0% found this document useful (0 votes)

101 views12 pagesArchitect's Building Specification

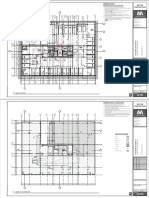

The document outlines the building specifications for new clubroom facilities for Drung GFC, detailing compliance with various regulations and standards. It includes specifications for site preparation, foundation construction, structural elements, insulation, damp proofing, and finishes. Additionally, it emphasizes the use of quality materials and adherence to health and safety regulations throughout the construction process.

Uploaded by

nandajoycesaCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

101 views12 pagesArchitect's Building Specification

The document outlines the building specifications for new clubroom facilities for Drung GFC, detailing compliance with various regulations and standards. It includes specifications for site preparation, foundation construction, structural elements, insulation, damp proofing, and finishes. Additionally, it emphasizes the use of quality materials and adherence to health and safety regulations throughout the construction process.

Uploaded by

nandajoycesaCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd