Professional Documents

Culture Documents

Two way Slab Design _2 kN m2

Uploaded by

pandianCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Two way Slab Design _2 kN m2

Uploaded by

pandianCopyright:

Available Formats

DOCUMENT.NO.

DATE DESIGNED DATE

PROJECT

MP

REVISION DATE CHECKED DATE

TITLE TWO WAY SLAB DESIGN

KMD

CL. NO. DESIGN CALCULATIONS REFERENCES

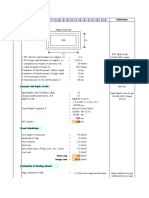

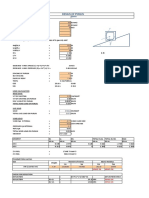

1.0 Design of Two Way Slab

1.0.1 Basic Input Data

Grade of concrete = M 30

Grade of steel = Fe 500

Thickness of slab D = 100 mm

Clear cover cc = 15 mm Table 16 Cl.26.4.2 ,

Effective thickness of slab (deff) = 100 - 15 - 4 = 81 mm IS 456 -2000

Unit weight of concrete = 25 KN/m 3

Cl 19.2.1, IS 456-2000

Effective Shorter Span Lx = 3.4 m

Effective Longer Span Ly = 5.5 m

Aspect ratio Ly/Lx = 1.62 < 2

Hence designed as Two way slab Cl D-1.11, IS 456-2000

Edge Condition : Interior panels

1.0.2 Load Data

Self Weight of Slab = 0.100 x 25 = 2.500 KN/m2

Floor finish = 0.750 KN/m2

Partition Load = 0.000 KN/m2

Sunken Filling = 0.000 KN/m2

Imposed Load = 2.000 KN/m2 IS 875 (Part 2) -1987

Extra Load, (if Any) = 0.000 KN/m 2

Total load = 5.250 KN/m2

Design load ( Wu ) = 1.5 x 5.25 = 7.875 KN/m2 Table 18 Cl 36.4.1

IS 456 -2000

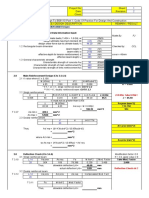

1.0.3 Moment and Shear Calculations

Short Span Direction

ax for positive moment 1.5 → 0.041 Table 26 Cl D-1.1,

1.75 → 0.045 IS 456 -2000

for 1.62 ax = 0.043

Positive moment Mx : 0.043 x 7.88 x 3.4 ^2 = 3.90 KN-m

ax for negative moment 1.5 → 0.053 Table 26 Cl D-1.1,

1.75 → 0.060 IS 456 -2000

for 1.62 ax = 0.056

Negative moment Mx : 0.056 x 7.88 x 3.4 ^2 = 5.12 KN-m

Long Span Direction

DOCUMENT.NO.DATE DESIGNED DATE

PROJECT

MP

REVISION DATE CHECKED DATE

TITLE TWO WAY SLAB DESIGN

KMD

CL. NO. DESIGN CALCULATIONS REFERENCES

For positive moment ay = 0.024 Table 26 Cl D-1.1,

Positive moment My : 0.024 x 7.88 x 3.4 ^2 = 2.18 KN-m IS 456 -2000

For negative moment ay = 0.032 Table 26 Cl D-1.1,

Negative moment My : 0.032 x 7.88 x 3.4 ^2 = 2.91 KN-m IS 456 -2000

Shear force V u = 7.88 x 3.4 x 0.5 = 13.39 KN

1.0.4 Check Effective Depth for Max.Bending Moment

Depth required = (Mx /(0.133x fck x b))1/2 = 35.84 mm Table C,SP 16 :1980

Depth provided = 100 - 15 - 8 /2 = 81 mm > 35.84 mm Cl 2.3

Hence the section is Safe against Bending

1.0.5 Check Depth for Shear

Nominal Shear Stress : tv = Vu / b d = 0.17 N/mm2 Cl.40.1, IS 456:2000

Design shear strength ( tc ) = 0.34 N/mm 2

Table 19 , IS 456:2000

k = 1.30 Cl.40.2.1.1,

k* tc = 0.44 N/mm 2

IS 456:2000

tv < k* tc Hence the section is Safe against Shear

1.0.6 Check for Maximum Shear Stress:

Nominal Shear Stress : tv = Vu / b d = 0.17 N/mm2 Cl.40.1, IS 456:2000

Maximum Shear Stress ( tc , max ) = 3.5 N/mm2 Table 20 , IS 456:2000

0.5 tc , max = 1.75 N/mm2

tv < 0.5 tc , max Hence the section is Safe against Max.Shear Stress Cl.40.2.3.1, IS 456:2000

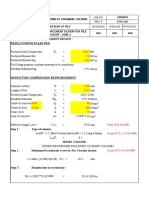

1.0.7 Reinforcement calculations

Short Span Direction @ Support

Mu/bd2 = 5.12 x 10 ^ 6 = 0.781

1000 x 81 x 81

Pt = 0.19 % Table 2-4, SP16 :1980

Area of steel Ast = 0.0019 x 1000 x 81 = 150.156 mm2

Minimum area of steel: 0.0012 x 1000 x 100 = 120.00 mm2 Cl:26.5.2.1

Spacing of Y 8 bars 50.27 x 1000 / 150.16 = 334.584 mm IS 456 -2000

DOCUMENT.NO.DATE DESIGNED DATE

PROJECT

MP

REVISION DATE CHECKED DATE

TITLE TWO WAY SLAB DESIGN

KMD

CL. NO. DESIGN CALCULATIONS REFERENCES

Check for Spacing

Minimum of 1) 3d = 243 mm

2) = 250 mm Cl:26.3.3.(b).1

3) = 334.58 mm IS 456 -2000

Therefore provide Y 8 @ 240 mm C/C

Short Span Direction @ Mid Span

Mu/bd2 = 3.90 x 10 ^ 6 = 0.595

1000 x 81 x 81

Pt = 0.140 % SP16 :1980 Table 2-4

Area of steel Ast = 0.0014 x 1000 x 81 = 113.499 mm2 IS 456:2000

Minimum area of steel: 0.0012 x 1000 x 100 = 120.00 mm 2

Cl:26.5.2.1

Spacing of Y 8 bars 50.27 x 1000 / 120.00 = 418.667 mm

Check for Spacing

Minimum of 1) 3d = 243 mm IS 456:2000

2) = 220 mm Cl:26.3.3.(b).1

3) = 418.67 mm

Therefore provide Y 8 @ 300 mm C/C 300

Provided % of Tension Reinforcement (pt) = 0.207 %

Long Span Direction @ Support

Mu/bd2 = 2.91 x 10 ^ 6 = 0.444

1000 x 81 x 81

Pt = 0.104 % SP16 :1980 Table 2-4

Area of steel Ast = 0.0010 x 1000 x 81 = 84.1762 mm2 IS 456:2000

Minimum area of steel: 0.0012 x 1000 x 100 = 120.00 mm 2

Cl:26.5.2.1

Spacing of Y 8 bars 50.27 x 1000 / 120.00 = 418.667 mm

Check for Spacing

Minimum of 1) 3d = 243 mm IS 456:2000

2) = 300 mm Cl:26.3.3.(b).1

3) = 418.67 mm

DOCUMENT.NO.DATE DESIGNED DATE

PROJECT

MP

REVISION DATE CHECKED DATE

TITLE TWO WAY SLAB DESIGN

KMD

CL. NO. DESIGN CALCULATIONS REFERENCES

Therefore provide Y 8 @ 240 mm C/C

Long Span Direction @ mid Span

Mu/bd2 = 2.18 x 10 ^ 6 = 0.333

1000 x 81 x 81

Pt = 0.078 % SP16 :1980 Table 2-4

Area of steel Ast = 0.0008 x 1000 x 81 = 62.8515 mm2 IS 456:2000

Minimum area of steel: 0.0012 x 1000 x 100 = 120.00 mm 2

Cl:26.5.2.1

Spacing of Y 8 bars 50.27 x 1000 / 120.00 = 418.667 mm

Check for Spacing

Minimum of 1) 3d = 243 mm IS 456:2000

2) = 300 mm Cl:26.3.3.(b).1

3) = 418.67 mm

Therefore provide Y 8 @ 240 mm C/C

1.0.8 Check for Deflection: (Simplified Approach)

Basic Span/depth Ratio = 26 IS 456:2000 Cl:23.2.1

% of Tension Reinforcement provided ( pt ) = 0.207 %

Service stress of steel (fs) 0.58 fy (Ast_R/Ast_P) = 196.45 N/mm2 IS456:2000 Fig 4

Modification Factor for Tension Reinforcement (F1) = 2.00 Page 38

Allowable Span / Effective Depth Ratio = 52 IS 456:2000 Cl:23.2.1

Actual Span/Eff Depth Rati = 3.4 x 1000 / 81 = 41.98

Hence Safe against Deflection

DOCUMENT.NO.DATE DESIGNED DATE

PROJECT

MP

REVISION DATE CHECKED DATE

TITLE TWO WAY SLAB DESIGN

KMD

CL. NO. DESIGN CALCULATIONS REFERENCES

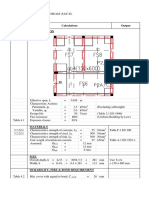

1.0 Design of Two Way Slab

1.0.1 Basic Input Data

Grade of concrete = M 30

Grade of steel = Fe 500

Thickness of slab D = 100 mm

Clear cover cc = 15 mm Table 16 Cl.26.4.2 ,

Effective thickness of slab (deff) = 100 - 15 - 4 = 81 mm IS 456 -2000

Unit weight of concrete = 25 KN/m 3

Cl 19.2.1, IS 456-2000

Effective Shorter Span Lx = 2.95 m

Effective Longer Span Ly = 4.7 m

Aspect ratio Ly/Lx = 1.59 < 2

Hence designed as Two way slab Cl D-1.11, IS 456-2000

Edge Condition : Two adjacent Edges Discontinous

1.0.2 Load Data

Self Weight of Slab = 0.100 x 25 = 2.500 KN/m2

Floor finish = 0.750 KN/m2

Partition Load = 0.000 KN/m2

Sunken Filling = 0.000 KN/m2

Imposed Load = 2.000 KN/m2 IS 875 (Part 2) -1987

Extra Load, (if Any) = 0.000 KN/m 2

Total load = 5.250 KN/m2

Design load ( Wu ) = 1.5 x 5.25 = 7.875 KN/m2 Table 18 Cl 36.4.1

IS 456 -2000

1.0.3 Moment and Shear Calculations

Short Span Direction

ax for positive moment 1.5 → 0.056 Table 26 Cl D-1.1,

1.75 → 0.063 IS 456 -2000

for 1.59 ax = 0.059

Positive moment Mx : 0.059 x 7.88 x 2.95 ^2 = 4.02 KN-m

ax for negative moment 1.5 → 0.075 Table 26 Cl D-1.1,

1.75 → 0.084 IS 456 -2000

for 1.59 ax = 0.078

Negative moment Mx : 0.078 x 7.88 x 2.95 ^2 = 5.37 KN-m

Long Span Direction

DOCUMENT.NO.DATE DESIGNED DATE

PROJECT

MP

REVISION DATE CHECKED DATE

TITLE TWO WAY SLAB DESIGN

KMD

CL. NO. DESIGN CALCULATIONS REFERENCES

For positive moment ay = 0.035 Table 26 Cl D-1.1,

Positive moment My : 0.035 x 7.88 x 2.95 ^2 = 2.40 KN-m IS 456 -2000

For negative moment ay = 0.047 Table 26 Cl D-1.1,

Negative moment My : 0.047 x 7.88 x 2.95 ^2 = 3.22 KN-m IS 456 -2000

Shear force V u = 7.88 x 3 x 0.5 = 11.62 KN

1.0.4 Check Effective Depth for Max.Bending Moment

Depth required = (Mx /(0.133x fck x b))1/2 = 36.69 mm Table C,SP 16 :1980

Depth provided = 100 - 15 - 8 /2 = 81 mm > 36.69 mm Cl 2.3

Hence the section is Safe against Bending

1.0.5 Check Depth for Shear

Nominal Shear Stress : tv = Vu / b d = 0.14 N/mm2 Cl.40.1, IS 456:2000

Design shear strength ( tc ) = 0.34 N/mm 2

Table 19 , IS 456:2000

k = 1.30 Cl.40.2.1.1,

k* tc = 0.44 N/mm 2

IS 456:2000

tv < k* tc Hence the section is Safe against Shear

1.0.6 Check for Maximum Shear Stress:

Nominal Shear Stress : tv = Vu / b d = 0.14 N/mm2 Cl.40.1, IS 456:2000

Maximum Shear Stress ( tc , max ) = 3.5 N/mm2 Table 20 , IS 456:2000

0.5 tc , max = 1.75 N/mm2

tv < 0.5 tc , max Hence the section is Safe against Max.Shear Stress Cl.40.2.3.1, IS 456:2000

