Professional Documents

Culture Documents

Valve Material Specification

Uploaded by

ibicengOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Valve Material Specification

Uploaded by

ibicengCopyright:

Available Formats

Forging Materials

Chemistry Element % Composition Mechanical Properties Chemistry Element % Composition Mechanical Properties

ASTM A105 Carbon Steel Where temperatures are moderate and corrosion resistance is not critical.

ASTM A182, Grade 5 4-6% Chromium 1/2% MoIybdenum With moderately corrosive fluids and in oil refineries where high temperature stability and oxidation resistance of the lower alloy steels are inadequate. C 0.15 Max. Mn 0.30 - 0.60 P .030 Max. S 0.015 - 0.035 Si 0.50 Max Ni 0.50 Max Cr 4.00 - 6.00 Mo 0.44 - 0.65 TS Min. psi(MPa) YS Min. psi(MPa) EL (2 Min.) RA Min. Hardness, Bhn 70,000(485) 40,000(275) 20% 35% 143-217

C 0.20 - 0.24 Mn 1.00 - 1.35 Si 0.15 - 0.30 P .030 Max. S 0.015 - 0.040 Cr 0.20 Ni 0.20 Mo 0.06 V 0.02 Cb 0.02 Cu 0.20 Pb 0.02 Total Residuals = 0.50

TS Min. psi(MPa) YS Min. psi(MPa) EL (2 Min.) RA Min. Hardness, Bhn

70,000(485) 36,000(250) 22% 30% Max. 187

ASTM A350, LF2 Where cold temperature (-50F) impact strength is essential. C 0.20 - 0.24 Mn 1.00 - 1.35 Si 0.15 - 0.30 P .030 Max. S 0.015 - 0.040 Cr 0.20 Ni 0.20 Mo 0.06 V 0.02 Cb 0.02 Cu 0.20 Pb 0.02 Total Residuals = 0.50 TS Min. psi(MPa) YS Min. psi(MPa) EL (2 Min.) RA Min. Hardness, Bhn -50F Charpy Energy (Ft./Lb.) Average of Each Set of 3 Specimen For One Specimen 70,000(485) 36,000(250) 22% 30% Max. 197 Min. Impact (J) 15(20) 12(16)

ASTM A182, Grade F9 9% Chromium For services where the higher chrome alloys are preferred and where high temperature stability and oxidation resistance of the lower alloy steels are inadequate. C 0.15 Max. Mn 0.30 - 0.60 P .030 Max. S 0.030 Max Si 0.50 - 1.00 Cr 8.00 - 10.00 Mo 0.90 - 1.10 TS Min. psi(MPa) YS Min. psi(MPa) EL (2 Min.) RA Min. Hardness, Bhn 85,000(585) 55,000(380) 20% 40% 179-217

ASTM A182, Grade F11, Class 2 1 1/4% Chromium 1/2% MoIybdenum

ASTM A182, Grade F316. Grade F316L 18% Chromium 8% Nickel 2-3% MoIybdenum

To minimize graphitization encountered with carbon and carbon moly steels at high temperatures. C 0.10 - 0.15 Mn 0.30 - 0.80 P .040 Max. S 0.015 - 0.035 Si 0.50 - 1.00 Cr 1.00 - 1.50 Mo 0.44 - 0.65 TS Min. psi(MPa) YS Min. psi(MPa) EL (2 Min.) RA Min. Hardness, Bhn 70,000(485) 40,000(275) 20% 30% 143-207

For corrosion resistance applications where high temperature strength is required. Has restricted carbon level to minimize sensitization. Do not use for service temperatures above 1000F. C 0.035 Max. Mn 2.00 Max. P .040 Max. S 0.020 - 0.030 Si 1.00 Max Ni 10.00 - 14.00 Cr 16.00 - 18.00 Mo 2.00 - 3.00 TS Min. psi(MPa) YS Min. psi(MPa) EL (2 Min.) RA Min. 75,000(515) 30,000(205) 30% 30%

ASTM A182, Grade F22, Class 3 2 1/4% Chromium 1% MoIybdenum Where elevated temperature, surface stability, and greater strength than F11 are needed. C 0.15 Max. Mn 0.30 - 0.60 P .040 Max. S 0.015 - 0.035 Si 0.50 Max Cr 2.00 - 2.50 Mo 0.87 - 1.13 TS Min. psi(MPa) YS Min. psi(MPa) EL (2 Min.) RA Min. Hardness, Bhn 75,000(515) 40,000(310) 20% 30% 156-207

ASTM A182, Grade F316H 18% Chromium 8% Nickel 2-3% MoIybdenum For corrosion resistance applications where extreme high temperature service is expected. Has a restricted carbon range for high temperature strength above 1000F. C 0.04 - 0.10 Mn 2.00 Max. P .040 Max. S 0.020 - 0.030 Si 1.00 Max Ni 10.00 - 14.00 Cr 16.00 - 18.00 Mo 2.00 - 3.00 TS Min. psi(MPa) YS Min. psi(MPa) EL (2 Min.) RA Min. 75,000(515) 30,000(205) 30% 30%

Valve Trim Materials

Description & General Use 13% Chromium Stainless Steel Type 410 ASTM A479 This stainless steel material lends itself readily to hardening by heat treatment and is excellent for contacting parts such as stems, gates, and discs. 13% Chromium Stainless Steel Type 416 ASTM A582 High quality stainless steel yoke nut material having excellent anti-galling characteristic for better operating threads. 18% Chromium 8% Nickel, 2% Molybdenum Stainless Steel Type 316 Type 316L ASTM A182 Provides excellent resistance to corrosive media at high temperatures and toughness for service at low temperatures. Chemistry Element % Composition C Mn P S Si Cr 0.10- 0.15 .60 Max. .040 Max. .030 Max. 1.00 Max 12 - 13.5 Description & General Use Cobalt Base and Nickel Base Hard Facing Materials ASME SFA 5.13 Hard facing materials, when used on seating surfaces of Gate, Globe, and Check Valves, give extended service life and troublefree operation. Nickel-Moly-Chromium ASTM B574, Grade N 10276 Hastelloy C-276 A high nickel alloy with exceptional resistance to corrosive attack by chlorine gas. Chemistry Element % Composition Cobalt, Chromium and Tungsten Alloy Nickel, Chromium and Boron Alloy

C Mn P S Si Cr Ni C Mn P S Si Cr Ni Mo C Mn S Ni Si Fe Al Ti Cu P Zn

0.11- 0.14 .60 Max. .060 Max. 0.25 - 0.35 1.00 Max 12.00 - 14.00 .60 Max. .035 Max. 2.00 Max. .040 Max. 0.020 - .030 1.00 Max 16.00 - 18.00 10.00 - 14.00 2.00 - 3.00 .25 Max. 1.50 Max. 0.010 Max. 63.00 - 70.00 .50 Max 2.00 Max 2.3 - 3.15 .35 - .85 27.0 - 33.0 0.020 0.020

C Ni Co Cr Mo W C Mn P S Si

.02 Max. Balance 2.5 Max. 14.50 - 16.50 15.00 - 17.00 3.00 - 4.50 0.07 Max 1.00 Max. .04 Max. .03 Max. 1.00 Max

Fe Si Mn V P S Cr Ni Cu Cb +Ta

4.00 - 7.00 0.08 Max 1.00 Max. .35 Max. .04 Max. .03 Max. 15.00 - 17.50 3.00 - 5.00 3.00 - 5.00 0.15 - 0.45

Precipitation Hardened Stainless Steel A564, Gr. 630 17-4 PH Provides corrosion resistance and high strength for stems in NACE applications.

Nickel-Copper Monel Alloy K500 FED-SPEC QQ-N-286F Class A

This wrought material is precipitation hardened and possesses excellent corrosion resistance, high strength properties and hardness for internal valve components.

S-Monel ASTM A-494, Grade M-25S Material used for Monel castings.

C Mn Si P

.25 Max. 1.50 3.5 - 4.5 .03

Ni Fe Cu

.03 Balance 3.5 27.00 - 33.00

Monel Alloy 400 ASTM B164 (N0400)

Non hardened alloy, except by work hardened, that has high strength and toughness over a wide temperature range. Has excellent corrosion resistance in chlorine and alkylation service.

Pb Sn C Mn S Si Ni Fe Cu

0.006 0.006 .030 Max. 2.00 Max. .024 Max. 0.50 Max 63.00 - 70.00 2.50 Max 27.0 - 33.0

ASTM A-743, Grade CA-15 Material used for 13 CR castings, the cast equivalent to type 410 Stainless Steel.

C Mn Si P

.15 Max. 1.00 1.50 Max. .040

S Cr Ni Mo

.040 Max. 11.50 - 14.00 1.0 Max. .50 Max.

Cast Cobalt ASME-SFA5.13 RCoCr-A Material used for Cobalt castings, the cast equivalent to Stellite #6. ASTM A351 Grade CF8M Material used for 18-8 castings, the cast equivalent to type 316 stainless steel.

C Mn Si Ni Cr C Mn P S Si

0.9-1.4 1.0 1.5 3.0 27.0 - 31.0 08 Max 1.50 Max .040 Max .040 Max 1.50 Max

Mo W Fe Others Co Cr Ni Mo

1.0 3.5 - 5.5 3.0 .50 Balance 18.0-21.0 9.0-12.0 2.0-3.0

You might also like

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- 6th Central Pay Commission Salary CalculatorDocument15 pages6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- API 650 FabricationDocument143 pagesAPI 650 Fabricationahmad_koros100% (1)

- List of EstandardsDocument10 pagesList of EstandardsCharles MunetsiNo ratings yet

- Doka FormworkDocument80 pagesDoka FormworkKG Rohilla83% (6)

- T 4520Document56 pagesT 4520ibicengNo ratings yet

- Structural Specification Final CompleteDocument37 pagesStructural Specification Final Completekanishka0% (1)

- Heat Shrink Sleeves Install Manual 2005Document3 pagesHeat Shrink Sleeves Install Manual 2005Engr Arfan Ali DhamrahoNo ratings yet

- Mechanical Design For Pressure VesselDocument26 pagesMechanical Design For Pressure VesselibicengNo ratings yet

- Ibic 205 250 Enq 0043Document142 pagesIbic 205 250 Enq 0043ibiceng100% (1)

- Chapter Nine Gauze and Leno WeavesDocument20 pagesChapter Nine Gauze and Leno Weavesshobsundar100% (2)

- Development of Woven FabricsDocument11 pagesDevelopment of Woven FabricsJoyDipuSahaNo ratings yet

- Lewis, A. Et Al. Conserving A Car Tonnage Foot Case. 2010Document8 pagesLewis, A. Et Al. Conserving A Car Tonnage Foot Case. 2010Trinidad Pasíes Arqueología-ConservaciónNo ratings yet

- 09 27 2020 21.59.04Document1 page09 27 2020 21.59.04ibicengNo ratings yet

- Surprise From AditiDocument1 pageSurprise From AditiibicengNo ratings yet

- Adu and GracuDocument2 pagesAdu and GracuibicengNo ratings yet

- Mee PlantDocument3 pagesMee PlantibicengNo ratings yet

- Life Insurance Corporation of India Detailed Policy Status ReportDocument1 pageLife Insurance Corporation of India Detailed Policy Status ReportibicengNo ratings yet

- Aditipatel-8a-R.no. - 9-Computer HWDocument5 pagesAditipatel-8a-R.no. - 9-Computer HWibicengNo ratings yet

- Vansh.N.Thakkar: X-C ROLL NO. - 39Document12 pagesVansh.N.Thakkar: X-C ROLL NO. - 39ibicengNo ratings yet

- Annexure:4B-Mail Communications With M/S. Alfalaval: Mail Title Description Remarkls SR NoDocument2 pagesAnnexure:4B-Mail Communications With M/S. Alfalaval: Mail Title Description Remarkls SR NoibicengNo ratings yet

- Ibic 205 200 TR 0042Document76 pagesIbic 205 200 TR 0042ibicengNo ratings yet

- Housing Manual 2012 EnglishDocument83 pagesHousing Manual 2012 EnglishVivekanandan MVNo ratings yet

- Aadhaar Update Request Form - CAMSV1.2Document1 pageAadhaar Update Request Form - CAMSV1.2praveen sudhatiNo ratings yet

- III Year Area Surface and Volume ModuleDocument35 pagesIII Year Area Surface and Volume Modulebecks7trNo ratings yet

- Seamless vs. Welded TubingDocument1 pageSeamless vs. Welded Tubingzero_cool_oooNo ratings yet

- R 014258Document3 pagesR 014258ibicengNo ratings yet

- 44 DWGDocument1 page44 DWGibicengNo ratings yet

- MR (04 09 2017)Document2 pagesMR (04 09 2017)ibicengNo ratings yet

- Ceramic Heat Exchanger Case HistoryDocument4 pagesCeramic Heat Exchanger Case HistoryibicengNo ratings yet

