0% found this document useful (0 votes)

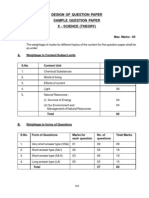

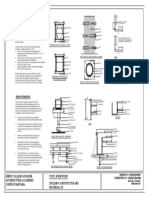

165 views5 pagesCulvert No. 6 Formwork Design Calculations

The document provides calculations for the design of formwork for a culvert base slab. It includes calculations for the design of horizontal and vertical stiffeners to reinforce the skin plate of the formwork. Load calculations are also provided to determine the lateral pressure from plastic concrete during pouring, considering factors like the pouring rate and concrete temperature. Dimensions and reinforcement are designed and checked for the stiffeners to withstand the calculated loads based on stipulated codes.

Uploaded by

munishant1Copyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as XLS, PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

165 views5 pagesCulvert No. 6 Formwork Design Calculations

The document provides calculations for the design of formwork for a culvert base slab. It includes calculations for the design of horizontal and vertical stiffeners to reinforce the skin plate of the formwork. Load calculations are also provided to determine the lateral pressure from plastic concrete during pouring, considering factors like the pouring rate and concrete temperature. Dimensions and reinforcement are designed and checked for the stiffeners to withstand the calculated loads based on stipulated codes.

Uploaded by

munishant1Copyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as XLS, PDF, TXT or read online on Scribd