1.0.7 Reinforcement calculations

Short Span Direction @ Support

Mu/bd2 = 5.37 x 10 ^ 6 = 0.818

1000 x 81 x 81

Pt = 0.19 % Table 2-4, SP16 :1980

Area of steel Ast = 0.0019 x 1000 x 81 = 157.589 mm2

Minimum area of steel: 0.0012 x 1000 x 100 = 120.00 mm2 Cl:26.5.2.1

Spacing of Y 8 bars 50.27 x 1000 / 157.59 = 318.805 mm IS 456 -2000

DOCUMENT.NO.DATE DESIGNED DATE

PROJECT

MP

REVISION DATE CHECKED DATE

TITLE TWO WAY SLAB DESIGN

KMD

CL. NO. DESIGN CALCULATIONS REFERENCES

Check for Spacing

Minimum of 1) 3d = 243 mm

2) = 250 mm Cl:26.3.3.(b).1

3) = 318.80 mm IS 456 -2000

Therefore provide Y 8 @ 240 mm C/C

Short Span Direction @ Mid Span

Mu/bd2 = 4.02 x 10 ^ 6 = 0.612

1000 x 81 x 81

Pt = 0.144 % SP16 :1980 Table 2-4

Area of steel Ast = 0.0014 x 1000 x 81 = 116.864 mm2 IS 456:2000

Minimum area of steel: 0.0012 x 1000 x 100 = 120.00 mm 2

Cl:26.5.2.1

Spacing of Y 8 bars 50.27 x 1000 / 120.00 = 418.667 mm

Check for Spacing

Minimum of 1) 3d = 243 mm IS 456:2000

2) = 220 mm Cl:26.3.3.(b).1

3) = 418.67 mm

Therefore provide Y 8 @ 300 mm C/C 300

Provided % of Tension Reinforcement (pt) = 0.207 %

Long Span Direction @ Support

Mu/bd2 = 3.22 x 10 ^ 6 = 0.491

1000 x 81 x 81

Pt = 0.115 % SP16 :1980 Table 2-4

Area of steel Ast = 0.0012 x 1000 x 81 = 93.2501 mm2 IS 456:2000

Minimum area of steel: 0.0012 x 1000 x 100 = 120.00 mm 2

Cl:26.5.2.1

Spacing of Y 8 bars 50.27 x 1000 / 120.00 = 418.667 mm

Check for Spacing

Minimum of 1) 3d = 243 mm IS 456:2000

2) = 300 mm Cl:26.3.3.(b).1

3) = 418.67 mm

DOCUMENT.NO.DATE DESIGNED DATE

PROJECT

MP

REVISION DATE CHECKED DATE

TITLE TWO WAY SLAB DESIGN

KMD

CL. NO. DESIGN CALCULATIONS REFERENCES

Therefore provide Y 8 @ 240 mm C/C

Long Span Direction @ mid Span

Mu/bd2 = 2.40 x 10 ^ 6 = 0.366

1000 x 81 x 81

Pt = 0.085 % SP16 :1980 Table 2-4

Area of steel Ast = 0.0009 x 1000 x 81 = 69.0914 mm2 IS 456:2000

Minimum area of steel: 0.0012 x 1000 x 100 = 120.00 mm 2

Cl:26.5.2.1

Spacing of Y 8 bars 50.27 x 1000 / 120.00 = 418.667 mm

Check for Spacing

Minimum of 1) 3d = 243 mm IS 456:2000

2) = 300 mm Cl:26.3.3.(b).1

3) = 418.67 mm

Therefore provide Y 8 @ 240 mm C/C

1.0.8 Check for Deflection: (Simplified Approach)

Basic Span/depth Ratio = 26 IS 456:2000 Cl:23.2.1

% of Tension Reinforcement provided ( pt ) = 0.207 %

Service stress of steel (fs) 0.58 fy (Ast_R/Ast_P) = 202.27 N/mm2 IS456:2000 Fig 4

