0% found this document useful (0 votes)

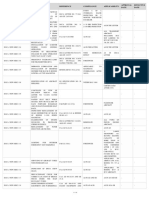

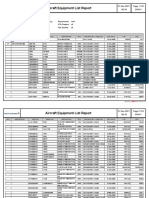

860 views16 pagesQA Directive On Kit Inspection For Electronics Mechanical Components and Consumables For Airborne LRUs Module

The document provides directives on kit inspection for electrical, electronic, mechanical components and consumables for airborne LRUs/modules. It defines key terms, describes required QA activities during kit inspection including visual inspection, compliance checking, and provides safety and handling instructions.

Uploaded by

Vismay kumar. NCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

860 views16 pagesQA Directive On Kit Inspection For Electronics Mechanical Components and Consumables For Airborne LRUs Module

The document provides directives on kit inspection for electrical, electronic, mechanical components and consumables for airborne LRUs/modules. It defines key terms, describes required QA activities during kit inspection including visual inspection, compliance checking, and provides safety and handling instructions.

Uploaded by

Vismay kumar. NCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd