100% found this document useful (1 vote)

5K views5 pagesP018F 00

Try this

Uploaded by

Mahipal MeenaCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

100% found this document useful (1 vote)

5K views5 pagesP018F 00

Try this

Uploaded by

Mahipal MeenaCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

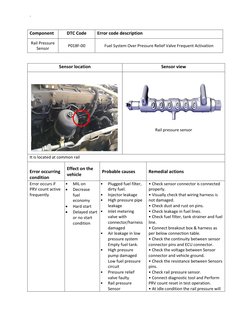

- Rail Pressure Sensor Details: Provides a detailed explanation of the Rail Pressure Sensor, including component details, error codes, effects on vehicles, probable causes, and remedial actions.

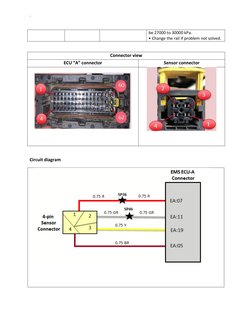

- Connector and Circuit Diagram: Displays detailed schematics of the connectors and circuit diagrams associated with the Rail Pressure Sensor, including labeling and pin configurations.

- Circuit Description and Inspection Procedures: Describes the wiring color codes, functions for the ECU and sensor connectors, and provides inspection and measurement procedures for circuit continuity and resistance.