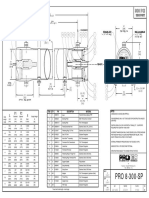

PRO-8-300-SP Vessel Specifications

Uploaded by

mantenimientoilpPRO-8-300-SP Vessel Specifications

Uploaded by

mantenimientoilp145 (P1)

L ±6 138 (P1)

or P1 (Standard) ±1.5 or

170 (P2) 164 (P2)

or P2 (Optional) ±1.5 or

151 (P3)

157 (P3)

P3 (Optional) ±1.5 Ø250

FEED CONCENTRATE MAX BELL Ø

21 20 19 18 15 17 16 9 1 4 5 6

Ø202

2

PERMEATE PORT

1-1/4" NPT MALE

31 3

7 MODEL PRO-8-300-SP

MAXIMUM OPERATING

149 ±0.75

OPERATING PRESSURE TEMPERATURE RANGE

300 PSI (20 BAR) 20 °F (-7°C) 120 °F (49°C)

MINIMUM MAXIMUM

Ø206 PERMEATE DANGER

CBORE TRACING CODE HIGH PRESSURE

DO NOT ATTEMPT TO OPEN OR OPERATE THIS VESSEL BEFORE CAREFULLY

READING THE ENGINEERING PACKET FOR THIS SPECIFIC MODEL

DO NOT REMOVE SCREWS FROM THIS PLATE TO REMOVE HEAD

DO NOT TOLERATE LEAKS OR CORROSION

FOR WATER USE ONLY

124 ±1

NOT FOR USE WITH COMPRESSED AIR

SERIAL Manufactured by

PROTEC ARISAWA EUROPE S.A.

NUMBER

XXX

Ø209 11 13

BODY Ø 51 5 to 15 GRIP

229

10 12

400

6 5 4

APPROX. BELL LENGTH S 8 14

FEED/CONCENTRATE

1-1/2" PIPE GROOVED

END

GENERAL DIMENSIONS BILL OF MATERIALS

ITEM QTY P/N DESCRIPTION MATERIAL

P1 P2 P3 Empty 1 1 4080019 Shell Filament Wound, Epoxy FRP

Shell L STANDARD Optional Optional S Weight

Length Span 2 2 4080028 Bearing Plate 6061-T6 Aluminum, Hard Anodized NOTES:

kg DIMENSIONS IN MM

Code mm mm mm mm mm 3 2 4080177-3 Sealing Plate Noryl

FOR REFERENCE ONLY, NOT FOR CONSTRUCTION UNLESS CERTIFIED

-1 1@635 32 4 2 4080244 Feed/Concentrate Port, 1.5", "D" Stainless Steel, 316L

1483 1194 1143 1168.4

5 4 6121187 Retaining Ring, F/C Port 1.5", "D" Stainless Steel, 316L FOR VESSEL INSTALLATION AND MAINTENANCE PLEASE REFER TO PROTEC ARISAWA

USER´S MANUAL

-1.5 1991 1702 1651 1676.4 1@1067 34 6 2 6184604 Seal, F/C Port 1.5", "D" Ethylene Propylene

CENTER VESSEL ON SUPPORTS AT SPAN(S) "S". 3 POINT SUPPORT QUOTED

*7 2 4080309 Permeate Port Noryl SEPARATELY FOR SHELL LENGTHS -4 AND LONGER.

-2 2499 2210 2159 2184.4 1@1422 36

8 2 6100442 Head Seal Ethylene Propylene INTERNAL PERMEATE PRESSURE MUST NOT EXCEED 125 PSI.

-3 3515 3226 3175 3200.4 1@2032 41 9 2 6180229 Permeate Port Seal Ethylene Propylene

ASME SECTION X, RP CODE STAMP OPTIONAL

10 2 4080320 Retaining Ring w/ Finger Pull Stainless Steel, 316L

PRO-8-300-SP MODEL AVAILABLE SIDE PORT SIZES: 1.5" / 2" / 2.5"

-4 4531 4242 4191 4216.4 2@1626 46

11 2 6121200 Retaining Ring, Permeate Port Stainless Steel, 316L DESIGN PRESSURE = 300 PSI

**12 2 4080173 Support Saddle Thermoplastic Rubber DESIGN TEMPERATURE = Min. -7ºC (20 °F) - Max. 49ºC (120ºF)

-5 5547 5258 5207 5232.4 2@1981 52 FOR OTHER TEMPERATURES OUT OF THIS RANGE CONTACT PROTEC ARISAWA

13 2 4080800 Strap Assembly [M8] Stainless Steel, 316L HYDROTEST PRESSURE: Nº x1.43 CE MARKING or Nº x1.1 ASME

-6 6563 6274 6223 6248.4 2@2337 57 14 4 6150072 Strap Screw [M8x70mm] Stainless Steel, A4

15 2 5080049 Membrane Adapter Noryl

-7 7579 7290 7239 7264.4 2@2692 62

16 1 4080165-1 Thrust Cone PVC Thermoplastic

-7.5 8087 7798 7747 7772.4 2@2896 64 17 2 6180326 Adapter Seal Ethylene Propylene

18 4 6180119 PWT Seal Ethylene Propylene

-8 8596 8306 8255 8280.4 2@3048 66 19 2 4080062 Shim, Adapter [5mm] Noryl

20 2 4080704 Shim, Adapter [2mm] Noryl ENGR

SIDE PORTS CONFIGURATION 21 2 6180031 Permeate Port Secondary Seal

* Different Permeate Port connections available upon request

Ethylene Propylene BOA

29/04/2021

QLTY

PRO-8-300-SP

2 x 1.5" PORTS ** 3 saddles are supplied when vessels are -4 elements or longer PM

29/04/2021

1D 5D MRKT ECO REVISED DRAWING REV

OB

(1 Vessels) 29/04/2021 21053 29/04/2021 101002 AB

SIDE PORT SIDE PORT

1-1/2" 1-1/2"

2" 2"

2-1/2" 2-1/2"

MODEL PRO-8-300-SP MODEL PRO-8-300-SP

MAXIMUM OPERATING MAXIMUM OPERATING

OPERATING PRESSURE TEMPERATURE RANGE OPERATING PRESSURE TEMPERATURE RANGE

300 PSI (20 BAR) 20 °F (-7°C) 120 °F (49°C) 300 PSI (20 BAR) 20 °F (-7°C) 120 °F (49°C)

MINIMUM MAXIMUM MINIMUM MAXIMUM

DANGER DANGER

TRACING CODE HIGH PRESSURE TRACING CODE HIGH PRESSURE

DO NOT ATTEMPT TO OPEN OR OPERATE THIS VESSEL BEFORE CAREFULLY DO NOT ATTEMPT TO OPEN OR OPERATE THIS VESSEL BEFORE CAREFULLY

READING THE ENGINEERING PACKET FOR THIS SPECIFIC MODEL READING THE ENGINEERING PACKET FOR THIS SPECIFIC MODEL

DO NOT REMOVE SCREWS FROM THIS PLATE TO REMOVE HEAD DO NOT REMOVE SCREWS FROM THIS PLATE TO REMOVE HEAD

DO NOT TOLERATE LEAKS OR CORROSION DO NOT TOLERATE LEAKS OR CORROSION

FOR WATER USE ONLY FOR WATER USE ONLY

NOT FOR USE WITH COMPRESSED AIR NOT FOR USE WITH COMPRESSED AIR

Manufactured by Manufactured by

PROTEC ARISAWA EUROPE S.A. PROTEC ARISAWA EUROPE S.A.

149 ±0.75 149 ±0.75

3.2 3.2

301.2 301.2

149 ±0.75 MODEL PRO-8-300-SP

MAXIMUM

OPERATING PRESSURE

OPERATING

TEMPERATURE RANGE

MODEL PRO-8-300-SP

MAXIMUM

OPERATING PRESSURE

OPERATING

TEMPERATURE RANGE

149 ±0.75

300 PSI (20 BAR) 20 °F (-7°C) 120 °F (49°C) 300 PSI (20 BAR) 20 °F (-7°C) 120 °F (49°C)

MINIMUM MAXIMUM MINIMUM MAXIMUM

3.2 3.2 3.2

DANGER DANGER

TRACING CODE HIGH PRESSURE TRACING CODE HIGH PRESSURE

DO NOT ATTEMPT TO OPEN OR OPERATE THIS VESSEL BEFORE CAREFULLY DO NOT ATTEMPT TO OPEN OR OPERATE THIS VESSEL BEFORE CAREFULLY

READING THE ENGINEERING PACKET FOR THIS SPECIFIC MODEL READING THE ENGINEERING PACKET FOR THIS SPECIFIC MODEL

DO NOT REMOVE SCREWS FROM THIS PLATE TO REMOVE HEAD DO NOT REMOVE SCREWS FROM THIS PLATE TO REMOVE HEAD

DO NOT TOLERATE LEAKS OR CORROSION DO NOT TOLERATE LEAKS OR CORROSION

FOR WATER USE ONLY FOR WATER USE ONLY

NOT FOR USE WITH COMPRESSED AIR NOT FOR USE WITH COMPRESSED AIR

Manufactured by Manufactured by

PROTEC ARISAWA EUROPE S.A. PROTEC ARISAWA EUROPE S.A.

NOTES:

DIMENSIONS IN MM

FOR REFERENCE ONLY, NOT FOR CONSTRUCTION UNLESS CERTIFIED

FOR VESSEL INSTALLATION AND MAINTENANCE PLEASE REFER TO PROTEC ARISAWA

USER´S MANUAL

CENTER VESSEL ON SUPPORTS AT SPAN(S) "S". 3 POINT SUPPORT QUOTED

SEPARATELY FOR SHELL LENGTHS -4 AND LONGER.

INTERNAL PERMEATE PRESSURE MUST NOT EXCEED 125 PSI.

ASME SECTION X, RP CODE STAMP OPTIONAL

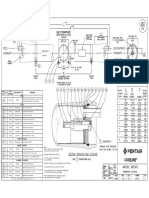

EXAMPLE FOR VICTAULIC COUPLING FOR PRO-8-300-SP MODEL AVAILABLE SIDE PORT SIZES: 1.5" / 2" / 2.5"

DESIGN PRESSURE = 300 PSI

ALLOWABLE PIPE END SEPARATION: DESIGN TEMPERATURE = Min. -7ºC (20 °F) - Max. 49ºC (120ºF)

FOR OTHER TEMPERATURES OUT OF THIS RANGE CONTACT PROTEC ARISAWA

HYDROTEST PRESSURE: Nº x1.43 CE MARKING or Nº x1.1 ASME

2.5" VICTAULIC : 3,2mm

2" VICTAULIC : 3,2mm

1.5" VICTAULIC : 3,2mm

For other coupling suppliers, please refer to their

technical spec. ENGR

BOA

29/04/2021

QLTY

PRO-8-300-SP

PM

29/04/2021

MRKT ECO REVISED DRAWING REV

OB

29/04/2021 21053 29/04/2021 101002 AB

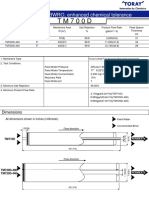

You might also like

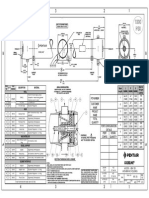

- DWG REF QTY Number Description Material Shell: Dash Length L IN (MM) P IN (MM) S IN (MM) Approx Weight LB (KG)No ratings yetDWG REF QTY Number Description Material Shell: Dash Length L IN (MM) P IN (MM) S IN (MM) Approx Weight LB (KG)3 pages

