Crystal Defects in Solids

Name Nishant Gaur

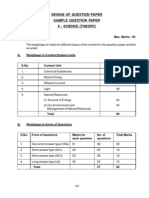

Roll No. O 43

Batch

O8

�Crystal Defects

Perfect crystals do not exist; even the best

crystals have 1ppb defects.

defects are imperfections in the regular repeating pattern and may be

classified in terms of their dimensionality (Point vs. Extended).

[Link] Defects

A. Vacancies

given a perfect crystal (e.g. of Cu), an atom can be placed on the

outside of the cell to produce a vacancy ( ); remember atom

migration.

e.g. TiO has 1:1 stoichiometry and NaCl structure, but has 15%

vacancies on the Ti sites and 15% vacancies on the O sites. Both sets

of vacancies are disordered.

�o driving force? movement of the atom requires breaking (endothermic)

and making (exothermic) of bonds. Because the atom is moving from

an internal site (w/say 6 bonds) to an external site (w/say 3 bonds),

there are more bonds broken than being made, so this is an overall

endothermic process.

o counteracting this is an obvious large increase in disorder (from perfect

crystal to defect); in addition, atoms around the vacated site can

vibrate more, further increasing the disorder.

G(n) = nH nTS

G(n)

max

min

n= #defects

Implications:

a)n 0; G = 0, so no driving

force.

b)there is some min value of n

which is most stable.

c)there is some minimum n after

which G becomes positive.

d)as T nmin and nmax will also

increase.

�B.

Ionic Crystal Defects

in pure metal compounds, dont need to

worry about electroneutrality.

in an ionic crystal, the interior and surface

must remain neutral.

1) Shottky Defect

take anions and cations and place them on

surface in equal numbers.

stoichiometric effect: equal numbers of anion

and cation vacancies.

may be randomly distributed, but tend to

cluster because of oppositely charged

vacancies.

most important with alkali halides.

at room temp, ~1 in 1015 pairs vacant in NaCl,

so 1mg sample has ~10,000 Shottky Defects.

�2) Frenkel Defect

o take cation out of position and cram it into an

interstitial site (void between normal atomic

position).

o Ag+ surrounded by 4Cl- stabilizes this defect.

o tendency for vacancy and interstitial to form

nearby pair.

o also a stoichiometric deffect (vacancies =

interstitials).

�3) Color Centers (aka F-center;

Ger: farbenzentre)

o electron trapped in an anion vacancy.

o possible mechanism: high energy radiation (xray, -ray) interacts with alkali halide, causing

halide to lose an electron. The electron moves

through the crystal until it encounters a halide

vacancy. It is trapped there by strong

electrostatic forces (i.e. 6 cations!).

o a series of energy levels are available for the

electron within the vacancy; often in the visible

region (deep purple in KCl; smoky quartz;

amethyst).

o found for a series of alkali halides:

o absorption energy, Emax a-1.8

a= cubic lattice parameter (length of the

edge of the cubic unit cell).

Note: E is

inversely

proportional to a.

�Large E;

little a.

Emax a-1.8

Large a;

little E.

�2. Extended Defects.

have seen that many vacancies are initially random,

but can cluster

when vacancy density gets high, the material will try

to do something to get rid of them.

A. Sheer Planes

e.g. ReO3: bright red, Re Oh h.s. d7, conducting.

normal crystal (cut through face); note metalcontaining Ohs with shared corners.

when heated, the compound starts losing O atoms;

these vacancies tend to line up in a plane through the

center of a unit cell.

the structure sheers itself ( unit cell length) so that

the octahedrons now have shared edges. There are

more and more sheer planes as Os are lost.

�B. Dislocations.

o

important class of defect;

responsible for the malleability of

metals; explains the process of

work hardening of metals.

dislocations are line-defects;

instead of the loss of atoms (as

with point defects), they can be

looked at as an extra partial line

or plane of atoms.

looks like a perfect crystal, but if

you look at the figure from a low

angle, you see an extra partial

line.

�o edge dislocations are easily moved by slipping; like a carpet: too heavy

to drag, but can move small wrinkle.

o the presence of a distortion relaxes the requirement that entire planes

of interatomic bonds must distort and break simultaneously for plastic*

deformation to occur. Instead, plastic deformation can accompany the

motion of a dislocation through a crystal.

*plastic = irreversible elongation (e.g. pulling wire) by movement of planes.

�o can get rid of dislocations; this gets rid of maleability and material

becomes brittle (e.g. bend Cu wire).

o movement of dislocations is key to plastic deformation, therefore,

increasing resistance to deformation (strengthening the metal) requires

either eliminating the distortions or preventing them from moving

(pinning them).

o dislocations are often pinned by other defects in the crystal; new

dislocations are created during deformation and become pinned by the

initial dislocation.

o the build-up of pinned dislocations leads to the hardening of the metal

in a process known as work hardening.

�o e.g. moving an entire rug requires lots of energy. A single wrinkle

serves as a dislocation in facilitating the movement of the rug; at any

time only a small part of the rug moves, so little energy required.

o work hardening is like having multiple tangled wrinkles in the rug---one

wrinkle pins the other.

o a work-hardened metal can be softened again by annealing (heating)

at high temperatures; increased thermal motion allows atoms to

rearrange and go to lower energy states.

o so, work hardening adds edge dislocations so that planes no longer

slip.

�o can strengthen materials with sheer planes by adding impurities.

edge dislocation

strains bond lengths,

etc.

if impurity prefers

shorted bond lengths,

then this is a stable

situation.

Cu + Zn bronze

Cu + Sn brass

Stress & Strain

Experiment: measure width and length

of wire; pull and re-measure; repeat.

o

o

o

initial =

pull =

breaks at =

= stress = force/unit area

= strain = l/lo

cross-sectional area (larger

yield strength

increases

asmore

dislocations

diameter would

require

increase.

force to break).

distortions get tangled up like spaghetti;

change

in length/

initialto become

too many

cause

material

[Link]

e.g. Fe sword: add impurities and pound;

becomes hard; dislocations climb to

surface; anealing makes material soft by

getting rid of distortions.

~0.1%

some materials, e.g.

glass break after a

certain point; brittle

fracture.

linear portion

reversible.

again, linear portion

reversible, so below yield

point no permanent

elongation occurs = elastic

deformation

~20%

above yield point

plastic elongation

occurs.

�Burgers Vectors (Bergers

Circuit)

Way to describe dislocation.

4

4

3

3

3

4

4

Above: Burgers circuit for dislocation-free material.

note compressed bonds and elongated bonds

To Right: Do same with dislocation and

end up past starting point.

Vector b = distance to get back to curcuit.

�Burgers Vectors

Screw dislocation with Bergers vector. Note direction is

direction of screw axis.

Crystals often will grow along screw dislocation.

�Impurities and Doping

Impurities are elements present in the material that

are different from those in the compound formula.

Dopants are intentionally added impurities (to make

alloys or affect changes in properties). Alloy formation

most likely when dopant anions and cations are close

in size to original material.

Isovalent dopants: substitution species have the same

charge.

NaCl:AgCl Na1-xAgxCl (alloy on cation site)

AgBr:AgCl AgBr1-xClx (alloy on anion site)

Aleovalent dopant: substitution species has different

vacancy

charge.

NaCl:CaCl2 could be either Na1-2xCaxxCl

interstitial

or Na1-xCaxClClxi

o either could happen; experimentally, first is found.