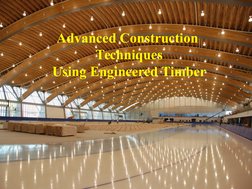

Advanced Construction

Techniques

Using Engineered Timber

�What is Engineered Timber ?

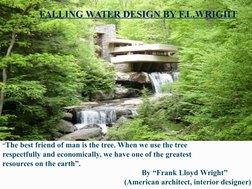

�FALLING WATER DESIGN BY F.L.WRIGHT

The

best friend of man is the tree. When we use the tree

respectfully and economically, we have one of the greatest

resources on the earth.

By Frank Lloyd Wright

(American architect, interior designer)

�CONTENTS: Introduction

Supply of Wood

Trees & wood

Manufacturing process

Product range

Design

Engineering limits(Wood properties)

Prefabrication

Embodied CO2

SUPERIOR Fire RESISTANCE

Connections

Wood modification

Inspiration

Conclusions

References

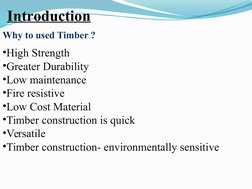

�Introduction

Why to used Timber ?

High Strength

Greater Durability

Low maintenance

Fire resistive

Low Cost Material

Timber construction is quick

Versatile

Timber construction- environmentally sensitive

�Supply of wood

Trees and wood

Approximately 20% of worlds land surface covered by trees.

97% of all softwood used in Europe comes from European

forests.

30% increase in wooded area in Europe between

Years 1990-2000.

Trees are on average 60-80 years old on harvest.

Primary softwoods used for construction are

Spruce (whitewood) and pine (redwood).

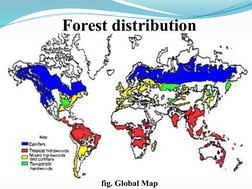

�Forest distribution

fig. Global Map

�Manufacturing Process

Fig. Timber manufacturing & treatment plant

�Fig. Factory cutting and arrangements

�Fig. Glue application process to make a combined product

�Fig. Different cuttings of Timber as per requirements

�Product range

Engineered timber

Glue laminated timber (Glulam)

Laminated veneer lumber (LVL)

Cross laminated timber panels (CLT)

Brettstapel

Plywood

�Engineered timber

Glulam

Spruce grades GL24 to GL36

Lamella thickness of type 40mm

Stock sizes up to 20cm x 65cm x

13.5m

Other sizes up to 28cm x 2.2m x

36m

Glues are melamine resin based.

Laminated Veneer Lumber (LVL)

Jumbo plywood made from 3mm thick

veneers.

Finn Forest Kerto (S & Q)

Different lay ups produce boards or

beams

Thickness up to 75mm

Panel sizes 2.5m x 20m+

�Engineered timber

Brettstapel

Solid timber panels

Glued, nailed, screwed or dowelled

Thickness up to 260mm

Lengths up to 18m

Widths up to 1.2m

Floor and roof spans up to 10m+

�Design

Engineering limits(Wood properties)

Timber is anisotropic

5 to 10x weaker across the grain

(similar to bundle of straws)

Affected by moisture

50% moisture content natural state,

12- 20% in use (hygroscopic)

20-40%loss in strength in damp

conditions

Strength

Defect free -100N/mm2

Typical wood-16-24N/mm2

Softwoods used in UK are

designed using 6N/mm2

� Strength and stiffness depends on a number of factors:

Species of timber

Moisture content of timber

Duration of load

Direction of stress within timber

Defects present in timber

Slenderness

Moisture content:

40% to 20% reduction in strength and stiffness for 20%+

moisture content

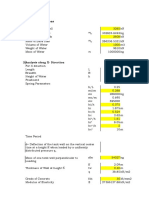

�Embodied CO2

�Prefabrication

Walls/floors

Slab/walls

Platform construction

�Fig. Lintels in an open & closed panel timber frame wall panel

�Fig. Floor to Floor construction

�SUPERIOR FIRE RESISTANCE

GLULAM

Structural glued laminated timbers known as Glulam.

Glulam is fabricated Timber made using individual pieces of high

strength, kiln-dried lumber, laminated together under pressure.

Traditional beauty of wood along with engineered strength,

extraordinary fire resistance, thermal efficiency and dimensional

stability.

Glulam is typically manufactured using Douglas fir, Hem-Fir, Southern

pine, Spruce-Pine-Fir, Alaskan Yellow cedar and Ponderosa pine.

�Efficient, Cost-Effective Fire Protection

Advances in test methods and fire technology have increased our

understanding of how glulam responds to fire exposure.

PERFORMANCE OF LARGE TIMBERS IN FIRES

When exposed to fire, wood retains its strength for a longer period of time

than metal.

Unprotected metals quickly lose their strength and collapse suddenly, often

with little warning.

In contrast, wood loses strength slowly.

As a rule, wood will not ignite until it reaches a temperature

of around 480F.

CONSTRUCTION APPROACHES

Buildings constructed with large structural timbers have excellent fire

-resistive qualities.

U.S. model building codes recognize these qualities and provide two distinct

approaches : Heavy Timber Construction and Fire Resistive Construction

�Other Fire-Resistance Considerations

Pressure impregnated, fire-retardant treatments are not recommen-ded

for large timber or glulam construction.

These treatments do not increase the fire-resistance rating of the large

timber or glulam.

Fire-retardant chemicals reduce the design properties of the wood. In

addition, for engineered wood products, the treatments may not be

compatible with the adhesives used.

SPRINKLER SYSTEMS

Automatic sprinkler systems have an excellent record of improving fire

safety and reducing losses.

Many fire codes require that automatic sprinkler systems be installed in

larger commercial buildings, and in some cases, added to existing

buildings.

Such sprinkler systems may improve the fire-resistance and flamespread ratings for a buildings structural

�Connections

Connection design critical in timber structures.

Typically connections determine the section sizes in multiple element

structures.

Recent years have seen major advances in fixing technology .

Glued connections strongest and stiffest.

Connections with multiple Small fixings (ie nails or screws) are also

efficient

�Fig . shear plates

Fig. Joist connections

Fig. Trusses featuring bolts and large washers

�Wood modification

Improve properties of wood

through chemical and thermal

modification

Potential to improve durability,

dimensional stability and strength

properties

Existing examples include

Accoya

acetylated wood and Thermowood

Cambridge University is Working

on the structural and architectural

use of polymerised wood

50m-span bridge into the city of Sneek in

the Netherlands

Submerged bridge at the restored Fort de

Roovere in the Netherlands

�Inspiration

Name :Tamedia office building

Zurich, switzerland

Storeys:7(including mezzanine

gallery)

Workplaces: 480

Floor area of the new building:

8,905 m2

Cubic volume of new building:

39,085 m3

Wood used in construction:

2,000 m3 of spruce (Styria)

Architect:Shigeru Ban Architect

Europe, Paris

��CONCULSIONS

In modern day construction, we can construct fire

resistive, light weight & lifelong structures with the help of

Engineered timber.

Timber gives good strength as similar steel & concrete

structures.

Timber material gives good appearance & natural feeling

to the structures.

To used similar advanced timber techniques in India.

References