0% found this document useful (0 votes)

36 views29 pages03) Mech Machine Design II

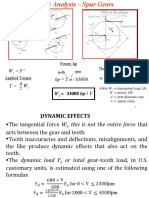

The document outlines the design guidelines for gear systems in the context of mechatronics engineering, emphasizing the importance of understanding required speeds, power transmission, and operating conditions. It details the design procedure, including preliminary and detailed design phases, focusing on factors such as bending fatigue strength and surface failure. Key objectives of gear design include compactness, smooth operation, longevity, cost-effectiveness, manufacturability, and compatibility with other machine elements.

Uploaded by

mahmoudeid0300Copyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

36 views29 pages03) Mech Machine Design II

The document outlines the design guidelines for gear systems in the context of mechatronics engineering, emphasizing the importance of understanding required speeds, power transmission, and operating conditions. It details the design procedure, including preliminary and detailed design phases, focusing on factors such as bending fatigue strength and surface failure. Key objectives of gear design include compactness, smooth operation, longevity, cost-effectiveness, manufacturability, and compatibility with other machine elements.

Uploaded by

mahmoudeid0300Copyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd