Professional Documents

Culture Documents

Cooling Tower Seminar

Uploaded by

Rupesh Desai100%(1)100% found this document useful (1 vote)

139 views67 pagesCooling towers function by bringing air and water into direct contact, allowing heat to transfer from the water to the air through evaporation. There are different types of cooling towers categorized by their air flow design and mechanical draft capabilities. The main types are counterflow, where air and water flow in opposite directions, and crossflow, where air flows horizontally across falling water. Cooling towers lower the temperature of circulating water and reject heat into the atmosphere, improving efficiency for cooling systems.

Original Description:

COOLING TOWER

Copyright

© © All Rights Reserved

Available Formats

PPT, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCooling towers function by bringing air and water into direct contact, allowing heat to transfer from the water to the air through evaporation. There are different types of cooling towers categorized by their air flow design and mechanical draft capabilities. The main types are counterflow, where air and water flow in opposite directions, and crossflow, where air flows horizontally across falling water. Cooling towers lower the temperature of circulating water and reject heat into the atmosphere, improving efficiency for cooling systems.

Copyright:

© All Rights Reserved

Available Formats

Download as PPT, PDF, TXT or read online from Scribd

100%(1)100% found this document useful (1 vote)

139 views67 pagesCooling Tower Seminar

Uploaded by

Rupesh DesaiCooling towers function by bringing air and water into direct contact, allowing heat to transfer from the water to the air through evaporation. There are different types of cooling towers categorized by their air flow design and mechanical draft capabilities. The main types are counterflow, where air and water flow in opposite directions, and crossflow, where air flows horizontally across falling water. Cooling towers lower the temperature of circulating water and reject heat into the atmosphere, improving efficiency for cooling systems.

Copyright:

© All Rights Reserved

Available Formats

Download as PPT, PDF, TXT or read online from Scribd

You are on page 1of 67

COOLING TOWER BASICS

COOLING TOWER TERMINOLOGY

COOLING TOWER FUNCTION

COOLING TOWER TYPES

COMPILED BY

RUPESH G DESAI

EXECUTIVE(ENGG SERVICES)

COOLING TOWER TERMINOLOGY

EVAPORATIVE COOLING

HEAT TRANSFER WHERE A LIQUID

CONDENSES INTO ITS GASOUS STATE

THEREBY GIVING UP ITS LATENT HEAT

RANGE

IT IS THE DIFFERENCE BETWEEN THE

WATER TEMPERATURE ENTERING THE

COOLING TOWER HOT WATER

DISTRIBUTION SYSTEM AND COLD

WATER TEMP LEAVING THE SUMP OF

COOLING TOWER.

The cooling tower efficiency can be expressed as:

= (ti - to) 100 / (ti - twb)

where

= cooling tower efficiency - common range

between 70 - 75%

ti = inlet temperature of water to the tower (oC, oF)

to = outlet temperature of water from the tower (oC,

oF)

twb = wet bulb temperature of air (oC, oF)

DRIFT

Water droplets that are carried out of the

cooling tower with the exhaust air. Drift

droplets have the same concentration of

impurities as the water entering the tower.

The drift rate is typically reduced by

employing baffle-like devices, called drift

eliminators, through which the air must travel

after leaving the fill and spray zones of the

tower.

BLOW-DOWN

The portion of the circulating water flow that

is removed in order to maintain the amount of

dissolved solids and other impurities at an

acceptable level.

BLOW-OUT

Water droplets blown out of the cooling tower

by wind, generally at the air inlet openings.

Water may also be lost, in the absence of

wind, through splashing or misting. Devices

such as wind screens, louvers, splash

deflectors and water diverters are used to

limit these losses.

Water Make-up

Water losses include evaporation, drift (water

entrained in discharge vapor), and blow down (water

released to discard solids).

Drift losses are estimated to be between 0.1 and

0.2% of water supply.

