Professional Documents

Culture Documents

California Bearing Ratio and Brazilian Tensile Strength of Mine Overburden-Fly Ash-Lime Mixtures For Mine Haul Road Construction

Uploaded by

Manoj Kumar MishraOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

California Bearing Ratio and Brazilian Tensile Strength of Mine Overburden-Fly Ash-Lime Mixtures For Mine Haul Road Construction

Uploaded by

Manoj Kumar MishraCopyright:

Available Formats

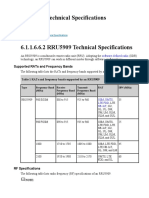

Geotech Geol Eng (2012) 30:449459 DOI 10.

1007/s10706-011-9479-9

ORIGINAL PAPER

California Bearing Ratio and Brazilian Tensile Strength of Mine OverburdenFly AshLime Mixtures for Mine Haul Road Construction

Banita Behera Manoj Kumar Mishra

Received: 17 May 2011 / Accepted: 7 November 2011 / Published online: 20 November 2011 Springer Science+Business Media B.V. 2011

Abstract The production and utilization of coal is based on well-proven and widely used technologies. Fly ash, a coal combustion byproduct, has potential to produce a composite material with controlled and superior properties. The major challenges with the production of y ash are in its huge land coverage, adverse impact on environment etc. It puts pressure on the available land particularly in a densely populated country like India. In India the ash utilization percentage has not been very encouraging in spite of many attempts. Stabilization of y ash is one of the methods to transfer the waste material into a safe construction material. This investigation is a step in that direction. This paper presents the results of an investigation on compressive strength and bearing ratio characteristics of surface coal mine overburden material and y ash mixes stabilized with lime for coal mine haul road construction. Tests were performed with different percentages of lime (2, 3, 6 and 9%). The effects of lime content and curing period on the bearing ratio and tensile strength characteristics of the stabilized overburden and y ash mixes are highlighted. Unconned compressive strength test results cured for 7, 28 and 56 days are presented to develop correlation between different tensile strengths and unconned compressive strength. Empirical models

B. Behera M. K. Mishra (&) Department of Mining Engineering, National Institute of Technology, Rourkela, India e-mail: mkmishra@nitrkl.ac.in

are developed to estimate bearing ratio and tensile strength of mine overburdeny ashquick lime mixtures from unconned compressive strength test results. Keywords Compressive strength Tensile strength Bearing ratio Fly ash Overburden Lime

1 Introduction Huge quantities of coal combustion byproducts are produced every year and only a small fraction of them are utilized. The current annual production of coal ash worldwide is estimated around 600 million tons, with y ash constituting about 500 million tons at 7580% of the total ash produced (Ahmaruzzaman 2010). Disposal of ash in dry or slurry form in the proximity of the thermal power plants not only occupies a large area but also causes environmental pollution (Pandian et al. 2000). Utilization of coal ash in construction helps in saving of precious land area. Considering the practical signicance of the problem, experimental investigations were carried out on y ash to establish its suitability for geotechnical applications. Mine overburdens (O/B) are very important raw materials which have been traditionally used in the mines throughout the world. The annual coal production from opencast coal mines in India was about 328 MT and overburden waste material of 535.08 Mm3 (Jamal and Sidharth 2008). The average stripping ratio

123

450

Geotech Geol Eng (2012) 30:449459

of Indian coal mines (overburden to coal) is about 2:1 (Chaulya et al. 2000). The overburden is highly heterogeneous. Gradation results suggest that nes and coarse grains are approximately equally represented in the soil reported by Ulusay et al. (1995). Fly ash, being very ner, is more reactive and consequently more suitable for haul road construction material as compared to other materials. Potential application of y ash alone or soil stabilized with y ash or y ash and admixtures for road construction has been reported by a number of researchers (Hobeda 1984; Bell 1996; Consoli et al. 2001; Acosta et al. 2003; Kumar 2005; Geiman 2005; Mohanty and Chugh 2006; Goswami and Mahanta 2007; Mackos et al. 2009). The enhancement of mechanical strength of y ash with addition of lime has been reported elsewhere (Sivapullaiah et al. 2000; Beeghly 2003; Mishra and Rao 2006; Ghosh and Subbarao 2007). But a conservative estimate puts the unutilised y ash occupying about 65,000 acres of land (Das and Yudhbir 2006) which demands increase the utilization percentage. According to Pandian (2004), y ash has good utilization potential for geotechnical applications. Its low specic gravity, freely draining nature, ease of compaction, insensitiveness to changes in moisture content, good frictional properties etc. can be gainfully exploited in the construction of roads, embankments etc. Prabakar et al. (2004) studied y ash and soil mixes and concluded that the addition of y ash reduced the dry density of the soil due to low specic gravity and unit weight. Sahu (2005) reported that the plasticity index and linear shrinkage of all types of soil decreased and CBR value increased with the addition of y ash which enhanced the suitability of the soils for construction of base and subbase in road works. There are many attempts to use y ash in raw stage in road construction, particularly in rural road construction (Vittal and Mathur 2005; Singh and Kumar 2005). The class-F y ash after stabilizing with 10% lime and 1% gypsum achieved a compressive strength of 6.308 MPa at 90 days curing and the CBR value of 172 at 28 days curing reported by Ghosh and Subbarao (2006). Tannant and Kumar (2000) reported that mine spoil or coal seam partings stabilized with y ash suitable for use in constructing haul road base and subbase layers. There have been many successful instances of y ash being used as road construction material. Yet its effectiveness in the surface coal mine haul road has

not been evaluated so as to establish it commercially. Surface coal mine haul road undergoes more stress/ strain due to multiple reasons such as poor surface course, traditional neglect in construction, high load concentration at xed locations, etc. A typical surface coal mine has about 25 km of permanent haul road, larger ones having longer lengths and various other lumpy roads that are constructed from locally available material found near to the mine property. In the past 30 years the carrying capacity of hauling equipments e.g. dumpers/trucks has grown from a tiny 10170 tons, 320 tons being envisioned at places, requiring better haul roads to carry heavy loads. These dumpers may achieve gross vehicle weight of more than 1,000 KN and the tire pressure used to support these tracks would be typically 600690 kPa (Tannant and Kumar 2000; Tannant and Regensburg 2001). But, the vehicular trafc exhibit gross vehicle weight of 1.78 KN to about 200 KN and the tire pressure is about 249550 kPa. The purpose of the present study is to develop a better subbase/base material with y ash, mine overburden and lime as ingredients and to determine their compressive strength, tensile strength and California bearing ratio values. The paper also develops empirical models to estimate bearing ratio and tensile strength of stabilized overburden y ash mixes from unconned compressive strength test results.

2 Materials and Methods The overburden used in this study was collected from Bharatpur opencast coal mine, Talcher, Odisha. The y ash used in the present study was collected from electrostatic precipitators of a thermal power unit of Rourkela Steel Plant, Odisha. The additive selected was commercially available superior grade quick lime. The tests for specic gravity, consistency limits, grain size distribution, free swell index, pH, loss on ignition and compaction characteristics were carried out as per the prescribed Indian Standards. The specic gravity of the mine overburden and y ash were determined using volumetric ask method as per IS: 2720-Part 3. The consistency limits of the mine overburden were determined as per IS: 2720-Part 5 and Part 6. The liquid limit of overburden was determined using Casagrande liquid limit device. The liquid limit of y ash was determined by the cone penetration method

123

Geotech Geol Eng (2012) 30:449459

451

as per BS 1377 due to difculty in cutting a groove using Casagrande device. The liquid limit is the minimum moisture content at which the soil can ow under a specied small disturbing force, the disturbing force being dened by the method of testing. The plastic limit is the minimum water content at which soil ceases to behave as a plastic material. The shrinkage limit is the maximum water content below which the soil ceases to decrease in volume on further drying. Free swell index was determined as per IS: 2720-Part 40. The pH value was determined as per IS: 2720-Part 26 to identify the acidic or alkaline characteristic of overburden and y ash. The measurement of pH was carried out using Systronics scale pH meter with accuracy up to 0.02 units. The instrument was standardized with three standard buffer solutions of pH 7.00, 4.00 and 10.00 at 25C as per the prescribed procedure. Loss on ignition (LOI) of overburden and y ash were determined as per IS: 1760-Part 1. The heavy compaction (modied Proctor compaction) test was performed to determine the maximum dry density and optimum moisture content of the overburden and y ash as per IS: 2720-Part 8. The chemical compositions of mine overburden and y ash were obtained using energy dispersive X-ray (EDX) technique. 2.1 Sample Preparation The following proportions of overburden y ash mixtures were considered as presented in Table 1. The aim of the study was to evaluate y ash utilization prospects to replace a part of the traditional sub base material i.e. the overburden. Hence experiments were carried out to maximum of 50% y ash addition in overburden as reported in the Table 1. The optimum

Table 1 Various proportions of FA ? O/B Fly ash (%) 15 20 25 30 35 40 45 50 FA y ash, O/B overburden Overburden (%) 85 80 75 70 65 60 55 50

lime content was determined to be 3% for the above combinations from pH test. Lime was added in the above combinations of overburdeny ash in varying percentage of 2, 3, 6 and 9% to determine respective geotechnical parameters. Heavy compaction (modied Proctor compaction) test were performed to determine the maximum dry density and optimum moisture content of all the mixes. Then samples were prepared at their respective optimum moisture content and maximum dry density. The raw materials such as y ash, mine overburden and lime were blended in the required proportion in dry condition. After dry mixing of the ingredients, respective water content was added to the mixes and mixed thoroughly. Then the mixture was left in a closed container for uniform mixing and prevents loss of moisture to atmosphere. The wet mixture of amount corresponding to the required dry density was compacted in the mould. Split mould of 38 mm diameter and 86 mm length was used for preparation of the unconned compressive strength (UCS) test samples. Samples were prepared with uniform tamping. Two circular metal spacer discs of height 5 mm and diameter 37.5 mm each with base (7 mm height, 50 mm diameter) were used at top and bottom ends of the mould to compact the sample such that the length of the specimen was maintained at 76 mm. Then the discs were removed and an another spacer disc of height 100 mm and diameter 37.5 mm with a base (height 7 mm, 50 mm diameter) was used to remove the sample from mould. The sample for Brazilian tensile strength test was prepared using the same mould of UCS test samples. For this purpose, two circular metal spacer discs of 5 and 62 mm heights and 37.5 mm diameters with base (height 7 mm, 50 mm diameter) were used. The California bearing ratio (CBR) test samples were prepared using standard CBR mould of 150 mm diameter and 175 mm height. The sample was statically compacted in the mould, such that the height was maintained at 127 mm. A circular metal spacer disc of 148 mm diameter and 47.7 mm height was used to compact the sample. 2.2 Unconned Compressive Strength Test Unconned compressive strength is a common criterion to determine the strength of stabilized materials. The specimens prepared for compressive strength test were of 38 mm diameter and 76 mm long. The specimens were then cured in a humidity chamber

123

452

Geotech Geol Eng (2012) 30:449459 Table 2 Physico-chemical properties of y ash and mine overburden Property Specic gravity Consistency limits Liquid limit (%) Plastic limit (%) Shrinkage limit (%) Plasticity index (%) Free swell index (%) pH value Loss on ignition (%) Fly ash 2.16 30.75 Non-plastic Negligible 7.2 2 Overburden 2.6 25.7 15.04 13.44 10.66 20 4.85 10

(relative humidity [ 95%) for 7, 28 and 56 days at 30 2C. The unconned compressive strength tests were conducted as per IS: 2720-Part-10 at a strain rate of 1.2 mm/min. Load and deformation data was recorded till failure of the specimen. 2.3 Brazilian Tensile Strength Test Brazilian test make the sample fail under tension though the loading pattern is compressive in nature. The tensile strength was determined as per ASTM D3967. The length (thickness) to diameter ratio of specimen is 0.5. The specimens prepared for tensile strength test were of 38 mm diameter and 19 mm thick. The specimens were placed diametrically during test. The sample fails diametrically in tension by application of load. The indirect tensile strength is calculated as follows: rt 2P pDL

where, rt = Brazilian tensile strength; P = failure load, D = diameter of the specimen; L = length of the specimen. 2.4 California Bearing Ratio Test California bearing ratio (CBR) tests were performed in accordance with IS: 2720-Part 16. The samples were statically compacted to 95% of maximum dry density in the mould for CBR test. The samples were soaked for 4 days in water and were allowed to drain for 15 min before test to obtain soaked condition results. The curing periods adopted were immediate, 7 days (3 days moist curing ? 4 days soaking) and 28 days (24 days moist curing ? 4 days soaking). CBR tests were carried out at the end of respective curing period. Two surcharge disks, each weighing 2.5 kg, were placed over the sample and a plunger, 50 mm in diameter, was used to penetrate the sample at a rate of 1.25 mm/min during CBR test.

