0% found this document useful (0 votes)

488 views12 pagesA60H Datasheet

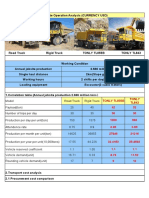

The document provides details about the Volvo A60H articulated hauler. It is the largest articulated hauler that can haul 55 metric tons and has a 630 horsepower engine. The document outlines the hauler's specifications, components, and features in detail.

Uploaded by

Reymond RoyCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

488 views12 pagesA60H Datasheet

The document provides details about the Volvo A60H articulated hauler. It is the largest articulated hauler that can haul 55 metric tons and has a 630 horsepower engine. The document outlines the hauler's specifications, components, and features in detail.

Uploaded by

Reymond RoyCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd