100% found this document useful (1 vote)

774 views7 pagesSimply Supported Beam Design

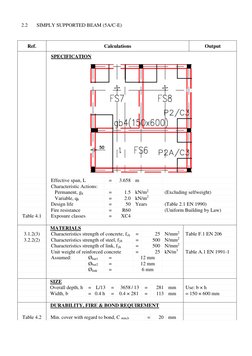

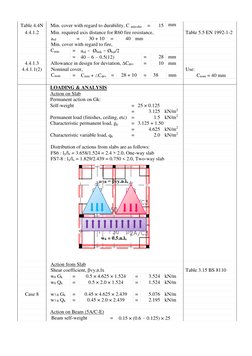

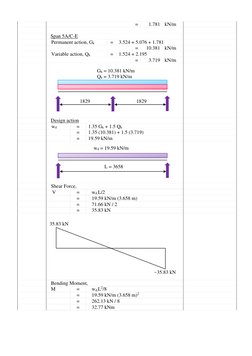

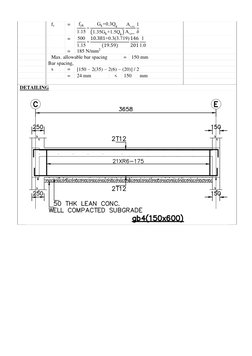

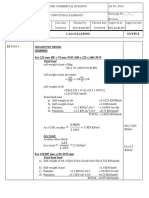

This document provides specifications, material properties, dimensions, and calculations for the design of a simply supported reinforced concrete beam. The beam has an effective span of 3.658 m and is subjected to permanent and variable loads. The calculations determine the required reinforcement including the main tension reinforcement of 4H8 bars and shear links of H6 bars spaced at 225 mm. Additional longitudinal reinforcement is also required near the supports.

Uploaded by

Hafiz95 ReactsCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

100% found this document useful (1 vote)

774 views7 pagesSimply Supported Beam Design

This document provides specifications, material properties, dimensions, and calculations for the design of a simply supported reinforced concrete beam. The beam has an effective span of 3.658 m and is subjected to permanent and variable loads. The calculations determine the required reinforcement including the main tension reinforcement of 4H8 bars and shear links of H6 bars spaced at 225 mm. Additional longitudinal reinforcement is also required near the supports.

Uploaded by

Hafiz95 ReactsCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

- Materials

- Specification

- Loading & Analysis

- Main Reinforcement

- Shear Reinforcement

- Deflection

- Detailing