0% found this document useful (0 votes)

1K views3 pagesPharmaceutical Yield Calculation

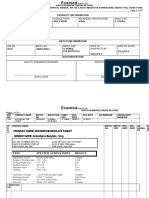

The document discusses pharmaceutical yield calculation, which is crucial for minimizing process loss in manufacturing. It explains how to calculate percent yield using the ratio of actual to theoretical product quantities, providing an example with a yield of 99.0%. It also emphasizes the importance of establishing tight yield limits and adhering to FDA regulations regarding yield determination during manufacturing phases.

Uploaded by

GAMES FOR ALL ,ALL FOR GESCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

1K views3 pagesPharmaceutical Yield Calculation

The document discusses pharmaceutical yield calculation, which is crucial for minimizing process loss in manufacturing. It explains how to calculate percent yield using the ratio of actual to theoretical product quantities, providing an example with a yield of 99.0%. It also emphasizes the importance of establishing tight yield limits and adhering to FDA regulations regarding yield determination during manufacturing phases.

Uploaded by

GAMES FOR ALL ,ALL FOR GESCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd