Professional Documents

Culture Documents

TSG-T-008 Jar Testing Procedure RevB

TSG-T-008 Jar Testing Procedure RevB

Uploaded by

TaufiqTaufiqOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

TSG-T-008 Jar Testing Procedure RevB

TSG-T-008 Jar Testing Procedure RevB

Uploaded by

TaufiqTaufiqCopyright:

Available Formats

Technical Service Guide

Troubleshooting

Jar Testing Procedure

The following jar test procedure is intended to simulate the coagulation/flocculation process and determine

appropriate dosages. The lab-scale results are used to optimize the performance of systems such as water

treatment plants by determining the concentration of coagulant to be added to the source water. For further

instruction, please contact MICRODYN-NADIR Technical Service.

Equipment

For the jar testing procedure, you will need the equipment listed in Table 1.

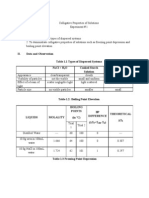

Table 1. Necessary equipment for jar test procedure.

Required Optimal

1,000 mL Graduated Cylinder 6 Magnetic Stirrers

(6) 1,000 mL Beakers* Magnetic Stirring Device

Aluminum Sulfate (Alum) Stock Solution (1.0% by weight)** Turbidimeter

(5) 10 mL Pipettes Sample Tubes

Stopwatch or Clock

*Alternative beaker sizes may be used; alum dosages should be adjusted accordingly.

**See Alum Solution Preparation for Dry Products and Liquid Products below.

Alum Solution Preparation

If an alum stock solution of 1.0% by weight is not on hand, please follow the guidelines below to prepare

a solution.

Dry Products:

Weigh 10 grams of chemical and dissolve in DI water to make a 1,000 mL solution. This is a 10 g/L

solution or 1.0% by weight. In a 1 L test beaker this solution yields 1 mL/L = 10 ppm.

Liquid Products:

Liquid aluminum sulfate (alum) is typically sold and accounted for on a dry basis which is 48.5%

Al2(SO4)3 • 14 H2O. Specific gravity is 1.335 ± 0.005. For example:

10.0 grams / (1.335 x 0.485) = 15.4 mL liquid alum for a 10 g/L (1.0% by weight) dry basis solution.

1 mL of this solution in a 1 L jar test beaker = 10 ppm dry alum.

Procedure

The procedure for a jar test is as follows:

1. Using a 1,000 mL graduated cylinder, add 1,000 mL of raw feed water to be coagulated to each

of the jar test beakers.

2. Using a prepared alum stock solution (1.0% by weight), dose each beaker with increasing amounts

of solution shown in Table 2.

Form No: TSG-T-008 // Revision: B // Date: May 25, 2017

Table 2. Increasing dosages of alum.

Jar # Alum Added Alum Dosage

(mL) (mg/L)

Control 0.0 0.0

1 0.5 5.0

2 1.0 10.0

3 1.5 15.0

4 2.0 20.0

5 2.5 25.0

3. After dosing each beaker, turn on the stirrers (if these aren’t available, swirl beaker by hand to mix

the alum and feed water solution) to a setting that best mimics the plant’s operation as shown in

Table 3.

Table 3. Plant operation vs. jar test procedure operating parameters.

Current Plant Operation Jar Test Procedure

1. Alum addition followed by static mixing 1. Alum addition followed by mixing at a high RPM

2. Flocculation for 35 minutes 2. Reduce mixing speed to match conditions in

the flocculator for 35 minutes

3. Settling for 90 minutes 3. Turn off mixer to match conditions in the settler

for 90 minutes

4. Examine the beakers and determine which dosage produced the best results (i.e. Figure 1). Under-

dosing coagulant will cause the sample to look cloudy with little or no floc and almost no settling.

Over-dosing coagulant will cause a dense fluffy floc to occur and will not settle well. The beaker

with an appropriate dosage of coagulant will have floc that has settled to the bottom and the water

above it will be clear. If none of the beakers appear to have good results then the procedure should

be run again using different dosages until the correct dosage is determined.

Figure 1. The beakers on

the left are under-dosed

with coagulant and appears

cloudy with little or no floc

and almost no settling. The

beakers on the far right,

however, appear to have

floc that has settled to the

bottom and the water

above looks clear. In this

figure, the beaker on the far

right exemplifies the correct

coagulant dosage.

Europe Americas Asia

Germany: +49 611 962 6001 USA: +1 805 964 8003 China: + 86 592 677 5500

Italy: +39 0721 1796201 Brazil: +55 11 3378 7500 Singapore: +65 6457 7533

info@microdyn-nadir.de info@microdyn-nadir.com infochina@microdyn-nadir.cn

A MANN + HUMMEL Company

Form No: TSG-T-004 // Revision: B // Date: May 25, 2017

Form No: TSG-T-008 // Revision: B // Date: May 25, 2017

You might also like

- Allison MT 600 Series PDFDocument3 pagesAllison MT 600 Series PDFDaniel Alex Sánchez100% (1)

- Internal Audit Report Format For Health & SafetyDocument24 pagesInternal Audit Report Format For Health & SafetyansariNo ratings yet

- Water Jar Test DoneDocument8 pagesWater Jar Test DoneNasEvan'sNo ratings yet

- Aluminum Alloys, Theory & Application - 2011Document390 pagesAluminum Alloys, Theory & Application - 2011Ahmadreza AminianNo ratings yet

- Estimation of Optimum Coagulant Dose by Jar Test ApparatusDocument6 pagesEstimation of Optimum Coagulant Dose by Jar Test ApparatusDani MughalNo ratings yet

- NORSOK M-630 Edition 5 of 100930 PKL 100930 EndeligDocument133 pagesNORSOK M-630 Edition 5 of 100930 PKL 100930 EndeligRob CarolusNo ratings yet

- Timing Belt Kit 2015Document114 pagesTiming Belt Kit 2015Armando JacintoNo ratings yet

- Toxicology of Textile DyesDocument31 pagesToxicology of Textile DyesWilson Anandaraj100% (5)

- Jar Test ReportDocument11 pagesJar Test ReportHalimi Honan100% (1)

- The Chemistry of Dairy Products - A Chemical Analysis of Milk, Cream and ButterFrom EverandThe Chemistry of Dairy Products - A Chemical Analysis of Milk, Cream and ButterNo ratings yet

- Control Chart For Attributes-AizrulDocument44 pagesControl Chart For Attributes-AizrulAizrul ShahNo ratings yet

- Reverse OsmosisDocument131 pagesReverse OsmosisTaufiqTaufiq100% (6)

- Jar Test Lab Report Environmental EngineeringDocument7 pagesJar Test Lab Report Environmental EngineeringNur Hazimah100% (1)

- Nalco 356: Material Safety Data SheetDocument13 pagesNalco 356: Material Safety Data SheetTaufiqTaufiqNo ratings yet

- CHM 421 Analytical Chemistry Experiment 1: Calibration of A Volumetric FlaskDocument10 pagesCHM 421 Analytical Chemistry Experiment 1: Calibration of A Volumetric FlaskIntan SapuraNo ratings yet

- CHEM 121: Kinetics: The Clock ReactionDocument11 pagesCHEM 121: Kinetics: The Clock ReactionMuthiani Denis100% (1)

- WAF / ModSec + OWASP CRSDocument61 pagesWAF / ModSec + OWASP CRSAdzmely MansorNo ratings yet

- Jar Testing Procedure: Technical Service GuideDocument2 pagesJar Testing Procedure: Technical Service GuideRyanNo ratings yet

- Jartest Alum LabDocument4 pagesJartest Alum LabskjonsbytNo ratings yet

- LDH OutlineDocument7 pagesLDH OutlinejahnNo ratings yet

- Sulfite: Iodate-Iodide Method Method 8071 0-500 MG/L As SO (Or 0 To More Than 500 MG/L) Buret TitrationDocument6 pagesSulfite: Iodate-Iodide Method Method 8071 0-500 MG/L As SO (Or 0 To More Than 500 MG/L) Buret Titrationahmad sutejaNo ratings yet

- Jar TestingDocument2 pagesJar TestingBalRam DhimanNo ratings yet

- Gravimetric AnalysisDocument3 pagesGravimetric Analysismeibis monteverdeNo ratings yet

- Lab 1 PDFDocument15 pagesLab 1 PDFRamesh KonakallaNo ratings yet

- TAPPIMethodT203om-93 Alpha-, Beta - and Gamma-Cellulose in PulpDocument7 pagesTAPPIMethodT203om-93 Alpha-, Beta - and Gamma-Cellulose in PulppoliveirauctNo ratings yet

