Solar PV System Design – Sample Calculation

1. Background

The aim of this document is to give an example of a system calculation for the design of a grid-tied

rooftop solar PV system.

The example is for demonstration purposes only and there may be other solutions beside the one

shown here.

The roof of the Master Artisan Academy (MSC) in Modderfontein was selected.

2. Data

The following data was provided

Address McGowan Avenue, Lethabong

GPS Coordinates -26.096, 28.169

https://goo.gl/maps/UmynqdoSqs32

Altitude Highveld

Picture:

Roof available for the installation: Approx. 15m x 4m

Further information Standard roof tiles

no feed in allowed, three-phase

azimuth -150° (North-West), tilt 30°

AC – grid-tied

Consumption: 13,000 kWh per year

For this example the following equipment choice is provided:

270Wp - 60-cell polycrystalline module (please refer to the datasheet provided)

SMA Sunny Tripower (3-phase inverter)

Note: The basic principles demonstrated in this calculation apply to all standard string inverters and

the SMA inverters can be exchanged for any other inverter you choose.

The use of other technologies, e.g. module-level optimisers may require a different approach.

1

� Solar PV System Design – Sample Calculation

3. Calculation

3.1. Location Information

Using PV GIS (http://re.jrc.ec.europa.eu/pvg_tools/en/tools.html#PVP) or a similar tool the

meteorological information for any site can be determined

We were given the azimuth angle (-150°) and the roof slope (30°).

(Please refer to the annex for the complete report from PV-GIS)

The annual specific energy production is given as 1,690 kWh/kWp

2

� Solar PV System Design – Sample Calculation

3.2. PV system sizing based on consumption

Note: This is a simplistic view of the sizing just as a rough estimate. Factors like night time

consumption fraction and other factors are ignored.

3.2.1. Required PV system size:

Annual Consumption given: 20,000 kWh

(Annual consumption) / (specific yield at the location)

= 13,000 kWh / 1,690 kWh/kWp

= 7.69 kWp

3.2.2. Number of modules required:

Module: 270 Wp (= 0.27 kWp)

(System size) / (Module size)

= 7.69 kWp / 0.27 kWp

= 28.49 modules (~28 modules)

3.2.3. Module layout:

Roof dimensions: 15 m x 4 m

Modules in portrait layout:

992mm

20mm

-------- 4m --------

1650mm

-------- 15m ---------

Number of modules per row:

(Roof length) / (module width + clamping space)

= 15 m / (0.992 m + 0.02 m)

= 14.82 modules; i.e. 14 modules

3

� Solar PV System Design – Sample Calculation

Number of rows:

(Roof width) / (module length)

= 4 m / 1.65 m

= 2.42 rows; i.e. 2 rows

Total number of modules:

14 x 2 = 28 modules

Modules in landscape layout:

1650 mm

992 mm

----- 4 m -----

20mm

----------- 15m ----------

Number of modules per row:

(Roof length) / (module length)

= 15 m / (1.650 m)

= 9.09 modules; i.e. 8 modules

Number of rows:

(Roof width) / (module width + clamping space)

= 4 m / (0.992 m + 0.02 m)

= 3.95 rows; i.e. 3 rows

Total number of modules:

8 x 3 = 24 modules

We need 28 modules, so decide to install in portrait mode

4

� Solar PV System Design – Sample Calculation

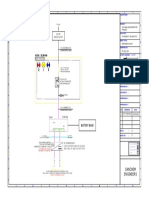

3.2.4. Inverter selection (DC sizing)

Note: The inverter sizing factor is assumed here to be in the range from 83% to 125% of the DC

rating of the PV system.

This is a rule-of-thumb and it is always a good idea to consult with the inverter manufacturer to

verify the system design and compatibility of an inverter for a specific installation.

PVdc = 28 modules x 270 Wp = 7,560 Wp = 7.56 kWp

PINV = PVdc / (sizing factor) = 7,560 Wp / 0.83 = 9,108 W (max. inverter size)

= 7,560 Wp / 1.25 = 6,048 W (min. inverter size)

Inverter options:

SMA Sunny Tripower 7000, 8000 or 9000

Decide on the “middle ground”, i.e. Sunny Tripower 8000

5

� Solar PV System Design – Sample Calculation

3.2.5. String sizing

Note to convert coefficients from % to V, multiply the Voc by the coefficient:

-0.31 %/°C = (-0.31 % x 37.9V)/°C = 0.11749 V/°C or 117.49 mV/°C

Maximum number of modules per string:

VInv,max / Voc, module = 1,000 V / 37.9 V = 26 modules

We have 28 modules, so will have to have at least 2 strings.

e.g. 2 x 14 modules

6

� Solar PV System Design – Sample Calculation

3.2.5.1. Parameter check

This parameter check entails the confirmation of system voltages at the extreme temperatures to be

expected at the given location.

Please note that the temperature used is the module temperature and not the ambient!

At STC:

Voc, string = No. of modules x Voc, module = 14 x 37.9 V = 530.6 V

Assumed temperature range for the location: tmin = 0°C ; tmax = 85°C

Maximum string voltage will be experienced at the minimum temperature.

ΔVoc, string, 0°C = temp. coeff. x Voc, module x (min. temp. – STC temp) x (no. of modules)

= (-0.31 %/°C) x 37.9 V x (0°C – 25°C) x 14 modules

= (-0.11749 V/°C) x (– 25°C) x 14 modules

= 41.12 V

So at 0°C the maximum string voltage will be:

Voc, string, 0°C = (14 modules x 37.9 V) + 41.12 V = 530.6 V + 41.12 V = 571.72 V

This is lower than the 1,000 V maximum voltage of the inverter, so acceptable.

Minimum string voltage will be experienced at the maximum temperature.

ΔVmpp, string,STC = Vmpp x no. of modules = 30.8 V x 14 modules = 431.2 V

ΔVmpp, string, 85°C = temp. coeff. x Vmpp, module x (max. temp. – STC temp) x (no. of modules)

= (-0.41 %/°C) x 30.8 V x (85°C – 25°C) x 14 modules

= (-0.1268 V/°C) x (60°C) x 14 modules = -7.608 V x 14 modules

= -106.512 V

So at 85°C the minimum string voltage will be:

Vmpp, string, 85°C = 431.2 V – 106.512 V = 324.688 V

This is slightly lower than the 330 V minimum Mpp voltage of the inverter. Seeing that the extreme

case may be expected to be quite rare, we can make a judgement call and accept the result.

7

� Solar PV System Design – Sample Calculation

4. Annex1 – PV GIS report

8

� Solar PV System Design – Sample Calculation

5. Annex2 – Module Data Sheet

9

� Solar PV System Design – Sample Calculation

6. Annex3 – Inverter Data Sheet

10