100%(1)100% found this document useful (1 vote) 374 views5 pagesCompressed Air Line Sizing

Calculate Compressed Air line sizes

Copyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content,

claim it here.

Available Formats

Download as PDF or read online on Scribd

Sizing Compressed Air Mains

The compressed air mains are the ali-importent

link between the compressor and the point of

usage.

It is thoroughly bad to install mains which

are too small and cause high pressure drop. If,

for example, a compressor has to work at

8 bar 120 psi, to cater for pressure drop condi-

tions, whereas 7 bar 100 psi would normally

meet’ the case, it calls for an additional power

input of as much as 10%.

Mains, which are too small also cause high

velocity, making it difficult to separate the

water from the air because much of the conden-

sed vapour running as a stream of water along

the bottorn of the pipe, will be whipped up by

and carried along with the fest moving air

stream.

Whilst watchful eye must be kept on the

pressure drop, it is common practice to size

compressed ait mains on velocity and a reason-

able figure for all practical problems is 6-9 m/s

20-30 ft/sec which is sufficiently low to

Prevent excessive pressure drop on most systems

and will allow moisture to precipitate out

without re-entrainment,

Many compressed air systems are working

inefficiently because the demand has outgrown

the supply — new pneumatic plant has been

added from time to time without addition to

‘the compressor plant or mains.

In designing a new plant, therefore, some

thought might be given to possible future

demands and allowance made in the mains

sizes

Sizing by velocity presents an easy form of

determining pipe size for a given duty, but it

must be remembered that the duty of a compr-

essor and the demand of the equipment is usu-

ally expressed in dm?/s of free air cubic feet of

free air per minute and that when compressed

the volume will be less.

Table 8 shows that ratio of compression and

the actual volume occupied at any given pressure

can be found by dividing the volume of free air

by the ratio of compression.

Example (Metric SI Units)

At a gauge pressure of 8 bar, Table 8 shows the

ratio of compression as 8:9 so if we have

At 2 gauge pressure of 120 psi, Table 8 shows

the ratio of compression as 9-16 so if we have

100 cubic feet of free air compressed to 120 psi,

it will occupy a space of:

400

S76 7 43-66 cubic feet

Table 9 shows the equivalent volume

already worked out for some of the more

everyday pressures.

Table 10 shows the volume of air which can

be carried by various sizes of pipes at given

velocities,

Pipe sizing is, therefore, reduced to simpli-

city by using these tables.

Example (Metric S! Units)

To determine the size of 2 main to carry

100 dm/s of free air at a working pressure of

7-0 bar.

From Table 8 it will be seen that at 7-0 bar

the ratio of compression is 7:91 so the actual

volume of 100 dm? of free air when compressed,

to 7-0 bar is:

100

a1

Alternatively, because 7:0 bar is a pressure in

everyday use Table 9 will give the answer

direct without the bother of working it out.

Having decided that the velocity shall not

exceed 6 m/s, from Table 10 we can determine

the size of pipe required to carry 12-64 dm°/s

of air.

Casting an eye along the line opposite 6 m/s

in the left hand column (Table 10) we find that

2.50 mm pipe will carry 13-00 dm*/s and is the

nearest commercial size to our requirements.

1264

Example (Imperial Units)

To determine the size of a main to carry

200 cubic feet of free air per minute at a

working pressure of 100 psi.

From Table & it will be seen that at 100 psi

the ratio of compression is 7-8 so the actual

volume of 200 cubic feet of free air when

compressed to 100 psi is:

190 dm” of free air compressed to 8 bar, it will 200 . i

See FE 2 eH cubic feet

190 = 21.35 dm?

89

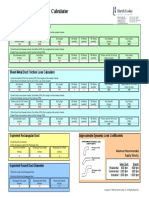

Table 8 Metric SI Units Ratio of Compression

Gauge Pressure bar [0-5|1 [2 [3 [4 [5 [6 [7 [8 [10 [12 |i4 [is

Ratio of Compression| 1-5 [1-99] 2-97 |3-96] 4-95] 5.94| 6-92|7-91| 8.9 |10-87] 12.85|1482|18-77

Table 8 Imperial Units Ratio of Compression

Gauge Pressure pat 70 20 | 30 En) 50 50 70 80

Ratio of Compression | 168 | 296 | 304 | 372 | 440 | 508 | 576 | 6-44

Gauge Pressure ps 30 700 _[ 110 | 120 | 130 | 140 750] 200

Ratio of Compression | 712 | 78 | 848 | 916 | 984 | 1052 | 112 | 146

7�Alternatively, because 100 psi is 2 pressure in

everyday use, Table 9 will give this answer

Girect without the bother of working it out.

Having decided that the velocity shali not

exceed 20 feet/second, from Table 10 we cen

determine the size of pipe required to carry

25-64 cubic feet of air per minute at this

velocity.

Casting an

20 feet/sec in the |

we find that 2 2” pipe

eye slong the fine opposite

hand column, (Table 10},

vill carry 28 cubic feet

and is the nearest commercial size to our

requirements.

For long runs the pressure loss through mains

sized by the velocity method may be higher

than desirable and it is as well to check what

the actual pressure drop will be.

It is of course only possible to obtain rough

estimates es so much depends on the type and

condition of the pipe and on the resistance of

the various fittings.

In calculations it is usual to allow for

fittings by considering them in terms of straight

lenth of pipe and Table 11 shows the equivalent

lengths in metres feet for typical fittings.

Table 9 Metric SI Units

Equivalent Volume of Compressed Air at

Common Pressures

By adding the equivalent lengths to the

actual length of pipe, the loss in each section

of a system can be easily found by reference

to the chart.

The nomogram in Table 12 gives a ready

means for determining pressure drops through

pipes often found in industry (this information

for smaller bore pipes is set out in Table 15). It

is based on the following formula which can

also be used for pipe sizes outside those shown

in the table.

Pressure Drop in bar = KLO2 _

Rees

Where

K= 800

Length of pipe in metres

The volume of free air in dm?/s passing

through the pipe.

R= The ratio of compression at the beginn-

ing of the pipe

The internal pipe diameter in mm

d=

Table 9 Imperial Units

Equivalent Volume of Compressed Air at

Common Pressures

Equivalent Volume (dm? )

Equivalent Volume (cu ft}

Volume of when compressed to Cubic Feet when compressed to

Free Air gauge pressures of Free Air pressures of

den? 4 bar 5 bar 7 bar 60 psi 20 psi__ 100 psi

5 101 084 063 10 1-96 1-55 1-28

10 2.02 168 1-26 20 3.94 3-10 2:56

15 3.03 252 1.90 30 5-69 465 3.84

20 4.04 3:37 2-53 40 7-86 6-20 5412

25 5.05 421 3-16 50 9-84 774 6-41

30 6-06 5-05 3-79 60 18 9.23 768

35 707 5-69 442 70 13-8 10-8 896

40 8.08 6-73 5-08 80 18-7 12-4 10-2

50 10-4 8-42 632 90 17-7 14.0 115

60 124 10-1 758 100 196 155 128

70 14-4 18 8-85 125 246 19-4 158

80 16-2 13-5 10-4 150 29-5 23-5 19-2

20 18-2 15-4 114 178 34.4 27-2 22-4

100 202 168 126 200 39-4 31.0 256

125 25-2 210 158 250 49-2 38-7 316

150 303 252 19.0 300 58.9 46-5 384

175 353 295 22-4 350 688 542 448

200 40-4 33-7 253 400 786 62.0 51-2

225 45-4 379 28-4 450 ge4 63-7 87-7

250 50-5 42-1 316 500 284 774 63.3

275 555 463 348 00 4180 929 769

300 606 50-5 379 700 138-0 108-0 89-6

350 70-7 ee eae 800 1570 1244 103-0

400 80-8 673 506 900 177-0 140.0 115-0

500 101-0 84-2 63-2 1000 196-0 155-0 127-0

780 151-0 126-0 95:0 1500 295-0 232.0 192-0

1000 202.0 168-0 126-0 2000 394-0 3100 256.0

1250 252.0 210-0 158-0 2500 432-0 3870 316.0

8�Table 10 Metric SI Units

Volume of Compressed Air (dim

Carried by

Grade Stee! Pipes, of Minimum Bore, to BS 1387, at Given Velocities

Velocity _ Volume of air through medium grade steel pipe, to BS 1387, minimum bore (mm)