Evaporation Loss = 0.00085 * water flow rate*(T1-T2)

Blow down Loss =Evaporation Loss/(COC-1)

where COC is the ratio of solids in the circulating

water to the solids in the make-up water

Total Losses = Drift Losses + Evaporation Losses +

Blow down Losses

DRY BULB TEMPERATURE

TEMPERATURE OF AMBIENT AIR

MEASURED IN REGULAR MANNER WITH

CONVENTIONAL INSTRUMENTS

DEW POINT

TEMPERATURE AT WHICH GIVEN

MIXTURE OF AIR AND WATER WILL HAVE

RELATIVE HUMIDITY OF 100%

SATURATOIN

WET BULB TEMPERATURE

The lowest temperature that can be obtained

by evaporating water into the air at constant

pressure. The name comes from the

technique of putting a wet cloth over the bulb

of a mercury thermometer and then blowing

air over the cloth until the water evaporates.

Since evaporation takes up heat, the

thermometer will cool to a lower temperature

than a thermometer with a dry bulb at the

same time and place.

PLENUM

THE ENCLOSED SPACE BETWEEN THE

DRIFT ELIMINATORS AND THE FAN

STACK IN INDUCED DRAFT TOWERS OF

THE ENCLOSED SPACE BETWEEN THE

FAN AND FILLING IN THE FORCED DRAFT

TOWER

PLUME

VISIBLE EXAUST FROM COOLING TOWER

FAN PITCH

THE ANGLE WHICH A FAN BLADE MAKES

WITH THE PALNE OF ROTATON ,

DEGREES FROM HORIZONTAL

CROSS FLOW

FUNCTION OF COOLING TOWER

The primary task of a cooling tower is to reject

heat into the atmosphere. This heat rejection is

accomplished through the natural process of

evaporation that takes place when air and

water are brought into direct contact in the

cooling tower. The evaporation is most efficient

when the maximum water surface area is

exposed to the maximum flow of air, for the

longest possible period of time

FUNCTION OF COOLING TOWER

The primary task of a cooling tower is to reject heat into the

atmosphere. This heat rejection is accomplished through the natural

process of evaporation that takes place when air and water are

brought into direct contact in the cooling tower. The evaporation is

most efficient when the maximum water surface area is exposed to

the maximum flow of air, for the longest possible period of time.

Cooling towers are designed in two different configurations, counter

flow and cross flow. The specific configuration indicates the direction

of air flow through the tower relative to the direction of the water

flow. Cooling tower water and air distribution systems are designed

in concert, with each playing an equally important role in

determining the efficiency and proper application of the cooling

tower.

COOLING TOWER TYPES

ATMOSPHERIC

MECHANICAL DRAFT

a. FORCED DRAFT

b. INDUCED DRAFT

HYBRID DRAFT

TYPED BY AIR FLOW

a. COUNTERFLOW

b. CROSSFLOW

b.1 DOUBLE-FLOW

b.2 SINGLE-FLOW

c. SPRAY-FILLED

TYPED BY CONSTRUCTION

a. FIELD-ERECTED

b. FACTORY-ASSEMBLED

TYPED BY SHAPE

a. RECTILINEAR

b. ROUND MECHANICAL DRAFT (RMD)

TYPED BY METHOD OF HEAT TRANSFER

a. EVAPORATIVE

b. DRY TOWER

c. PLUME ABATEMENT

ATMOSPHERIC

The atmospheric cooling towers utilize no

mechanical fan to create air flow through

the tower, its air is derived from a natural

induction flow provided by a pressure spray.

We can see it in the following picture:

ATMOSPHERIC COOLING TOWERS

MECHANICAL DRAFT

Mechanical draft towers uses fans (one or more) to move large

quantities of air through the tower. They are two different classes:

Forced draft cooling towers

Induced draft cooling towers

The air flow in either class may be cross flow or counter flow with

respect to the falling water. Cross flow indicates that the airflow is

horizontal in the filled portion of the tower while counter flow means

the air flow is in the opposite direction of the falling water.

The counter flow tower occupies less floor space than a cross flow

tower but is taller for a given capacity. The principle advantages of

the cross flow tower are the low pressure drop in relation to its

capacity and lower fan power requirement leading to lower energy

costs.

All mechanical towers must be located so that the discharge air

diffuses freely without recirculation through the tower, and so that air

intakes are not restricted. Cooling towers should be located as near

as possible to the systems they serve, but should never be located

below them so as to allow the condenser water to drain out of the

system through the tower basin when the system is shut down.

