Fcom 1 100

Uploaded by

SlimeFcom 1 100

Uploaded by

SlimeA318/A319/A320/A321

FLIGHT CREW

OPERATING MANUAL

The content of this document is the property of Airbus. It is supplied in confidence and commercial

security on its contents must be maintained. It must not be used for any purpose other than that for

which it is supplied, nor may information contained in it be disclosed to unauthorized persons. It must

not be reproduced in whole or in part without permission in writing from the owners of the copyright.

© AIRBUS 2005. All rights reserved.

REFERENCE: GLG A318/A319/A320/A321 For A/C: HC-CLF ISSUE DATE: 17 OCT 17

FCOM

Intentionally left blank

PROCEDURES

NORMAL PROCEDURES

A318/A319/A320/A321

FLIGHT CREW PRELIMINARY PAGES - TABLE OF CONTENTS

OPERATING MANUAL

PRO-NOR-SOP Standard Operating Procedures

PRO-NOR-SOP-01 General Information

Foreword.................................................................................................................................................................. A

PRO-NOR-SOP-02 Flight Preparation

Technical Condition of the Aircraft.......................................................................................................................... A

Weather Briefing...................................................................................................................................................... B

NOTAMs.................................................................................................................................................................. C

GPS PRIMARY Availability (If Installed)................................................................................................................. D

Flight Plan and Operational Requirements............................................................................................................. E

Optimum Flight Level...............................................................................................................................................F

Fuel Requirements.................................................................................................................................................. G

PRO-NOR-SOP-03 Safety Exterior Inspection

Safety Exterior Inspection........................................................................................................................................A

PRO-NOR-SOP-04 Preliminary Cockpit Preparation

General.....................................................................................................................................................................A

Aircraft Setup........................................................................................................................................................... B

Battery Check/Setup................................................................................................................................................C

APU Fire Test/APU Start........................................................................................................................................ D

AIR COND............................................................................................................................................................... E

Cargo Heat ..................................................................................................................................................... F

Cockpit Lights.......................................................................................................................................................... G

ECAM.......................................................................................................................................................................H

FMGS Pre-Initialization............................................................................................................................................. I

EFB........................................................................................................................................................................... J

Before Walkaround.................................................................................................................................................. K

PRO-NOR-SOP-05 Exterior Walkaround

General.....................................................................................................................................................................A

Exterior Walkaround................................................................................................................................................ B

PRO-NOR-SOP-06 Cockpit Preparation

Introduction...............................................................................................................................................................A

Overhead Panel....................................................................................................................................................... B

CTR Instrument Panel.............................................................................................................................................C

Pedestal................................................................................................................................................................... D

RMP......................................................................................................................................................................... E

ACARS..................................................................................................................................................................... F

FMGS Preparation...................................................................................................................................................G

Continued on the following page

GLG A318/A319/A320/A321 For A/C: HC-CLF PRO-NOR-PLP-TOC P 1/8

FCOM 05 SEP 17

PROCEDURES

NORMAL PROCEDURES

A318/A319/A320/A321

FLIGHT CREW PRELIMINARY PAGES - TABLE OF CONTENTS

OPERATING MANUAL

Continued from the previous page

Glareshield............................................................................................................................................................... H

Lateral Consoles....................................................................................................................................................... I

Instrument Panels.....................................................................................................................................................J

ECAM Control Panel............................................................................................................................................... K

ADIRS.......................................................................................................................................................................L

Takeoff Briefing....................................................................................................................................................... M

PC Dedicated to Maintenance ....................................................................................................................... N

Flow Pattern............................................................................................................................................................ O

PRO-NOR-SOP-07 Before Pushback or Start

Before Start Clearance............................................................................................................................................ A

At Start Clearance................................................................................................................................................... B

PRO-NOR-SOP-08 Engine Start

Automatic Engine Start............................................................................................................................................A

Ground Run Up - Danger Areas............................................................................................................................. B

PRO-NOR-SOP-09 After Start

After Start.................................................................................................................................................................A

PRO-NOR-SOP-10 Taxi

Taxi...........................................................................................................................................................................A

PRO-NOR-SOP-11 Before Takeoff

Before Takeoff......................................................................................................................................................... A

PRO-NOR-SOP-12 Takeoff

Takeoff..................................................................................................................................................................... A

PRO-NOR-SOP-13 After Takeoff

After Takeoff............................................................................................................................................................ A

PRO-NOR-SOP-14 Climb

Climb........................................................................................................................................................................ A

PRO-NOR-SOP-15 Cruise

Cruise....................................................................................................................................................................... A

PRO-NOR-SOP-16 Descent Preparation

Descent Preparation................................................................................................................................................ A

Continued on the following page

GLG A318/A319/A320/A321 For A/C: HC-CLF PRO-NOR-PLP-TOC P 2/8

FCOM 05 SEP 17

PROCEDURES

NORMAL PROCEDURES

A318/A319/A320/A321

FLIGHT CREW PRELIMINARY PAGES - TABLE OF CONTENTS

OPERATING MANUAL

Continued from the previous page

PRO-NOR-SOP-17 Descent

Descent Initiation..................................................................................................................................................... A

Descent Monitoring.................................................................................................................................................. B

Descent Adjustment.................................................................................................................................................C

Approach Checklist..................................................................................................................................................D

10 000 ft Flow Pattern.............................................................................................................................................E

PRO-NOR-SOP-18 Approach

PRO-NOR-SOP-18-A Approach General

Introduction...............................................................................................................................................................A

Cross-Reference Table............................................................................................................................................B

Flying Reference......................................................................................................................................................C

Stabilization Criteria.................................................................................................................................................D

Approach Speed Technique.................................................................................................................................... E

Discontinued Approach............................................................................................................................................ F

PRO-NOR-SOP-18-B Aircraft Configuration Management

Initial Approach........................................................................................................................................................ A

Intermediate/Final Approach....................................................................................................................................B

PRO-NOR-SOP-18-C Aircraft Guidance Management

Approach using LOC G/S Guidance....................................................................................................................... A

Approach using FINAL APP Guidance................................................................................................................... B

Approach using FPA Guidance...............................................................................................................................C

Circling Approach.................................................................................................................................................... D

RNAV Visual Approach........................................................................................................................................... E

Visual Approach....................................................................................................................................................... F

PRO-NOR-SOP-19 Landing

Manual Landing....................................................................................................................................................... A

Autoland................................................................................................................................................................... B

PRO-NOR-SOP-20 Go-Around

Go Around with FD..................................................................................................................................................A

PRO-NOR-SOP-21 After Landing

After Landing............................................................................................................................................................A

PRO-NOR-SOP-22 Parking

Parking..................................................................................................................................................................... A

Continued on the following page

GLG A318/A319/A320/A321 For A/C: HC-CLF PRO-NOR-PLP-TOC P 3/8

FCOM 05 SEP 17

PROCEDURES

NORMAL PROCEDURES

A318/A319/A320/A321

FLIGHT CREW PRELIMINARY PAGES - TABLE OF CONTENTS

OPERATING MANUAL

Continued from the previous page

PRO-NOR-SOP-23 Securing the Aircraft

Securing the Aircraft................................................................................................................................................ A

PRO-NOR-SOP-90 Standard Callouts

Communications and Standard Terms....................................................................................................................A

Checklist Callouts.................................................................................................................................................... B

Actions Commanded by PF.................................................................................................................................... C

FMA..........................................................................................................................................................................D

Altitude..................................................................................................................................................................... E

Flaps or Gear Callouts............................................................................................................................................ F

Flight Parameters.................................................................................................................................................... G

PF/PM Duties Transfer............................................................................................................................................H

Summary for Each Phase.........................................................................................................................................I

PRO-NOR-SUP Supplementary Procedures

PRO-NOR-SUP-SUP Supplementary Procedures Menu

Supplementary Procedures..................................................................................................................................... A

PRO-NOR-SUP-ADVWXR Adverse Weather

Airframe Deicing/Anti-Icing Procedure on Ground.................................................................................................. A

Ground Operations in Cold Weather Conditions.....................................................................................................B

Ground Operations in Heavy Rain..........................................................................................................................C

Minimum Speed with Ice Accretion.........................................................................................................................D

Operations on Contaminated Airports..................................................................................................................... E

Operations with Volcanic Ash, Sand or Dust.......................................................................................................... F

Securing the Aircraft for Cold Soak........................................................................................................................ G

For Draining Water Procedure................................................................................................................................ H

Water System Draining............................................................................................................................................. I

PRO-NOR-SUP-COM Communication

VHF, HF Utilization.................................................................................................................................................. A

Continued on the following page

GLG A318/A319/A320/A321 For A/C: HC-CLF PRO-NOR-PLP-TOC P 4/8

FCOM 05 SEP 17

PROCEDURES

NORMAL PROCEDURES

A318/A319/A320/A321

FLIGHT CREW PRELIMINARY PAGES - TABLE OF CONTENTS

OPERATING MANUAL

Continued from the previous page

PRO-NOR-SUP-ENG Engines

Manual Engine Start................................................................................................................................................ A

Engine Start with External Pneumatic Power......................................................................................................... B

Crossbleed Engine Start......................................................................................................................................... C

Engine Start Valve Manual Operation.....................................................................................................................D

Engine Ventilation (Dry Cranking)........................................................................................................................... E

One Engine Taxi - General..................................................................................................................................... F

One Engine Taxi - At Departure.............................................................................................................................G

One Engine Taxi - At Arrival...................................................................................................................................H

PRO-NOR-SUP-FUEL Fuel

Refueling.................................................................................................................................................................. A

Refueling with One Engine Running....................................................................................................................... B

Ground Fuel Transfer.............................................................................................................................................. C

Defueling.................................................................................................................................................................. D

PRO-NOR-SUP-LG L/G

PRO-NOR-SUP-LG-LG_DN Flight with Landing Gear Down

General.....................................................................................................................................................................A

Limitations................................................................................................................................................................ B

Procedures...............................................................................................................................................................C

Takeoff..................................................................................................................................................................... D

Flight Planning......................................................................................................................................................... E

Climb........................................................................................................................................................................ F

Cruise.......................................................................................................................................................................G

Holding..................................................................................................................................................................... H

Descent......................................................................................................................................................................I

Go-Around................................................................................................................................................................ J

One Engine Inoperative...........................................................................................................................................K

PRO-NOR-SUP-LG-LG Operation with Nosewheel Steering Offset

Operation with Nosewheel Steering Offset............................................................................................................. A

PRO-NOR-SUP-MISC Miscellaneous

PRO-NOR-SUP-MISC-D Pushback with Power Push Unit

Pushback with Power Push Unit Via the Main Landing Gear.................................................................................A

PRO-NOR-SUP-MISC-A Hight Altitude Airport Operations

High Altitude Airport Operations..............................................................................................................................A

Continued on the following page

GLG A318/A319/A320/A321 For A/C: HC-CLF PRO-NOR-PLP-TOC P 5/8

FCOM 05 SEP 17

PROCEDURES

NORMAL PROCEDURES

A318/A319/A320/A321

FLIGHT CREW PRELIMINARY PAGES - TABLE OF CONTENTS

OPERATING MANUAL

Continued from the previous page

PRO-NOR-SUP-NAV Navigation

Insertion of Approach Minima..................................................................................................................................A

PRO-NOR-SUP-SURV Surveillance

Enhanced Ground Proximity Warning System (EGPWS)....................................................................................... A

PRO-NOR-SRP Systems Related Procedures

PRO-NOR-SRP-01 FMS

PRO-NOR-SRP-01-05 Introduction

Introduction...............................................................................................................................................................A

PRO-NOR-SRP-01-10 Cockpit Preparation

FMGS Initialization...................................................................................................................................................A

Flight Plan Initialization............................................................................................................................................B

FMGS Data Insertion...............................................................................................................................................C

FMGS Re-Initialization After a Canceled Flight...................................................................................................... D

PRO-NOR-SRP-01-15 Before Pushback or Start

Change of Runway.................................................................................................................................................. A

TAKEOFF FROM INTERSECTION.........................................................................................................................B

PRO-NOR-SRP-01-20 Taxi

FCU Selection for Takeoff.......................................................................................................................................A

FMA Mode Check....................................................................................................................................................B

Selecting a Navigation Display................................................................................................................................C

Selecting Takeoff Displays for Pilot's and Copilot's MCDU.................................................................................... D

PRO-NOR-SRP-01-30 Takeoff

Monitoring the Takeoff.............................................................................................................................................A

PRESELECTING A HDG OR A TRK......................................................................................................................B

Normal Takeoff Profile.............................................................................................................................................C

No Flight Director Takeoff....................................................................................................................................... D

TAKEOFF WITH NO V2 ENTRY............................................................................................................................ E

Takeoff Using the Localizer of the Opposite Runway.............................................................................................F

PRO-NOR-SRP-01-40 Climb

Monitoring the Climb Phase.................................................................................................................................... A

Immediate Return to Origin Airport......................................................................................................................... B

Continued on the following page

GLG A318/A319/A320/A321 For A/C: HC-CLF PRO-NOR-PLP-TOC P 6/8

FCOM 05 SEP 17

PROCEDURES

NORMAL PROCEDURES

A318/A319/A320/A321

FLIGHT CREW PRELIMINARY PAGES - TABLE OF CONTENTS

OPERATING MANUAL

Continued from the previous page

PRO-NOR-SRP-01-50 Cruise

Reaching Cruise Flight Level.................................................................................................................................. A

Monitoring the Navigation Accuracy........................................................................................................................B

Monitoring the Fuel Predictions...............................................................................................................................C

Entering a Step Climb or a Step Descent.............................................................................................................. D

Immediate Change of Level in Cruise.....................................................................................................................E

