Professional Documents

Culture Documents

Questions of T1 Trial: Elite Moulding Co., Limited

Uploaded by

Marian PatrascuOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Questions of T1 Trial: Elite Moulding Co., Limited

Uploaded by

Marian PatrascuCopyright:

Available Formats

Web www.elite-moulding.

com

E-mailvicky@elite-moulding.com

Tel0086 755-84282600

Fax: (0086 755-86380589)

Elite Moulding Co., Limited

Questions of T1 Trial

Elite Moulding Co., Limited

Regarding the lower part,due to the surface requirements not mentioned before,so at present,here is the polish surface.

Pls confirm whether it is the polish surface or texture surface?

Re: The surface here must be textured. No polish here! Surface like here

EliteOK.

Here is the texture surface

Elite Moulding Co., Limited

Here is general polish,in order not to affect the assembly and size,the high polish will be arranged

after the assembly and size are confirmed.

Re: OK. Polish must be better. It must look like this:

EliteOK.

Elite Moulding Co., Limited

Here is the semicircle which was processed as per your drawing,but the structure of right semicircle is connected with the part.

pls confirm whether the left semicircle should be make the same with the right semicircle?

Re: Please add semicircle on upper part too, to close this hole like cover part.

We observed that you didnt study 2D drawings too. The 2D drawings completes the 3D drawing in the event of any errors in this.

Elite:The mould will be processed just according to 3D,not 2D.please note,thanks.In order to avoid any mistakes,please kindly check

attached modified 3D and confirm if it is ok?just make sure of it,thanks.

Re: Your 3D drawing is not correct. We will send you the correct 3D drawing later tomorrow.

Elite Moulding Co., Limited

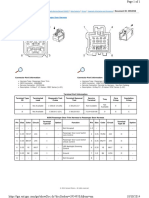

In the core side,many of ribs are lack of plastic due to the ribs are too thin,pls confirm if we can add plastic?

Re: You can add plastic to increase the thickness of the ribs from 1,00mm on base to 0,80mm on the end

on the ribs.

EliteThe surface will be sink mark if increase the thickness of the ribs,and if 1.00mm to 0.80mm,it will stick in mould.

Re: you may increase the thickness of ribs to 1mm x 1mm as you suggest in your last e-mail.

1. It is necessary to make some air vents opposite the injection points. This way, these trace gases accumulated

during the injection process, wont be visible anymore.

2. As you can see in this picture, the cover and base are very curved, please make sure these won't be curved

anymore.

EliteOK

The air vents should be made opposite the injection points. This way, these trace gases accumulated

during the injection process, wont be visible anymore.

EliteIt will caused flash if make air vents for gas with 0.2mm depth,it can be only made up to 0.02mm.

Re: OK, Please make the air vents at 0.02mm.

Air vents for gas 0.2mm depth

Air vents for gas 0.2mm depth

Air vents for gas 0.02mm depth

Air vents for gas 0.02mm depth

The surfaces here must be textured. No polish here

Elite:OK

The surfaces here must be textured. No polish here.

Elite:OK

Elite:At the bottom of low part,also will be textured.

Re: Ok, it doesnt matter. It can also remain like it is

in this moment also.

The change insert for switch should be made for cover side and core side also. You realized the change insert only for cover

side. It is absolutely necessary to make this change insertion for core side too.

Elite:Please send us the drawing of change insert or provide us the size,thanks.

Re: 3D drawing of change insert for core side added in the attachment.

Elite Moulding Co., Limited

Elite:In order to improve the injection point and cancel the turbulences,we suggest to add the thickness of the ribs with 1mmX1mm

on the core side as per the present point,please confirm if it is ok?

Re: OK

Elite Moulding Co., Limited

Elite:In order to improve the injection point and cancel the turbulences,we suggest to add the thickness of the ribs with 1mmX1mm

on the core side as per the present point,please confirm if it is ok?

Re: OK

PLEASE IMPROVE ALL BELOW:

1. On the cover side, there are aspects of turbulences nearby injection points, on textured part (generated by the small area

points of injection).

2. There are shiny areas on the opposite side of injection, around the switch and nearby the median part of cover side.

3. 4 lines are visible, about 4mm each Nearby switch, opposite the injection point.

4. The cover is curved in length with a deviation of more than 3 mm and the base with a deviation of approx. 2mm, generated

either by opening the half-molds or the way of extraction of the part from the mold, by the operator.

5. Visible weld line on base.

Elite:OK,We will improve it.

Re: OK. We just have to mention that the final assembly of the product does not reduce the curvature of the cover and base

sides.

1

2

3

5

4

Elite Moulding Co., Limited

You might also like

- Plastic Injection Mold Design for Toolmakers - Volume II: Plastic Injection Mold Design for Toolmakers, #2From EverandPlastic Injection Mold Design for Toolmakers - Volume II: Plastic Injection Mold Design for Toolmakers, #2No ratings yet

- Improving The Sealing On Spin-On Oil Filter AdaptorsDocument2 pagesImproving The Sealing On Spin-On Oil Filter AdaptorsBob Le BrocqNo ratings yet

- (Boat-Building) Bait Boat Plans 06Document1 page(Boat-Building) Bait Boat Plans 06inekefrank1No ratings yet

- F 15 ManualDocument17 pagesF 15 Manualscimionetta0% (1)

- King Quad 700 Tips 101 Ver 1.2Document36 pagesKing Quad 700 Tips 101 Ver 1.2Andy House100% (1)

- FD3 Turbine (PDF Library)Document19 pagesFD3 Turbine (PDF Library)l75aukkanen100% (3)

- Hangar One InstructionsDocument13 pagesHangar One InstructionsDan BeakeNo ratings yet

- Improving The Gearshift Feel in An SW20.: Part OneDocument13 pagesImproving The Gearshift Feel in An SW20.: Part OnePoubelleNo ratings yet

- Butuan Oz Goose #1 Hole Repair: DamageDocument5 pagesButuan Oz Goose #1 Hole Repair: DamagePrado EugeneNo ratings yet

- Panbrake PDFDocument39 pagesPanbrake PDFluisimtzNo ratings yet

- Wooden Gear Clocks UK: Build Manual For "Clockerel" Electromechanical Wooden Geared ClockDocument25 pagesWooden Gear Clocks UK: Build Manual For "Clockerel" Electromechanical Wooden Geared ClockKovačević Darko100% (1)

- Exhaust and CombustionDocument1 pageExhaust and CombustionKhoinguyen NguyenNo ratings yet

- 02 Building A Model Steam Engine From Scratch Chapter 2 246Document15 pages02 Building A Model Steam Engine From Scratch Chapter 2 246schelankoNo ratings yet

- Let's Build A Can Stirling Engine: Step 1 - Material Preparation and StructureDocument3 pagesLet's Build A Can Stirling Engine: Step 1 - Material Preparation and StructurebioriskNo ratings yet

- Weld Repair: Antonius P. BramonoDocument38 pagesWeld Repair: Antonius P. BramonofaridNo ratings yet

- Voron B - The ManualDocument63 pagesVoron B - The ManualDaniel Leonardo AlbeNo ratings yet

- Cerec 3d Preparation Guidelines en PDFDocument10 pagesCerec 3d Preparation Guidelines en PDFMarian Si Teofana HasnaNo ratings yet

- Sliding Core Tutorial (Using Side Core Tool) : Modelling The ComponentDocument6 pagesSliding Core Tutorial (Using Side Core Tool) : Modelling The ComponentNithNo ratings yet

- Build Instructions:: Download Extra 300 - 900 MM Plans Download Extra 300 - 900 MM Mazda DecalsDocument16 pagesBuild Instructions:: Download Extra 300 - 900 MM Plans Download Extra 300 - 900 MM Mazda Decalsfer freeNo ratings yet

- Wooden Gear Clocks UK: Build Manual For "Clockerel" Electromechanical Wooden Geared ClockDocument25 pagesWooden Gear Clocks UK: Build Manual For "Clockerel" Electromechanical Wooden Geared ClockJosé OrdoñezNo ratings yet

- PLANS Lamborghini CountachDocument33 pagesPLANS Lamborghini CountachRichard NevilleNo ratings yet

- Plans To Build A Lamborghini Countach On A Fiero Chassis 33 Pages Stolen Full Dont Pay Those Assholes - Matrix Reloaded Bruce AlmightyDocument33 pagesPlans To Build A Lamborghini Countach On A Fiero Chassis 33 Pages Stolen Full Dont Pay Those Assholes - Matrix Reloaded Bruce AlmightyCarlosMSCandeias100% (2)

- Apron: Apron To Saddle ConnectionDocument10 pagesApron: Apron To Saddle ConnectionFernando EricesNo ratings yet

- Objective-:) Option To Select The Intersecting Cone and Cylinder of Casing and Use Inverse Option. We See OnlyDocument3 pagesObjective-:) Option To Select The Intersecting Cone and Cylinder of Casing and Use Inverse Option. We See OnlyRohan JoshiNo ratings yet

- Home Made Stirling EngineDocument11 pagesHome Made Stirling EngineDouglas MendesNo ratings yet

- Plastic Design Guide: Designing Parts For Up & Down Molding Helps Control CostDocument3 pagesPlastic Design Guide: Designing Parts For Up & Down Molding Helps Control CostDEVELOPMENT EPITOMENo ratings yet

- Guppyassemblymanual PDFDocument11 pagesGuppyassemblymanual PDFmarianospenza100% (1)

- Saginaw Box Rebuild - How To..Document62 pagesSaginaw Box Rebuild - How To..api-26140644100% (2)

- TKC ARTICLE Mind The GapDocument2 pagesTKC ARTICLE Mind The GaphydrotechnixNo ratings yet

- Bultaco Swingarm Needle Roller Conversion Installation Guide R1Document6 pagesBultaco Swingarm Needle Roller Conversion Installation Guide R1Steve NewmanNo ratings yet

- AFV Modeller - Issue 10 - 6 - T55 - Back To BasicsDocument12 pagesAFV Modeller - Issue 10 - 6 - T55 - Back To BasicsAndrás Huszti100% (4)

- Injection Molding Lecture 09-04-08Document20 pagesInjection Molding Lecture 09-04-08viswaforuNo ratings yet

- Spitfire MKI 1500 InstructionsDocument13 pagesSpitfire MKI 1500 InstructionsSteven D100% (1)

- XT1200z Water DeflectorDocument4 pagesXT1200z Water DeflectorDriss ChahirNo ratings yet

- BMW E31 8 Series - Roof RackDocument10 pagesBMW E31 8 Series - Roof RackaudioimagenNo ratings yet

- In Take PortingDocument6 pagesIn Take PortingSutikno100% (1)

- Build Your Own TurbineDocument16 pagesBuild Your Own TurbineJack D'Roca100% (5)

- 3X1600mm Auto Slitting Line Installation ManualDocument16 pages3X1600mm Auto Slitting Line Installation ManualFernando GaleanoNo ratings yet

- Step by Step DIY Windmill PlansDocument10 pagesStep by Step DIY Windmill Planskeratoconos100% (2)

- Blow Molding Design GuidlinesDocument13 pagesBlow Molding Design Guidlinesmayank123No ratings yet

- Manufacturing Process For CollarDocument5 pagesManufacturing Process For CollarRenier MoolmanNo ratings yet

- BOXSTERConvtopconversion PARTIformattDocument16 pagesBOXSTERConvtopconversion PARTIformattChase kinneyNo ratings yet

- Double Top BuildingDocument18 pagesDouble Top BuildingaboutsoundcraftNo ratings yet

- Glass Edge Work and ProcessingDocument8 pagesGlass Edge Work and ProcessingAndreaski LamboNo ratings yet

- Striker ManualDocument51 pagesStriker ManualDani Garcia AlvarezNo ratings yet

- Stationary Clamp ReportDocument21 pagesStationary Clamp Reportapi-233198198No ratings yet

- Fine Blanking Design GuideDocument33 pagesFine Blanking Design GuideVikram Borkhediya100% (5)

- ArcylicDocument10 pagesArcylicFatih DEMİRCANNo ratings yet

- From Flat To Fab: Pattern Metals With The Economy Compact Rolling MillDocument30 pagesFrom Flat To Fab: Pattern Metals With The Economy Compact Rolling MillWiredlotus100% (7)

- Battle Station Practicum - 1-32 PracticumDocument49 pagesBattle Station Practicum - 1-32 PracticumVojislav LakovićNo ratings yet

- Lyman Filament Extruder v4.1 ManualDocument41 pagesLyman Filament Extruder v4.1 ManualHoang LeNo ratings yet

- A Grinding SpindleDocument4 pagesA Grinding Spindlewillows300No ratings yet

- ASG-32 Glider Assembly InstructionsDocument19 pagesASG-32 Glider Assembly InstructionsxnsrtNo ratings yet

- Offroad Kart PlanDocument24 pagesOffroad Kart PlanAnshul Kothari100% (1)

- Plastic Injection Mold Design for Toolmakers - Volume III: Plastic Injection Mold Design for Toolmakers, #3From EverandPlastic Injection Mold Design for Toolmakers - Volume III: Plastic Injection Mold Design for Toolmakers, #3No ratings yet

- Plastic Injection Mold Design for Toolmakers - Volume I: Plastic Injection Mold Design for Toolmakers, #1From EverandPlastic Injection Mold Design for Toolmakers - Volume I: Plastic Injection Mold Design for Toolmakers, #1Rating: 5 out of 5 stars5/5 (2)

- Grant Miller Resume-ColliersDocument3 pagesGrant Miller Resume-ColliersDeven GriffinNo ratings yet

- Civpro RevDocument102 pagesCivpro RevJocelyn Baliwag-Alicmas Banganan BayubayNo ratings yet

- Risk, Return & Capital BudgetingDocument18 pagesRisk, Return & Capital BudgetingMuhammad Akmal HussainNo ratings yet

- DCF ModelDocument14 pagesDCF ModelTera ByteNo ratings yet

- Nirma - Marketing PresentationDocument22 pagesNirma - Marketing PresentationJayRavasa100% (2)

- Tavera Vs Valdez 1 Phil 468Document2 pagesTavera Vs Valdez 1 Phil 468John AmbasNo ratings yet

- 7MWTW1710YM0Document8 pages7MWTW1710YM0Izack-Dy JimZitNo ratings yet

- Final Answers Chap 002Document174 pagesFinal Answers Chap 002valderramadavid67% (6)

- 15.910 Draft SyllabusDocument10 pages15.910 Draft SyllabusSaharNo ratings yet

- Computer Graphics Mini ProjectDocument25 pagesComputer Graphics Mini ProjectGautam Singh78% (81)

- San Francisco Chinese Christian Union, Et Al. v. City and County of San Francisco, Et Al. ComplaintDocument25 pagesSan Francisco Chinese Christian Union, Et Al. v. City and County of San Francisco, Et Al. ComplaintFindLawNo ratings yet

- Problems of Spun Concrete Piles Constructed in Soft Soil in HCMC and Mekong Delta - VietnamDocument6 pagesProblems of Spun Concrete Piles Constructed in Soft Soil in HCMC and Mekong Delta - VietnamThaoNo ratings yet

- SCI 121 Disaster Readiness and Risk ReductionDocument163 pagesSCI 121 Disaster Readiness and Risk ReductionLEONIEVEVE L LIMBAGANo ratings yet

- Book Notes Covering: Andy Kirk's Book, Data Visualization - A Successful Design ProcessDocument10 pagesBook Notes Covering: Andy Kirk's Book, Data Visualization - A Successful Design ProcessDataVersed100% (1)

- Home Work (Satistics AIUB)Document5 pagesHome Work (Satistics AIUB)fukscribdNo ratings yet

- 1.reasons For VariationsDocument2 pages1.reasons For Variationsscribd99190No ratings yet

- Maverick Research: World Order 2.0: The Birth of Virtual NationsDocument9 pagesMaverick Research: World Order 2.0: The Birth of Virtual NationsСергей КолосовNo ratings yet

- Design of Accurate Steering Gear MechanismDocument12 pagesDesign of Accurate Steering Gear Mechanismtarik RymNo ratings yet

- Uporedna Tabela Addinol-Ovih UljaDocument4 pagesUporedna Tabela Addinol-Ovih UljaasimpeksNo ratings yet

- Step Recovery DiodesDocument3 pagesStep Recovery DiodesfahkingmoronNo ratings yet

- Sage 200 Evolution Training JourneyDocument5 pagesSage 200 Evolution Training JourneysibaNo ratings yet

- Learning Activity Sheet Science 10 Second Quarter - Week 8Document4 pagesLearning Activity Sheet Science 10 Second Quarter - Week 8Eller Jansen AnciroNo ratings yet

- O-CNN: Octree-Based Convolutional Neural Networks For 3D Shape AnalysisDocument11 pagesO-CNN: Octree-Based Convolutional Neural Networks For 3D Shape AnalysisJose Angel Duarte MartinezNo ratings yet

- X606 PDFDocument1 pageX606 PDFDany OrioliNo ratings yet

- Quality ManualDocument34 pagesQuality Manualchao gao100% (9)

- PFMEA Reference Card PDFDocument2 pagesPFMEA Reference Card PDFRajesh Yadav100% (5)

- Craske - Mastering Your Fears and FobiasDocument174 pagesCraske - Mastering Your Fears and Fobiasjuliana218No ratings yet

- Telstra InterviewsDocument3 pagesTelstra InterviewsDaxShenNo ratings yet

- Solar Power Plant in Iit HyderabadDocument9 pagesSolar Power Plant in Iit HyderabadHimanshu VermaNo ratings yet

- Evaluating The Policy Outcomes For Urban Resiliency in Informal Settlements Since Independence in Dhaka, Bangladesh: A ReviewDocument14 pagesEvaluating The Policy Outcomes For Urban Resiliency in Informal Settlements Since Independence in Dhaka, Bangladesh: A ReviewJaber AbdullahNo ratings yet