mis 15 201-25 32 40 506580100125 150200

3-0 O06 17 17 30 41 65 109 157 257 392 562 O85

35 07 13 20 35 47 76 127 176 300 45:7 655 115.0

4.0 08 14 23 40 54 87 146 20-1 34.2 52:2 749 131.0

45 09 16 26 45 61 98 164 226 385 58:8 842 147.0

5-0 10 18 28 50 68 108 182 25-1 428 654 936 164.0

55 11 20 34 55 74 119 200 276 47:1 71:9 103-0 181-0

60 12 27 34 60 814 130 218 30-1 513 785 1120 197-0

6-5 13°23 37 65 88 141 237 326 556 85:0 1220 213-0

7-0 14° 25 40 70 95 151 255 35-1 599 91:5 131-0 230-0

75 15 27 43 75 101 162 273 376 642 98:0 140-0 246-0

80 16 28 45 80 108 17:3 29-1 40-1 685 105-0 150-0 263-0

85 17 30 48 85 115 184 31:0 426 728 111-0 159-0 278-0

2-0 18 3:2 51 90 122 195 328 45-1 77-1 118-0 169-0 296-0

Table 10 Imperial Units Volume of Compr

Steel Pipes, of Minimum Bore, to BS 1387, at Given Velocities

sed Air (cfm) Carried by Medium Grade

Velocity Volume of air t mn grade steel Dip jinimum bor

ftlsec "a a pt 6

10 73 23 36 14 3584127

12 1528 44 16 28 «39° 86101145

14 1B 3:20 54 19 33 45° «77 «4118169

16 20 37 59 103 140 22 38 52 88 135 193

18 23 41 66 116 160 25 42 58 99 152 217

20 25 46 73 128 17:0 28 47 65 110 168 242

22 28 51 81 1417 190 31 52 71 121 185 266

24 30 55 88 154 21:0 34 56 78 132 202 290

26 33°59 96 167 230 36 61 84 144 219 314

28 35 64 103 179 240 39 66 91 154 236 338

30 38 69 41.0 193 26.0 42 71 97 166 _253 362

Table 11 Metric SI Units Resistance of Pipe Fittings (Equivalent Length in m)

Nominal Pipe Size (mm)

Type of Fitting 15: __ 201 25_32._40'_50_65_80_100._ 125

Elbow 0-26 037 049 067 076 107 1-37 183 244 32

90°Bend (long) 0-15 0-18 024 038 046 061 0-76 091 1:2 1:52

Return Bend 0-46 061 0-76 107 1-2 168 198 26 366 488

Globe Valve 0-76 107 1:37 198 2.44 3.36 396 518 7:32 9.45

Gate Valve 0-107 0-14 048 0:27 032 040 049 064 091 1.20

Run of Standard Tee 0-12 0-18 0-24 038 040 052 067 085 1:2 152

Through Side Outlet of Tee 0-52 0-70 0-91 1.37 1:58 214 2.74 366 4-88 6-40

Table 11 imperial Units Resistance of Pipe

Fittings (Equivalent Le

ngth in feet)

Nominal Pipe Size (inches)

Type of Fitting Pie ah Med 2 OE OS 45

Elbow 09 12 16 22 25 35 45 60 80 105

90°Bend (long) 05 06 08 147 «15 20 2 40 50

Return Bend 15 20 25 35 40 55 65 85 120 160

Globe Valve 25 35 45 65 80 110 130 170 240 310

Gate Valve 04 05 06 09 10 13 16 24 30 -40

Run of Standard Tee 04 06 08 11 13 17 22 22 28 50

Through Side Outlet of Tee 17 23 3:0 45 52 70 90 120 160 21.0�= The volume of free air in cu ft/minute

passing through the pipe

Table 12 Metric SI Units Pressure Drop in

Internal die

of Pipe in mm

Flow of Free

Air in drm3/s

5000

2000

20

Medium Weight Steel Pipe to BS 1387

Example (Metric SI Units)

To determine size of pipe needed to pass

300 dm3/s free air with a pressure drop of not

more than 300 mbar in 125 m of pipe. Air

pressure is 9 ber.

300

300 mbar.in 125 m is equivalent to ——

125

= 2-4 mbar/m.

Join 9 ber on the air pressure line to 2-4

20

The length of pipe in feet

The ratio of compression at the beginn-

ing of the pipe

@ = The internal pipe diemeter in inches

Steel Pipes (15 mm to 100 mm)

Pressure Drop

Through Pipe Air Pressure

in mbar/m in bar

Reference

Line

30

2

20

3

4

10

5

6

5.0 7

40 8

9.

30 16

18

mbar/m on the pressure drop line and project

to cut reference line at X. Join X to 300 dm Vs

and project to cut pipe size line at approxi

mately 61 mm.

Therefore choose pipe having @ minimum

bore of at least 61 mm (a 65 mm nominal bore

pipe to BS 1387 has 2 bore of 69 mm and

would therefore meet the case and give some

margin}.�Table 12 Imperial Units Pressure Drop in Steel Pipes (14 to 4”)

Internal dia

of Pipein Flowof Free

inches Air in cfm

40

a le

3000

@ NT F 2000

@) S gf 15°

1000

@Q-120

& 15

@)

© 1.0

@)

Or1os

Pressure drop in

Reference psi through 100 ft Air pressure

Line of steel pipe in psi

ae 20

12

10 3

9

8

7

gi 50

5

4

75

100

125

Example ({mperial Units)

To determine the pipe size to pass 1000 cu ft

free eir per minute with a pressure drop of not

more then 5 psi in 500 ft of pipe and @ line

pressure of 150 psi.

5 psi in 500 ftis equivalent to 1 psi in 100 ft.

Therefore join 150 psi on the pressure scale to

1 psi on the pressure drop scale to cut the

reference line at X.

Join the point X tp the 1000 cfm point,

and project it to cut the pipe diameter line at

point Y. So choose @ 3” pipe.

a