoilage). No

beginning WIP. Ending WIP was 4,000 units, each unit 100% complete as to direct material

cost. Spoilage is detected up on completion of the process.

Requirement: Assign direct material cost to completed units and units in WIP ending using

approach A&B. Solution

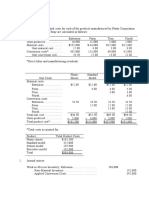

Approach A Approach B

1. Costs to account for $270,000 $270,000

2. Equivalent Units

- Completed & T.O ……………... 5,000 5,000

- Ending WIP …………………... 4,000 4,000

- Normal Spoilage ……………… 1,000 -----

- EU of Work done to date 10,000 9,000

Cost and Management Accounting I Hand Out Chapter 5 Page 1 of 8

3. Cost per EU of work done (1/2) $27 $30

4. Assignment of Costs

- Good units completed & T. O

- A: 27 x 5,000 ………………………….. $135,000

- B: 30 x 5,000 …………………………... ……………… $150,000

5. Normal Spoilage

- A: 27 x 1,000 ………………………….. $27,000

- B: no counting ………………………… ……………… ------

6. Total cost of good units completed & T.O $162,000 $150,000

7. Ending WIP

- A: 27 x 4,000 ………………………… $108,000

- B: 30 x 4,000 ………………………… …………….. $120,000

8. Total cost Counted for ………………….. $270,000 $270,000

The Five Step Procedure for Process Costing With Spoilage

Example 2: Spoilage using WA and FIFO

ABC Company manufactures a wooden recycling container in its forming department. Direct

materials for this product are added at the beginning of the production cycle. Conversion costs

are added evenly during production. Some units of this product are spoiled as result of defects,

which are detected only up on inspection of finished units. Normally spoiled units are 10%of the

good units completed. That is for 10 good units produced; there is one of normal spoilage.

Summarized data for July 2003 are

Physical units for July 2003

WIP beginning …………………………………1,500

DM: 100%complete

CC: 60%complete

Started during July ……………………………….8, 500

Completed and transferred out ……………………7,000

WIP ending ………………………………………..2,000

DM: 100% complete

CC: 50%complete

Total cost for July

WIP beginning

DM: ……………………………….12, 000

CC: ………………………………….9, 000…………………21,000

DM cost added during July …………………………………….....76,500

CC cost added during July …………………………………………89,100

Total cost to account for …………………………………………..186,600

Requirements: using WA&FIFO

A. Identify units of both normal and abnormal spoilage

B. Summarize the flow of physical unit

C. Compute output in terms of equivalent unit

D. Compute cost per equivalent unit

E. Summarize total cost to account for

F. Assign total cost to unit completed and to units in ending WIP

G. Compare the result under WA&FIFO

H. Record the required journal entry

Solution

The five steps procedure for process costing with spoilage

Cost and Management Accounting I Hand Out Chapter 5 Page 2 of 8

Using WA method

a) Total Spoilage = [Unit in Beg. WIP + Units Started in Current Period] –

[Good Units Completed + Units in Ending WIP]

= [1,500 + 8,500] – [7,000 + 2,000]

= [10,000 – 9,000] = 1,000

Normal Spoilage = 10% of 7,000 = 700 ; Abnormal Spoilage = 1,000- 700 = 300

b) Physical flow of Units Physical Units

- Beginning WIP ……………………. 1,500

- Started during July …………… 8,500

- Units to account for ………………… 10,000

- Good Units Completed & T.O ……. 7,000

- Ending WIP ………………………... 2,000

- Normal Spoilage ………………………. 700

- Abnormal Spoilage …………………….. 300

- Units accounted for ……………….... 10,000

c) Equivalent Unit of Production Equivalent Units

DM CC

- Good Units Completed & T.O 7,000 7,000

- Normal Spoilage ………………………. 700 700

- Abnormal Spoilage …………………….. 300 300

- Ending WIP - DM: (100% x 2,000) 2,000

- CC: (50% x 2,000) ……… _____ 1,000

- Total EU for Work done in current period 10,000 9,000

d) Cost per EU Equivalent Unit Cost

DM CC Total

- Beginning WIP ….……………………. $12,000 $9,000 $21,000

- Cost added during July ……….………… $76,500 $89,100 $165,600

1. Cost incurred to date ………………….. $88,500 $98,100

2. Equivalent Units (EU) to date …………. 10,000 9,000

3. Cost per EU (1/2) ……………………. $8.85 $10.9

e) Total Cost to account for $186,600

f) Assignment of Costs

DM CC Total

- Good Units Completed and T.O (7,000)

