0% found this document useful (0 votes)

69 views6 pagesWorksheet II

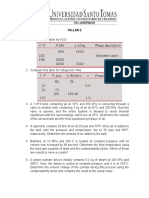

The document is a worksheet from Addis Ababa University focusing on various thermodynamic problems related to mechanical and industrial engineering. It includes questions on heat transfer, piston-cylinder devices, gas expansion, refrigeration systems, and energy calculations in different scenarios. Each problem requires the application of thermodynamic principles to determine various properties such as pressure, temperature, work done, and mass flow rates.

Uploaded by

ashenafi.henok-ugCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

69 views6 pagesWorksheet II

The document is a worksheet from Addis Ababa University focusing on various thermodynamic problems related to mechanical and industrial engineering. It includes questions on heat transfer, piston-cylinder devices, gas expansion, refrigeration systems, and energy calculations in different scenarios. Each problem requires the application of thermodynamic principles to determine various properties such as pressure, temperature, work done, and mass flow rates.

Uploaded by

ashenafi.henok-ugCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd