Professional Documents

Culture Documents

Pressure Vessel-80S100

Uploaded by

Ibrahim0 ratings0% found this document useful (0 votes)

20 views2 pagesCopyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

20 views2 pagesPressure Vessel-80S100

Uploaded by

IbrahimCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 2

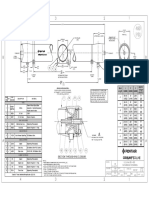

DWG PART Approx

QTY DESCRIPTION MATERIAL Dash L P S

REF NUMBER Weight

SHELL Length IN(MM) IN(MM) IN(MM)

LB(KG)

Filament Wound Epoxy/Glass

63.15 47 25X1 137

1 1 SHELL composites - Head locking grooves -1

ORDER integrally wound in place. (1604) (1194) (635) (62)

2 A/R SECTION F/C Port CD3MWCuN * 103.15 87 56X1 170

3 A/R F/C Port Seal Ethylene Propylene

-2

(2620) (2210) (1422) (77)

HEAD 143.15 127 80X1 203

6061-T6 Aluminium alloy - Hard -3

4 2 96158 Bearing Plate (3636) (3226) (2032) (92)

anodized

183.15 167 64X2 236

5 2 96160 Sealing Plate Engineering Thermoplastic. -4

(4652) (4242) (1626) (107)

6 2 96162 Permeate Port Engineering Thermoplastic.

223.15 207 78X2 269

7 2 45066 Port Nut Engineering Thermoplastic. -5

(5668) (5258) (1981) (122)

8 2 96000 Head Seal Ethylene Propylene - O - Ring

263.15 247 92X2 303

9 2 45312 Perm Port Seal Ethylene Propylene - O - Ring -6

(6684) (6274) (2337) (137)

HEAD INTERLOCK 336

303.15 287 106X2

10 2 47336 Quick Release Spiral Ring 316 Stainless Steel. -7

(7700) (7290) (2692) (152)

VESSEL SUPPORT 343.15 327 120X2 369

-8

11 *2 52169 Saddle Engineering Thermoplastic. (8716) (8306) (3048) (167)

12 *2 45042 Strap Assy. 304 Stainless Steel-PVC Cushion.

13 4 46265 Strap screw. 5/16-18 UNC, 18-8 Stainless Steel.

ELEMENT INTERFACE

14 2 A/R Adapter Engineering Thermoplastic.

15 2 52245 Adapter seal Ethylene Propylene - O - Ring

16 4 A/R PWT Seal Ethylene Propylene - O - Ring

17 1 96163 Thrust Cone Engineering Thermoplastic.

* 3 each furnished with length code 4,5,6,7 & 8.

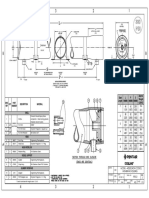

PRECAUTIONS:

RATING: DO…read, understand and follow all instructions; ORDERING:

failure to take every precaution will void warranty Using the chart below, please check the features you require and fax them with your purchase order to our

DESIGN PRESSURE……………....1000 PSIG at 150°F and may result in vessel failure customer service department for further processing.

(6.9 MPa at 66°C) DO…mount the shell on horizontal members at span For optional materials and / or feature not listed below, please consult the factory for pricing and availability

MIN. OPERATING TEMP…………...…..………...20°F “S” using compliant vessel supports furnished;

(-7°C) Shim saddles if required. Tighten hold down straps VESSEL LENGTH CODE – please check one

FACTORY TEST PRESSURE……..CE / ASME just snug

1500 PSIG / 1100 PSIG DO…align and center side ports with the manifold MODEL 80S100 -1 -2 -3 -4 -5 -6 -7 -8

(10.34 MPa) (7.58 MPa) header. Correct, causes of misalignment in a row of

QUALIFICATION PRESSURE...………..…..6000 PSI vessels connected to the same header MEMBRANE BRAND AND MODEL – please check one and fill in information

(41.37 MPa) DO…use flexible type grooved-end pipe couplings,

Victaulic® Style 77 or equal, at side ports; allow Please supply adapters for the following membrane brand and specific model