DM: $8.85 x 7,000 …....................... 61,950

CC: $10.9 x 7,000 ………………….. ………..... 76,300

- Total cost for good units Completed & T.O ………….. ………… 138,250

- Normal Spoilage (700)

DM: $8.85 x 700 …....................... 6,195

CC: $10.9 x 700 ………………….. …………. 7,630

- Total cost for Normal Spoilage …………… …………. …………. 13,825

- Total cost for good units Completed & T.O …………... ……….. 152,075

- Abnormal Spoilage (300)

DM: $8.85 x 300 …....................... 2,655

CC: $10.9 x 300 ………………….. …………. 3,270

- Total cost for Abnormal Spoilage ………… …………. …………. 5,925

- Ending WIP (2,000 units)

DM: $8.85 x 2,000 …..................... 17,700

CC: $10.9 x 1,000 ……………….. …………. 10,900

- Total Cost of Ending WIP ……………….. …………. ………… 28,600

Total cost accounted for 186,600

Cost and Management Accounting I Hand Out Chapter 5 Page 3 of 8

Using FIFO Method

b) Physical flow of Units Physical Units

- Beginning WIP …………………………….. 1,500

- Started during July ……………………… 8,500

- Units to account for ………………………… 10,000

- Good Units Completed & T.O (7,000)

- From WIP Beg. …………………..1,500

- Started & Completed units ………5,500 7,000

- Ending WIP ………………………................... 2,00

- Normal Spoilage …………………………….. 700

- Abnormal Spoilage ………………………….. 300

- Units accounted for ………………................... 10,000

c) Equivalent Unit of Production Equivalent Units

DM CC

- Good Units Completed & T.O (7,000)

- From Beg. WIP (1,500)

DM: 0% x 1,500 ………………………... 0

CC: 40% x 1,500 ……………………….. …………. 600

- Started & completed & T.O (5,500)

DM: 100% x 5,500 …………………… 5,500

CC: 100% x 5,500 …………………….. ……….. 5,500

- Normal Spoilage

- (DM: 100%x700); CC: 100%x700) ……… 700 700

- Abnormal Spoilage

- (DM: 100%x300); CC: 100%x300) ……… 300 300

- Ending WIP - DM: (100% x 2,000) 2,000

- CC: (50% x 2,000) ……… _____ 1,000

- Total EU for Work done in current period 8,500 8,100

d) Cost per EU in July only Equivalent Unit Cost

DM CC Total

- Cost incurred during July ……….…………. $76,500 $89,100 $165,600

1. Equivalent Units (EU) to date ……………. 8,500 8,100

2. Cost per EU (1/2) ………………………….. $9 $11

- Beginning WIP ….………………………….. $12,000 $9,100 $21,000

e) Total Cost to account for $186,600

f) Assignment of Costs

DM CC Total

- Good Units Completed and T.O (7,000)

- From Beg. WIP (1,500) ……………………. …. ………….. …………. $21,000

DM: $9 x 0 …........................................... $0

CC: $11 x 600 ……………………….. ………..... $6,600 $6,600

- Started & completed (5,500)

DM: $9 x 5,500 …............................... $49,500

CC: $11 x 5,500 ……………………. …………. $60,500 $110,000

- Normal Spoilage (700)

DM: $9 x 700 …........................................ $6,300

CC: $11 x 700 ……………………….. …………. $7,700

- Total cost for Normal Spoilage ……………… …………. …………. $14,000

- Total cost for good units Completed & T.O ………….. …………. $151,600

Cost and Management Accounting I Hand Out Chapter 5 Page 4 of 8

- Abnormal Spoilage (300)

DM: $9 x 300 …....................... $2,700

CC: $11 x 300 ………………….. …………. $3,300

- Total cost for Abnormal Spoilage ………… …………. …………. $6,000

- Ending WIP (2,000 units)

