71% found this document useful (7 votes)

3K views12 pagesControl Plans

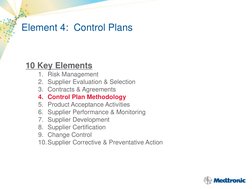

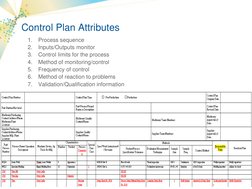

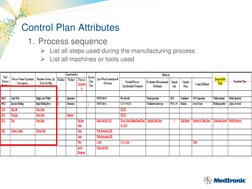

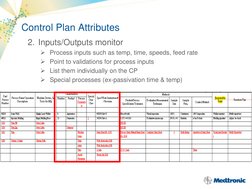

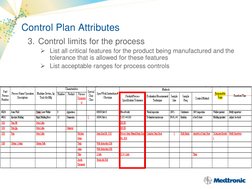

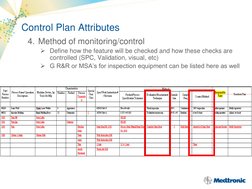

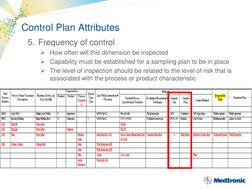

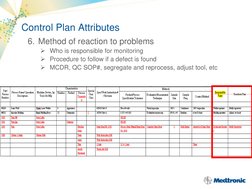

A control plan is a process management tool used to identify and monitor critical inputs and outputs of a process to ensure goals are continually met. Key elements of a control plan include risk management, supplier evaluation, contracts, control plan methodology, product acceptance, supplier performance monitoring, development, certification, change control, and corrective action. Attributes of a control plan outline the process sequence, inputs/outputs monitoring, control limits, monitoring methods, monitoring frequency, problem reaction methods, and validation/qualification information.

Uploaded by

aman_ranhotraCopyright

© Attribution Non-Commercial (BY-NC)

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PPT, PDF, TXT or read online on Scribd

71% found this document useful (7 votes)

3K views12 pagesControl Plans

A control plan is a process management tool used to identify and monitor critical inputs and outputs of a process to ensure goals are continually met. Key elements of a control plan include risk management, supplier evaluation, contracts, control plan methodology, product acceptance, supplier performance monitoring, development, certification, change control, and corrective action. Attributes of a control plan outline the process sequence, inputs/outputs monitoring, control limits, monitoring methods, monitoring frequency, problem reaction methods, and validation/qualification information.

Uploaded by

aman_ranhotraCopyright

© Attribution Non-Commercial (BY-NC)

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PPT, PDF, TXT or read online on Scribd