- DWG REF QTY Number Description Material Shell: Order SectionNo ratings yetDWG REF QTY Number Description Material Shell: Order Section2 pages

- DWG REF QTY Number Description Material Shell: Dash Length L IN (MM) P IN (MM) S IN (MM) Approx Weight LB (KG)No ratings yetDWG REF QTY Number Description Material Shell: Dash Length L IN (MM) P IN (MM) S IN (MM) Approx Weight LB (KG)3 pages

- Codeline Ecoline Drawing 80-450 Rev Q Total PDFNo ratings yetCodeline Ecoline Drawing 80-450 Rev Q Total PDF2 pages

- CodeLine 80S120 RO Pressure Vessel SpecsNo ratings yetCodeLine 80S120 RO Pressure Vessel Specs3 pages

- High Rejection BWRO Membrane SpecificationsNo ratings yetHigh Rejection BWRO Membrane Specifications2 pages

- (2012) Complete IELTS Bands 5-6.5 Student's Book0% (1)(2012) Complete IELTS Bands 5-6.5 Student's Book3 pages

- Operator'S Manual 66605X-X: 1/2" Diaphragm PumpNo ratings yetOperator'S Manual 66605X-X: 1/2" Diaphragm Pump8 pages

- Robot User Manual: Hoisting & Mechanical PartsNo ratings yetRobot User Manual: Hoisting & Mechanical Parts26 pages

- Goulds 3186: High-temperature/Pressure Paper Stock/ Process PumpsNo ratings yetGoulds 3186: High-temperature/Pressure Paper Stock/ Process Pumps8 pages

- Manual 310a Installation Guide Fisher en en 7889368No ratings yetManual 310a Installation Guide Fisher en en 78893684 pages

- Bomba de Agua Shurflo 8007-593-836 Sup SH 12V 35 MTSNo ratings yetBomba de Agua Shurflo 8007-593-836 Sup SH 12V 35 MTS2 pages

- Comprehensive Floor Assembly Parts ListNo ratings yetComprehensive Floor Assembly Parts List37 pages

- Spring Constants and Deflection AnalysisNo ratings yetSpring Constants and Deflection Analysis7 pages

- DPWH Material Engineer Exam Review GuideNo ratings yetDPWH Material Engineer Exam Review Guide12 pages

- Food & Hotel Vietnam 2019 Exhibitor GuideNo ratings yetFood & Hotel Vietnam 2019 Exhibitor Guide50 pages

- Lookahead Planning The Missing Link in Production Control 01No ratings yetLookahead Planning The Missing Link in Production Control 011 page

- Masterkidz Toys Catalog Lite Version 2024 SpringNo ratings yetMasterkidz Toys Catalog Lite Version 2024 Spring61 pages

- Double Direction Angular Contact BearingsNo ratings yetDouble Direction Angular Contact Bearings10 pages

- 2.9.3 Ashrae 90 Analysis: Overall Roof U-ValueNo ratings yet2.9.3 Ashrae 90 Analysis: Overall Roof U-Value3 pages

- Peter C. McKeighan and Narayanaswami Ranganathan, Editors-Fatigue Testing and Analysis Under Variable Amplitude Loading Conditions (ASTM Special Technical Publication, 1439) (2005)100% (1)Peter C. McKeighan and Narayanaswami Ranganathan, Editors-Fatigue Testing and Analysis Under Variable Amplitude Loading Conditions (ASTM Special Technical Publication, 1439) (2005)588 pages

- Metallic Materials in Civil EngineeringNo ratings yetMetallic Materials in Civil Engineering28 pages

- Boq Interior & Furnishing Estimate Sbi Racpc Kalyan BranchNo ratings yetBoq Interior & Furnishing Estimate Sbi Racpc Kalyan Branch15 pages