- Seismic Zoning Map of India-1Document1 pageSeismic Zoning Map of India-1ibicengNo ratings yet

- 11 TZ 7501Document2 pages11 TZ 7501ibicengNo ratings yet

- Annexure 4a - Ms. Godreg & BoyceDocument6 pagesAnnexure 4a - Ms. Godreg & BoyceibicengNo ratings yet

- III Year Area Surface and Volume ModuleDocument35 pagesIII Year Area Surface and Volume Modulebecks7trNo ratings yet

- Breather ValveDocument1 pageBreather ValveibicengNo ratings yet

- Final Documents StatusDocument6 pagesFinal Documents StatusibicengNo ratings yet

- Project Documentation: IBIC-205-300-CBA-0001 H2O2-Plant-3-Gacl-DahejDocument4 pagesProject Documentation: IBIC-205-300-CBA-0001 H2O2-Plant-3-Gacl-DahejibicengNo ratings yet

- Water Going Down in The Drainfer Nothing. Water Is Most Precious Resource On Earth. How To Conserve Water by Avoiding Dripping. 2. 3. 4Document1 pageWater Going Down in The Drainfer Nothing. Water Is Most Precious Resource On Earth. How To Conserve Water by Avoiding Dripping. 2. 3. 4ibicengNo ratings yet

- 5 Ikat BataDocument7 pages5 Ikat BatahafizNo ratings yet

- Comparitive Study of SGI & GCIDocument3 pagesComparitive Study of SGI & GCIKunal Pandey100% (1)

- AA Unideck PDFDocument2 pagesAA Unideck PDFDouglas TaylorNo ratings yet

- Rivet Materials AL U MIN U M AlloysDocument4 pagesRivet Materials AL U MIN U M AlloysSergio Nieves MoranNo ratings yet

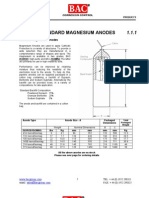

- 1.1.1 ISOLINE MG Anode StandardDocument2 pages1.1.1 ISOLINE MG Anode StandardJaka SembungNo ratings yet

- BibliographyDocument6 pagesBibliographybernadineNo ratings yet

- SCI Industrial PVF CatalogDocument184 pagesSCI Industrial PVF Catalogluonganh89No ratings yet

- Ariane Fine Porcelain PrsentataionDocument30 pagesAriane Fine Porcelain PrsentataionMaya SharmaNo ratings yet

- Code For Awning DesignDocument38 pagesCode For Awning DesignmdeenkNo ratings yet

- f38 - Aquapanel Floor EngDocument8 pagesf38 - Aquapanel Floor Engcristy_icNo ratings yet

- Binder Group Catalogue - 2010 - Rev 0Document172 pagesBinder Group Catalogue - 2010 - Rev 0benedictdelepazNo ratings yet

- Single Core Low VoltageDocument1 pageSingle Core Low VoltageZia Sultan AwanNo ratings yet

- 20 X 70Document102 pages20 X 70MatAlengNo ratings yet

- Yarn Manufacturing - IDocument1 pageYarn Manufacturing - ISiva Jagadish Kumar M100% (2)

- My Con Pds Sikagard 61 TZDocument3 pagesMy Con Pds Sikagard 61 TZlaurenjiaNo ratings yet

- What Is Exothermic Welding - AIWELD®Document4 pagesWhat Is Exothermic Welding - AIWELD®JayNo ratings yet

- Dynapol Types Can CoatingDocument4 pagesDynapol Types Can CoatingYousry ElToukhee100% (1)

- Seasoning of TimberDocument4 pagesSeasoning of TimberMihir SaveNo ratings yet

- Recycling Brochures PDFDocument16 pagesRecycling Brochures PDFSuman Prusty KhuntiaNo ratings yet

- Hilti HIT HY 70 Injection Mortar For MasonryDocument26 pagesHilti HIT HY 70 Injection Mortar For MasonryVenkatesh PadmanabhanNo ratings yet

- Stratobel General Brochure 2010Document16 pagesStratobel General Brochure 2010majmunicahuhuhuNo ratings yet

- 2012 01 30 BAM PresentationDocument19 pages2012 01 30 BAM PresentationJoão GomesNo ratings yet

- SOUDAL Product Catalogue 2016 129171Document68 pagesSOUDAL Product Catalogue 2016 129171Candice Diaz100% (1)