Preparation for Descent and Approach................................................................................................................... F

PRO-NOR-SRP-01-60 Descent

DESCENT INITIATION............................................................................................................................................ A

Descent Monitoring.................................................................................................................................................. B

Expedite Descent (If installed)................................................................................................................................ C

Monitoring the Navigation in the Terminal Control Area.........................................................................................D

Too Steep Path........................................................................................................................................................E

Holding Pattern........................................................................................................................................................ F

MANUAL TERMINATION........................................................................................................................................G

PRO-NOR-SRP-01-70 Approach

Initial Approach........................................................................................................................................................ A

ILS/MLS/GLS/FLS Approach................................................................................................................................... B

Switching from Non ILS to ILS Approach............................................................................................................... C

Landing Categories..................................................................................................................................................D

Warnings for ILS Approach..................................................................................................................................... E

PRO-NOR-SRP-01-80 Go-Around

MONITORING THE GO-AROUND..........................................................................................................................A

Go-Around Profile.................................................................................................................................................... B

Missed Approach: Try Again...................................................................................................................................C

Missed Approach: Divert......................................................................................................................................... D

Task Sharing During a Go-Around..........................................................................................................................E

GLG A318/A319/A320/A321 For A/C: HC-CLF PRO-NOR-PLP-TOC P 7/8

FCOM 05 SEP 17

PROCEDURES

NORMAL PROCEDURES

A318/A319/A320/A321

FLIGHT CREW PRELIMINARY PAGES - TABLE OF CONTENTS

OPERATING MANUAL

Intentionally left blank

GLG A318/A319/A320/A321 For A/C: HC-CLF PRO-NOR-PLP-TOC P 8/8

FCOM 05 SEP 17

PROCEDURES

NORMAL PROCEDURES

A318/A319/A320/A321

FLIGHT CREW STANDARD OPERATING PROCEDURES - GENERAL INFORMATION

OPERATING MANUAL

FOREWORD

Ident.: PRO-NOR-SOP-01-00010142.0001001 / 02 MAY 17

Applicable to: ALL

The procedures contained in this Chapter are recommended by Airbus, and are consistent with the

other Chapters of this manual.

The Authorities do not certificate Standard Operating Procedures. The manufacturer presents them

herein as the best way to proceed, from a technical and operational standpoint. They are continually

updated and the revisions take into account Operator input, as well as manufacturer experience.

In addition, Operators may amend them, as needed. However, the manufacturer recommends that

Operators using the FCOM as onboard operational manual submit suggested changes to expedite

publication, and maintain consistency of the manual. The Operator should note that they may rewrite

this Chapter, at their own responsibility; this could, however, make it difficult to update the manual

and keep it consistent with the other Chapters.

The following sections contain expanded information on normal procedures.

Standard Operating Procedures consist of inspections, preparations, and normal procedures. All

items of a given procedure are listed in a sequence that follows a standardized scan of the cockpit

panels, unless that sequence goes against the action priority logic, to ensure that all actions are

performed in the most efficient way.

These procedures assume that all systems are operating normally, and that all automatic functions

are used normally.

The FCOM also contains normal procedures that are non-routine procedures in the Supplementary

Procedures chapter and in the Special Operations chapter.

GLG A318/A319/A320/A321 For A/C: HC-CLF PRO-NOR-SOP-01 P 1/2

FCOM A 19 JUN 17

PROCEDURES

NORMAL PROCEDURES

A318/A319/A320/A321

FLIGHT CREW STANDARD OPERATING PROCEDURES - GENERAL INFORMATION

OPERATING MANUAL

Intentionally left blank

GLG A318/A319/A320/A321 For A/C: HC-CLF PRO-NOR-SOP-01 P 2/2

FCOM 19 JUN 17

PROCEDURES

NORMAL PROCEDURES

A318/A319/A320/A321

FLIGHT CREW STANDARD OPERATING PROCEDURES - FLIGHT PREPARATION

OPERATING MANUAL

TECHNICAL CONDITION OF THE AIRCRAFT

Ident.: PRO-NOR-SOP-02-00010147.0001001 / 05 AUG 10

Applicable to: ALL

The crew will verify the technical state of the aircraft (deferred defect list), with regard to

airworthiness, acceptability of malfunctions (MEL), and influence on the flight plan.

WEATHER BRIEFING

Ident.: PRO-NOR-SOP-02-00010148.0001001 / 05 AUG 10

Applicable to: ALL

‐ The crew will get a weather briefing

‐ The briefing should include:

• Actual and expected weather conditions, including runway conditions for takeoff and climb-out

• Significant weather enroute, including winds and temperatures

• Terminal forecasts for destination and alternate airports

• Actual weather for destination and alternates, for short range flights and recent past weather, if

available

• Survey of the meteorological conditions at airports along the planned route.

Weather can affect the choice of routing (for example, influence which route is quickest) and

the choice of flight level. The flight crew must also consider the possibility of runways being

contaminated at the departure and destination airfields. The flight crew must also verify ISA

deviations and enroute icing conditions, and must consider the possibility of holding due to weather

at the destination.

NOTAMS

Ident.: PRO-NOR-SOP-02-00010149.0002001 / 29 MAY 13

Applicable to: ALL

‐ The flight crew must examine NOTAMs for changes to routings, unserviceable navaids, availability

of runways and approach aids etc, all of which may affect the final fuel requirement

‐ In order to prevent the risks of projection of debris towards the trimmable horizontal stabilizer

and the elevators, it is not recommended to takeoff from runways in bad condition (loose surface,

under repair, covered with debris...)

GLG A318/A319/A320/A321 For A/C: HC-CLF PRO-NOR-SOP-02 P 1/4

FCOM A to C 22 MAR 17

PROCEDURES

NORMAL PROCEDURES

A318/A319/A320/A321

FLIGHT CREW STANDARD OPERATING PROCEDURES - FLIGHT PREPARATION

OPERATING MANUAL

GPS PRIMARY AVAILABILITY (IF INSTALLED)

Ident.: PRO-NOR-SOP-02-00014998.0001001 / 20 MAR 17

Applicable to: ALL

For RNP1 operations, RNAV(GNSS) approaches and RNAV (RNP) approaches:

If required by operational regulation, an appropriate Ground-Based Prediction Program should

be used to check the RAIM/AIME for each intended procedure (arrival, departure, alternate if

required).

FLIGHT PLAN AND OPERATIONAL REQUIREMENTS

Ident.: PRO-NOR-SOP-02-00010150.0001001 / 18 MAR 11

Applicable to: ALL

‐ The crew will check the company flight plan for routing, altitudes, and flight time

‐ The Captain will check the ATC flight plan and ensure that:

• It is filled in and filed, in accordance with the prescribed procedures

• It agrees with the fuel flight plan routing.

‐ The crew will check the estimated load figures, and will calculate the maximum allowable takeoff

and landing weights.

OPTIMUM FLIGHT LEVEL

Ident.: PRO-NOR-SOP-02-00010151.0001001 / 22 MAR 17

Applicable to: ALL

The flight crew should choose a flight level that is as close to the optimum as possible. To determine

the optimum flight level, Refer to QRH/PER-M Optimum & Maximum Altitudes (Paper Only) or use

the performance application of FlySmart with Airbus.

As a general rule, an altitude that is 4 000 ft below the optimum produces a significant penalty

(approximately 5 % of fuel). Flight 8 000 ft below the optimum altitude produces a penalty of more

than 10 % against trip fuel. (The usual contingency allowance is 5 %).

FUEL REQUIREMENTS

Ident.: PRO-NOR-SOP-02-00010152.0001001 / 05 AUG 10

Applicable to: ALL

COMPUTERIZED FLIGHT PLAN CHECK

In most cases the flight crew uses a computer-derived flight plan to obtain the correct fuel

requirements. Although these computerized requirements are normally accurate, the flight crew

must check them for gross errors.

The easiest way to do this is to use the “Quick Determination of F-PLN ” tables (Refer to

PER-FPL-FLP-QFP-40 FLIGHT PLANNING M.78). Although the aircraft will fly at ECON MACH

GLG A318/A319/A320/A321 For A/C: HC-CLF PRO-NOR-SOP-02 P 2/4

FCOM D to G → 22 MAR 17

PROCEDURES

NORMAL PROCEDURES

A318/A319/A320/A321

FLIGHT CREW STANDARD OPERATING PROCEDURES - FLIGHT PREPARATION

OPERATING MANUAL

that is based on the cost index, the M 0.78 table is accurate enough to permit the crew to check for

gross error.

Ensure that both the captain and the first officer have verified that the fuel calculations and

required fuel on board are correct and that the figure complies with the applicable regulations.

FUEL TRANSPORTATION

The flight crew must check the policy covering the “tankering” of fuel on sectors where there is a

favourable fuel price differential or operational requirement.

Remember that carrying unnecessary extra fuel increases the fuel consumption for that sector and

therefore reduces the economy of the operation (lower flex temperature, more tire and brake wear,

more time in climb phase, lower optimum flight level etc).

GLG A318/A319/A320/A321 For A/C: HC-CLF PRO-NOR-SOP-02 P 3/4

FCOM ←G 22 MAR 17

PROCEDURES

NORMAL PROCEDURES

A318/A319/A320/A321

FLIGHT CREW STANDARD OPERATING PROCEDURES - FLIGHT PREPARATION

OPERATING MANUAL

Intentionally left blank

GLG A318/A319/A320/A321 For A/C: HC-CLF PRO-NOR-SOP-02 P 4/4

FCOM 22 MAR 17

PROCEDURES

NORMAL PROCEDURES

A318/A319/A320/A321 STANDARD OPERATING PROCEDURES

FLIGHT CREW

OPERATING MANUAL - SAFETY EXTERIOR INSPECTION

SAFETY EXTERIOR INSPECTION

Applicable to: ALL

Ident.: PRO-NOR-SOP-03-A-00010153.0001001 / 05 AUG 10

Items marked by (*) are the only steps to be completed during a transit stop.

This inspection ensures that the aircraft and its surroundings are safe for operations.

On arriving at the aircraft, check for obstructions in the vicinity, engineering activity, refueling, etc.

Ident.: PRO-NOR-SOP-03-A-00010154.0001001 / 04 MAR 14

* WHEEL CHOCKS.................................................................................................................. CHECK

If the wheel chocks are not in position, the flight crew must check that the parking brake is set with

sufficient accumulator pressure.

Ident.: PRO-NOR-SOP-03-A-00010155.0001001 / 18 MAR 11

* LANDING GEAR DOORS....................................................................................CHECK POSITION

WARNING Do not pressurize the green hydraulic system without clearance from ground

personnel, if any gear door is open. Remember that the green hydraulic system is

pressurized if the yellow system is pressurized and the PTU is on AUTO.

Ident.: PRO-NOR-SOP-03-A-00010156.0001001 / 05 AUG 10

* APU AREA............................................................................................................................. CHECK

Observe that the APU inlet and outlet are clear.

GLG A318/A319/A320/A321 For A/C: HC-CLF PRO-NOR-SOP-03 P 1/2

FCOM A 24 JAN 17

PROCEDURES

NORMAL PROCEDURES

A318/A319/A320/A321 STANDARD OPERATING PROCEDURES

FLIGHT CREW

OPERATING MANUAL - SAFETY EXTERIOR INSPECTION

Intentionally left blank

GLG A318/A319/A320/A321 For A/C: HC-CLF PRO-NOR-SOP-03 P 2/2

FCOM 24 JAN 17

PROCEDURES

NORMAL PROCEDURES

A318/A319/A320/A321 STANDARD OPERATING PROCEDURES

FLIGHT CREW

OPERATING MANUAL - PRELIMINARY COCKPIT PREPARATION

GENERAL

Ident.: PRO-NOR-SOP-04-00010164.0001001 / 20 MAR 17

Applicable to: ALL

Items marked by asterisks (*) are the only steps to be completed after a transit stop without flight

crew change. Otherwise, the new flight crew performs all the items.

The following procedure, performed by the PM, ensures that all the required checks are performed

before applying electrical power to avoid inadvertent operation of systems and danger to the aircraft

and personnel.

Included is APU starting and the establishment of electrical and pneumatic power.

For EFB operations, the following procedure performed by both pilots is based on the use of two

EFBs/eQRH in order to reduce the risk of erroneous inputs.

Airbus recommends operating with two EFBs.

DOCUMENTATION AND MAINTENANCE

On entering the aircraft, obtain the technical (maintenance) log and verify that the certificate of

maintenance and daily inspection (or similar) are up to date and signed. Check the deferred or

carried-forward defects. If refueling has already been completed, check the uplift.

AIRCRAFT SETUP

Applicable to: ALL

Ident.: PRO-NOR-SOP-04-A-00021906.0001001 / 30 AUG 17

WARNING Do not pressurize the hydraulic systems until clearance is obtained from ground

personnel.

Ident.: PRO-NOR-SOP-04-A-00010165.0001001 / 03 MAR 14

ENG

ENG MASTERS 1, 2................................................................................................................... OFF

ENG MODE selector................................................................................................................NORM

Ident.: PRO-NOR-SOP-04-A-00011188.0001001 / 22 APR 16

*WEATHER RADAR

* RADAR sw ..............................................................................................................................OFF

* WINDSHEAR / PWS sw .................................................................................................. OFF

* GAIN knob ................................................................................................................... AUTO/CAL

* MODE selector ..............................................................................................................AS RQRD

GLG A318/A319/A320/A321 For A/C: HC-CLF PRO-NOR-SOP-04 P 1/10

FCOM A to B → 05 SEP 17

PROCEDURES

NORMAL PROCEDURES

A318/A319/A320/A321 STANDARD OPERATING PROCEDURES

FLIGHT CREW

OPERATING MANUAL - PRELIMINARY COCKPIT PREPARATION

Ident.: PRO-NOR-SOP-04-A-00010166.0001001 / 03 MAR 14

L/G

L/G lever.................................................................................................................................. DOWN

Ident.: PRO-NOR-SOP-04-A-00010167.0001001 / 03 MAR 14

WIPERS

Both WIPER selectors................................................................................................................. OFF

BATTERY CHECK/SETUP

Ident.: PRO-NOR-SOP-04-00010168.0001001 / 30 AUG 17

Applicable to: ALL

If the aircraft has not been electrically supplied for 6 h or more, perform the following

check:

BAT 1 pb and BAT 2 pb......................................................................................... CHECK OFF

BAT 1 and 2 VOLTAGE......................................................................... CHECK ABOVE 25.5 V

Battery voltage above 25.5 V ensures a charge above 50 %.

