Contact:

5-15 Cromer Street

+44 (0)20 3397 7279

London, Kings Cross

hello@[Link]

WC1H 8LS

[Link]

ADNOC, Dubai

I N S TA L L AT I O N G U I D E

[Link]

COMPANY REGISTERED NO: 06980029 COMPANY VAT NO: 996499723

Copyright Pavegen Systems Ltd, 2022. It is illegal to reproduce this document without the permission of the owner, Pavegen Systems Ltd

1 Company Registered no: 06980029 Company VAT no: 996499723

Copyright Pavegen Systems Ltd. 2020, it is illegal to reproduce this document without the permission of the owner, Pavegen Systems Ltd.

� Contact:

5-15 Cromer Street

+44 (0)20 3397 7279

London, Kings Cross

hello@[Link]

WC1H 8LS

[Link]

INTRODUCTION

This document describes the components and the assembly of our V3.5 system.

Any installation, maintenance, alteration, modification or adjustment must be performed by:

A Pavegen employee, representative, etc. or;

by an appropriate number of suitably qualified and experienced personnel, with prior written

approval of Pavegen; using reasonable skill and care.

The steps of the installation should be conducted in the order they are presented below.

CONTENTS

1. Installation Guide p 3

Components p 3-5

Tool List p 7

Installation Process p 8-14

2. Final Commissioning p 14

Pre Start Checks p 14

Testing Procedure p 14

3. Appendix p 15-24

Please use Metric quantities for accuracy.

For any further information or queries, please contact: hello@[Link] and +44 (0) 2033 977 279

2

� Contact:

5-15 Cromer Street

+44 (0)20 3397 7279

London, Kings Cross

hello@[Link]

WC1H 8LS

[Link]

1. INSTALLATION GUIDE

COMPONENTS (INCLUDED IN SHIPMENT)

Top Surface

Full Tile Half Tile (Left) Full Tile (Right)

Sub-Frame

Pedestal GRP Mid-Sheet Joist

Joist Connector (Corner)

Pedestal Adjustment Tool Semi-Circular Support Pad Corner Support Pad

3

� Contact:

5-15 Cromer Street

+44 (0)20 3397 7279

London, Kings Cross

hello@[Link]

WC1H 8LS

[Link]

Sub-Frame

Generator Spider Edge Spiders Corner Spiders

Triangular Rubber Sheet PCB Holder

Edge-Frames

1250mm 2 Pad Frame 1250mm 3 Pad Frame 865mm Frame

Corner Frame 1 Corner Frame 2

4

� Contact:

5-15 Cromer Street

+44 (0)20 3397 7279

London, Kings Cross

hello@[Link]

WC1H 8LS

[Link]

Electrical

Devices Installed:

• Edge Device (NUC)

• Charge Controller

• Temperature Sensor

• Switch

Generator & PCB Electrical Cabinet

DC Bus Cable Flex Cable Connector

5

� Contact:

5-15 Cromer Street

+44 (0)20 3397 7279

London, Kings Cross

hello@[Link]

WC1H 8LS

[Link]

Fixings

Locking Screw and Washer 13mm Pan Head (MX8) Generator Screw

Self-Tapping Screw

35mm Self-Tapping Screw

6

� Contact:

5-15 Cromer Street

+44 (0)20 3397 7279

London, Kings Cross

hello@[Link]

WC1H 8LS

[Link]

Tool/Component List (Not Included in Shipment)

• Laser Level

• Spirit level

• Measuring Tape

• Impact driver/ Drill

- T25 head

- SQ3 head

- PZ2 head

• Angle grinder/circular saw

• Basic wiring tools: cutters, connectors, electrical tape etc.

• Laptop (with TeamViewer App installed), wireless keyboard and mouse

• HDMI Cable

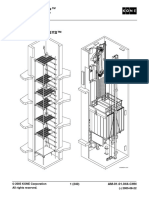

Exploded Component View

Section View Edge Frame

GRP Midsheet

12mm

25mm

38mm

Joist

150mm

Pedestal

75mm

7

� Contact:

5-15 Cromer Street

+44 (0)20 3397 7279

London, Kings Cross

hello@[Link]

WC1H 8LS

[Link]

INSTALLATION PROCESS

Joist Frame

1. Lay out the joist frame using the spacing shown

(see Appendix A).

2. The space between the first two joists should be

163mm. Each subsequent gap must be 385mm.

3. Joists are secured together using the Joist

Connectors provided and 13mm Pan Head Self-

Tapping Screws.

4. Check all joists to ensure they are properly

fastened.