less iron content. The materials with higher iron content have relatively high specic gravity (Sridharan and Prakash 2007). The y ash tested was non-plastic and hence plastic limit could not be determined. It was also not possible to carry out shrinkage limit tests since the ash pats crumbled upon drying. Since the amount of shrinkage was very less, the shrinkage limit would be high. Hence shrinkage would not be a constraint. Free swell index of the y ash was found to be negligible due to occulation (Pandian 2004). The pH values indicate that y ash was alkaline and overburden was acidic depending on alkaline oxide content and free lime content. The chemical compositions of mine overburden and y ash are presented in Table 3. The chemical composition of y ash indicates that it has less calcium content. Thus, it is classied as Class F y ash as per ASTM 618 specications. 3.1 Compaction Characteristics The maximum dry density (MDD) and optimum moisture content (OMC) achieved by the heavy compaction tests, made on y ash, mine overburden individually and also on their aggregate mixture with varying percentages of lime are shown in Figs. 1, 2, 3 and 4. The maximum dry density of y ash was lower than that obtained for mine overburden as y ash is non-cohesive in nature. 3.2 Unconned Compressive Strength The unconned compression test is one of the widely used laboratory tests in pavement and soil stabilization

3 Results and Discussion The physico-chemical properties of y ash and mine overburden are reported in Table 2. The specic gravity of y ash was found to be less than that of mine overburden, due to the presence of cenospheres and

123

Geotech Geol Eng (2012) 30:449459 Table 3 Chemical composition (% by weight) of O/B and y ash Constituents O/B Fly ash SiO2 55.33 52.13 Al2O3 31.65 35.64 Fe2O3 9.24 6.47 CaO 1.21 0.53 K2O 0.43 1.46 MgO 1.37 0.52 TiO2 0.77 3.02

453

Na2O 0.2

Fig. 1 Compaction curves of y ash and overburden

Fig. 3 Compaction curves of the mixes containing 30, 35 and 40% y ash

Fig. 2 Compaction curves of the mixes containing 15, 20 and 25% y ash

applications. The unconned compressive strength (UCS) of overburden material is considerably one of the most important designing parameters. It is often used as an index to quantify the improvement of materials due to treatment. Compressive strengths of mine overburden stabilized with 15, 20, 25, 30, 35, 40, 45, and 50% y ash were 0.713.14 MPa after 7, 28 and 56 days of curing (Figs. 5, 6, 7). The mine overburden mixed with 30% y ash and 9% lime exhibited maximum compressive strength as compared to that for other mixes at 7, 28 and 56 days of

Fig. 4 Compaction curves of the mixes containing 45 and 50% y ash

curing. Addition of lime improved the strength of y ashoverburden mixes. Tannant and Kumar (2000) reported that the stresses at the base layer of mine haul road are about 300650 kPa with 23170 tonne dumpers. The strength achieved in all the mixes in this study are above these values after a period of curing and hence would be useful for mine haul road construction.

123

454

Geotech Geol Eng (2012) 30:449459

Fig. 7 Effect of lime on compressive strength of overburden y ash mixes at 56 days curing Fig. 5 Effect of lime on compressive strength of overburden y ash mixes at 7 days curing

Fig. 8 Effect of lime on tensile strength of overburdeny ash mixes at 28 days curing

Fig. 6 Effect of lime on compressive strength of overburden y ash mixes at 28 days curing

3.3 Brazilian Tensile Strength The tensile strength is a vital parameter to evaluate the suitability of the stabilized soil or y ash as road base material. This investigation reports the Brazilian tensile strengths of mine overburden and y ash (15, 20, 25, 30, 35, 40, 45 and 50%) mixes stabilized with 2, 3 6 and 9% of lime. Brazilian tensile strength test results were 55.7291 kPa and 73357 kPa at 28 and 56 days of curing respectively (Figs. 8, 9). The mine overburden mixed with 30% y ash and 9% lime exhibited maximum tensile strength as compared to that of other mixes at 28 and 56 days of curing respectively. The Brazilian tensile strength as a percentage of unconned compressive strength

Fig. 9 Effect of lime on tensile strength of overburdeny ash mixes at 56 days curing

against curing period are plotted, as shown in Figs. 10 and 11. The average value of Brazilian tensile strength as a percentage of unconned

123

Geotech Geol Eng (2012) 30:449459

455

Fig. 10 Effect of curing period on tensile strength as percentage of unconned compressive strength of the mixes containing 15, 20, 25 and 30% y ash

Fig. 11 Effect of curing period on tensile strength as percentage of unconned compressive strength of the mixes containing 35, 40, 45 and 50% y ash

compressive strength was 8.4% at 28 days and 10% at 56 days. It is clearly observed that the tensile strength was a function of the amount of cementitious compounds formed, which increased with increase in curing period. This compares favourably with that observed for the y ash stabilized with 10% lime only (Ghosh and Subbarao 2006). Consoli et al. (2001) observed that the average ratio of Brazilian tensile strength and unconned compressive strength increased from 4% at 7 days to about 15% at 180 days for the mixes containing soil and 25% y ash stabilized with 4, 7 and 10% of lime. The current investigation conrms these observations. 3.4 California Bearing Ratio Behavior The CBR values of y ash, mine overburden and the mixes are reported in Table 4. In unsoaked condition, the bearing ratio of overburden stabilized with 35% y ash was more as compared to that of other