- Experiment 2 Isolation and Characterization of Proteins Protein Assay Using The Bradford MethodDocument7 pagesExperiment 2 Isolation and Characterization of Proteins Protein Assay Using The Bradford MethodCHRISTIN SCHLITTNo ratings yet

- Catalase in Yeast SpheresDocument4 pagesCatalase in Yeast Spheresabdelrahmanadelm2008No ratings yet

- CHE 2303 Chemical KineticsDocument19 pagesCHE 2303 Chemical KineticsomoljavanNo ratings yet

- CM124-1L B12 Group5 EXP5 PDFDocument27 pagesCM124-1L B12 Group5 EXP5 PDFjosiah_comiaNo ratings yet

- Pipeting and Dilution Lab: Biochemistry Laboratory Experiment No. 1Document12 pagesPipeting and Dilution Lab: Biochemistry Laboratory Experiment No. 1Adellaine Lois GreyNo ratings yet

- 205report 2Document11 pages205report 2RPh Krishna Chandra JagritNo ratings yet

- SS BWT STD Ox CSDocument2 pagesSS BWT STD Ox CSMandeep Singh Kahlon100% (2)

- CHEM 335 Aldol ReactionDocument4 pagesCHEM 335 Aldol Reactiontyler_4No ratings yet

- StoichlabDocument4 pagesStoichlabapi-242446055No ratings yet

- Changing The Rate of A Reaction (Part I)Document2 pagesChanging The Rate of A Reaction (Part I)Shahid Ur RehmanNo ratings yet

- WEEK 2 - Level 0 - Jar TestDocument2 pagesWEEK 2 - Level 0 - Jar TestWHfamilyNo ratings yet

- Jar TestDocument2 pagesJar TestKaith GallegoNo ratings yet

- Experiment 1 Calibration of Volumetric GlasswareDocument39 pagesExperiment 1 Calibration of Volumetric GlasswareJernyNo ratings yet

- Jar Test Lab ReportDocument7 pagesJar Test Lab ReportTeCkMunNo ratings yet

- Chloride: Silver Nitrate Method Method 10246 100 To 200,000 MG/L As CL Digital TitratorDocument6 pagesChloride: Silver Nitrate Method Method 10246 100 To 200,000 MG/L As CL Digital Titratorkrishna karuturiNo ratings yet

- Chemistry Content Based ExpirimentsDocument22 pagesChemistry Content Based ExpirimentsHari VaarthanNo ratings yet

- Manual Lab CMT450 - Unit OperationDocument17 pagesManual Lab CMT450 - Unit OperationNur Hafikah MustaphaNo ratings yet

- Practical 10 - Effect of Starch Concentration On Diastase - ANS - Ms TohDocument8 pagesPractical 10 - Effect of Starch Concentration On Diastase - ANS - Ms Tohjavierheng314No ratings yet

- Thermo. Titr. Application Note NoDocument3 pagesThermo. Titr. Application Note NoRuben HernandezNo ratings yet

- Lab Manual CHM138 (Eks 1,2&5)Document21 pagesLab Manual CHM138 (Eks 1,2&5)Aminah AwangNo ratings yet

- Chloride: Silver Nitrate Method Method 8207 10 To 10,000 MG/L As CL Digital TitratorDocument6 pagesChloride: Silver Nitrate Method Method 8207 10 To 10,000 MG/L As CL Digital TitratorAlbertoNo ratings yet

- Metodo Hach 8206 para Cloruros Por Nitrato de MercurioDocument6 pagesMetodo Hach 8206 para Cloruros Por Nitrato de MercurioAIDEENo ratings yet

- Chloride - Mercuric Nitrate Method PDFDocument6 pagesChloride - Mercuric Nitrate Method PDFYajNo ratings yet

- April 19, 2020 Experiment No. 5 Determination of Phosphate in Detergent Samples: A Molecular Spectroscopy Application MembersDocument27 pagesApril 19, 2020 Experiment No. 5 Determination of Phosphate in Detergent Samples: A Molecular Spectroscopy Application Membersjosiah_comiaNo ratings yet

- Lab ReportDocument6 pagesLab Reportapi-392376456No ratings yet

- Jar Test ProcedureDocument6 pagesJar Test ProcedureleonardseniorNo ratings yet

- Aluminum, Method 8012, 02-2009, 9th Ed PDFDocument6 pagesAluminum, Method 8012, 02-2009, 9th Ed PDFMuhammad SuffyanazwanNo ratings yet

- 1314lab StoichiometryandmeasurementslabDocument6 pages1314lab Stoichiometryandmeasurementslabapi-239464058No ratings yet

- Experiment (1) Volumetric Glassware and BalancesDocument8 pagesExperiment (1) Volumetric Glassware and BalancesMarah mazNo ratings yet

- Mark Marlatt - Photosynthesis Lab and Report Track D - 5261224Document8 pagesMark Marlatt - Photosynthesis Lab and Report Track D - 5261224api-544304176No ratings yet

- Lab ReportDocument8 pagesLab Reportapi-392375614No ratings yet

- Results Discussion W TPDocument9 pagesResults Discussion W TPJesús Rodríguez RodríguezNo ratings yet

- Chemistry PracticalsDocument15 pagesChemistry PracticalsKashish ChoudharyNo ratings yet

- Quantitative Estimation of Amino Acids by Ninhydrin: TheoryDocument11 pagesQuantitative Estimation of Amino Acids by Ninhydrin: TheoryNamrata KulkarniNo ratings yet

- Silica: Heteropoly Blue Rapid Liquid Method Method 8282 Ulr 3 To 1000 Μg/L Sio Pour-Thru CellDocument8 pagesSilica: Heteropoly Blue Rapid Liquid Method Method 8282 Ulr 3 To 1000 Μg/L Sio Pour-Thru CellJoselito CortesNo ratings yet

- UV-vis Spectroscopy Lab #2Document4 pagesUV-vis Spectroscopy Lab #2hand.drawn.studios.101No ratings yet

- Postlab 3Document6 pagesPostlab 3Ice cream dudeNo ratings yet

- Hardness, Calcium: Titration Method With Edta Method 8222 0-25,000 MG/L As Caco Buret TitrationDocument8 pagesHardness, Calcium: Titration Method With Edta Method 8222 0-25,000 MG/L As Caco Buret TitrationYanuar PaksiNo ratings yet

- DOC316.53.01153 8ed PDFDocument6 pagesDOC316.53.01153 8ed PDFHugo Armando Iral MaldonadoNo ratings yet

- Silica: Heteropoly Blue Method Method 8282 3 To 1000 Μg/L Sio Reagent SolutionDocument6 pagesSilica: Heteropoly Blue Method Method 8282 3 To 1000 Μg/L Sio Reagent SolutionShesharam ChouhanNo ratings yet

- Kolej Kemahiran Tinggi Mara Sri Gading Diploma in Construction Technology (Building Forensic & Maintenance) Technical Science (DCC 1052) Lab ReportDocument13 pagesKolej Kemahiran Tinggi Mara Sri Gading Diploma in Construction Technology (Building Forensic & Maintenance) Technical Science (DCC 1052) Lab ReportMuhammad AsyrafNo ratings yet

- Exp 1 Colligative Properties of SolutionsDocument8 pagesExp 1 Colligative Properties of SolutionsChristina RentinoNo ratings yet

- OBJECTIVE: The Objective of This Lab Was Divided Into A Three-Part Symposium: The FirstDocument5 pagesOBJECTIVE: The Objective of This Lab Was Divided Into A Three-Part Symposium: The FirstTinpinay523No ratings yet

- Jar Floc TestDocument9 pagesJar Floc TestNanaNo ratings yet

- Processes: The Use of Polymers in The Flotation Treatment of WastewaterDocument12 pagesProcesses: The Use of Polymers in The Flotation Treatment of WastewaterTaufiqTaufiqNo ratings yet

- Poly Aluminium Chlorida (Pac) 300 Liquid: Product SpecificationDocument1 pagePoly Aluminium Chlorida (Pac) 300 Liquid: Product SpecificationTaufiqTaufiqNo ratings yet

- Activation of (Na, Ca) - Bentonites With Soda and Mgo and Their Utilization As Drilling MudDocument8 pagesActivation of (Na, Ca) - Bentonites With Soda and Mgo and Their Utilization As Drilling MudTaufiqTaufiqNo ratings yet

- Brosur EnerpacDocument4 pagesBrosur EnerpacTaufiqTaufiqNo ratings yet

- DOWEX Ion Exchange Resins: Tech FactsDocument2 pagesDOWEX Ion Exchange Resins: Tech FactsTaufiqTaufiqNo ratings yet