Modification Factor for Tension Reinforcement (F1) = 2.00 Page 38

Allowable Span / Effective Depth Ratio = 52 IS 456:2000 Cl:23.2.1

Actual Span/Eff Depth Rati = 2.95 x 1000 / 81 = 36.42

Hence Safe against Deflection

DOCUMENT.NO.DATE DESIGNED DATE

PROJECT

MP

REVISION DATE CHECKED DATE

TITLE TWO WAY SLAB DESIGN

KMD

CL. NO. DESIGN CALCULATIONS REFERENCES

1.0 Design of Two Way Slab

1.0.1 Basic Input Data

Grade of concrete = M 30

Grade of steel = Fe 500

Thickness of slab D = 100 mm

Clear cover cc = 15 mm Table 16 Cl.26.4.2 ,

Effective thickness of slab (deff) = 100 - 15 - 4 = 81 mm IS 456 -2000

Unit weight of concrete = 25 KN/m 3

Cl 19.2.1, IS 456-2000

Effective Shorter Span Lx = 3.4 m

Effective Longer Span Ly = 5.5 m

Aspect ratio Ly/Lx = 1.62 < 2

Hence designed as Two way slab Cl D-1.11, IS 456-2000

Edge Condition : Interior panels

1.0.2 Load Data

Self Weight of Slab = 0.100 x 25 = 2.500 KN/m2

Floor finish = 0.750 KN/m2

Partition Load = 0.000 KN/m2

Sunken Filling = 0.000 KN/m2

Imposed Load = 2.000 KN/m2 IS 875 (Part 2) -1987

Extra Load, (if Any) = 0.000 KN/m 2

Total load = 5.250 KN/m2

Design load ( Wu ) = 1.5 x 5.25 = 7.875 KN/m2 Table 18 Cl 36.4.1

IS 456 -2000

1.0.3 Moment and Shear Calculations

Short Span Direction

ax for positive moment 1.5 → 0.041 Table 26 Cl D-1.1,

1.75 → 0.045 IS 456 -2000

for 1.62 ax = 0.043

Positive moment Mx : 0.043 x 7.88 x 3.4 ^2 = 3.90 KN-m

ax for negative moment 1.5 → 0.053 Table 26 Cl D-1.1,

1.75 → 0.060 IS 456 -2000

for 1.62 ax = 0.056

Negative moment Mx : 0.056 x 7.88 x 3.4 ^2 = 5.12 KN-m

Long Span Direction

DOCUMENT.NO.DATE DESIGNED DATE

PROJECT

MP

REVISION DATE CHECKED DATE

TITLE TWO WAY SLAB DESIGN

KMD

CL. NO. DESIGN CALCULATIONS REFERENCES

For positive moment ay = 0.024 Table 26 Cl D-1.1,

Positive moment My : 0.024 x 7.88 x 3.4 ^2 = 2.18 KN-m IS 456 -2000

For negative moment ay = 0.032 Table 26 Cl D-1.1,

Negative moment My : 0.032 x 7.88 x 3.4 ^2 = 2.91 KN-m IS 456 -2000

Shear force V u = 7.88 x 3.4 x 0.5 = 13.39 KN

1.0.4 Check Effective Depth for Max.Bending Moment

Depth required = (Mx /(0.133x fck x b))1/2 = 35.84 mm Table C,SP 16 :1980

Depth provided = 100 - 15 - 8 /2 = 81 mm > 35.84 mm Cl 2.3

Hence the section is Safe against Bending

1.0.5 Check Depth for Shear

Nominal Shear Stress : tv = Vu / b d = 0.17 N/mm2 Cl.40.1, IS 456:2000

Design shear strength ( tc ) = 0.34 N/mm 2

Table 19 , IS 456:2000

k = 1.30 Cl.40.2.1.1,

k* tc = 0.44 N/mm 2

IS 456:2000

tv < k* tc Hence the section is Safe against Shear

1.0.6 Check for Maximum Shear Stress:

Nominal Shear Stress : tv = Vu / b d = 0.17 N/mm2 Cl.40.1, IS 456:2000

Maximum Shear Stress ( tc , max ) = 3.5 N/mm2 Table 20 , IS 456:2000

0.5 tc , max = 1.75 N/mm2

tv < 0.5 tc , max Hence the section is Safe against Max.Shear Stress Cl.40.2.3.1, IS 456:2000

1.0.7 Reinforcement calculations

Short Span Direction @ Support

Mu/bd2 = 5.12 x 10 ^ 6 = 0.781

1000 x 81 x 81

Pt = 0.19 % Table 2-4, SP16 :1980

Area of steel Ast = 0.0019 x 1000 x 81 = 150.156 mm2

Minimum area of steel: 0.0012 x 1000 x 100 = 120.00 mm2 Cl:26.5.2.1

Spacing of Y 8 bars 50.27 x 1000 / 150.16 = 334.584 mm IS 456 -2000

DOCUMENT.NO.DATE DESIGNED DATE

PROJECT

MP

REVISION DATE CHECKED DATE

TITLE TWO WAY SLAB DESIGN

KMD

CL. NO. DESIGN CALCULATIONS REFERENCES

Check for Spacing

Minimum of 1) 3d = 243 mm

2) = 250 mm Cl:26.3.3.(b).1

3) = 334.58 mm IS 456 -2000

Therefore provide Y 8 @ 240 mm C/C

Short Span Direction @ Mid Span

Mu/bd2 = 3.90 x 10 ^ 6 = 0.595

1000 x 81 x 81

Pt = 0.140 % SP16 :1980 Table 2-4

Area of steel Ast = 0.0014 x 1000 x 81 = 113.499 mm2 IS 456:2000

Minimum area of steel: 0.0012 x 1000 x 100 = 120.00 mm 2

Cl:26.5.2.1

Spacing of Y 8 bars 50.27 x 1000 / 120.00 = 418.667 mm

Check for Spacing

Minimum of 1) 3d = 243 mm IS 456:2000

2) = 220 mm Cl:26.3.3.(b).1

3) = 418.67 mm

Therefore provide Y 8 @ 300 mm C/C 300

Provided % of Tension Reinforcement (pt) = 0.207 %

Long Span Direction @ Support

Mu/bd2 = 2.91 x 10 ^ 6 = 0.444

1000 x 81 x 81

Pt = 0.104 % SP16 :1980 Table 2-4

Area of steel Ast = 0.0010 x 1000 x 81 = 84.1762 mm2 IS 456:2000

Minimum area of steel: 0.0012 x 1000 x 100 = 120.00 mm 2

Cl:26.5.2.1

Spacing of Y 8 bars 50.27 x 1000 / 120.00 = 418.667 mm

Check for Spacing

Minimum of 1) 3d = 243 mm IS 456:2000

2) = 300 mm Cl:26.3.3.(b).1

3) = 418.67 mm

DOCUMENT.NO.DATE DESIGNED DATE

PROJECT

MP

REVISION DATE CHECKED DATE

TITLE TWO WAY SLAB DESIGN

KMD

CL. NO. DESIGN CALCULATIONS REFERENCES

Therefore provide Y 8 @ 240 mm C/C

Long Span Direction @ mid Span

Mu/bd2 = 2.18 x 10 ^ 6 = 0.333

1000 x 81 x 81

Pt = 0.078 % SP16 :1980 Table 2-4

Area of steel Ast = 0.0008 x 1000 x 81 = 62.8515 mm2 IS 456:2000

Minimum area of steel: 0.0012 x 1000 x 100 = 120.00 mm 2

Cl:26.5.2.1

Spacing of Y 8 bars 50.27 x 1000 / 120.00 = 418.667 mm

Check for Spacing

Minimum of 1) 3d = 243 mm IS 456:2000

2) = 300 mm Cl:26.3.3.(b).1

3) = 418.67 mm

Therefore provide Y 8 @ 240 mm C/C

1.0.8 Check for Deflection: (Simplified Approach)

Basic Span/depth Ratio = 26 IS 456:2000 Cl:23.2.1

% of Tension Reinforcement provided ( pt ) = 0.207 %

Service stress of steel (fs) 0.58 fy (Ast_R/Ast_P) = 196.45 N/mm2 IS456:2000 Fig 4

Modification Factor for Tension Reinforcement (F1) = 2.00 Page 38

Allowable Span / Effective Depth Ratio = 52 IS 456:2000 Cl:23.2.1

Actual Span/Eff Depth Rati = 3.4 x 1000 / 81 = 41.98

Hence Safe against Deflection

DOCUMENT.NO.DATE DESIGNED DATE

PROJECT

MP

REVISION DATE CHECKED DATE

TITLE TWO WAY SLAB DESIGN

KMD

CL. NO. DESIGN CALCULATIONS REFERENCES

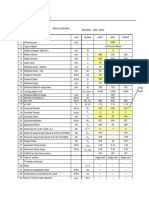

1.0 Design of Two Way Slab

1.0.1 Basic Input Data

Grade of concrete = M 20

Grade of steel = Fe 500

Thickness of slab D = 150 mm 75

Clear cover cc = 15 mm Table 16 Cl.26.4.2 ,

Effective thickness of slab (deff) = 150 - 15 - 4 = 131 mm IS 456 -2000

Unit weight of concrete = 25 KN/m 3

Cl 19.2.1, IS 456-2000

Effective Shorter Span Lx = 3.15 m

Effective Longer Span Ly = 4.5 m

Aspect ratio Ly/Lx = 1.43 < 2

Hence designed as Two way slab Cl D-1.11, IS 456-2000

Edge Condition : Two Long Edges Discontinuous

1.0.2 Load Data

Self Weight of Slab = 0.150 x 25 = 2.155 KN/m2

Floor finish = 0.700 KN/m2

Partition Load = 0.000 KN/m2

Sunken Filling = 0.000 KN/m2

Imposed Load = 2.000 KN/m2 IS 875 (Part 2) -1987

Extra Load, (if Any) = 0.000 KN/m 2

Total load = 4.855 KN/m2

Design load ( Wu ) = 1.5 x 4.855 = 7.282 KN/m2 Table 18 Cl 36.4.1

IS 456 -2000

1.0.3 Moment and Shear Calculations

Short Span Direction

ax for positive moment 1.4 → 0.063 Table 26 Cl D-1.1,

1.5 → 0.068 IS 456 -2000

for 1.43 ax = 0.064

Positive moment Mx : 0.064 x 7.28 x 3.15 ^2 = 4.66 KN-m

ax for negative moment 1.4 → 0.000 Table 26 Cl D-1.1,

1.5 → 0.000 IS 456 -2000

for 1.43 ax = 0.000

Negative moment Mx : 0.000 x 7.28 x 3.15 ^2 = 0.00 KN-m

Long Span Direction

DOCUMENT.NO.DATE DESIGNED DATE

PROJECT

MP

REVISION DATE CHECKED DATE

TITLE TWO WAY SLAB DESIGN

KMD

CL. NO. DESIGN CALCULATIONS REFERENCES

For positive moment ay = 0.035 Table 26 Cl D-1.1,

Positive moment My : 0.035 x 7.28 x 3.15 ^2 = 2.53 KN-m IS 456 -2000

For negative moment ay = 0.045 Table 26 Cl D-1.1,

Negative moment My : 0.045 x 7.28 x 3.15 ^2 = 3.25 KN-m IS 456 -2000

Shear force V u = 7.28 x 3 x 0.5 = 11.47 KN

1.0.4 Check Effective Depth for Max.Bending Moment

Depth required = (Mx /(0.133x fck x b))1/2 = 41.84 mm Table C,SP 16 :1980

Depth provided = 150 - 15 - 8 /2 = 131 mm > 41.84 mm Cl 2.3

Hence the section is Safe against Bending

1.0.5 Check Depth for Shear

Nominal Shear Stress : tv = Vu / b d = 0.09 N/mm2 Cl.40.1, IS 456:2000

Design shear strength ( tc ) = 0.28 N/mm 2

Table 19 , IS 456:2000

k = 1.30 Cl.40.2.1.1,

k* tc = 0.36 N/mm 2

IS 456:2000

tv < k* tc Hence the section is Safe against Shear

1.0.6 Check for Maximum Shear Stress:

Nominal Shear Stress : tv = Vu / b d = 0.09 N/mm2 Cl.40.1, IS 456:2000

Maximum Shear Stress ( tc , max ) = 2.8 N/mm2 Table 20 , IS 456:2000

0.5 tc , max = 1.4 N/mm2

tv < 0.5 tc , max Hence the section is Safe against Max.Shear Stress Cl.40.2.3.1, IS 456:2000

1.0.7 Reinforcement calculations

Short Span Direction @ Support

Mu/bd2 = 0.00 x 10 ^ 6 = 0.000

1000 x ### x ###

Pt = 0.00 % Table 2-4, SP16 :1980

Area of steel Ast = 0.0000 x 1000 x 131 = 0 mm2

Minimum area of steel: 0.0012 x 1000 x 75 = 0.00 mm2 Cl:26.5.2.1

Spacing of Y 8 bars 50.27 x 1000 / 0.00 = 0 mm IS 456 -2000

DOCUMENT.NO.DATE DESIGNED DATE

PROJECT

MP

REVISION DATE CHECKED DATE

TITLE TWO WAY SLAB DESIGN

KMD

CL. NO. DESIGN CALCULATIONS REFERENCES

Check for Spacing

Minimum of 1) 3d = 393 mm

2) = 250 mm Cl:26.3.3.(b).1

3) = 0.00 mm IS 456 -2000

Therefore provide Y 8 @ 0 mm C/C

Short Span Direction @ Mid Span

Mu/bd2 = 4.66 x 10 ^ 6 = 0.271

1000 x ### x ###

Pt = 0.063 % SP16 :1980 Table 2-4

Area of steel Ast = 0.0006 x 1000 x 131 = 83.0569 mm2 IS 456:2000

Minimum area of steel: 0.0012 x 1000 x 75 = 180.00 mm 2

Cl:26.5.2.1

Spacing of Y 8 bars 50.27 x 1000 / 180.00 = 279.111 mm

Check for Spacing

Minimum of 1) 3d = 393 mm IS 456:2000

2) = 220 mm Cl:26.3.3.(b).1

3) = 279.11 mm

Therefore provide Y 8 @ 300 mm C/C 300

Provided % of Tension Reinforcement (pt) = 0.128 %

Long Span Direction @ Support

Mu/bd2 = 3.25 x 10 ^ 6 = 0.189

1000 x ### x ###

Pt = 0.044 % SP16 :1980 Table 2-4

Area of steel Ast = 0.0004 x 1000 x 131 = 57.7274 mm2 IS 456:2000

Minimum area of steel: 0.0012 x 1000 x 75 = 180.00 mm 2

Cl:26.5.2.1

Spacing of Y 8 bars 50.27 x 1000 / 180.00 = 279.111 mm

Check for Spacing

Minimum of 1) 3d = 393 mm IS 456:2000

2) = 300 mm Cl:26.3.3.(b).1

3) = 279.11 mm

DOCUMENT.NO.DATE DESIGNED DATE

PROJECT

MP

REVISION DATE CHECKED DATE

TITLE TWO WAY SLAB DESIGN

KMD

CL. NO. DESIGN CALCULATIONS REFERENCES

Therefore provide Y 8 @ 270 mm C/C

Long Span Direction @ mid Span

Mu/bd2 = 2.53 x 10 ^ 6 = 0.147

1000 x ### x ###

Pt = 0.034 % SP16 :1980 Table 2-4

Area of steel Ast = 0.0003 x 1000 x 131 = 44.7872 mm2 IS 456:2000

Minimum area of steel: 0.0012 x 1000 x 75 = 90.00 mm 2

Cl:26.5.2.1

Spacing of Y 8 bars 50.27 x 1000 / 90.00 = 558.222 mm

### 7.1828

Check for Spacing

Minimum of 1) 3d = 393 mm IS 456:2000

2) = 300 mm Cl:26.3.3.(b).1

3) = 558.22 mm

Therefore provide Y 8 @ 300 mm C/C

1.0.8 Check for Deflection: (Simplified Approach)

Basic Span/depth Ratio = 26 IS 456:2000 Cl:23.2.1

% of Tension Reinforcement provided ( pt ) = 0.128 %

Service stress of steel (fs) 0.58 fy (Ast_R/Ast_P) = 143.76 N/mm2 IS456:2000 Fig 4

Modification Factor for Tension Reinforcement (F1) = 2.00 Page 38

Allowable Span / Effective Depth Ratio = 52 IS 456:2000 Cl:23.2.1

Actual Span/Eff Depth Rati = 3.15 x 1000 / 131 = 24.05

Hence Safe against Deflection

You might also like

- Case NoDocument13 pagesCase NoGovendan GopalakrishnanNo ratings yet

- DESIGN OF SLAB - ContdDocument4 pagesDESIGN OF SLAB - ContdmeenuNo ratings yet

- TWO-WAY SLAB CALCULATIONSDocument6 pagesTWO-WAY SLAB CALCULATIONSMohd Azual JaafarNo ratings yet

- 11 CulvertDesign v22Document2 pages11 CulvertDesign v22Lee See VoonNo ratings yet

- Purlin and RunnerDocument8 pagesPurlin and RunnerBabu Sundararaman0% (1)

- Installation - Typical 3.3m.precast Concrete Beam Design (EN1992)Document5 pagesInstallation - Typical 3.3m.precast Concrete Beam Design (EN1992)zms msswiNo ratings yet

- CK 2 CM CK 2 2 CTM 2 CK 2 2/3 2 CM 2 CM 2 0.3 2 Cu2 Cu3: Project Job NoDocument3 pagesCK 2 CM CK 2 2 CTM 2 CK 2 2/3 2 CM 2 CM 2 0.3 2 Cu2 Cu3: Project Job NorameshkaaNo ratings yet

- Calculations For Design of Slab (Aci Method) : Spread SheetDocument9 pagesCalculations For Design of Slab (Aci Method) : Spread Sheetvenkatesh19701No ratings yet

- DESIGN OF SLAB-CantileverDocument10 pagesDESIGN OF SLAB-CantilevermeenuNo ratings yet

- New Plan House Epsom Project Job No. Calcs For Start Page No./revision Calcs by Calcs Date Checked by Checked Date Approved by Approved DateDocument4 pagesNew Plan House Epsom Project Job No. Calcs For Start Page No./revision Calcs by Calcs Date Checked by Checked Date Approved by Approved DateGirinathNo ratings yet

- Slab Design (Typical Floor Tower-A)Document72 pagesSlab Design (Typical Floor Tower-A)Prolay MannaNo ratings yet

- Aluminium TransomDocument2 pagesAluminium TransomRaju SainiNo ratings yet

- BMRCL Mahalaxmi Station Purlin DesignDocument6 pagesBMRCL Mahalaxmi Station Purlin DesignrammohanNo ratings yet

- 2) End & Int DiaphragmDocument11 pages2) End & Int DiaphragmrachanaNo ratings yet

- SVP010053 - Bih-C-Des - 131Document56 pagesSVP010053 - Bih-C-Des - 131AJAY SHINDENo ratings yet

- Kuantan Cement Plant Engineering Office Beam DesignDocument36 pagesKuantan Cement Plant Engineering Office Beam DesignMuhamad Amirul Md. RazdiNo ratings yet

- Final Pile Design - ResultantDocument3 pagesFinal Pile Design - Resultantvishnumani3011No ratings yet

- SLABDocument6 pagesSLABLagnajit DasNo ratings yet

- Checker PlateDocument1 pageChecker PlateGulam MohammedNo ratings yet

- Min AxisDocument3 pagesMin AxisjasekanNo ratings yet

- Design For Steel Circular Columns (R1)Document8 pagesDesign For Steel Circular Columns (R1)rahul1433No ratings yet

- Wind Load Calculator For Solar (IS 875 Part 3)Document1 pageWind Load Calculator For Solar (IS 875 Part 3)JaaiBadgujarNo ratings yet

- Example 5.1Document6 pagesExample 5.1Aisyah JamalNo ratings yet

- Chequered Plate PlatformDocument3 pagesChequered Plate PlatformFilip RisteskiNo ratings yet

- 2015-0075 1 5 KH Tann 3/20/2018 Dawson Deep Beam Formworks: 149b Selegie Road Singapore 188314Document6 pages2015-0075 1 5 KH Tann 3/20/2018 Dawson Deep Beam Formworks: 149b Selegie Road Singapore 188314jasekan.dcNo ratings yet

- RC Mini ProjekDocument11 pagesRC Mini ProjekMohd HisbullahNo ratings yet

- Design of The PoleDocument3 pagesDesign of The Polemsiddiq1No ratings yet

- Design of Formwork For Column R0 - 3.7 MTRDocument5 pagesDesign of Formwork For Column R0 - 3.7 MTRrahul1433No ratings yet

- Simply supported beam analysisDocument7 pagesSimply supported beam analysisHafiz95 ReactsNo ratings yet

- LANDINGDocument2 pagesLANDINGGaneshalingam Ramprasanna2No ratings yet

- Loads:: Housing Layout-Sd-EastDocument2 pagesLoads:: Housing Layout-Sd-Eastpvrk_78No ratings yet

- RC Beam Design CalculationsDocument4 pagesRC Beam Design CalculationsBuvanendran SanjeevanNo ratings yet

- Tedds RC Beam Design 2Document3 pagesTedds RC Beam Design 2Hor Ka WaiNo ratings yet

- Tata Consulting Engineers LimitedDocument24 pagesTata Consulting Engineers LimitedNitish TakalkarNo ratings yet

- Design of PurlinDocument2 pagesDesign of PurlinRAVI PRAKASH SAININo ratings yet

- Design of Wall Girt: Input DataDocument3 pagesDesign of Wall Girt: Input DataAnonymous V6up3d0QGNo ratings yet

- Combined Footing DesignDocument7 pagesCombined Footing DesignAditya KasarNo ratings yet

- Footing F: Q P A My IDocument6 pagesFooting F: Q P A My IaberraNo ratings yet

- PilecapDocument2 pagesPilecapBudi SimatupangNo ratings yet

- Calculation Sheet: Test Job Member Design For SB2Document2 pagesCalculation Sheet: Test Job Member Design For SB2bungykitNo ratings yet

- N111 - Outrigger Parking - FinalDocument5 pagesN111 - Outrigger Parking - FinalcheeseonglawNo ratings yet

- Footing F3 C3: Q P A My IDocument8 pagesFooting F3 C3: Q P A My IaberraNo ratings yet

- Tedds RC Beam DesignDocument5 pagesTedds RC Beam DesignHor Ka WaiNo ratings yet

- Pad Foundation DesignDocument4 pagesPad Foundation Designg4goharNo ratings yet

- Code Ref. Calculations Output: Column Size: 254 X 146 X 44.64kg/m UBDocument9 pagesCode Ref. Calculations Output: Column Size: 254 X 146 X 44.64kg/m UBkhewzyNo ratings yet

- Staircase DesignDocument2 pagesStaircase Designbalaji gmscNo ratings yet

- Design of MACH Deck Panel - Slab (300mm THK)Document7 pagesDesign of MACH Deck Panel - Slab (300mm THK)Sankar AnandNo ratings yet

- Wind Load Calculation (Parking-1 Monoslope)Document2 pagesWind Load Calculation (Parking-1 Monoslope)Partha Roy/Engineering/HO Noida/InterarchNo ratings yet

- Rafters British Standards 06-02-2023 0931Document4 pagesRafters British Standards 06-02-2023 0931João SidônioNo ratings yet

- Fea Report - Mini Rail SystemDocument14 pagesFea Report - Mini Rail SystemPrince MittalNo ratings yet

- Fea 40mm End Clamp r0Document12 pagesFea 40mm End Clamp r0Prince MittalNo ratings yet

- Strctural Calculation For Canopy-R-2Document32 pagesStrctural Calculation For Canopy-R-2Abdul khaliquNo ratings yet

- Pile CapDocument400 pagesPile CapMITHUN BDML100% (1)

- Fea 35mm End Clamp r0Document2 pagesFea 35mm End Clamp r0Prince MittalNo ratings yet

- Busugan Part 2 Design BSDSDocument257 pagesBusugan Part 2 Design BSDSmarco miguelNo ratings yet

- Design of One-Way Slab: LoadsDocument49 pagesDesign of One-Way Slab: LoadsRassal KarimNo ratings yet

- MS Channel-ACP CopingDocument20 pagesMS Channel-ACP CopingNizar AhamedNo ratings yet

- Steel Bunker DesignDocument13 pagesSteel Bunker Designsreenivasulu chenchugariNo ratings yet

- Circular Foundation Design For PoleDocument2 pagesCircular Foundation Design For PoleJayNo ratings yet

- Base Plate Design Is 800 2007Document147 pagesBase Plate Design Is 800 2007pandian100% (1)

- Anchor-Bolt-Base-Plate-Max-FXcompDocument9 pagesAnchor-Bolt-Base-Plate-Max-FXcomppandianNo ratings yet

- Isolated FootingDocument117 pagesIsolated FootingpandianNo ratings yet

- Planar TrussesDocument123 pagesPlanar TrussespandianNo ratings yet

- Ship Impact Analysis.pptDocument49 pagesShip Impact Analysis.pptpandianNo ratings yet

- Fob Final PptDocument52 pagesFob Final PptpandianNo ratings yet

- 5143 EDB Steel GradeDocument1 page5143 EDB Steel GradepandianNo ratings yet

- Numerical Study of Oil Storage Tanks During Planar SettlementDocument10 pagesNumerical Study of Oil Storage Tanks During Planar SettlementBagus HadiwibowoNo ratings yet

- Ship Impact Analysis.pptDocument49 pagesShip Impact Analysis.pptpandianNo ratings yet

- FootingsDocument21 pagesFootingsManuel GONo ratings yet

- Pile Helical Reinforcement Design Calculation - RevisedDocument3 pagesPile Helical Reinforcement Design Calculation - RevisedpandianNo ratings yet

- Ground Improvement With Stone Columns - Methods of Calculating Settlement Improvement FactorDocument48 pagesGround Improvement With Stone Columns - Methods of Calculating Settlement Improvement FactorAnkitaNo ratings yet

- Punching ShearDocument2 pagesPunching ShearpandianNo ratings yet

- Neutral AxisDocument2 pagesNeutral AxispandianNo ratings yet

- Analysis of Bubble Deck Slab Design by Finite Element MethodDocument8 pagesAnalysis of Bubble Deck Slab Design by Finite Element MethodIJSTENo ratings yet