Table 4 CBR values of FA, O/B and mixes Sample CBR (%) Unsoaked condition Fly ash only Mine overburden only 15% FA ? 85% O/B 20% FA ? 80% O/B 25% FA ? 75% O/B 30% FA ? 70% O/B 35% FA ? 65% O/B 40% FA ? 60% O/B 45% FA ? 55% O/B 50% FA ? 50% O/B 22.42 23.65 32.07 27.09 26.16 26.47 45.31 34.57 32.7 32.23 Soaked condition 0.72 2.95 2.34 1.87 1.4 1.31 1.64 1.12 1.03 0.82

mixes by 50%. But, in case of soaked condition, the CBR value of 15% y ash was higher than that for other mixes by 78%. The CBR value of overburden

123

456

Geotech Geol Eng (2012) 30:449459

Fig. 14 Relationship between Brazilian tensile strength and unconned compressive strength for mine overburdeny ash lime mixtures at 28 days of curing Fig. 12 Effect of lime on CBR behavior of overburdeny ash mixes at 7 days curing

Fig. 15 Relationship between Brazilian tensile strength and unconned compressive strength for mine overburdeny ash lime mixtures at 56 days of curing

Fig. 13 Effect of lime on CBR behaviour of overburdeny ash mixes at 28 days curing

increased with the addition y ash in unsoaked condition and decreased in soaked condition due to saturation. The CBR values under soaked condition were less than that of the unsoaked condition due to decrease in effective stresses and loss of surface tension forces upon soaking (Toth et al. 1988).The increase in CBR value of overburden upon addition of y ash is attributed mainly due to the relative

contribution of frictional resistance between them (Pandian and Krishna 2002). Generally, additives like cement or lime improve the strength of the soil or y ash. A series of CBR tests were conducted with 2, 3, 6 and 9% of lime content in overburdeny ash mixtures to observe the effect of lime. The effect of lime content on CBR behavior of overburdeny ash mixes are shown in Figs. 12 and 13. It is observed from the results that the CBR values increased from 42 to 149% and 85 to 195% at 7 and 28 days of curing respectively. The mine overburden mixed with 30% y ash and 9% lime resulted in maximum bearing ratio as compared to other mixes at 7 and 28 days curing respectively. It can be compared with the CBR value of the soil stabilized with y ash (10 and 20%) and lime kiln

123

Geotech Geol Eng (2012) 30:449459

457

dust (2.5 and 5%) obtained by Cetin et al. (2010) to be 69142% at 7 days curing and greater than 164% at 28 days curing.

4 Empirical Model to Estimate Tensile Strength, Bearing Ratio From UCS Test Results The variation of tensile strength and bearing ratio with unconned compressive strength are shown in Figs. 14, 15, 16 and 17. The data are analyzed using linear regression model. The parameters in linear regression model are estimated by the method of least squares. There are many attempts have been made to correlate compressive strength of y ash/lime and y ash/lime and gypsum mixes with chemical composition, loss on ignition, CBR and tensile strength using power model (Das and Yudhbir 2006; Ghosh and Subbarao 2006). In the present investigation, it is observed that linear regression model suits for the y ash and overburden mixes stabilized with lime. The empirical models along with the value of correlation coefcient (R) are presented in the scatter plots (Figs. 14, 15, 16, 17). It is observed from the relationship between tensile strength and compressive strength that R value is more at 56 days than that at 28 days curing. It conrms that the relationship between tensile strength and compressive strength become stronger with increasing curing period. Similar results were also observed between bearing ratio and unconned compressive strength. The results of linear regression model between California bearing ratio values, unconned compressive strength and tensile strength at different curing period are reported in Table 5.

Fig. 16 Relationship between bearing ratio and unconned compressive strength for mine overburdeny ashlime mixtures at 7 days of curing

5 Conclusions The following conclusions are drawn from the above study:

Fig. 17 Relationship between bearing ratio and unconned compressive strength for mine overburdeny ashlime mixtures at 28 days of curing

1.

The unconned compressive strength increased with increase in curing period. The unconned compressive strength of mine overburden mixed

Table 5 Results of linear regression model between California bearing ratio values, unconned compressive strength and tensile strength at different curing period Dependent Brazilian tensile strength, rt Brazilian tensile strength, rt California bearing ratio (CBR) California bearing ratio (CBR) Best t equation rt = 121.2rc - 60.84 rt = 130.36rc - 61.763 CBR = 108.8rc - 14.14 CBR = 56.45rc ? 39.12 R value 0.899 0.952 0.847 0.873 No. of observation 32 32 32 32 Curing period (days) 28 56 7 28

123

458

Geotech Geol Eng (2012) 30:449459

2.

3.

4.

5.

6.

with 30% y ash and 9% lime achieved was 3.14 MPa at 56 days curing as compared to that of other mixes. The Brazilian tensile strength and California bearing ratio of all the mixes increased with increase in lime content and curing period. The mine overburden mixed with 30% y ash and 9% lime produced highest compressive strength, tensile strength and bearing ratio value as compared to that of other mixes at 7, 28 and 56 days of curing respectively. Linear regression modeling showed that there exists a strong relationship (high R value) between Brazilian tensile strength and unconned compressive strength and California bearing ration and unconned compressive strength. A very strong correlation (R = 0.95) between Brazilian tensile strength and unconned compressive strength was observed for mine overburdeny ashlime mixtures at 56 days of curing. Similarly, strong correlation was observed with increase in curing period from 7 to 28 days in case of bearing ratio. The results reported were developed for the coal mine materials and y ash from specic sites in India and they should not be used for other sites without any verication.

Acknowledgments The authors would like to acknowledge the fund provided by Fly Ash Unit, Department of Science and Technology, Govt. of India under R&D Scheme vide approval No: FAU/DST/600(17)/2008-09 dated 12.09.2008.

References

ASTM C 618-08a (2008) Standard specication for coal y ash and raw or calcined natural pozzolan for use in concrete. American Society for Testing and Materials. West Conshohocken, PA, pp 13 Acosta HA, Edil TB, Benson CH, (2003) Soil stabilization and drying using y ash. Geo Engineering Report No. 03-03, University of Wisconsin, Madison, USA Ahmaruzzaman M (2010) A review on the utilization of y ash. J Prog Energy Combust Sci 36:327363 ASTM D3967-08 (2008) Standard test method for splitting tensile strength of intact rock core specimens. American Society for Testing and Materials. West Conshohocken, PA, pp 14 Beeghly JH (2003) Recent Experiences with limey ash stabilization of pavement subgrade soils, base and recycled asphalt. Int. Ash Utilization Symposium03, Centre for Applied Energy Research, University of Kentucky, Paper # 46, pp 118

Bell FG (1996) Lime stabilization of clay minerals and soils. J Eng Geol 42:223237 BS: 1377 Part 2 (1990) Method of test for soils for civil engineering purposes. British Standard Institution, London Cetin B, Aydilekb AH, Guneyc Y (2010) Stabilization of recycled base materials with high carbon y ash. J Resour Conserv Recycl 54:878892 Chaulya SK, Singh RS, Chakraborty MK, Tewary BK (2000) Bioreclamation of coal mine overburden dumps in India. J Land Contam Reclam 8:189199 Consoli NC, Prietto PDM, Carraro JAH, Heineck KS (2001) Behaviour of compacted soil-y ash-carbide lime mixtures. J Geotech Geoenviron Eng ASCE 127:774782 Das SK, Yudhbir (2006) Geotechnical properties of low calcium and high calcium y ash. J Geotech Geol Eng 24:249263 Geiman CG (2005) Stabilization of soft clay subgrades in Virginia phase I laboratory study. M.S. (Thesis), Faculty of the Virginia Polytechnic Institute and State University, Department of Civil Engineering, Blacksburg, Virginia Ghosh A, Subbarao C (2006) Tensile strength bearing ratio and slake durability of class F y ash stabilized with lime and gypsum. J Mater Civil Eng ASCE 18:1827 Ghosh A, Subbarao C (2007) Strength characteristics of class F y ash modied with lime and gypsum. J Geotech Geoenviron Eng 133:757766 Goswami RK, Mahanta C (2007) Leaching characteristics of residual lateritic soils stabilised with y ash and lime for geotechnical applications. J Waste Manage 27:466481 Hobeda P (1984) Use of waste material from coal combustion in road construction. Transportation Research Board Report No. VTI-285. NTIS, USA IS: 1760 Part 1 (1991) Determination of Loss on ignition. Indian Standard for Chemical analysis of limestone, dolomite and allied materials. Bureau of Indian Standards, New Delhi, pp 1 IS: 2720 Part 3 (1980) Determination of Specic gravity. Indian Standard methods of test for soils. Bureau of Indian Standards, New Delhi, pp 18 IS: 2720 Part 5 (1985) Determination of liquid and plastic limit. Indian Standard methods of test for soils. Bureau of Indian Standards, New Delhi, pp 116 IS: 2720 Part 6 (1972) Determination of shrinkage factors. Indian Standard methods of test for soils. Bureau of Indian Standards, New Delhi, pp 111 IS: 2720 Part 8 (1983) Laboratory determination of water contentdry density relation using heavy compaction. Indian Standard methods of test for soils. Bureau of Indian Standards, New Delhi, pp 19 IS: 2720 Part 10 (1991) Determination of Unconned compressive strength. Indian Standard methods of test for soils. Bureau of Indian Standards, New Delhi, pp 14 IS: 2720 Part 16 (1987) Laboratory determination of CBR. Indian Standard methods of test for soils. Bureau of Indian Standards, New Delhi, pp 115 IS: 2720 Part 26 (1987) Determination of pH value. Indian Standard methods of test for soils. Bureau of Indian Standards, New Delhi, pp 19 IS: 2720 Part 40 (1977) Determination of free swell index of soils. Indian Standard methods of test for soils. Bureau of Indian Standards, New Delhi, pp 15