If the battery voltage is at or below 25.5 V:

A charging cycle of about 20 min is required.

BAT 1 pb and BAT 2 pb..............................................................................................AUTO

EXT PWR pb-sw.............................................................................................................. ON

Check on ELEC SD page, that the battery contactor is closed and the batteries are

charging.

After 20 min:

BAT 1 + 2 pb........................................................................................................... OFF

BAT 1 and 2 VOLTAGE............................................................ CHECK ABOVE 25.5 V

BAT 1 + 2 pb........................................................................................................ AUTO

If the battery voltage is above 25.5 V:

BAT 1 pb and BAT 2 pb..............................................................................................AUTO

If the APU is started on batteries only, it should be started within 30 min after the selection

of batteries to AUTO (35 min after battery selection to AUTO, the battery charge is less

than 25 % of maximum capacity).

If the aircraft has been electrically supplied during the last 6 h:

BAT 1 pb and BAT 2 pb.................................................................................................... AUTO

GLG A318/A319/A320/A321 For A/C: HC-CLF PRO-NOR-SOP-04 P 2/10

FCOM ← B to C → 05 SEP 17

PROCEDURES

NORMAL PROCEDURES

A318/A319/A320/A321 STANDARD OPERATING PROCEDURES

FLIGHT CREW

OPERATING MANUAL - PRELIMINARY COCKPIT PREPARATION

If the AVAIL light is on:

EXT PWR pb-sw.....................................................................................................................ON

APU FIRE TEST/APU START

Applicable to: ALL

Ident.: PRO-NOR-SOP-04-B-00010170.0001001 / 07 JUN 16

APU FIRE

APU FIRE pb-sw.....................................................................................CHECK IN and GUARDED

AGENT lights ................................................................................................................CHECK OFF

APU FIRE TEST pb...................................................................................... PRESS and MAINTAIN

Check :

‐ APU FIRE warning on ECAM + CRC + MASTER WARN light (if AC Power available).

‐ APU FIRE pb-sw lighted red.

‐ SQUIB light and DISCH light on

Ident.: PRO-NOR-SOP-04-B-00010171.0015001 / 17 MAR 17

APU START

If the EXT PWR pb-sw ON light is on:

APU MASTER SW pb-sw ..................................................................................................... ON

APU START pb-sw ................................................................................................................ON

Note: Wait at least 3 s before selecting APU START pb-sw.

For more information on the APU start, Refer to DSC-49-20 Overhead Panel - Illustration.

For more information on APU starter limitations and APU operations during refueling:

‐ Refer to LIM-APU APU Start

‐ Refer to LIM-APU APU Start/Shutdown during Refueling/Defueling.

EXT PWR pb-sw ........................................................................................................ AS RQRD

The flight crew should keep ON the external power units to reduce the APU load, particularly

in hot weather conditions.

If the EXT PWR pb-sw ON light is off:

APU MASTER SW pb-sw ..................................................................................................... ON

APU START pb-sw ................................................................................................................ON

Note: Wait at least 3 s before selecting APU START pb-sw.

For more information on the APU start, Refer to DSC-49-20 Overhead Panel - Illustration.

GLG A318/A319/A320/A321 For A/C: HC-CLF PRO-NOR-SOP-04 P 3/10

FCOM ← C to D → 05 SEP 17

PROCEDURES

NORMAL PROCEDURES

A318/A319/A320/A321 STANDARD OPERATING PROCEDURES

FLIGHT CREW

OPERATING MANUAL - PRELIMINARY COCKPIT PREPARATION

For more information on APU starter limitations and APU operations during refueling:

‐ Refer to LIM-APU APU Start

‐ Refer to LIM-APU APU Start/Shutdown during Refueling/Defueling.

AIR COND

Ident.: PRO-NOR-SOP-04-00010177.0001001 / 14 OCT 15

Applicable to: ALL

AIR COND

When the APU is AVAIL:

APU BLEED pb-sw................................................................................................................. ON

Do not use APU BLEED, if the ground personnel confirms that a LP or HP ground air unit is

connected to the aircraft.

To determine if an HP ground air unit is connected, the flight crew should also check on the

BLEED SD page, if there is pressure in the bleed air system.

ALL WHITE LIGHTS............................................................................................................. OFF

X BLEED selector.............................................................................................................. AUTO

Zone temperature selectors.........................................................................................AS RQRD

Full range temperature 24 ± 6 °C (75 ± 11 °F).

CARGO HEAT

Ident.: PRO-NOR-SOP-04-00010178.0001001 / 03 MAR 14

Applicable to: ALL

CARGO HEAT

TEMPERATURE selector ................................................................................................. AS RQRD

COCKPIT LIGHTS

Ident.: PRO-NOR-SOP-04-00010172.0002001 / 23 JUN 15

Applicable to: ALL

COCKPIT LIGHTS

* COCKPIT LIGHTS..........................................................................................................AS RQRD

Set INT LT, FLOOD LT, INTEG LT (included glareshield and FCU).

GLG A318/A319/A320/A321 For A/C: HC-CLF PRO-NOR-SOP-04 P 4/10

FCOM ← D to G 05 SEP 17

PROCEDURES

NORMAL PROCEDURES

A318/A319/A320/A321 STANDARD OPERATING PROCEDURES

FLIGHT CREW

OPERATING MANUAL - PRELIMINARY COCKPIT PREPARATION

ECAM

Ident.: PRO-NOR-SOP-04-00010204.0001001 / 04 SEP 17

Applicable to: ALL

* ECAM

* RCL pb ........................................................................................................................PRESS 3 s

This action recalls all the warnings that the flight crew cleared or cancelled during the last flight.

* Check MEL if required.

On the DOOR SD page:

* OXY ....................................................................................................... CHECK PRESSURE

If the OXY pressure is half boxed in amber:

MIN FLT CREW OXY CHART............................................................. CHECK PRESSURE

Verify that the pressure is sufficient for the scheduled flight (Refer to LIM-OXY Minimum

Flight Crew Oxygen Pressure).

On the HYD SD page:

* RESERVOIR FLUID LEVEL................................................CHECK WITH NORMAL RANGE

Note: The volume of the hydraulic fluid in the reservoirs may change with Outside Air

Temperature. As a result, the reservoir fluid level that appears on the HYD SD page

may be outside of the normal range with no HYD RSVR LO AIR PR or HYD RSVR LO

LVL warning. If the fluid level is outside of the normal range, contact maintenance to

determine if service is required.

On the ENG SD page:

* ENG OIL QUANTITY.................................................................................. CHECK NORMAL

Check that the oil quantity is at or above 9.5 qt + estimated consumption (average estimated

consumption ~ 0.5 qt/h).

FMGS PRE-INITIALIZATION

Applicable to: ALL

Ident.: PRO-NOR-SOP-04-C-00014422.0001001 / 20 MAR 17

Perform FMGS Pre-Initialization in the case of ACARS operations, or EFB operations with

SYNCHRO AVIONICS .

At electrical power-up, the FMGS s and FCU run through various internal tests. Allow enough time

(3 min) for tests’ completion, and do not start to press pushbuttons until the tests are over. If the

“PLEASE WAIT” message appears, do not press any MCDU key until the message clears.

* FLT NBR................................................................................................................................ INSERT

* FROM/TO...............................................................................................................................INSERT

GLG A318/A319/A320/A321 For A/C: HC-CLF PRO-NOR-SOP-04 P 5/10

FCOM H to I 05 SEP 17

PROCEDURES

NORMAL PROCEDURES

A318/A319/A320/A321 STANDARD OPERATING PROCEDURES

FLIGHT CREW

OPERATING MANUAL - PRELIMINARY COCKPIT PREPARATION

EFB

Applicable to: ALL

Ident.: PRO-NOR-SOP-04-F-00021232.0001001 / 21 MAR 17

EFB/EQRH START

ALL EFB/eQRH....................................................................................................................... START

In accordance with the Operator's policy or if required by operational regulation:

EFB/eQRH VERSION......................................................................................................CHECK

If required, the flight crew performs this check unless a specific procedure is established as

per Operator's policy to ensure that the correct version is onboard.

On the EFB STATUS page and the eQRH My aircraft page, check the EFB VERSION number

and compare it with the valid version number given as reference by the Operator (e.g. on the

company flight plan).

*OPERATION ENGINEERING BULLETINS (OEB)

* OEB in eQRH.....................................................................................................................CHECK

Go to the OEB section of the eQRH and review all OEB s (particularly red OEBs) that are

applicable to the aircraft.

Note: If there is a transfer of duties during this flight, the flight crew must remind the incoming

flight crew of the applicable OEB(s) during the briefing that is done when transferring the

duties.

* EFB SYNCHRO AVIONICS ......................................................................................... CLICK

Each flight crewmember checks (if retrieved from FMS) or enters:

‐ Aircraft Type

‐ Aircraft Registration

‐ Flight Number

‐ The departure and arrival airports

Both flight crewmembers crosscheck all the data.

REQUIRED APPLICATIONS.................................................................................................. START

Ident.: PRO-NOR-SOP-04-F-00021234.0001001 / 20 MAR 17

*ECAM/LOGBOOK CHECK

* RCL pb......................................................................................................................... PRESS 3 s

This action recalls all the warnings that the flight crew cleared or cancelled during the last flight

* Check MEL if required.

GLG A318/A319/A320/A321 For A/C: HC-CLF PRO-NOR-SOP-04 P 6/10

FCOM J→ 05 SEP 17

PROCEDURES

NORMAL PROCEDURES

A318/A319/A320/A321 STANDARD OPERATING PROCEDURES

FLIGHT CREW

OPERATING MANUAL - PRELIMINARY COCKPIT PREPARATION

* LOGBOOK or EFB E-LOGBOOK ...............................................................................CHECK

‐ In the logbook or EFB e-logbook, check the technical condition of the aircraft (deferred defect

list) with regard to airworthiness, acceptability of the MEL , or the Configuration Deviation List

(CDL), and influence on the flight plan.

‐ Crosscheck with ECAM recall.

* MEL /CDL ITEMS (as appropriate)......................................... CHECK DISPATCH CONDITIONS

Access the MEL and CDL items via the Ops Library Browser.

* MEL ITEMS (as appropriate)........................................................................................ ACTIVATE

As appropriate, the activated MEL items are sent to the applicable performance applications.

* CDL ITEMS (as appropriate)................................................................ ACTIVATE & COMPLETE

Complete missing items of CDL items. As appropriate, the activated CDL items are sent to the

applicable performance applications.

* AIRCRAFT ACCEPTANCE...........................................................................................PERFORM

Ident.: PRO-NOR-SOP-04-F-00021233.0001001 / 20 MAR 17

*PRELIMINARY PERFORMANCE DATA CALCULATION

Each flight crewmember independently computes the preliminary performance data in accordance

with the technical condition of the aircraft and/or any other criteria that may impact the aircraft

performance (e.g. NOTAM, runway condition, aircraft configuration).

* AIRFIELD DATA................................................................................................................ OBTAIN

Obtain data needed for initializing the system, preparing the cockpit and for preliminary takeoff

performance computation. The airfield data should include: RUNWAY IN USE, ALTIMETER

SETTING, and WEATHER DATA.

If the LOADSHEET application is used :

PRELIMINARY LOADING.......................................................COMPUTE AND CROSSCHECK

If dispatch under MEL and in accordance with the logbook:

* MEL /CDL ITEMS (as appropriate)........................................................ CHECK ACTIVATED

As appropriate, check that the MEL and CDL items are activated in the applicable

performance application.

PRELIMINARY TAKEOFF PERF.................................................. COMPUTE AND CROSSCHECK

GLG A318/A319/A320/A321 For A/C: HC-CLF PRO-NOR-SOP-04 P 7/10

FCOM ←J 05 SEP 17

PROCEDURES

NORMAL PROCEDURES

A318/A319/A320/A321 STANDARD OPERATING PROCEDURES

FLIGHT CREW

OPERATING MANUAL - PRELIMINARY COCKPIT PREPARATION

BEFORE WALKAROUND

Applicable to: ALL

Ident.: PRO-NOR-SOP-04-E-00010173.0001001 / 05 AUG 10

F/CTL

FLAPS.................................................................................................................. CHECK POSITION

Check the upper ECAM display to confirm that the FLAPS position agrees with the handle

position.

* SPEEDBRAKE lever........................................................ CHECK RETRACTED and DISARMED

WARNING If flight control surface positions do not agree with the control handle positions,

check with the maintenance crew before applying hydraulic power.

Ident.: PRO-NOR-SOP-04-E-00010174.0001001 / 18 MAY 16

* PARKING BRAKE

ACCU PRESS indicator......................................................................................................... CHECK

The ACCU PRESS indication must be in the green band. If required use the electric pump on

yellow hydraulic system to recharge the brake accumulator.

PARKING BRAKE handle............................................................................................................. ON

When one brake temperature is above 500 °C, avoid applying the parking brake, unless

operationally necessary.

BRAKES PRESS indicator.....................................................................................................CHECK

Check for normal indications.

WARNING Yellow and green hydraulic systems are pressurized from yellow electric pump.

Get ground crew clearance before using the electric pump.

Ident.: PRO-NOR-SOP-04-E-00010175.0001001 / 30 JUN 15

ALTERNATE BRAKING SYSTEM

Note: The purpose of this check is to verify, before the first flight of the day, the efficiency of the

alternate braking system (absence of “spongy pedals”).

Y ELEC PUMP pb-sw....................................................................................................CHECK OFF

CHOCKS.............................................................................................................. CHECK IN PLACE

PARK BRK handle.......................................................................................................................OFF

BRAKE PEDALS.....................................................................................................................PRESS

Apply maximum pressure on both pedals.

GLG A318/A319/A320/A321 For A/C: HC-CLF PRO-NOR-SOP-04 P 8/10

FCOM K→ 05 SEP 17

PROCEDURES

NORMAL PROCEDURES

A318/A319/A320/A321 STANDARD OPERATING PROCEDURES

FLIGHT CREW

OPERATING MANUAL - PRELIMINARY COCKPIT PREPARATION

BRAKE PRESSURE (on BRAKE press indicator)................................................................. CHECK

Pressure must build up without delay symmetrically on left and right sides for the same application

simultaneously applied on left and right pedals. With full pedal deflection, the pressure must be

between 2 000 and 2 700 PSI.

BRAKE PEDALS................................................................................................................ RELEASE

PARK BRK handle........................................................................................................................ ON

The parking brake must be on during the exterior inspection to allow the flight crew to check brake

wear indicators.

Ident.: PRO-NOR-SOP-04-E-00010206.0001001 / 23 JUN 15

EMERGENCY EQUIPMENT

EMER EQPT.......................................................................................................................... CHECK

Check the emergency equipments as follows:

‐ Life jackets stowed

‐ Axe stowed

‐ Smoke hoods or portable oxygen equipment and full face masks stowed and

serviceable

‐ Portable fire extinguisher lockwired and pressure in the green area

‐ Smoke goggles stowed (smoke hoods )

‐ Oxygen masks stowed

‐ Flashlights stowed

‐ Escape ropes stowed

Ident.: PRO-NOR-SOP-04-E-00010207.0001001 / 14 SEP 12

RAIN REPELLENT

RAIN RPLNT indicators.......................................................... CHECK PRESSURE and QUANTITY

CAUTION Never use rain repellent to wash the windshield and never use it on a dry

windshield.

Ident.: PRO-NOR-SOP-04-E-00010208.0001001 / 05 AUG 10

REAR AND OVERHEAD CIRCUIT BREAKERS PANELS

REAR and OVERHEAD CIRCUIT BREAKERS panels......................................................... CHECK

Check that all circuit breakers are set. Reset as necessary.

GLG A318/A319/A320/A321 For A/C: HC-CLF PRO-NOR-SOP-04 P 9/10

FCOM ←K→ 05 SEP 17

PROCEDURES

NORMAL PROCEDURES

A318/A319/A320/A321 STANDARD OPERATING PROCEDURES

FLIGHT CREW

OPERATING MANUAL - PRELIMINARY COCKPIT PREPARATION

Ident.: PRO-NOR-SOP-04-E-00010209.0001001 / 25 JAN 17

LANDING GEAR PINS AND COVERS

* GEAR PINS and COVERS..................................................... CHECK ONBOARD and STOWED

Check that three are on board and stowed.

GLG A318/A319/A320/A321 For A/C: HC-CLF PRO-NOR-SOP-04 P 10/10

FCOM ←K 05 SEP 17

PROCEDURES

NORMAL PROCEDURES

A318/A319/A320/A321

FLIGHT CREW STANDARD OPERATING PROCEDURES - EXTERIOR WALKAROUND

OPERATING MANUAL

GENERAL

Ident.: PRO-NOR-SOP-05-00010360.0001001 / 17 MAY 17

Applicable to: ALL

The exterior walkaround ensures that the general condition of the aircraft is satisfactory and that the

visible aircraft components and equipment are safe for the flight:

‐ There is no impact damage to the structure

‐ There is no evident fuel, oil, or hydraulic leak

‐ All ground access doors are closed.

The flight crew must perform a complete walkaround before each flight.

The parking brake must be set to ON during the exterior walkaround, in order to enable the flight

crew to check brake wear indicators.

WARNING If any landing gear door is open, do not apply hydraulic power until clearance is

obtained from ground personnel.

GLG A318/A319/A320/A321 For A/C: HC-CLF PRO-NOR-SOP-05 P 1/8

FCOM A 05 SEP 17

PROCEDURES

NORMAL PROCEDURES

A318/A319/A320/A321

FLIGHT CREW STANDARD OPERATING PROCEDURES - EXTERIOR WALKAROUND

OPERATING MANUAL

EXTERIOR WALKAROUND

Applicable to: ALL

Ident.: PRO-NOR-SOP-05-A-00010361.0001001 / 04 MAY 15

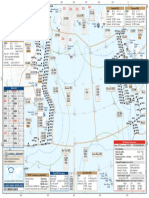

SCHEMATIC

(1) Refer to PRO-NOR-SOP-05 Exterior Walkaround - LH FWD Fuselage

GLG A318/A319/A320/A321 For A/C: HC-CLF PRO-NOR-SOP-05 P 2/8

FCOM B→ 05 SEP 17

PROCEDURES

NORMAL PROCEDURES

A318/A319/A320/A321

FLIGHT CREW STANDARD OPERATING PROCEDURES - EXTERIOR WALKAROUND

OPERATING MANUAL

(2) Refer to PRO-NOR-SOP-05 Exterior Walkaround - Nose Section

(3) Refer to PRO-NOR-SOP-05 Exterior Walkaround - Nose L/G

(4) Refer to PRO-NOR-SOP-05 Exterior Walkaround - RH FWD Fuselage

(5) Refer to PRO-NOR-SOP-05 Exterior Walkaround - Lower Center Fuselage

(6) Refer to PRO-NOR-SOP-05 Exterior Walkaround - RH Center Wing

(7) Refer to PRO-NOR-SOP-05 Exterior Walkaround - ENG 2 LH Side

(8) Refer to PRO-NOR-SOP-05 Exterior Walkaround - ENG 2 RH Side

(9) Refer to PRO-NOR-SOP-05 Exterior Walkaround - RH Wing Leading Edge

(10) Refer to PRO-NOR-SOP-05 Exterior Walkaround - RH Wing Trailing Edge

(11) Refer to PRO-NOR-SOP-05 Exterior Walkaround - RH L/G and Fuselage

(12) Refer to PRO-NOR-SOP-05 Exterior Walkaround - RH AFT Fuselage

(13) Refer to PRO-NOR-SOP-05 Exterior Walkaround - TAIL

(14) Refer to PRO-NOR-SOP-05 Exterior Walkaround - APU

(15) Refer to PRO-NOR-SOP-05 Exterior Walkaround - LH AFT Fuselage

(16) Refer to PRO-NOR-SOP-05 Exterior Walkaround - LH Landing Gear

(17) Refer to PRO-NOR-SOP-05 Exterior Walkaround - LH Wing Trailing Edge

(18) Refer to PRO-NOR-SOP-05 Exterior Walkaround - LH Wing Leading Edge

(19) Refer to PRO-NOR-SOP-05 Exterior Walkaround - ENG 1 LH Side

(20) Refer to PRO-NOR-SOP-05 Exterior Walkaround - ENG 1 RH Side

(21) Refer to PRO-NOR-SOP-05 Exterior Walkaround - LH Center Wing

Ident.: PRO-NOR-SOP-05-A-00010363.0001001 / 17 MAY 17

LH FWD FUSELAGE

AOA probes.................................................................................................................... CONDITION

