0% found this document useful (0 votes)

61 views3 pagesElevator Brochure

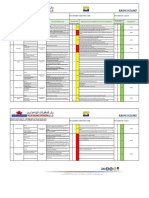

The document outlines the requirements for elevator installation, including necessary tools, personal protective equipment, and maintenance procedures. It details the operational manual and tasks involved in the installation process, such as site inspections and testing. Additionally, it emphasizes team building for installation and maintenance tasks, highlighting the need for proper documentation and safety measures.

Uploaded by

TolulopeCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as DOCX, PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

61 views3 pagesElevator Brochure

The document outlines the requirements for elevator installation, including necessary tools, personal protective equipment, and maintenance procedures. It details the operational manual and tasks involved in the installation process, such as site inspections and testing. Additionally, it emphasizes team building for installation and maintenance tasks, highlighting the need for proper documentation and safety measures.

Uploaded by

TolulopeCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as DOCX, PDF, TXT or read online on Scribd