INTENDED USE: Brand_________________________ Model_______________________

full, 0.125 inch gap between port and piping, and

The CodeLine 80S100 Fiberglass RO Pressure Vessel is position piping to maximize flexibility of

connection. Membrane brand and model information is not currently available, but will be supplied to Pentair Water

designed for continuous, long term use as a housing for

DO…provide flexibility in, and support for piping on or before the following date. ___ / ___ / ___

reverse osmosis membrane elements to desalt typical

brackish and sea waters at pressures up to 1000 psi. Any manifolds so that vessel can grow in length under

make of eight-inch nominal diameter spiral-wound pressure without undue restraint; provide additional

element is easily accommodated; the appropriate flexible joints in large pipes leading to manifold

header. CERTIFICATION REQUIRED

interfacing hardware for the element specified is

furnished with the vessel. DO…provide overpressure protection for vessel set at

ASME Stamped and National Board Registered (please consult factory for pricing)

not more than 105% of design pressure

The CodeLine 80S100 is designed in accordance with the DO…inspect end closures regularly; replace CE Marked

engineering standards of the Boiler and Pressure Vessel components that have deteriorated and correct

Standard, Certified by Pentair water.

Code of the American Society of Mechanical Engineers causes of corrosion

(ASME) Code. At small additional cost vessels can be DO… Lubricate seals sparingly, using nonpetroleum MATERIAL OPTIONS – please check one

inspected during construction by an ASME Authorized Based lubricants, i.e. Parker Super O-lube®,

Inspector and ASME Code stamped. Glycerin or suitable silicone based lubricants. Standard: all materials as per drawing 99163 on the previous page

NOTE: The options listed below will increase the vessel price. Call factory for pricing details.

The CodeLine 80S100 must be installed, operated and DO NOT…work on any component until first verifying Option: Customer specified Material of Construction.(Please consult factory as these options will affect

that pressure is relieved from vessel pricing and vessel lead time)

maintained in accordance with the listed precautions and

good industrial practice to assure safe operation over a DO NOT…make rigid piping connections to ports or PORT SIZE CODE

clamp vessel in any way that resists growth of FEED/CONCENTRATE PORT CONFIGURATION

long service life. D 1½” GROOVED END

fiberglass shell under pressure;

***ǻDIA = 0.015 in. (0.4mm) and Standard – 1½” IPS pipe, grooved ends, with ports in-line E 2” GROOVED END

The high performance Filament wound FRP shell must be F 2½” GROOVED END

***ǻL = 0.2 in. (6mm) for a length code –8 vessel Optional – Multi-PortsTM

allowed to expand under pressure; undue restraint at

Using the instructions in Order Specification Sheet #99007

support points or piping connections can cause leaks to DO NOT… hang piping manifolds from ports or use

vessel in any way to support other components please fill out your feed port configuration in the space below.

develop in the shell. This side-ported vessel requires

List port location first, followed by port size for each choice.

special precautions in mounting and connection to piping DO NOT…tighten Permeate Port connection more than

one turn past hand tight 1.5”, 2”, 2.5” Ports not available in 900 configurations.

so that the vessel will not be subjected to excessive stress

due to bending moments acting at the side openings in the DO NOT… operate vessel without connecting both

fiberglass shell. The end closure, incorporating close Permeate Ports internally to complete set of

fitting, interlocking metal components, must be kept dry elements or otherwise plug ports internally so that Serial number end

and free of corrosion; deterioration can lead to external piping connection is not subjected to feed

pressure Opposite end

catastrophic mechanical failure of the head.

DO NOT…install Spacer on downstream end of vessel

Pentair Water will assist the purchaser in determining the DO NOT…operate vessel without Thrust Cone

installed downstream PERMEATE PORT CONFIGURATION

suitability of this standard vessel for their specific

operating conditions. The final determination however, DO NOT…pressurize vessel until double-checking to Standard 1” FNPT.

including evaluation of the standard material of verify that the Locking Ring is in place and fully

seated. Optional – 1.25” MNPT.

construction for compatibility with the specific corrosive

environment, shall be the responsibility of the purchaser. DO NOT…operate vessel at pressure and temperature

Alternate materials with enhanced corrosion resistance are in excess of its rating.

available on special order. DO NOT…operate vessel with permeate pressure in

For complete information on proper use of the vessel

excess of 125 psi at 150°F (0.86 MPa at 66°C). Please refer to the 80S Series USER’S GUIDE 94182.

Specifications are subject to change without notice. DO NOT…tolerate leaks or allow end closures to be

routinely wetted in any way

DO NOT…operate outside the pH range 3-10.

Note: This vessel can be operated at 190°F (88°C) upto 600 psi (4.1 MPa)

DWG. NO. 99163-E © Pentair Water. PAGE 2 OF 2.

You might also like

- Codeline Drawing 80S30Document3 pagesCodeline Drawing 80S30Hardik VavdiyaNo ratings yet

- Codeline Drawing 80S45Document3 pagesCodeline Drawing 80S45betow_No ratings yet

- Codeline Ecoline Drawing 80-450 Rev Q Total PDFDocument2 pagesCodeline Ecoline Drawing 80-450 Rev Q Total PDFHardik VavdiyaNo ratings yet

- Codeline Drawing 80S45 PDFDocument3 pagesCodeline Drawing 80S45 PDFHardik VavdiyaNo ratings yet

- Codeline Drawing 40E100Document2 pagesCodeline Drawing 40E100Hoàng Anh Tuấn NguyễnNo ratings yet

- DWG REF QTY Number Description Material Shell: Dash Length L IN (MM) P IN (MM) S IN (MM) Approx Weight LB (KG)Document3 pagesDWG REF QTY Number Description Material Shell: Dash Length L IN (MM) P IN (MM) S IN (MM) Approx Weight LB (KG)Dillip DasNo ratings yet

- Codeline Drawing 80S15Document3 pagesCodeline Drawing 80S15jugal ranaNo ratings yet

- Appendix E - Drawings & Data SheetDocument21 pagesAppendix E - Drawings & Data SheetsajanchaudhariNo ratings yet

- Drawing Codeline-80S30 PDFDocument3 pagesDrawing Codeline-80S30 PDFjohandi johandiNo ratings yet

- Codeline Drawing 40L30NDocument2 pagesCodeline Drawing 40L30NArmando Corral BlancoNo ratings yet

- Codeline Drawing 40S30 Non CodedDocument2 pagesCodeline Drawing 40S30 Non CodedHardik VavdiyaNo ratings yet

- Codeline Drawing 80E30Document2 pagesCodeline Drawing 80E30Aravind RaoNo ratings yet

- Drawing 80AQ15-60 Non CodedDocument2 pagesDrawing 80AQ15-60 Non Codeddaus nasNo ratings yet

- Stellite 21Document2 pagesStellite 21Mohsen ParpinchiNo ratings yet

- Stellite 6Document2 pagesStellite 6백승훈No ratings yet

- Stellite Grade 12-DatasheetDocument2 pagesStellite Grade 12-DatasheetNinad PawarNo ratings yet

- Transmission ProductsDocument42 pagesTransmission ProductsPritam SinghNo ratings yet

- stellite 6Document2 pagesstellite 6Shreenivas ThakurNo ratings yet

- Tabla Compartiva Fluidos Hidraulicos - FormexDocument4 pagesTabla Compartiva Fluidos Hidraulicos - Formexirvingsr91No ratings yet

- Heritage Smoke-Spill Series: N NO Oiissee D DA Atta ADocument2 pagesHeritage Smoke-Spill Series: N NO Oiissee D DA Atta AAhmed ShahenNo ratings yet

- Stellite 12 Technical DataDocument2 pagesStellite 12 Technical DataJakeTheSnake69No ratings yet

- Codeline - Octa 80S Series - 80S15, 80S30, 80S45,: Exploded View & Details (Coded Models)Document1 pageCodeline - Octa 80S Series - 80S15, 80S30, 80S45,: Exploded View & Details (Coded Models)igo badrNo ratings yet

- Rsgv-As: Resilient Seated Gate Valve Approved To As2638.2Document3 pagesRsgv-As: Resilient Seated Gate Valve Approved To As2638.2MaloneNo ratings yet

- Tsa 2Document6 pagesTsa 2Amit SurtiNo ratings yet

- Prensa Cables Armados Con Compound - 02Document1 pagePrensa Cables Armados Con Compound - 02Vipper80No ratings yet

- Hgtd7N60B3S, Hgt1S7N60B3S, Hgtp7N60B3: 14A, 600V, Ufs Series N-Channel Igbts FeaturesDocument7 pagesHgtd7N60B3S, Hgt1S7N60B3S, Hgtp7N60B3: 14A, 600V, Ufs Series N-Channel Igbts FeaturesnudufoqiNo ratings yet

- Stellite 6 DS01-21708 (S R0808)Document2 pagesStellite 6 DS01-21708 (S R0808)bwv1006No ratings yet

- Pipes and TubesDocument16 pagesPipes and TubesDaniel Sandoval FernándezNo ratings yet

- High Static Ducted DX Split System Technical ManualDocument149 pagesHigh Static Ducted DX Split System Technical ManualsoqhNo ratings yet

- Avk Gate Valve, Flanged, Pn25 02/67-030: EN 558-2 S.15/DIN F5, Bronze CC499K Wedge Nut, DN50-300Document2 pagesAvk Gate Valve, Flanged, Pn25 02/67-030: EN 558-2 S.15/DIN F5, Bronze CC499K Wedge Nut, DN50-300kad-7No ratings yet

- R1-Ff-Bhadra Dam-30mt Hoist - Under Sluice Gate - r1Document15 pagesR1-Ff-Bhadra Dam-30mt Hoist - Under Sluice Gate - r1ajwalNo ratings yet

- 1078 Butter y Valve (Wafer Type) PN 16 With S.G Iron Disc: Salient FeaturesDocument17 pages1078 Butter y Valve (Wafer Type) PN 16 With S.G Iron Disc: Salient FeaturesSanket PhatangareNo ratings yet

- AVKDocument2 pagesAVKpiscesguy78No ratings yet

- FK76M E LoresDocument18 pagesFK76M E LoresFRANCONo ratings yet

- Fivalco 3g20r (LR) 1508Document1 pageFivalco 3g20r (LR) 1508lesystemsb systemNo ratings yet

- XXAAXXDocument8 pagesXXAAXXMuhammad Emirzan FirdausNo ratings yet

- NTTF Press Tool Standards Ebook GeneralDocument207 pagesNTTF Press Tool Standards Ebook GeneralRagunathan GNo ratings yet

- STRH12P10: Rad-Hard 100 V, 12 A P-Channel Power MOSFETDocument18 pagesSTRH12P10: Rad-Hard 100 V, 12 A P-Channel Power MOSFETHllmanDvlosNo ratings yet

- 775 enDocument5 pages775 enAvishay TufikianNo ratings yet

- AVK Gate Valve Series 37 50 004 IOMDocument9 pagesAVK Gate Valve Series 37 50 004 IOMomarNo ratings yet

- Recoil Check Valve Data SheetDocument2 pagesRecoil Check Valve Data SheetDeepak JoyNo ratings yet

- API SPEC 6D cryogenic valve specificationDocument1 pageAPI SPEC 6D cryogenic valve specificationMaffone NumerounoNo ratings yet

- 10148755Document2 pages10148755kev YNo ratings yet

- 38G-4 Safety Thermal Relief ValvesDocument1 page38G-4 Safety Thermal Relief ValvesThiên KhánhNo ratings yet

- AND 4" N A Slaved: Edo-Aire Mitceell Installation ManualDocument37 pagesAND 4" N A Slaved: Edo-Aire Mitceell Installation Manualalex castro83% (6)

- Butterfly ValveDocument2 pagesButterfly ValveKELVIN TECHNOLOGIESNo ratings yet

- Sink CSMDocument2 pagesSink CSMZulfiqar AhmedNo ratings yet

- Cut-Out Fuse (92123R3-P-D)Document1 pageCut-Out Fuse (92123R3-P-D)Genius DacpanoNo ratings yet

- Avk Supa Plus™ Flange Adaptor, PN 10/16 623/10: Tensile, For PE and PVC Pipes, Incl. Flange Gasket 004Document3 pagesAvk Supa Plus™ Flange Adaptor, PN 10/16 623/10: Tensile, For PE and PVC Pipes, Incl. Flange Gasket 004Ariane Joy LucasNo ratings yet

- Rhino Valves CatalogueDocument174 pagesRhino Valves CatalogueLizaDuPlessisNo ratings yet

- CT-201/KXF-W1010: Service ManualDocument14 pagesCT-201/KXF-W1010: Service ManualGrigor IvanovNo ratings yet

- 3642 3742 Repair Parts - R36 3742 R4 02 21 - WebDocument2 pages3642 3742 Repair Parts - R36 3742 R4 02 21 - Webcristhian.sebastian.12No ratings yet

- 06-Air Inlet and Exhaust SystemDocument29 pages06-Air Inlet and Exhaust SystemSidney RodriguesNo ratings yet

- 621-41-001 - Avk130 - en 2206 - 478821Document2 pages621-41-001 - Avk130 - en 2206 - 478821bre brilianNo ratings yet

- Materials Data for Cyclic Loading: Low-Alloy SteelsFrom EverandMaterials Data for Cyclic Loading: Low-Alloy SteelsRating: 5 out of 5 stars5/5 (2)

- Anglo–American Microelectronics Data 1968–69: Manufacturers A–PFrom EverandAnglo–American Microelectronics Data 1968–69: Manufacturers A–PNo ratings yet

- Token Ring Technology ReportFrom EverandToken Ring Technology ReportNo ratings yet

- CCTV Surveillance: Video Practices and TechnologyFrom EverandCCTV Surveillance: Video Practices and TechnologyRating: 4 out of 5 stars4/5 (1)

- 110826-A SMART CELL - BILGE - Installation CertificateDocument1 page110826-A SMART CELL - BILGE - Installation CertificateIbrahimNo ratings yet

- Watermaker - Dafoss Pressure ControlDocument5 pagesWatermaker - Dafoss Pressure ControlIbrahimNo ratings yet

- Watermaker-Watertek-Parts ListDocument2 pagesWatermaker-Watertek-Parts ListIbrahimNo ratings yet

- Alkaline Membrane CleanerDocument4 pagesAlkaline Membrane CleanerIbrahimNo ratings yet

- Solenoid Driven Metering Pumps MAGDOS LTDocument2 pagesSolenoid Driven Metering Pumps MAGDOS LTIbrahimNo ratings yet

- PermaClean PC-67Document9 pagesPermaClean PC-67IbrahimNo ratings yet

- Acidic Membrane CleanerDocument4 pagesAcidic Membrane CleanerIbrahim100% (1)

- Differential AerationDocument1 pageDifferential AerationPradeepNo ratings yet

- Offshore Pipeline Design Course ChaptersDocument6 pagesOffshore Pipeline Design Course ChaptersDonald.K100% (1)

- Api-582-2016-Welding-Guidelines-For-The-Chemical-Oil-And-Gas-Industries-Apiasme-Practice-Test Clause 11.3Document4 pagesApi-582-2016-Welding-Guidelines-For-The-Chemical-Oil-And-Gas-Industries-Apiasme-Practice-Test Clause 11.3Ahmed ElsharkawNo ratings yet

- Aircraft MaterialsDocument23 pagesAircraft MaterialsShaubori SarkarNo ratings yet

- Electrodeposited Zinc and Zinc Alloy Coatings For Components Manufactured From Ferrous MaterialsDocument16 pagesElectrodeposited Zinc and Zinc Alloy Coatings For Components Manufactured From Ferrous Materials김동훈No ratings yet

- F 2129 - 04 - RjixmjkDocument8 pagesF 2129 - 04 - RjixmjkPrakash MakadiaNo ratings yet

