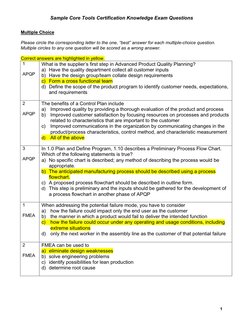

Sample Core Tools Certification Knowledge Exam Questions

Multiple Choice

Please circle the corresponding letter to the one, “best” answer for each multiple-choice question.

Multiple circles to any one question will be scored as a wrong answer.

Correct answers are highlighted in yellow.

1 What is the supplier’s first step in Advanced Product Quality Planning?

a) Have the quality department collect all customer inputs

APQP b) Have the design group/team collate design requirements

c) Form a cross functional team

d) Define the scope of the product program to identify customer needs, expectations,

and requirements

2 The benefits of a Control Plan include

a) Improved quality by providing a thorough evaluation of the product and process

APQP b) Improved customer satisfaction by focusing resources on processes and products

related to characteristics that are important to the customer

c) Improved communications in the organization by communicating changes in the

product/process characteristics, control method, and characteristic measurement

d) All of the above

3 In 1.0 Plan and Define Program, 1.10 describes a Preliminary Process Flow Chart.

Which of the following statements is true?

APQP a) No specific chart is described; any method of describing the process would be

appropriate.

b) The anticipated manufacturing process should be described using a process

flowchart.

c) A proposed process flowchart should be described in outline form.

d) This step is preliminary and the inputs should be gathered for the development of

a process flowchart in another phase of APQP

1 When addressing the potential failure mode, you have to consider

a) how the failure could impact only the end user as the customer

FMEA b) the manner in which a product would fail to deliver the intended function

c) how the failure could occur under any operating and usage conditions, including

extreme situations

d) only the next worker in the assembly line as the customer of that potential failure

2 FMEA can be used to

a) eliminate design weaknesses

FMEA b) solve engineering problems

c) identify possibilities for lean production

d) determine root cause

1

� Sample Core Tools Certification Knowledge Exam Questions

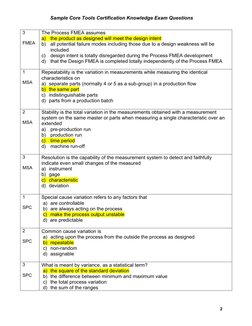

3 The Process FMEA assumes

a) the product as designed will meet the design intent

FMEA b) all potential failure modes including those due to a design weakness will be

included

c) design intent is totally disregarded during the Process FMEA development

d) that the Design FMEA is completed totally independently of the Process FMEA

1 Repeatability is the variation in measurements while measuring the identical

characteristics on

MSA a) separate parts (normally 4 or 5 as a sub-group) in a production flow

b) the same part

c) indistinguishable parts

d) parts from a production batch

2 Stability is the total variation in the measurements obtained with a measurement

system on the same master or parts when measuring a single characteristic over an

MSA extended

a) pre-production run

b) production run

c) time period

d) machine run-off

3 Resolution is the capability of the measurement system to detect and faithfully

indicate even small changes of the measured

MSA a) instrument

b) gage

c) characteristic

d) deviation

1 Special cause variation refers to any factors that

a) are controllable

SPC b) are always acting on the process

c) make the process output unstable

d) are predictable

2 Common cause variation is

a) acting upon the process from the outside the process as designed

SPC b) repeatable

c) non-random

d) assignable

3 What is meant by variance, as a statistical term?

a) the square of the standard deviation

SPC b) the difference between minimum and maximum value

c) the total process variation

d) the sum of the ranges