NELLIANDAVAR INSTITUTE OF TECHNOLOGY

PUDHUPALAYAM

DEPARTMENT OF MECHANICAL ENGINEERING

MODEL EXAM

DEPARTMENT : MECHANICAL ENGINEERING SEM: V

COURSE TITLE : DESIGN OF MACHINE ELEMENTS CODE: ME 3591

MAX MARKS: 100 DURATION: 3 hrs

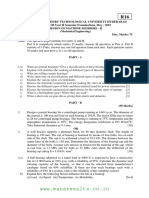

Q. BT

QUESTION MARKS CO

NO. LEVEL

PART - A

1 What is the factor of safety, why it is important in design? 2 CO1 BT1

2 List out the various phases of design process. 2 CO1 BT1

3 List out types of stresses that induced in shafts. 2 CO2 BT2

4 Differentiate between keys and splines. 2 CO2 BT2

5 What is knuckle joint, and where is it typically used? 2 CO3 BT1

6 What is a transverse fillet weld? 2 CO3 BT1

7 List two common types of springs and their applications. 2 CO4 BT2

8 List out the main function of a flywheel in an engine. 2 CO4 BT2

9 List the physical characteristics of a good bearing material. 2 CO5 BT1

10 Why ball and roller bearings are called “antifriction” bearings? 2 CO5 BT2

PART- B

a) An electric generator rotates at 200rpm and receives 300KW from

the driving engine. The armature of the generator is 60cm long and

located between bearing 120cm center to center. Owing to the

11.a) combined weight of armature and magnetic pull, the shaft is 13 CO1 BT1

subjected to 9000kg acting at right angles to the shaft. The ultimate

stress for the shaft is 4480kg/cm 2 and shear stress is

3920kg/[Link] the diameter of the shaft for a f actor of safety of 6.

OR

A shaft to transmit 50KW at 1200rpm. It is also subjected to a

bending moment of [Link] shear stress is 60N/mm [Link]

b) 13 CO1 BT2

shaft is not to twist more than 20 in a length of

2m.G=80XI03N/[Link] a shaft

A 45mm diameter shaft is made of steel with yield strength of

400 MPa. A parallel key of size 14mm wide and 9mm thick

made of steel with yield strength of 340 MPa is to be used.

12. a) 13 CO2 BT5

Find the required length of key. If the shaft is loaded to

transmit the maximum permissible torque. Use maximum

shear stress theory and assume a factor of safety of 2.

OR

A shaft to transmit 50KW at 1200rpm. It is also subjected to a

bending moment of [Link] shear stress is 60N/mm [Link]

shaft is not to twist more than 20 in a length of

b) 13 CO2 BT3

2m.G=80XI03N/[Link] a shaft.

� A steel member is subjected to a 3-D stress system and resulting

principal stress are 120N/mm2 tension, 80N/mm2and 40N/mm2

13.a) compression. If the proportional limit of the material in simple 13 CO3 BT2

tension is 280N/mm2 and its poison's ratio is [Link] the

factor of safety according to (a) Maximum principal stress theory (b)

Maximum principal strain theory (c) Maximum shear stress theory.

OR

Design and draw a cast iron flange coupling for a mild steel shaft

transmitting 90KW at 250rpm. The allowable shear stress in the

b) shaft is 40MPa and the angle of twist is not to exceed 10mm in a 13 CO3 BT2

length of 20mm diameters. The allowable shear stress in the

coupling bolt is 30MPa.

OR

A safety valve of 60 mm diameter is to blow off at a pressure

of 1.2 N/mm2. It is held on its seat by a close coiled helical

spring. The maximum lift of the valve is 10 mm. Design a

suitable compression spring of spring index 5 and providing an

initial compression of 35 mm. The maximum shear stress in

14.a) 13 CO4 BT2

the material of the wire is limited to 500 MPa. The modulus of

rigidity for the spring material is 80 kN/mm 2. Calculate: 1.

Diameter of the spring wire, 2. Mean coil diameter, 3. Number

of active turns, and 4. Pitch of the coil.

A composite spring has two closed coil helical springs as

shown in Fig. The outer spring is 15 mm larger than the inner

spring. The outer spring has 10 coils of mean diameter 40 mm

and wire diameter 5mm. The inner spring has 8 coils of mean

b) diameter 30 mm and wire diameter 4 mm. When the spring is 13 CO4 BT5

subjected to an axial load of 400 N, find (1) compression of

each spring, (2) load shared by each spring, and (3) shear

stress induced in each spring. The modulus of rigidity may be

taken as 84 kN/[Link] dimensions in mm

Design a journal bearing for a centrifugal pump with the

following data: load on the journal = 2000N, Speed of journal

= 900rpm, type of oil is SAE10, for which the absolute

15.a) viscosity at 55 degree Celsius= 0.017 kg/m-s. Ambient 13 CO5 BT5

temperature of oil=15.5 degree Celsius. Calculate the mass of

the lubricating oil required for artificial cooling.

OR

Load on a hydrodynamic full journal bearing is 30KN. The

diameter and speed of a shaft are 150 mm respectively.

Diameter clearance 0.2 mm. Summerfield number is 0.631.

b) 13 CO6 BT1

L/D ratio 1:1. Calculate temperature rise of oil, quantity of oil,

heat generated and types of oil required.

� PART-C

A hollow shaft of 0.5 m outside diameter and 0.3 m inside

diameter is used to drive a propeller of a marine vessel. The

shaft is mounted on bearings 6 metre apart and it transmits

5600 kW at 150 r.p.m. The maximum axial propeller thrust is

16.a) 15 CO1 BT3

500 kN and the shaft weighs 70 kN. Determine (1) The

maximum shear stress developed in the shaft, and [Link]

angular twist between the bearings.

OR

1. The shaft of an overhang crank is subjected to a force F of

2KN as shown in figure 1 below. The shaft is made of 30Mn2

2

steel having allowable shear strength equal to100N/mm .

Determine the diameter of the shaft.

b) 15 CO2 BT5

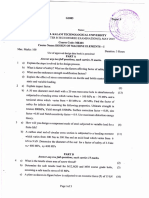

COURSE OUTCOMES:

SLNO QUESTION NUMBER CO’S

1 1,2,11a,11b,16a CO1

2 3,4,12a,12b,16b CO2

3 5,6,13a,13b CO3

4 7,8,14a,14b CO4

5 9,10,15a,15b CO5

BLOOM’S TAXONOMY:

BT1-Remember, BT2- Understand, BT3 –Apply, BT4- Analyse, BT5-Evaluate, BT6 - Create

Level BT1 BT2 BT3 BT4 BT5 BT6

Percentage 31% 40% 13.6% - 18.18%

COURSE INSTUCTOR HOD PRINCIPAL