FORCED DRAFT

The forced draft tower, shown in the picture,

has the fan, basin, and piping located within

the tower structure. In this model, the fan is

located at the base. There are no louvered

exterior walls. Instead, the structural steel or

wood framing is covered with paneling made

of aluminum, galvanized steel, or asbestos

cement boards

FORCED DRAFT

FORCED DRAFT

During operation, the fan forces air at a low

velocity horizontally through the packing and

then vertically against the downward flow of

the water that occurs on either side of the

fan. The drift eliminators located at the top of

the tower remove water entrained in the air.

Vibration and noise are minimal since the

rotating equipment is built on a solid

foundation. The fans handle mostly dry air,

greatly reducing erosion and water

condensation problems.

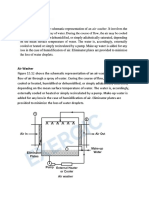

INDUCED DRAFT

The induced draft tower show in the following

picture has one or more fans, located at the

top of the tower, that draw air upwards

against the downward flow of water passing

around the wooden decking or packing. Since

the airflow is counter to the water flow, the

coolest water at the bottom is in contact with

the driest air while the warmest water at the

top is in contact with the moist air, resulting in

increased heat transfer efficiency.

INDUCED DRAFT

HYBRID DRAFT

They are equipped with mechanical draft

fans to augment airflow. Consequently, they

are also referred to as fan-assisted natural

draft towers. The intent of their design is to

minimize the horsepower required for the air

movement, but to do so with the least

possible stack cost impact. Properly

designed the fans may need to be operated

only during periods at high ambient and

peak loads.

HYBRID DRAFT

CHARACTERIZATION BY AIR FLOW

COUNTERFLOW:

IN the counter flow towers, the air moves vertically upward

through the fill, counter to the downward fall of water. Because

of the need for extended intake and discharge plenums; the

use of high pressure spray systems; and the typically higher air

pressure losses, some of the smaller counter flow towers are

physically higher; require more pump head; and utilize more

fan power than their cross flow counterparts. In a larger

counter flow towers, however, the use of low pressure gravity-

related distribution systems, plus the availability of generous

intake areas and plenum spaces for the air management, is

tending to equalize, or even reverse, this situation. The

enclosed nature of a counter flow tower also restricts exposure

of the water to direct sunlight, thereby retarding the growth of

the algae.

COUNTER FLOW

CROSSFLOW:

The cross flow towers have a fill configuration

through, which the air flows horizontally,

across the downward fall of water. Water to

be cooled is delivered to hot water inlet

basins located atop the fill areas, and is

distributed to the fill by gravity throught

metering orifices in the floor of those basins.

The cross flow towers can be divided in:

DOUBLE-FLOW:

In this kind of towers the fan is inducting air through

two inlets and across two banks of fill.

SINGLE-FLOW:

This kind of towers only has one air inlet and one fill

bank, the remaining three sides of the towers being

cased. Single-flow towers are customarily used in

locations where are unrestricted air path to the tower

is available from only one direction.

SINGLE FLOW

SPRAY FILLED

This kind of towers has not a heat transfer

surface, depending only upon the water

break-up af-forded by the distribution

system to promote maximum water-to-air

SPRAY FILLED

CHARACTERIZATION BY CONSTRUCTION

FIELD-ERECTED:

The field-erected cooling towers are those on which

the primary construction activity takes place at the

site of ultimate use. All large towers, and many of

the smaller towers, are prefabricated, piece-market

and shipped to the site for the cooling towers

manufacturer usually provides final assembly.

FACTORY-ASSEMBLED:

The factory-assembled cooling towers undergo

virtually complete assembly at their point of

manufacture, whereupon there are shipped to the

site in as a few sections as mode of transportation

will permit.

TYPED BY SHAPE

RECTILINEAR:

These towers are constructed in cellular fashion,

increasing linearly to the length and numbers of

cells necessary to accomplish a special thermal

performance.

ROUND MECHANICAL DRAFT:

Are towers as the name implies, are essentially

round in plan configuration, with fans clustered as

close practicable around the center point of the

tower. Multi-faceted towers, such as the octagonal

mechanical draft (OMD) also fall in the general

classification of round towers.

RECTILINEAR

ROUND MECHANICAL DRAFT

TYPED BY METHOD OF HEAT TRANSFER

All of the cooling towers described here are evaporative type

towers, in that they derive their primary cooling effect from the

evaporation that takes place when air and water are brought

into the direct contact. At the other end of the spectrum is the

Dry tower, where by full utilization of dry surface coil sections,

no direct contact (and no evaporation) occurs between air and

water. Hence sensible heat transfer cools the water totally.

IN between these extremes are the plume abatement and

water conservation towers, wherein progressively greater

portions of dry surface coil sections are introduced into the

overall heat transfer system to alleviate specific problems or to

accomplish specific requirements.

HOT WATER DISTRIBUTION SYSTEMS

The overall efficiency of a cooling tower is directly related to the

design of the tower's hot water distribution system. The primary

consideration in selecting the type of hot water distribution

system for a specific application is pump head. The pump head

imposed by a cooling tower consists of the static lift (related to

the height of the inlet) plus the pressure necessary to move the

water through the distribution system and over the fill. The pump

head varies according to the cooling tower configuration.

Counter flow towers use a high pressure spray nozzle hot water

distribution system to achieve water coverage of the fill. The

nozzle spray pattern is sensitive to changes in water flow, and

consequent change in nozzle pressure. The air movement is

vertically upward through the fill, counter to the downward fall of

the water (Figure 1). Counter flow towers typically have a smaller

footprint than cross flow towers, but require additional height,

static lift, and dynamic head to achieve the same cooling effect.

Cross flow towers utilize a distinctly different type of water

distribution system. Hot water is distributed to the fill by gravity

through metering orifices in the floor of the inlet basin. There is

no pressure spray distribution system. The air movement is

horizontally through the fill, across the downward fall of the water

(Figure 2). In cross flow towers, the internal pressure component

of pump head is insignificant because maximum flow is achieved

by gravity.

Compared to cross flow towers, counter flow towers may require

up to five or six psig added pump head to achieve the proper

spray distribution. The high counter flow pumping head

requirement (tower height plus nozzle pressure) leads to a higher

first cost pumping system and significantly higher annual pump

energy consumption and operating costs. If the system

condenser pumps are not properly sized, the additional pump

head required in counter flow towers may result in inadequate

hot water flow, reducing tower efficiency and performance

AIR FLOW DISTRIBUTION SYSTEMS

Cooling tower performance is also related to the amount of air

moving through the tower and coming into direct contact with the

water. In counter flow towers the air movement is vertically

upward through the fill, counter to the downward fall of the water.

This configuration, along with the finer water droplet size

available from pressurized spray nozzles,

allows counter flow towers to make more efficient use of

available air. However, the resistance to upward air travel against

the falling water results in higher static pressure loss and greater

fan horsepower than a cross flow system.

Cross flow towers have a fill configuration through which air flows

horizontally across the downward flow of the water. Cross flow

towers utilize essentially the full tower height for inlet louvers,

reducing air inlet velocity and minimizing recirculation and drift

loss. The air inlet louvers in counter flow towers are restricted to

the tower base, increasing inlet velocities and susceptibility to

airborne trash and other debris

CROSS FLOW

CROSS FLOW

ADVANTAGES OF CROSSFLOW cooling towers due to their

gravity flow hot water distribution system:

Low pumping head.

Lower first cost pumping systems.

Lower annual energy consumption and operating costs.

Accepts larger variation in water flow without adverse effect on

the water distribution pattern (flat plate heat exchanger operation

in winter).

Easy maintenance access to distribution nozzles.

DISADVANTAGES OF CROSSFLOW cooling towers due to their

gravity flow hot water distribution system:

Low pressure head on the distribution pan may encourage orifice

clogging and less water breakup at spray nozzle.

Exposure to air in the hot water basin may accelerate algae

growth. Larger footprint.