123

Geotech Geol Eng (2012) 30:449459 Jamal A, Sidharth S (2008) Value added constructional bricks from overburden of opencast coal mines. J Sci Ind Res 67:445450 Kumar V (2005) Fly ash-An opportunity for India. In: Proceedings of Fly ash India conference. DST, New Delhi Mackos R, Butalia T, Wolfe W, Walker HW (2009) Use of limeactivated class F y ash in the full depth reclamation of asphalt pavements: environmental aspects. World of Coal Ash Conference09, Lexington, Kentucky, USA. Paper no 121 Mishra MK, Rao KUM (2006) Geotechnical characterisation of y ash composites for backlling mine voids. J Geotech Geol Eng 24:17491765 Mohanty S, Chugh YP (2006) Structural performance monitoring of an unstabilised y ash based road subbase. J Transp Eng 132:964969 Pandian NS (2004) Fly ash characterization with reference to geotechnical applications. J Indian Inst Sci 84:189216 Pandian NS, Krishna KC (2002) California Bearing Ratio Behavior of cement stabilized y ash-soil mixes. J Test Eval ASTM 30:492496 Pandian NS, Sridharan A, Srinivas S (2000) Angle of internal friction for pond ashes. J Test Eval ASTM 28:443454 Prabakar J, Dendorkar N, Morchhale RK (2004) Inuence of y ash on strength behaviour of typical soils. J Const Build Mater 18:263267 Sahu BK (2005) Use of y ash for stabilizing sub-standard road construction materials in Botswana. In: Proceedings of Fly ash India conference, DST, New Delhi

459 Singh SP, Kumar P (2005) Utilisation of bre reinforced y ash in road sub-bases. In: Proceedings of Fly ash India conference, DST, New Delhi Sivapullaiah PV, Prashanth JP, Sridharan A (2000) Optimum lime content for y ashes and the role of the curing period. J Test Eval ASTM 28:499506 Sridharan A, Prakash K (2007) Physical properties. Geotechnical engineering characterization of coal ashes, Chap 3, 1st edn. CBS Publishers & Distributors, New Delhi, India, pp 2653 Tannant DD, Kumar V (2000) Properties of y ash stabilized haul road construction materials. Int J Surf Min Reclam Environ 14:121135 Tannant DD, Regensburg B (2001) Guidelines for mine haul road design. School of Mining and Petroleum Engineering, Dept. of Civil and Environmental Engineering, University of Alberta, Canada, pp 2842 Toth PS, Chan HT, Cragg CB (1988) Coal ash as structural ll with special reference to Ontario experience. Can Geotech J 25:694704 Ulusay R, Arlkan F, Yoleri MF, Caglan D (1995) Engineering geological characterization of coal mine waste material and an evaluation in the context of back-analysis of spoil pile instabilities in a strip mine, SW Turkey. J Eng Geol 40:77101 Vittal UKG, Mathur S (2005) Construction of rural roads using y ash-Some case studies. In: Proceedings of Fly ash India conference, DST, New Delhi

123

You might also like

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5795)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- RRU5909 Technical SpecificationsDocument7 pagesRRU5909 Technical SpecificationsDmitry059100% (1)