- Corrugated Gaskets With Soft Layers,: Gaskets - Packings - Expansion Joints - Rubber and Plastic MaterialsDocument4 pagesCorrugated Gaskets With Soft Layers,: Gaskets - Packings - Expansion Joints - Rubber and Plastic MaterialsTaufiqTaufiqNo ratings yet

- Boilerproblems 181026115558 PDFDocument23 pagesBoilerproblems 181026115558 PDFTaufiqTaufiqNo ratings yet

- Msds 1. Chemical Product and Company Identification: Polypropylene Topilene J740Document8 pagesMsds 1. Chemical Product and Company Identification: Polypropylene Topilene J740TaufiqTaufiqNo ratings yet

- Installation & Operation ManualDocument25 pagesInstallation & Operation ManualDiego Mauricio Zapata GarciaNo ratings yet

- Distributed System 25 QuestionsDocument19 pagesDistributed System 25 QuestionsparassinghalNo ratings yet

- Sony WM-EX20 Service ManualDocument20 pagesSony WM-EX20 Service Manuallunar7No ratings yet

- Etika Hukum & Bisnis - Tugas 1Document14 pagesEtika Hukum & Bisnis - Tugas 1Firda SartikaNo ratings yet

- Metodo MRMRDocument12 pagesMetodo MRMRRaul Carrasco PolancoNo ratings yet

- ST 150NVNF User ManualDocument92 pagesST 150NVNF User Manualthilan87No ratings yet

- SparkLabs Global Ventures' Technology and Internet Market Bi-Monthly Review 0728 2014Document10 pagesSparkLabs Global Ventures' Technology and Internet Market Bi-Monthly Review 0728 2014SparkLabs Global VenturesNo ratings yet

- DWD Training Calendar Jan 2023Document1 pageDWD Training Calendar Jan 2023Anonymous UpWci5No ratings yet

- THS00 Dual Temperature Humidity Sensor PDFDocument3 pagesTHS00 Dual Temperature Humidity Sensor PDFgimbar MailNo ratings yet

- DC-to-DC Converter in Maximum Power Point Tracking (THE PHOTOVOLTAIC POWER SYSTEM)Document14 pagesDC-to-DC Converter in Maximum Power Point Tracking (THE PHOTOVOLTAIC POWER SYSTEM)Andrei - Cristian SIMIONNo ratings yet

- Linking Competitive Strat With HR Practice Schuler Jackson 87Document15 pagesLinking Competitive Strat With HR Practice Schuler Jackson 87Karthik ShanklaNo ratings yet

- Pilot-URC2002-P Daljinski PDFDocument18 pagesPilot-URC2002-P Daljinski PDFisko ahmetovic100% (1)

- Basant Tech ProfileDocument36 pagesBasant Tech ProfileNasser Fahed AljumahNo ratings yet

- Schrack RM732024 DatasheetDocument4 pagesSchrack RM732024 Datasheetpaula09No ratings yet

- A ? ?MMXM (Market Maker Thread by Casper SMC Nov 28, 22 From RattibhaDocument9 pagesA ? ?MMXM (Market Maker Thread by Casper SMC Nov 28, 22 From RattibhalakshanbrogeekNo ratings yet

- Improving The Transient Stability of Nigerian 330 KV Network Using SVCDocument13 pagesImproving The Transient Stability of Nigerian 330 KV Network Using SVCDavor JunušićNo ratings yet

- Valvula DBDH REXROTH PDFDocument8 pagesValvula DBDH REXROTH PDFCARLOS RAMIREZNo ratings yet

- List Bajaj Re 205 205D Parts With Photo 2011-12 ModelDocument10 pagesList Bajaj Re 205 205D Parts With Photo 2011-12 ModelPower DomesticNo ratings yet

- Sensor de Flujo 9500ADocument40 pagesSensor de Flujo 9500AJuan Francisco Mora ZeladaNo ratings yet

- Worldwide Always in Stock: The Festo Core Product Range For AutomationDocument4 pagesWorldwide Always in Stock: The Festo Core Product Range For AutomationAlex Vaz - Vtech Automação e EngenhariaNo ratings yet

- Chapter04.pdf - How To Write A Project Report - ResearchDocument8 pagesChapter04.pdf - How To Write A Project Report - Researchbrownsugar26No ratings yet