COUNTERFLOW

COUNTERFLOW

ADVANTAGES OF COUNTERFLOW cooling towers due to their

pressurized spray water distribution system:

Increased tower height accommodates longer ranges and closer

approaches.

More efficient use of air due to finer droplet size from pressure

sprays.

DISADVANTAGES OF COUNTERFLOW cooling towers due to

their pressurized spray water distribution system:

Increased system pumping head requirements.

Increased energy consumption and operating costs.

Distribution nozzles difficult to inspect and clean.

Requires individual risers for each cell, increasing external piping

costs.

CROSSFLOW

ADVANTAGES OF CROSSFLOW cooling towers due to their

horizontal air distribution system:

Low static pressure drop.

Reduced drift.

Reduced recirculation.

More air per fan horsepower.

Larger diameter fans can be used so that fewer cells are required

for a given capacity.

Lower energy and operating costs.

DISADVANTAGES OF CROSSFLOW cooling towers due to their

horizontal air distribution system:

Larger louver surface area makes icing more difficult to control.

COUNTERFLOW

ADVANTAGES OF COUNTERFLOW cooling towers due to their

vertical air distribution system:

The vertical air movement across the fill allows the coldest water

to be in contact with the driest air maximizing tower performance.

DISADVANTAGES OF COUNTERFLOW cooling towers due to

their vertical air distribution system:

The resistance to upward air travel against the falling water

results in higher static pressure loss and a greater fan

horsepower than in cross flow towers.

The restricted louver area at the base with high velocity of inlet

air increases the fan horsepower.

Tendency for uneven distribution of air through the fill with very

little movement near the walls and center of the tower.

High inlet velocities are liable to suck airborne trash and dirt into

the tower.

CONCLUSIONS AND RECOMMENDATIONS

The air and water distribution systems for counter flow and cross flow

cooling towers have advantages and disadvantages inherent in their

respective designs. It cannot be said that one is better than the other.

Rather, with the proper application, both configurations are cost

effective and can serve the end user well.

Cross flow cooling towers should be specified when the following

criteria and limitations are important:

To minimize pump head.

To minimize pumping and piping first costs.

To minimize operating costs.

When condenser water flow variance is expected.

When ease of maintenance is a concern.

Counter flow cooling towers should be specified when the following

criteria and limitations are important:

When space (footprint) is restricted.

When icing is of extreme concern.

When pumping is designed for additional pressure drop.

You might also like

- ME 331 Refrigeration & Air Conditioning: M AsfandyarDocument20 pagesME 331 Refrigeration & Air Conditioning: M AsfandyarSuaid Tariq BalghariNo ratings yet

- Livchak ASHRAE Journal Chilled Beam & DOASDocument10 pagesLivchak ASHRAE Journal Chilled Beam & DOAS윤병택No ratings yet

- Redline Ashrae 41.1 2013-1986R2006Document64 pagesRedline Ashrae 41.1 2013-1986R2006Huzaifah Bin YounusNo ratings yet

- Hvac Design Manual: First EditionDocument124 pagesHvac Design Manual: First EditionNathan Tom100% (7)

- CondenserDocument12 pagesCondenserPrabir Kumar Pati100% (1)

- Cooling Tower DefinitionsDocument68 pagesCooling Tower Definitionszubi13No ratings yet

- P030 Chiller Operating ManualDocument44 pagesP030 Chiller Operating ManualshsecoNo ratings yet

- Timken Seal Specification GuideDocument204 pagesTimken Seal Specification GuideRupesh DesaiNo ratings yet

- 25-01-10 Networking Event EMS FinalDocument41 pages25-01-10 Networking Event EMS FinalajeeshsivanNo ratings yet

- Humidification Operation and Cooling Tower: Introduction, Performance, and DesignDocument31 pagesHumidification Operation and Cooling Tower: Introduction, Performance, and DesignSafyan ManzoorNo ratings yet

- Faculty of Engineering TechnologyDocument11 pagesFaculty of Engineering TechnologyRidzwan IqbalNo ratings yet

- BS 5422 - 2001 Insulation of DuctworkDocument61 pagesBS 5422 - 2001 Insulation of DuctworkNeels van PK100% (1)

- Cooling TowersDocument40 pagesCooling Towers1000 Subscribers Without a Video100% (2)

- Cascade Refrigeration System (Report)Document8 pagesCascade Refrigeration System (Report)THE PUBGTV100% (1)

- Sydney, NSW - Australia, March 8-9, 2010: E-Mail: Phone: +6053687732 Mobile: +60125012590Document19 pagesSydney, NSW - Australia, March 8-9, 2010: E-Mail: Phone: +6053687732 Mobile: +60125012590Rupesh Desai100% (1)

- Price List SystemairDocument175 pagesPrice List SystemairSRL Gamaplast100% (2)

- Cooling TowerDocument10 pagesCooling TowerKeshav Rao100% (1)

- Cooling Tower Project Report: Drift Air To Atmospher eDocument24 pagesCooling Tower Project Report: Drift Air To Atmospher eDinesh VermaNo ratings yet

- HVAC Design I - Class 8Document7 pagesHVAC Design I - Class 8Wyatt C. Lewis100% (1)

- Cooling Tower - BaltimoreDocument7 pagesCooling Tower - BaltimoreОсама А.ШоукиNo ratings yet

- Air Cooled and Water Cooled ChillerDocument17 pagesAir Cooled and Water Cooled ChillerAbdelhameed NadyNo ratings yet

- Cooling Tower Thermal CapabilityDocument8 pagesCooling Tower Thermal CapabilityforuzzNo ratings yet

- Cooling Tower PresentationDocument44 pagesCooling Tower PresentationAmi Desai100% (1)

- Cooling TowerDocument47 pagesCooling TowerVenkitaraj K P100% (1)

- Cooling Water System DesignDocument66 pagesCooling Water System Designraghuragoo100% (2)

- Air WasherDocument5 pagesAir WasherManral SaurabhNo ratings yet

- Cooling TowerDocument11 pagesCooling TowerAshok PatelNo ratings yet

- District CoolingDocument16 pagesDistrict Coolingmazzam75No ratings yet

- Cooling Towers: Cold Water BasinDocument13 pagesCooling Towers: Cold Water BasinmichsantosNo ratings yet

- Cooling Tower ComponentsDocument4 pagesCooling Tower ComponentsMohamed Mohsen100% (2)

- Presentation On Cooling TowersDocument52 pagesPresentation On Cooling TowersMuhammad Haris HamayunNo ratings yet

- Master Chilled Wate Entrance No HX Rev JMD 20120817-1Document8 pagesMaster Chilled Wate Entrance No HX Rev JMD 20120817-1AshNo ratings yet

- Storm Water System 4Document10 pagesStorm Water System 4Kent Jonas C. GensisNo ratings yet

- District CoolingDocument17 pagesDistrict CoolingNexus Zubin KondoorNo ratings yet

- Cooling TowerDocument23 pagesCooling TowerHasan Farooq100% (1)

- Cycle of Concentration in Cooling Tower PDFDocument1 pageCycle of Concentration in Cooling Tower PDFNgoc Vũ TrầnNo ratings yet

- Project - 1 PPT (Cooling Tower)Document16 pagesProject - 1 PPT (Cooling Tower)harshilshah122No ratings yet

- Chiller and Tower Sizing Formulas PDFDocument2 pagesChiller and Tower Sizing Formulas PDFnagarjuna reddy mNo ratings yet

- Best Practices For Energy Efficient Cleanrooms: Control of Chilled Water SystemDocument6 pagesBest Practices For Energy Efficient Cleanrooms: Control of Chilled Water SystemSing Yew LamNo ratings yet

- Lacos Sweeping Basin SystemDocument18 pagesLacos Sweeping Basin SystemSanto ENo ratings yet

- Chiller ConfigurationDocument8 pagesChiller Configurationavid_ankurNo ratings yet

- Chiller Cooling Tower AHUDocument9 pagesChiller Cooling Tower AHUAli Hassan RazaNo ratings yet

- Chapter 10 - Cooling TowerDocument24 pagesChapter 10 - Cooling TowerAsyraf Sabri100% (1)

- CFD SimulationDocument39 pagesCFD SimulationSambhav JainNo ratings yet

- Heat Load Estimation E20 Form SIDocument1 pageHeat Load Estimation E20 Form SISaul CastroNo ratings yet

- Types of Cooling Tower: Mass Transfer Operations-2Document27 pagesTypes of Cooling Tower: Mass Transfer Operations-2Chintan ModiNo ratings yet

- Spirax Sarco PDFDocument4 pagesSpirax Sarco PDFandresaroNo ratings yet

- Dean Paul Cueto 2 0 0 6 - 1 8 3 0 8: Me 188: Powerplant EngineeringDocument40 pagesDean Paul Cueto 2 0 0 6 - 1 8 3 0 8: Me 188: Powerplant EngineeringDean Paul100% (1)

- ERT 318/4 Unit Operations SEMESTER 1 (2013/2014) : Water Cooling TowerDocument18 pagesERT 318/4 Unit Operations SEMESTER 1 (2013/2014) : Water Cooling TowerNorzaifee NizamudinNo ratings yet

- Supersedes Bulletin # 006/2000Document15 pagesSupersedes Bulletin # 006/2000almig200100% (2)

- Improving Efficiency With Variable-Primary Flow - Air Conditioning Content From HPAC EngineeringDocument7 pagesImproving Efficiency With Variable-Primary Flow - Air Conditioning Content From HPAC EngineeringminiongskyNo ratings yet

- B7.2KENNEDYKILTECHIDEA Presentation Miami June 2013smallDocument30 pagesB7.2KENNEDYKILTECHIDEA Presentation Miami June 2013smallSMBEAUTYNo ratings yet

- Cooling Tower Efficiency and ApproachDocument8 pagesCooling Tower Efficiency and Approachjeevitha jeeviNo ratings yet

- Air Conditioning Processes Illustrated On A Psychrometric ChartDocument2 pagesAir Conditioning Processes Illustrated On A Psychrometric Chartvv260513No ratings yet

- P2Document158 pagesP2John MackenzieNo ratings yet

- Cooling Towers ProjectDocument25 pagesCooling Towers ProjectSuhail A MansooriNo ratings yet

- Team Submittalcustom AhuDocument62 pagesTeam Submittalcustom AhuCHRISNo ratings yet

- Reducing Steam Header PressureDocument1 pageReducing Steam Header Pressuresj_scribdNo ratings yet

- Evacuated Tube Soalr CollectorDocument14 pagesEvacuated Tube Soalr CollectorSuman PaulNo ratings yet

- Cooling TowerDocument12 pagesCooling TowerLillianLinNo ratings yet

- Understanding Pump Curves: Taco Radiant Made Easy Application Guide Technical DocumentsDocument4 pagesUnderstanding Pump Curves: Taco Radiant Made Easy Application Guide Technical DocumentsmohdnazirNo ratings yet

- Water Cooled PackageDocument37 pagesWater Cooled PackageLeed EN100% (1)

- SYS-APM001-En Chiller System Design and ControlDocument2 pagesSYS-APM001-En Chiller System Design and ControlAtiqNo ratings yet

- Condensation On Air Distribution ProductsDocument2 pagesCondensation On Air Distribution ProductsSonny Ramos100% (1)

- Distributed Computer Control System: Proceedings of the IFAC Workshop, Tampa, Florida, U.S.A., 2-4 October 1979From EverandDistributed Computer Control System: Proceedings of the IFAC Workshop, Tampa, Florida, U.S.A., 2-4 October 1979T. J. HarrisonNo ratings yet

- ابراج التبريدDocument8 pagesابراج التبريدemad_sayed_5No ratings yet

- Cooling Towers TypesDocument9 pagesCooling Towers TypesPeter Frank LoboNo ratings yet

- Cooling Tower and Cooling Water System: A Brief Presentation: Part-1 of 3Document16 pagesCooling Tower and Cooling Water System: A Brief Presentation: Part-1 of 3Syed ImranNo ratings yet

- CHAPTER 7 - COOLING TOWER Edit MOSH 211220Document25 pagesCHAPTER 7 - COOLING TOWER Edit MOSH 211220subash1111111No ratings yet