- Spring Design HandbookDocument199 pagesSpring Design Handbooklakshmanakumarr97% (31)

- Self-Healing at The Cut Edge of Coil-Coated Galvanised SteelDocument145 pagesSelf-Healing at The Cut Edge of Coil-Coated Galvanised SteelEwo50 NewNo ratings yet

- Sand Trap LiteratureDocument237 pagesSand Trap LiteratureBop AlberthaNo ratings yet

- Factors Affecting Lifetime Costs of Water Supply PipelinesDocument10 pagesFactors Affecting Lifetime Costs of Water Supply Pipelinesmailmaverick8167No ratings yet

- SS 6mo - 1.4547Document1 pageSS 6mo - 1.4547f_riseNo ratings yet

- CBSE PHYSICS - 8th Chemical Effects of Electric Current PDFDocument8 pagesCBSE PHYSICS - 8th Chemical Effects of Electric Current PDFginga7160% (1)

- Galvalume Rolling ShuttersDocument40 pagesGalvalume Rolling ShuttersLloyd R. PonceNo ratings yet

- Ancon Masonry Support, Windposts & LintelsDocument44 pagesAncon Masonry Support, Windposts & LintelsMelissa GrahamNo ratings yet

- 复合材料防撞设施设计Document5 pages复合材料防撞设施设计Huy ChungNo ratings yet

- Steel Framed Multi Storey Car Parks by CORUS - GKK 14may2012Document36 pagesSteel Framed Multi Storey Car Parks by CORUS - GKK 14may2012Kuvochi Karanja100% (2)

- Visual Inspection of CrankshaftsDocument40 pagesVisual Inspection of Crankshaftsbetoven8437No ratings yet

- Aria PDFDocument172 pagesAria PDFPrashantNo ratings yet

- Corrosion Behavior of AISI 316 Stainless Steel in Formic and Acetic Acid SolutionsDocument8 pagesCorrosion Behavior of AISI 316 Stainless Steel in Formic and Acetic Acid SolutionsSoh Ming LunNo ratings yet

- AWS Foam Cleaner PISDocument1 pageAWS Foam Cleaner PISjack jansenNo ratings yet

- Enhanced Sintering, Microstructure Evolution and Mechanical Properties of 316LDocument4 pagesEnhanced Sintering, Microstructure Evolution and Mechanical Properties of 316LDaniel SolesNo ratings yet

- Ansul 36 Gallon Bladder Tank Manual Part No. 76135-02Document38 pagesAnsul 36 Gallon Bladder Tank Manual Part No. 76135-02lipetrol007No ratings yet

- Cathelco: C-Shield IccpDocument75 pagesCathelco: C-Shield IccpJuan Carlos ZavalaNo ratings yet

- Introduction To OCTG SyllabusDocument5 pagesIntroduction To OCTG SyllabusABC100% (1)

- 5baee5df 4235 4aee 930d 13671813b398 Investment Workshop 3 Oilfield ChemicalsDocument40 pages5baee5df 4235 4aee 930d 13671813b398 Investment Workshop 3 Oilfield ChemicalsamitNo ratings yet

- API 653 Tank Inspections, Maintenance, and Causes of FailureDocument43 pagesAPI 653 Tank Inspections, Maintenance, and Causes of FailureAnderson ReyesNo ratings yet

- A Case Study On Hydrogen Damage in A CFBC BoilerDocument38 pagesA Case Study On Hydrogen Damage in A CFBC Boilerparthi20065768100% (1)

- Bridge Condition Survey ManualDocument25 pagesBridge Condition Survey ManualkmabdNo ratings yet

- Fema 484 Part 4Document68 pagesFema 484 Part 4וויסאם חטארNo ratings yet

- Experimental Investigation On The Cyclic Behaviors of Corroded Coastal Bridge Piers With Transfer of Plastic Hinge Due To Non-Uniform Corrosion PDFDocument12 pagesExperimental Investigation On The Cyclic Behaviors of Corroded Coastal Bridge Piers With Transfer of Plastic Hinge Due To Non-Uniform Corrosion PDFnagarajuNo ratings yet