DM: $9 x 2,000 …..................... $18,000

CC: $11 x 1,000 ……………….. …………. $11,000

- Total Cost of Ending WIP ……………….. …………. ………… $29,000

Total cost accounted for 186,600

g) Comparison of WA and FIFO Methods

WA FIFO Difference (FIFO-WA)

Completed and Transferred Out $152,075 $151,600 - $475

Abnormal Spoilage $5,925 $6,000 $75

Ending WIP $28,600 $29,000 $400

Total cost account for $186,600 $186,600 0

h) Required Journal Entries

WA FIFO

- To record direct material purchased and used in the Forming department during July

WIP-Forming Department ………………………… 76,500 76,500

Account Payable Control ……………………… 76,500 76,500

- To record consumption of CC in the Forming department during July

WIP-Forming department ……………………….. 89,100 89,100

Various Account ……………………………… 89,100 89,100

- To record cost of goods completed and transferred out to Finished Goods

Finished Goods …….……………………………… 152,075 151,600

WIP-Forming department …………………… 152,075 151,600

- To record cost of loss from Abnormal Spoilage

Loss from Abnormal Spoilage …………………….... 5,925 6,000

WIP – Forming Department ……………………. 5,925 6,000

Additional question (Assignment)

Q1. Daniel manufacturing company uses the weighted average method of process costing. All

direct materials are added at the beginning of the process, and conversion costs are added evenly

during the process. Spoilage units are detected upon inspection at the end of the process and are

disposed at zero net disposal value

Summary data for March 2009 are:

Physical units DM CC

WIP, Nov. 1 1,000 $ 1,423 $ 1,110 = 2,533

Started in Nov ?

Good units completed & transf-

erred –out during Nov 9,000

Normal spoilage in Nov. 100

Abnormal spoilage 50

WIP, Nov. 30 2,000

Costs added during march $12,180 $ 27,750 = 39,930

Degree of completion; direct material, 100%; conversion costs, 50% (as to beginning WIP)

Cost and Management Accounting I Hand Out Chapter 5 Page 5 of 8

Degree of completion: direct materials; 100%; conversion cots, 30% (as to ending WIP)

Required: Compute: by using WA&FIFO

1. Equivalent units

2. Cost per equivalent units

3. Assign costs to units completed and transferred-out (normal spoilage, to abnormal spoilage and to units in ending WIP.

4. Compare WA&FIFO

Job Order Costing System; Spoilage, Rework & Scrap

When assigning costs, job costing system generally distinguishes between normal spoilage

attributable to a specific job and normal spoilage common to all jobs.

Normal spoilage attributable to specific job is assigned to that job.

Example 3: In the JK machine shop 5 aircraft parts out of a job a lot of 50 aircraft parts are

spoiled. Costs assigned prior to the inspection point are $2,000 per part. JK calculates these costs

on the basis of it inventory costing assumption WA&FIFO. We do not however emphasize cost

flow assumptions in our presentation here or in subsequent sections. The current disposal price

of the spoiled parts is estimated to be $600 per part. When the spoilage is detected, the spoiled

goods are inventoried at $600per part.

- When normal spoilage occurs because of the specifications of a particular job, that job bears the

cost of the spoilage reduced by the current disposal value of that spoilage

DM-ctrl (spoiled goods at current disposal value): 5*$600…………………3000

WIP-ctrl (specific job):5*$600………………………………………………3000

- Total normal spoilage (5*$2,000per part) 10,000

- Less spoiled goods at current disposal value (5*$600) 3,000

-Net normal spoilage (10,000-3,000) 7,000

-Total cost of 45(50-5) good units (45*$2,000) 90,000

-add net normal spoilage +7,000

Total cost of good units 97,000

Normal spoilage common to all jobs; in some cases, spoilage inherent in production only

confidentially occurs when a specific job is being worked on. The spoilage then is not

attributable and hence is not changed; to the specific job instead it is cosseted as manufacturing

overhead. The journal entry is.

DM ctrl. (Spoiled goods at current disposal value) 5*$600……………………3,000

MOH-ctrl. (Normal spoilage)(10,000-3,000)……………………………………7,000

WIP-ctrl (specific job) 5*$2,000 …………………………………………………..10,000

Abnormal Spoilage: if the spoilage is abnormal, the net loss is highlighted and always charged to

an abnormal loss account. Unlike normal spoilage costs, abnormal spoilage costs are not included

as part of the cost of good units produced the total cost of the 45 (50-5) good units is 90,000

(45units X $2,000

DM ctrl. (Spoiled goods at current disposal value) 5*$600……………………3,000

Loss from.(abnormal spoilage)(10,000-3,000)……………………………………7,000

WIP-ctrl (specific job) 5*$2,000 …………………………………………………..10,000

Even though, for external reporting purposes, abnormal spoilage costs are written off in the

period and are not liked to specific jobs or units, often identify the specific reasons for abnormal

spoilage and where appropriate, link abnormal spoilage with specific jobs or units for cost

management purposes

Cost and Management Accounting I Hand Out Chapter 5 Page 6 of 8

Rework

Rework is unacceptable units of production that are subsequently repaired and sold as

acceptable finished goods for rework, we again distinguish.

1. Normal rework attributable to a specific job

2. Normal rework common to all jobs

3. Abnormal rework

Consider the JK machine shop data example 1. Assume that the five spoiled part used in our

illustration are reworked. The journal entry for the $10,000 of total costs assigned to the five

spoiled unit before considering rework cost are as follows:

WIP-ctrl ……………………………………10,000

DM-ctrl ………………………………………….4, 000

Wages payable-ctrl……………………………….4, 000

MOH-allocated ……………………………………2,000

Assume that rework costs equal ($3,800 (DM $800; DL $2,000; MOH $1,000)

Normal rework attributable to a specific job: - if the rework is normal but occurs of the

requirements of a specific job, the rework costs are changed to that job. The journal entry as

follows

WIP-ctrl ……………………………………3,800

DM-ctrl ……………………………………………800

Wages payable-ctrl………………………………2,000

MOH-allocated ……………………………………1,000

Normal rework common to all jobs when rework is normal and not attributable top any specific

job, the costs of rework are charged to manufacturing overhead and spread, through overhead

allocation over all job.

MOH-ctrl (rework cost) ……………………………………3,800

DM-ctrl ……………………………………………………………800

Wages payable-ctrl…………………………………………………2,000

MOH-allocated ……………………………………………………1,000

Abnormal rework if the rework is abnormal, it is recorded by charging abnormal rework to a

separate loss account.

Loss from abnormal rework ……………………………………3,800

DM-ctrl …………………………………………………………………800

Wages payable-ctrl……………………………………………………....2,000

MOH-allocated …………………………………………………………1,000

Costing rework highlights to managers the resources wasted on activities that would not have to

be undertaken if the product were made correctly. It prompts to seek ways to reduce, rework.

E.g. By designing new products or processes, training workers, or investing in new machines.

Calculating rework costs helps managers perform cost-benefit analyses for various alternative

ways to reduce or eliminate rework. To emphasize the importance of eliminating rework and to

simplify the accounting, some companies set a standard of zero rework. All rework is then

treated as abnormal and written off as a cost of the current period.

Accounting for scrap

Scrap: is material left over when making a product it has low sale value compared with the sale

value of the product. There is no distinction of normal and abnormal scrap, but scarp

attributable to a specific job is distinguished from scrap common to all jobs.

There are two major aspects of accounting for scrap:

1. Planning and control including physical tracking

2. Inventory costing including when and how to affect operating income

Cost and Management Accounting I Hand Out Chapter 5 Page 7 of 8

Recognizing scrap at the time of its sale

To illustrate we extend our JK machine shop example assuming that the manufacture of

aircraft parts generates scrap. We further assume that the scrap from a job has a total sale

value of $900

Cash /a/receivable ………………………………900

Sale of scrap ……………………………………. 900

When the dollar amount of scrap is immaterial, the simplest accounting is to make a memo of

the quantity of scrap returned to store room. There is no entry for this returned scrap.

Scrap attributable to specific job: job order costing systems sometimes trace the sale of scrap to

the jobs that yielded the scrap. This method is used only when the tracing can be done in an

economically feasible way.