- Escape Velocity PDFDocument5 pagesEscape Velocity PDFRatriNo ratings yet

- LYNQ 2020 Installation GuideDocument16 pagesLYNQ 2020 Installation GuideasdfsadfasdfNo ratings yet

- Design, Development, Fabrication and Testing of Small Vertical Axis Wind TurbinevDocument4 pagesDesign, Development, Fabrication and Testing of Small Vertical Axis Wind TurbinevEditor IJTSRDNo ratings yet

- Cbse - Department of Skill Education Curriculum For Session 2021-2022Document13 pagesCbse - Department of Skill Education Curriculum For Session 2021-2022Dushyant SinghNo ratings yet

- Amritsar Jamnagar Pavement Crust ThicknessDocument5 pagesAmritsar Jamnagar Pavement Crust ThicknessPurshottam SharmaNo ratings yet

- Ec1102n - Mimi Nur Nabila Binti Alias - 2019293128 - Final ExamDocument17 pagesEc1102n - Mimi Nur Nabila Binti Alias - 2019293128 - Final ExammimiNo ratings yet

- Embedded Linux Course SlidesDocument571 pagesEmbedded Linux Course SlidesKuan Xing Li100% (2)

- Fork LiftDocument4 pagesFork Lifttamer goudaNo ratings yet

- Compliance Statement - FormDocument16 pagesCompliance Statement - Formaqil khanNo ratings yet

- CAGF5-90 Transmission Service ManualDocument70 pagesCAGF5-90 Transmission Service Manualgustavo100% (2)

- Age ProblemsDocument4 pagesAge ProblemsBen JNo ratings yet

- Warrick 26m Control de Nivel AuxiliarDocument3 pagesWarrick 26m Control de Nivel AuxiliarCarlos WayNo ratings yet

- Juniper SRX Quickstart-12.1r3Document455 pagesJuniper SRX Quickstart-12.1r3Pichai Ng-arnpairojhNo ratings yet

- Dosing Technology: eco-CONTROL EC200-KDocument2 pagesDosing Technology: eco-CONTROL EC200-KMario Vargas VegaNo ratings yet

- FSX Cessna 172SP OldDocument4 pagesFSX Cessna 172SP Oldaccgh5No ratings yet

- Guidelines On Water ProofingDocument88 pagesGuidelines On Water ProofingViệt Đặng XuânNo ratings yet

- Solutions and Solubility 2021Document3 pagesSolutions and Solubility 2021Mauro De LollisNo ratings yet

- Oracle Alerts: Mona Lisa SahuDocument35 pagesOracle Alerts: Mona Lisa Sahuanishokm2992No ratings yet

- Indian Pharmacopoeia 2020 - Vol. 1 (PART 1)Document255 pagesIndian Pharmacopoeia 2020 - Vol. 1 (PART 1)the reader100% (1)

- Btech Ec 7 Sem Digital Image Processing Nec032 2019Document1 pageBtech Ec 7 Sem Digital Image Processing Nec032 2019Deepak SinghNo ratings yet

- What Is Host Program? How To Create Host Program? and What Is .Prog File?Document5 pagesWhat Is Host Program? How To Create Host Program? and What Is .Prog File?redroNo ratings yet

- Syllabus For Admission Test For Admission To Class Xi 2020-21 Physics ChemistryDocument2 pagesSyllabus For Admission Test For Admission To Class Xi 2020-21 Physics ChemistryAdhara MukherjeeNo ratings yet

- An Experimental and Statistical Study of Olfactory PreferencesDocument7 pagesAn Experimental and Statistical Study of Olfactory Preferencesjungseong parkNo ratings yet

- Foundations of Nonlinear Algebra (John Perry)Document425 pagesFoundations of Nonlinear Algebra (John Perry)Tao-Wei HuangNo ratings yet

- Quiz Questions TD 1Document6 pagesQuiz Questions TD 1Susmita PandaNo ratings yet

- Module 3 Q2 Gen Chem IIDocument10 pagesModule 3 Q2 Gen Chem IIMengieNo ratings yet

- Linear Motion4Document9 pagesLinear Motion4Jai GaizinNo ratings yet

- How To Build An Offshore CraneDocument5 pagesHow To Build An Offshore CraneWestMarineNo ratings yet

- Steel and Timber Structures Part Two:: Design of Structural Steel MembersDocument28 pagesSteel and Timber Structures Part Two:: Design of Structural Steel MembersDhinesh KalaimaranNo ratings yet