- Bolt TorqueDocument1 pageBolt TorqueRupesh DesaiNo ratings yet

- TD62LM and TD62M Thermodynamic Steam Traps With Replaceable Seats (Screwed /socket Weld)Document2 pagesTD62LM and TD62M Thermodynamic Steam Traps With Replaceable Seats (Screwed /socket Weld)Rupesh DesaiNo ratings yet

- Computation of Cooling LoadDocument10 pagesComputation of Cooling LoadYancy BagsaoNo ratings yet

- ENG Quantum FolderDocument9 pagesENG Quantum FolderAnonymous TThmYKFpNo ratings yet

- ThermodynamicsDocument14 pagesThermodynamicssarathNo ratings yet

- Chapter 02Document14 pagesChapter 02stephen jamesNo ratings yet

- Me Lab 9Document14 pagesMe Lab 9BensoyNo ratings yet

- Passive-Cooling-Techniques 220917Document16 pagesPassive-Cooling-Techniques 220917Cebo DharuNo ratings yet

- Bill of Quantities: Project: Centro HotelDocument8 pagesBill of Quantities: Project: Centro HotelAslamNo ratings yet

- Quayle Movable Air Cond ManualDocument8 pagesQuayle Movable Air Cond ManualAnonymous fE2l3DzlNo ratings yet

- Syllabus of Subject RAC - 05.092018Document3 pagesSyllabus of Subject RAC - 05.092018Hamidullah TotakhailNo ratings yet

- Equilibrium Moisture Content (Emc) Chart: Relative Humidity % Ambient Air Temp (Deg. F)Document1 pageEquilibrium Moisture Content (Emc) Chart: Relative Humidity % Ambient Air Temp (Deg. F)inezNo ratings yet

- Window Ac: Ashi Chandak Akriti Dubey Ritvika Singh Shweta BaisDocument25 pagesWindow Ac: Ashi Chandak Akriti Dubey Ritvika Singh Shweta BaisAshi ChandakNo ratings yet

- Kirkuk University College of Engineering Civil Engineering DepartmentDocument4 pagesKirkuk University College of Engineering Civil Engineering Departmentبه شدار ازاد عبدالرحمن عليNo ratings yet

- Honda Civice 023-03 HvacDocument58 pagesHonda Civice 023-03 Hvactong SaetungNo ratings yet

- Txy Diagram For Ethanol/Water at 760Mmhg: Model, Bubble Point Model, Dew Point Data, Bubble Point Data, Dew PointDocument3 pagesTxy Diagram For Ethanol/Water at 760Mmhg: Model, Bubble Point Model, Dew Point Data, Bubble Point Data, Dew PointjunomarsNo ratings yet

- REFSYS - 3ME-8 (2ND SEM/ A.Y. 2020-2021) Midterm ExaminationDocument3 pagesREFSYS - 3ME-8 (2ND SEM/ A.Y. 2020-2021) Midterm ExaminationRobert GarlandNo ratings yet

- Phase Changes SeDocument5 pagesPhase Changes Seankitjakhar350% (1)

- AQI Bulletin 20201126Document10 pagesAQI Bulletin 20201126Kartik PrabhakarNo ratings yet

- Healthy Building Training Series: Master Training: Ir. John Budi Harjanto Listijono, M.Eng - SC, IPUDocument3 pagesHealthy Building Training Series: Master Training: Ir. John Budi Harjanto Listijono, M.Eng - SC, IPUFahmy Rinanda SaputriNo ratings yet

- C D F S: Proposal of A Revision of EN 14511-1 "Terms and Definitions"Document14 pagesC D F S: Proposal of A Revision of EN 14511-1 "Terms and Definitions"Bruno de RossoNo ratings yet

- Thermometer: by A.J.Abubakkar SiddiqueDocument10 pagesThermometer: by A.J.Abubakkar SiddiqueA.J. Abubakkar SiddiqueNo ratings yet

- Calculation of Penmen Monteith PaperDocument10 pagesCalculation of Penmen Monteith PaperMoonByeolNo ratings yet

- Chapter 6 Temperature MeasurementDocument37 pagesChapter 6 Temperature MeasurementYasser ElshaerNo ratings yet