Scrap returned to the store room: no entry

Memo of quantity received and related job is entered in the

inventory record

Sale of Scrap Cash / A/receivable ……………………900

WIP-ctrl. ……………………………………. 900

Unlike spoilage and rework, there is no cost attached to the scrap to the specific job. Scrap sale

reduce the cost of the job

Scrap common to all jobs: the journal entry in this case is

Scrap returned to the store room: no entry

Memo of qty received and related job is entered in the

inventory record

Sale of Scrap Cash / A/receivable………………………900

MOH-ctrl. ……………………………………. 900

This method dose not link scrap with any particular job or product instead, all products bear

regular production costs without any credit for scrap sales except in an indirect manner;

The expected sale of scrap are considered when setting the budgeted MOH rate thus, the

budgeted overhead rate is lower than it would be if the OH budget had not been reduced by the

expected sales of scrap. This accounting for scrap is used in both process and job order costing

system.

Recognizing scrap the time of its production

Scrap is some times reused as direct materials rather than sold as scrap. In this case it should be

debited to materials control as a type of direct materials and carried at its estimated net realizable

value

E.g. the entries when the scrap generated is common to all jobs are:

Scrap returned to the store room: DM-ctrl……………………………900

MOH-ctrl……………………………900

Reuse of scrap: WIP-ctrl…………………………….900

DM-ctrl………………………………900

The accounting for scrap under process costing is like the accounting under job costing when

scrap is common to all jobs b/c process costing applies to the manufacture of masses of identical

or similar units. The high cost of scrap focuses manager’s attention on ways to reduce scrap to

use it more profitably.

Cost and Management Accounting I Hand Out Chapter 5 Page 8 of 8

You might also like

- Nama: Nabila Indri Yani No. BP: 2010931037 Tugas 1: Analisis Dan Estimasi BiayaDocument4 pagesNama: Nabila Indri Yani No. BP: 2010931037 Tugas 1: Analisis Dan Estimasi BiayaInnabilaNo ratings yet

- Brand Archetypes PDFDocument2 pagesBrand Archetypes PDFAmir MushtaqNo ratings yet

- YDS Kelime ListesiDocument34 pagesYDS Kelime Listesibilal kocabaş100% (1)

- Multidimensional Perfectionism ScaleDocument5 pagesMultidimensional Perfectionism ScaleMagda CazacuNo ratings yet

- Migrant LabourersDocument19 pagesMigrant LabourersKhalil AhmadNo ratings yet

- Chapter 4-Exercises-Managerial AccountingDocument3 pagesChapter 4-Exercises-Managerial AccountingSheila Mae LiraNo ratings yet

- 19 Process CostingDocument30 pages19 Process Costingsabinaeghan1No ratings yet

- 20210213174013D3066 - Soal Cost System and Cost AccumulationDocument6 pages20210213174013D3066 - Soal Cost System and Cost AccumulationLydia limNo ratings yet

- Ab Costing - ProblemsDocument8 pagesAb Costing - ProblemsMarcial VillegasNo ratings yet

- Advincula Vs Macabata (A.C. No. 7204 March 7, 2007)Document2 pagesAdvincula Vs Macabata (A.C. No. 7204 March 7, 2007)Kevin Degamo50% (2)

- Charles James Beneath The Dress Final BookDocument59 pagesCharles James Beneath The Dress Final Bookapi-266539853100% (3)

- FTTX Network Configuration: Issue 1.0Document48 pagesFTTX Network Configuration: Issue 1.0Muhammad YaseenNo ratings yet

- Chapter Six SolutionsDocument7 pagesChapter Six SolutionsSalma TariqNo ratings yet

- Chapter 2 Selected Answers PDFDocument16 pagesChapter 2 Selected Answers PDFsadiaNo ratings yet

- Bài tập nhóm số 6 - nhóm 4Document11 pagesBài tập nhóm số 6 - nhóm 4Lúa PhạmNo ratings yet

- CH 3Document12 pagesCH 3Firas HamadNo ratings yet

- Flexible Budget and VarianceDocument8 pagesFlexible Budget and VarianceLhorene Hope DueñasNo ratings yet

- Key Chapter 2 & 3Document9 pagesKey Chapter 2 & 3bxp9b56xv4No ratings yet

- Chapter 111Document4 pagesChapter 111ym5c2324No ratings yet

- ANSWERS TO PRACTICE MIDTERM (Multiple Choice) : RequiredDocument5 pagesANSWERS TO PRACTICE MIDTERM (Multiple Choice) : RequiredGwendolyn Chloe PurnamaNo ratings yet

- Chapter 2Document16 pagesChapter 2Manish SadhuNo ratings yet

- Ccfylv: Ch. 2 Practice QuizDocument11 pagesCcfylv: Ch. 2 Practice QuizFrank LovettNo ratings yet

- Job Order QuizDocument6 pagesJob Order QuizJohn Elly Cadigoy CoproNo ratings yet

- Nabila Indri Yani 2010931037 Tugas AEBDocument4 pagesNabila Indri Yani 2010931037 Tugas AEBInnabilaNo ratings yet

- Tutorial On Process Costing Amp Solution PDF FreeDocument5 pagesTutorial On Process Costing Amp Solution PDF Freeatty lesNo ratings yet

- Chapter 1 2 SolutionsDocument10 pagesChapter 1 2 SolutionsShiv AchariNo ratings yet

- Stat Cost MGT Midterms RevisedDocument7 pagesStat Cost MGT Midterms Revisedjoneth.duenasNo ratings yet

- ABCDocument8 pagesABCanggandakonoh33% (3)

- CH 12Document15 pagesCH 12Firas HamadNo ratings yet

- Ila-Assessment 4Document4 pagesIla-Assessment 4Charlyn LapeñaNo ratings yet

- Managerial Accounting Solutions Ch3Document12 pagesManagerial Accounting Solutions Ch3Marwan Al-Asbahi75% (4)

- Answers CH 2,3 and 4Document18 pagesAnswers CH 2,3 and 4Yousef Abdullah GhundulNo ratings yet

- Unit 8: Accounting For Spoilage, Reworked Units and Scrap ContentDocument26 pagesUnit 8: Accounting For Spoilage, Reworked Units and Scrap Contentዝምታ ተሻለ0% (1)

- Kerjakan 4-12 Dan 4 - 17: 1. "Plantwide"Document4 pagesKerjakan 4-12 Dan 4 - 17: 1. "Plantwide"natan. lieNo ratings yet

- AFAR Set BDocument11 pagesAFAR Set BRence Gonzales0% (2)

- Cost AccountingDocument5 pagesCost Accountingalexandra CarataoNo ratings yet

- Process Costing Test Bank SOLUTION PDFDocument7 pagesProcess Costing Test Bank SOLUTION PDFAshNor RandyNo ratings yet

- Process Costing Sample ProblemsDocument7 pagesProcess Costing Sample ProblemsChelseyNo ratings yet

- Exercise 1 - Cost Concepts-1Document7 pagesExercise 1 - Cost Concepts-1Vincent PanisalesNo ratings yet

- Akuntansi BiayaDocument4 pagesAkuntansi BiayaIntan Bella YuspramanaNo ratings yet

- Ch7 Variable Absoorption Extra ExcersisesDocument7 pagesCh7 Variable Absoorption Extra ExcersisesSarah Al MuallaNo ratings yet

- Financial Accounting Questions and Solutions Chapter 3Document7 pagesFinancial Accounting Questions and Solutions Chapter 3bazil360No ratings yet

- AF2110 Management Accounting 1 Assignment 05 Suggested Solutions Exercise 6-13 (20 Minutes)Document12 pagesAF2110 Management Accounting 1 Assignment 05 Suggested Solutions Exercise 6-13 (20 Minutes)Shadow IpNo ratings yet

- Just-in-Time and Backflushing 1Document6 pagesJust-in-Time and Backflushing 1Claudette ClementeNo ratings yet

- Chapter 3Document11 pagesChapter 3worknehNo ratings yet

- Cost and MGT Acct AssignmentDocument3 pagesCost and MGT Acct Assignmentasnake libsieNo ratings yet

- Sanders CompanyDocument6 pagesSanders CompanyculadiNo ratings yet

- Solutions To Relevant Cost ProblemsDocument13 pagesSolutions To Relevant Cost ProblemsAndrian VillanuevaNo ratings yet

- Solution To Questions On Decision MakingDocument27 pagesSolution To Questions On Decision Makingdanishbashir786No ratings yet

- Chapter 3: Job CostingDocument4 pagesChapter 3: Job CostingmurtleNo ratings yet

- Selected Tutorial Solutions CHPT 1-5Document22 pagesSelected Tutorial Solutions CHPT 1-5Silo KetenilagiNo ratings yet

- ACCT 2302 Summer II, 2007 Exam 3 Chapter 10-13: Answer: C Level: Easy LO: 2Document13 pagesACCT 2302 Summer II, 2007 Exam 3 Chapter 10-13: Answer: C Level: Easy LO: 2Chris Jay LatibanNo ratings yet

- Chapter 4 SpoilageDocument9 pagesChapter 4 Spoilageendegenaalemayehu4545No ratings yet

- Assgnment 2 (f5) 10341Document11 pagesAssgnment 2 (f5) 10341Minhaj AlbeezNo ratings yet

- Problem 4.36,37Document3 pagesProblem 4.36,37Hương GiangNo ratings yet

- UNIT 8 SpoilageDocument16 pagesUNIT 8 SpoilageKale MessayNo ratings yet

- Solutions of Exercises - Management Accounting - Chapter 2 - 3 - 4Document9 pagesSolutions of Exercises - Management Accounting - Chapter 2 - 3 - 4ngochoangbich2004No ratings yet

- Class Exercise CH 10Document5 pagesClass Exercise CH 10Iftekhar AhmedNo ratings yet

- Chapter 8-SolutiondocxDocument17 pagesChapter 8-Solutiondocxevani1998No ratings yet

- Problem 1.: Beginnin G EndingDocument3 pagesProblem 1.: Beginnin G EndingMarsha Zhafira ANo ratings yet

- Solution CH.6Document14 pagesSolution CH.6Thanawat PHURISIRUNGROJNo ratings yet

- Job Order Costing QuizbowlDocument27 pagesJob Order Costing QuizbowlsarahbeeNo ratings yet

- 602 Assignment 1Document8 pages602 Assignment 1Irina ShamaievaNo ratings yet

- Asynchronous - 01Document8 pagesAsynchronous - 01Joshua SantiagoNo ratings yet

- BACOSTMX Module 2 Learning Activity 2Document7 pagesBACOSTMX Module 2 Learning Activity 2lc100% (1)

- Problem Solving AccountingDocument7 pagesProblem Solving AccountingKen Ken EsguerraNo ratings yet

- Production and Maintenance Optimization Problems: Logistic Constraints and Leasing Warranty ServicesFrom EverandProduction and Maintenance Optimization Problems: Logistic Constraints and Leasing Warranty ServicesNo ratings yet

- Course Outline of Financial Institution and MarketDocument1 pageCourse Outline of Financial Institution and MarketMinaw BelayNo ratings yet

- Public Finance ModelDocument1 pagePublic Finance ModelMinaw BelayNo ratings yet

- FIM COURSE OUTLINE-EDITDocument2 pagesFIM COURSE OUTLINE-EDITMinaw BelayNo ratings yet

- CHAPTER 4-BUDGET-F (1)Document23 pagesCHAPTER 4-BUDGET-F (1)Minaw BelayNo ratings yet

- FCP 01 2020Document50 pagesFCP 01 2020Minaw BelayNo ratings yet

- h2020 wp1617 Focus - enDocument124 pagesh2020 wp1617 Focus - enMinaw BelayNo ratings yet

- CHAPTER 3 ETHIOPIAN TAX SYSTEMDocument28 pagesCHAPTER 3 ETHIOPIAN TAX SYSTEMMinaw BelayNo ratings yet

- Final Paper Sebmitted To St. Marys Unversty by Aberash TadeDocument101 pagesFinal Paper Sebmitted To St. Marys Unversty by Aberash TadeMinaw BelayNo ratings yet

- Yitayew MihretDocument102 pagesYitayew MihretMinaw BelayNo ratings yet

- Esubalew TakeleDocument65 pagesEsubalew TakeleMinaw BelayNo ratings yet

- Conceptual Framework FDCDocument10 pagesConceptual Framework FDCMinaw BelayNo ratings yet