F/O and CAPT static ports..................................................................................................... CLEAR

Avionics equipment vent air inlet valve.......................................................................... CONDITION

Oxygen bay.......................................................................................................................... CLOSED

Oxygen overboard discharge indicator.................................................................................. GREEN

Toilet servicing door ..................................................................................................... CLOSED

GLG A318/A319/A320/A321 For A/C: HC-CLF PRO-NOR-SOP-05 P 3/8

FCOM ←B→ 05 SEP 17

PROCEDURES

NORMAL PROCEDURES

A318/A319/A320/A321

FLIGHT CREW STANDARD OPERATING PROCEDURES - EXTERIOR WALKAROUND

OPERATING MANUAL

Ident.: PRO-NOR-SOP-05-A-00010364.0001001 / 17 MAY 17

NOSE SECTION

Pitot probes.....................................................................................................................CONDITION

STBY static ports.................................................................................................................... CLEAR

TAT probes..................................................................................................................... CONDITION

Radome and latches..................................................................................... CONDITION/LATCHED

Forward avionics compartment door....................................................................................CLOSED

Ground electrical power door (if not required.)....................................................................CLOSED

Ident.: PRO-NOR-SOP-05-A-00010365.0001001 / 17 MAY 17

NOSE L/G

Nose wheel chocks............................................................................................................ IN PLACE

Wheels and tires.............................................................................................................CONDITION

Nose gear structure........................................................................................................ CONDITION

Taxi, TO, turn-off lights...................................................................................................CONDITION

Hydraulic lines and electrical wires................................................................................ CONDITION

Wheel well.............................................................................................................................. CHECK

Safety pin.......................................................................................................................... REMOVED

Ident.: PRO-NOR-SOP-05-A-00010366.0001001 / 17 MAY 17

RH FWD FUSELAGE

RH + AFT avionic compartment doors................................................................................ CLOSED

Avionic equipment vent air outlet valve..........................................................................CONDITION

F/O -CAPT static ports........................................................................................................... CLEAR

AOA probe...................................................................................................................... CONDITION

Forward cargo door and selector panel.................................................................................CHECK

Ident.: PRO-NOR-SOP-05-A-00010367.0001001 / 20 DEC 16

LOWER CENTER FUSELAGE

Potable water drain panel ............................................................................................ CLOSED

Antennas......................................................................................................................... CONDITION

Drain mast.......................................................................................................................CONDITION

Emergency ram air inlet flap.......................................................................................... CONDITION

LP and HP ground connection doors.................................................................................. CLOSED

Anticollision light..................................................................................................................... CHECK

CTR TK magnetic fuel level....................................................................................................FLUSH

Pack air intakes and outlets................................................................................................... CLEAR

GLG A318/A319/A320/A321 For A/C: HC-CLF PRO-NOR-SOP-05 P 4/8

FCOM ←B→ 05 SEP 17

PROCEDURES

NORMAL PROCEDURES

A318/A319/A320/A321

FLIGHT CREW STANDARD OPERATING PROCEDURES - EXTERIOR WALKAROUND

OPERATING MANUAL

Ident.: PRO-NOR-SOP-05-A-00010368.0002001 / 17 MAY 17

RH CENTER WING

Yellow hydraulic bay door....................................................................................................CLOSED

Fuel panel.............................................................................................................................CLOSED

Inner tank magnetic fuel......................................................................................................... FLUSH

Fuel water drain valve inner tank....................................................................................... NO LEAK

Landing light....................................................................................................................CONDITION

Slat 1...............................................................................................................................CONDITION

Ident.: PRO-NOR-SOP-05-A-00010370.0015001 / 17 MAY 17

ENG 2 LH SIDE

Oil fill access door................................................................................................................CLOSED

Thrust reversers................................................................................................. CLOSED/LATCHED

Fan cowl doors................................................................................................... CLOSED/LATCHED

Drain mast......................................................................................................CONDITION/NO LEAK

Engine inlet and fan blades................................................................................................... CHECK

Ident.: PRO-NOR-SOP-05-A-00010371.0006001 / 17 MAY 17

ENG 2 RH SIDE

Vent inlet................................................................................................................................. CLEAR

Pressure-relief/Start valve handle access door................................................................... CLOSED

Thrust reversers................................................................................................. CLOSED/LATCHED

Fan cowl doors................................................................................................... CLOSED/LATCHED

Turbine exhaust ..................................................................................................................... CLEAR

Pylon/access panel......................................................................................... CONDITION/CLOSED

Ident.: PRO-NOR-SOP-05-A-00010372.0001001 / 17 MAY 17

RH WING LEADING EDGE

Slats 2, 3, 4, 5................................................................................................................ CONDITION

Inner and outer cells magnetic fuel level................................................................................FLUSH

Fuel water drain valve (outer cell, surge tank)................................................................... NO LEAK

Refuel coupling.....................................................................................................................CLOSED

Surge tank air inlet................................................................................................................. CLEAR

Fuel ventilation overpressure disc......................................................................................... INTACT

Navigation light.............................................................................................................. CONDITION

Wing tip........................................................................................................................... CONDITION

GLG A318/A319/A320/A321 For A/C: HC-CLF PRO-NOR-SOP-05 P 5/8

FCOM ←B→ 05 SEP 17

PROCEDURES

NORMAL PROCEDURES

A318/A319/A320/A321

FLIGHT CREW STANDARD OPERATING PROCEDURES - EXTERIOR WALKAROUND

OPERATING MANUAL

Ident.: PRO-NOR-SOP-05-A-00010373.0001001 / 01 SEP 17

RH WING TRAILING EDGE

Static dischargers................................................................................................................... CHECK

Control surfaces..............................................................................................................CONDITION

Flaps and fairings........................................................................................................... CONDITION

ANTENNAS ON TOP OF FUSELAGE............................................................. CHECK CONDITION

Ident.: PRO-NOR-SOP-05-A-00010374.0001001 / 17 MAY 17