- IITK-GSDMA Wind Codes DocumentDocument105 pagesIITK-GSDMA Wind Codes DocumentMadusha Galappaththi100% (2)

- Section Height of Tower: PorticoDocument2 pagesSection Height of Tower: PorticopandianNo ratings yet

- Reinforced Concrete Continuous Beam Analysis and Design (ACI 318-14) PDFDocument44 pagesReinforced Concrete Continuous Beam Analysis and Design (ACI 318-14) PDFsteveNo ratings yet

- IITK-GSDMA Wind Codes DocumentDocument105 pagesIITK-GSDMA Wind Codes DocumentMadusha Galappaththi100% (2)

- IITK-GSDMA Wind Codes DocumentDocument105 pagesIITK-GSDMA Wind Codes DocumentMadusha Galappaththi100% (2)

- 1112 PDFDocument1 page1112 PDFpandianNo ratings yet

- SYSTEM-1 (Metering Skid To Loading Arm)Document7 pagesSYSTEM-1 (Metering Skid To Loading Arm)pandianNo ratings yet

- Demountable Flare RGB PDFDocument4 pagesDemountable Flare RGB PDFpandianNo ratings yet

- SYSTEM-3 (Metering Skid To Loading Arm)Document6 pagesSYSTEM-3 (Metering Skid To Loading Arm)pandianNo ratings yet

- Behavior of End-Plate Moment Connections With Bolts in The Extended Portion PDFDocument102 pagesBehavior of End-Plate Moment Connections With Bolts in The Extended Portion PDFdxzaberNo ratings yet

- Demountable Flare RGB PDFDocument4 pagesDemountable Flare RGB PDFpandianNo ratings yet

- IITK-GSDMA Wind Codes DocumentDocument105 pagesIITK-GSDMA Wind Codes DocumentMadusha Galappaththi100% (2)

- 18m Dia Rafter DrawingDocument1 page18m Dia Rafter DrawingpandianNo ratings yet

- Beam Design Beam Mark:B1 Similar Beams:: Sl. NoDocument3 pagesBeam Design Beam Mark:B1 Similar Beams:: Sl. NopandianNo ratings yet

- Soil and Soil Mechanics Textbook Jaafar MOHAMMEDDocument145 pagesSoil and Soil Mechanics Textbook Jaafar MOHAMMEDpandianNo ratings yet

- 2170908Document33 pages2170908bhavikNo ratings yet

- PenstockDocument7 pagesPenstockmodest_dhuNo ratings yet

- 2011 Abstract Book-1Document292 pages2011 Abstract Book-1Sai Krishna YellapuNo ratings yet

- WPS - Merd-01Document3 pagesWPS - Merd-01Phuong NguyenNo ratings yet

- Room Occupiency Tag in Revit Along With ScheduleDocument10 pagesRoom Occupiency Tag in Revit Along With ScheduleraviNo ratings yet

- Series QuestionsDocument5 pagesSeries QuestionsAnushka BijarniaNo ratings yet

- Arindam Sarkar ABAPDocument5 pagesArindam Sarkar ABAPMowmita MandalNo ratings yet

- DS Ass IDocument2 pagesDS Ass Inalluri_08No ratings yet

- Business Class m2 Workshop ManualDocument2,354 pagesBusiness Class m2 Workshop ManualWilfredo A Molina63% (8)

- Data Warehousing - FundamentalsDocument3 pagesData Warehousing - FundamentalsJinendraabhiNo ratings yet

- Basics of Seismic InterpretationDocument21 pagesBasics of Seismic InterpretationMahmoud Said100% (5)

- Stabilization and Solidification of Hazardous, Radioactive, and Mixed Wastes PDFDocument391 pagesStabilization and Solidification of Hazardous, Radioactive, and Mixed Wastes PDF김혜인No ratings yet

- 10.03.2020-CeramicMicrospheres 410 TechPaper 9842346 PDFDocument4 pages10.03.2020-CeramicMicrospheres 410 TechPaper 9842346 PDFhomeros76No ratings yet

- Zhang 2016Document8 pagesZhang 2016Roberto GutierrezNo ratings yet

- ZF6HP19-26-32 G1 With 053-SepPlateDocument1 pageZF6HP19-26-32 G1 With 053-SepPlatenorrqvarn-nedreNo ratings yet

- Regulations For Color Code For Piping SystemsDocument16 pagesRegulations For Color Code For Piping SystemsMohammed Najim93% (14)

- Delta RPI-Commercial Series: RPI - M12 / M15A / M20A / M30Document2 pagesDelta RPI-Commercial Series: RPI - M12 / M15A / M20A / M30David SaymonNo ratings yet

- Oracle Fusion ProcurementDocument173 pagesOracle Fusion ProcurementPritesh Mogane100% (9)

- Roof CoveringDocument30 pagesRoof CoveringDipal ParakhNo ratings yet

- Student Information Maintenance System ProjectDocument4 pagesStudent Information Maintenance System ProjectHarshpreet Singh0% (1)

- Chemical Engineering Facts at Your Fingertips Guidebook - 2016 PDFDocument14 pagesChemical Engineering Facts at Your Fingertips Guidebook - 2016 PDFKimberly Conley50% (2)

- ADP II - Vicky (Main)Document70 pagesADP II - Vicky (Main)thupten tsundueNo ratings yet

- CATALAGO ZITRON Rev 1Document16 pagesCATALAGO ZITRON Rev 1Vaibhav GuptaNo ratings yet

- SIMD-Accelerated Regular Expression MatchingDocument7 pagesSIMD-Accelerated Regular Expression Matching蘇意喬No ratings yet

- Debug 1214Document9 pagesDebug 1214D-rifkyNo ratings yet

- AHU DetailsDocument2 pagesAHU DetailsamitbslpawarNo ratings yet

- 9 Ray Optics and Optical Instruments: SolutionsDocument48 pages9 Ray Optics and Optical Instruments: SolutionsVISHAL SINGHNo ratings yet

- 8th ChapterDocument39 pages8th ChapterMasthan BabuNo ratings yet

- 10VM03P22T6PVBE: Operating DataDocument3 pages10VM03P22T6PVBE: Operating DataSergio S. Zegarra TumiNo ratings yet

- Problem Set Mock Exam - CHE PDFDocument11 pagesProblem Set Mock Exam - CHE PDFBenzene100% (1)