- Cost Accounting Policies and Procedures Manual of The CUPPCAA CommissionDocument87 pagesCost Accounting Policies and Procedures Manual of The CUPPCAA CommissionMinaw BelayNo ratings yet

- FRS 13 2012jan31Document145 pagesFRS 13 2012jan31Minaw BelayNo ratings yet

- Artami PublishedDocument7 pagesArtami PublishedMinaw BelayNo ratings yet

- Bhs Inggris17Document1 pageBhs Inggris17Desi SantiNo ratings yet

- Building-Integrated MicrogridDocument8 pagesBuilding-Integrated MicrogridElena CioroabaNo ratings yet

- Channel DynamicsDocument14 pagesChannel DynamicsNeha GoyalNo ratings yet

- Co-Authors Agreement RevDocument3 pagesCo-Authors Agreement RevViper VenomNo ratings yet

- Paper - Session 2 (A) - Mohd Helmi (BNM)Document38 pagesPaper - Session 2 (A) - Mohd Helmi (BNM)dalina husainNo ratings yet

- Personell Form - Payroll Tax Form: Alejandro Zamora 47300485L 323845630Document2 pagesPersonell Form - Payroll Tax Form: Alejandro Zamora 47300485L 323845630Alex ZetaNo ratings yet

- Government Owned Fixed Asset Management Training Manual AmharicDocument89 pagesGovernment Owned Fixed Asset Management Training Manual Amharicawlachew67% (3)

- Earl Johnson v. General Electric, 840 F.2d 132, 1st Cir. (1988)Document11 pagesEarl Johnson v. General Electric, 840 F.2d 132, 1st Cir. (1988)Scribd Government DocsNo ratings yet

- Food Defense Plan: B G A in N N S I A T L Ea Industries Limited / 1 Aug 2022 / KanavDocument4 pagesFood Defense Plan: B G A in N N S I A T L Ea Industries Limited / 1 Aug 2022 / Kanavvaishnavi100% (1)

- A Nun's TestimonyDocument39 pagesA Nun's TestimonyLois Maillet LynnNo ratings yet

- Toughened Fin: Section A-A Section A-ADocument1 pageToughened Fin: Section A-A Section A-ASACHIDANANDA SNo ratings yet

- SR Bommai and Ors Vs Union of India UOI and Ors 111021s940105COM314203Document15 pagesSR Bommai and Ors Vs Union of India UOI and Ors 111021s940105COM314203Kirithika HariharanNo ratings yet

- September 2016 High School Lunch MenuDocument1 pageSeptember 2016 High School Lunch Menuapi-329327258No ratings yet

- Thomas Jones - Instrumental Stakeholder Theory - A Synthesis of Ethics and EconomicsDocument34 pagesThomas Jones - Instrumental Stakeholder Theory - A Synthesis of Ethics and EconomicsramaNo ratings yet

- Martin Luther King III Opens Washington DC Interfaith MeetingDocument2 pagesMartin Luther King III Opens Washington DC Interfaith MeetingFrank KaufmannNo ratings yet

- Anand Kumar Periwal (Updated Resume)Document3 pagesAnand Kumar Periwal (Updated Resume)Anand PeriwalNo ratings yet

- Lockheed C-130 Hercules (Part I)Document15 pagesLockheed C-130 Hercules (Part I)Giora MinorNo ratings yet

- The Learned of Business Philoloph y As Core Value of Integrity and AcademicDocument4 pagesThe Learned of Business Philoloph y As Core Value of Integrity and AcademicDjhayrille FajardoNo ratings yet

- Christmas in Spain Worksheet: Spanish Words TranslationDocument3 pagesChristmas in Spain Worksheet: Spanish Words TranslationMai RodasNo ratings yet

- Updated PPT On 26 June 2013Document35 pagesUpdated PPT On 26 June 2013api-210835544No ratings yet

- East Riding News September 2009Document29 pagesEast Riding News September 2009RayDuffNo ratings yet

- DEsign of Water TanedcsdwqDocument7 pagesDEsign of Water TanedcsdwqaliNo ratings yet

- Case Study Medical Social Worker Amrat PDFDocument4 pagesCase Study Medical Social Worker Amrat PDFRachelle BainNo ratings yet