5. Fix the Joist Perimeter to the outside edge of

the joist frame with the 13mm Pan Head Self-

Tapping Screw. **This is to close the gap

between the array and the surrounding flooring.

It will need to be cut down to for the frame to fit

inside the excavation.**

6. Place the completed joist frame into the

excavation.

8

� Contact:

5-15 Cromer Street

+44 (0)20 3397 7279

London, Kings Cross

hello@[Link]

WC1H 8LS

[Link]

Pedestal Placement

1. Assemble all pedestals (see Pedestal Assembly.

mp4).

2. Set all pedestals to a base height of 75mm.

3. Clip the pedestals around the joist frame (max

600mm apart). They should be positioned so

that the frame is fully and evenly supported.

See Appendix C for guidance.

4. Mount the pedestals to the joists off-centre as

shown (below) to allow space for the pedestal

adjustment tool.

5. Some pedestal bases (especially around outside

edges) will need to be cut down to fit inside the

excavation.

Height Adjustment

1. Set up the laser level. Make sure the elevated

joist frame is level and that it is the correct height

with respect to the finished surface. See ‘Section

View’ (Page 6) for component measurements.

2. Individual pedestals may need to be adjusted

slightly with the Pedestal Adjustment Tool.

9

� Contact:

5-15 Cromer Street

+44 (0)20 3397 7279

London, Kings Cross

hello@[Link]

WC1H 8LS

[Link]

Electrical Cabinet

1. Mount the electrical cabinet in the chosen location.

2. Install a mains power socket into the electrical cabinet.

3. Run ethernet cable into the electrical cabinet and connect to the Switch.

4. Connect the NUC to the Switch and also to power.

5. Run both DC BUS cables and both LED power cables from the array, through the conduit into

the electrical cabinet.

6. Connect the DC Bus cables to the Wago connectors (labelled DC Bus).

7. Connect HDMI cable from the screen into the NUC.

**THE ELECTRICAL CABINET SHOULD NOT BE MODIFIED WITHOUT PAVEGEN’S AUTHORISATION**

Example electrical cabinet shown below:

10

� Contact:

5-15 Cromer Street

+44 (0)20 3397 7279

London, Kings Cross

hello@[Link]

WC1H 8LS

[Link]

GRP Mid-Sheets & Edge Frame

1. On the underside of each large GRP mid-sheet,

ensure that there is a PCB holder next to each of

the 5 generator holes.

2. Lay down GRP mid-sheets on top of the joist

frame using Appendix E as a guide.

3. The GRP sheets should overhang the edge

of the joist frame by 6mm on each side and the

pilot holes on the edge of each GRP sheet

should line up with the ridge in the centre of the

joists.

4. Ensure that the DC bus cables coming from the

electrical cabinet are visible and accessible.

5. Lay out the Edge Frames on the outer edge of

each GRP sheet using Appendix F as a guide.

6. Line up the edge frame with the GRP mid-sheet,

then secure the edge frames into the mid-

sheet using 35mm Self-Tapping Screw. The

screw will secure the frame, mid-sheet and the

joist together.

7. When securing the Corner Frame pieces,

position the Corner Support Pads in place

first.

8. The top of the edge frame should now be the

same height as the final adjacent floor surface.

11

� Contact:

5-15 Cromer Street

+44 (0)20 3397 7279

London, Kings Cross

hello@[Link]

WC1H 8LS

[Link]

Fitting & Connecting Generators

The generators are connected in a “daisy chain topology” (in parallel electrically), with the first and

last generators connected to the charge controller via the DC Bus cables - see example illustration

below.

1. Pull one DC Bus cable up through the first generator hole and one through the last (see

diagram above).

2. Starting at the first hole, connect the short cable from a generator to the DC Bus cable via

a Flex Cable Connector.

3. Reach into the hole and clip the generator’s PCB to the PCB Holder on the underside of the

GRP. Place the generator into the hole and rotate approx 90 degrees, lining up the pilot

holes.

4. Connect the long cable from the first generator to the short cable on the next generator.

5. Repeat step 3.

6. Continue this process, connecting all generators.

7. At the last generator, connect the short cable to the other DC Bus cable via a Flex Cable

Connector. The circuit is now complete.

8. Fasten the generators to the GRP mid sheet with 2x Generator Screws using the guide

holes provided.

***Do not test or depress any generators until they are connected to the charge controller***

12

� Contact:

5-15 Cromer Street

+44 (0)20 3397 7279

London, Kings Cross

hello@[Link]

WC1H 8LS

[Link]

GRP Mid-sheet Finishing, Support Pads and Rubber Sheets

1. Finish securing the GRP sheets to the joists via the guide holes, using 35mm Self-

Tapping Screw.

2. Position all the Semi Circular Support Pads - they should not be secured down.

3. Lay rubber pads between generators where the tiles will be laid. Use the

Appendix H) as a guide.

4. Attach rubber spiders to the tops of all generators and support pads - use

Appendix H for a guide to placement.

Fit Tiles

1. Ensure the rubber generator protector ring is in position on top of each generator.

2. Lay tiles according to Appendix K

3. Fix tiles with Locking Screw and Washer. Over-tightening may cause the screw head to

break.

4. Check that the tiles are level and seated properly.

13

� Contact:

5-15 Cromer Street

+44 (0)20 3397 7279

London, Kings Cross

hello@[Link]

WC1H 8LS

[Link]

Software Installation & Testing

1. The Pavegen team will now need to connect to the NUC (Edge Device) and remotely test

the system. The NUC will need to be connected to the internet.

2. Turn on the screen and the NUC. Connect a wireless mouse and keyboard to the NUC.

3. TeamViewer will open automatically. Ensure the green “ready’ dot (which signifies

successful connection) is visible at the bottom of the window.

4. This could take a few hours. Pavegen will notify you once the update has finished.

5. Once the NUC is turned on, the software should appear on the screen automatically

within 30-60 seconds. Contact Pavegen for any troubleshooting.

6. Step on every generator 3-4 times. Check that steps are registering on the screen.

2. FINAL COMMISSIONING

PRE-START CHECKS

Mechanical Tests

• Check gradient/fall of top surface-angle and direction

• Check all tiles are seated correctly

• Check all tile retention screws are present, seated correctly and tightened to the

recommended torque.

Electrical Tests

• Check for electrical shorts by conducting a continuity test with a multimeter. Depress a

generator then probe across the DC bus terminal which connects to the Charge Controller.

• Check Charge Controller is properly labelled and secured, with all the covers on.

• Check NUC is secured and protected.

• Check cables are labelled and tidy.

TESTING PROCEDURE

Mechanical Tests

• Check the free movement and feel of all generators. Measurements of performance are

carried out in the Electrical Test.

Electrical Tests

• Electrical testing is monitored remotely by the Pavegen team via the Mindshpere platform. A

person on site will need to assist in this by taking steps on the array.

14

� Contact:

5-15 Cromer Street

+44 (0)20 3397 7279

London, Kings Cross

hello@[Link]

WC1H 8LS

[Link]

3. APPENDIX

• Appendix A - Joist Layout

• Appendix C - Pedestal Layout

• Appendix D - DC Bus Layout

• Appendix E - GRP Layout

• Appendix F - Edge Frame Layout

• Appendix G - Generator Layout

• Appendix H - Support Pad, Rubber Spider and Mat Placement

• Appendix J - Full Tile Layout

15

� Contact:

5-15 Cromer Street

+44 (0)20 3397 7279

London, Kings Cross

hello@[Link]

WC1H 8LS

[Link]

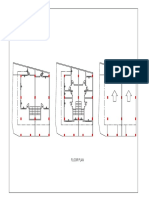

Appendix A - Joist Layout

16

� Contact:

5-15 Cromer Street

+44 (0)20 3397 7279

London, Kings Cross

hello@[Link]

WC1H 8LS

[Link]

Appendix C - Pedestal Layout

17

� Contact:

5-15 Cromer Street

+44 (0)20 3397 7279

London, Kings Cross

hello@[Link]

WC1H 8LS

[Link]

Appendix D - DC Bus Layout

18

� Contact:

5-15 Cromer Street

+44 (0)20 3397 7279

London, Kings Cross

hello@[Link]

WC1H 8LS

[Link]

Appendix E - GRP Layout

19

� Contact:

5-15 Cromer Street

+44 (0)20 3397 7279

London, Kings Cross

hello@[Link]

WC1H 8LS

[Link]

Appendix F - Edge Frame Layout

20

� Contact:

5-15 Cromer Street

+44 (0)20 3397 7279

London, Kings Cross

hello@[Link]

WC1H 8LS

[Link]

Appendix G - Generator Layout

21

� Contact:

5-15 Cromer Street

+44 (0)20 3397 7279

London, Kings Cross

hello@[Link]

WC1H 8LS

[Link]

Appendix H - Support Pad, Rubber Spider and Rubber Mat Placement

22

� Contact:

5-15 Cromer Street

+44 (0)20 3397 7279

London, Kings Cross

hello@[Link]

WC1H 8LS

[Link]

Appendix J - Full Tile Layout

23

�Contact:

+44 (0)20 3397 7279

hello@[Link]

[Link]