0% found this document useful (0 votes)

851 views7 pagesStructural Slab Design Guide

The document provides specifications for designing a continuous one-way slab that is 24m x 9m with beams spaced at 4m centers. It specifies a grade C25 concrete and grade 500 reinforcement. The slab is designed to have a minimum thickness of 150mm to meet fire resistance requirements and control deflection. It is analyzed as a one-way slab with characteristic loads of 1.0 kN/m2 permanent and 3.5 kN/m2 variable. Reinforcement sizes are designed at various locations to resist the bending moments and shear forces calculated using tables from BS8110:1997. The design meets requirements for durability, fire resistance, cracking control and deflection limits.

Uploaded by

scribd1991Copyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

851 views7 pagesStructural Slab Design Guide

The document provides specifications for designing a continuous one-way slab that is 24m x 9m with beams spaced at 4m centers. It specifies a grade C25 concrete and grade 500 reinforcement. The slab is designed to have a minimum thickness of 150mm to meet fire resistance requirements and control deflection. It is analyzed as a one-way slab with characteristic loads of 1.0 kN/m2 permanent and 3.5 kN/m2 variable. Reinforcement sizes are designed at various locations to resist the bending moments and shear forces calculated using tables from BS8110:1997. The design meets requirements for durability, fire resistance, cracking control and deflection limits.

Uploaded by

scribd1991Copyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

- Continuous One Way Slab: Describes the design of a continuous slab with specifics about dimensions, materials, and design life.

- Specification: Covers the detailed specifications for the slab including span lengths, material properties, and other engineering characteristics.

- Loading and Analysis: Discusses the loads applied to the slab and the analytical approach for assessing the structural forces.

- Main Reinforcement: Explains the main reinforcement guidelines including effective depths and bar selections for structural integrity.

- Shear: Provides calculations and specifications for handling shear forces within the slab design.

- Deflection: Covers the deflection criteria and reinforcement required to manage deflection under load.

- Cracking: Discusses cracking considerations and the reinforcement needed to control potential cracking scenarios.

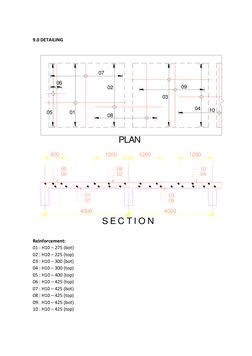

- Detailing: Provides detailed illustrations and notes on slab detailing including reinforcement plans.