LARSEN & TOUBRO LIMITED

ECC Division - GES

PROJECT:

SIDRA MEDICAL AND RESEARCH CENTER,QATAR

HOSPITAL BUILDING - DESIGN OF PLAZA BEAMS & SLABS

DOCUMENT NO

DATE

1861B-CS-05-00304

DESIGNED CHECKED

21/05/09

SHEET

TITLE:

ASN/STN

CSR/MDS

PART -4 ONE WAY SLAB DESIGN

(AT PLAZA LEVEL IN TOWER BLOCK OF HOSPITAL BUILDING)

�LARSEN & TOUBRO LIMITED

ECC Division - GES

PROJECT:

SIDRA MEDICAL & RESEARCH CENTER, DOHA

HOSPITAL BUILDING - DESIGN OF PLAZA BEAMS & SLABS

DOCUMENT NO

DATE

21/0509

1861B-CS-05-00304

TITLE: DESIGNED CHECKED STN CSR/MDS

SHEET

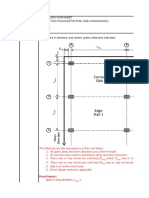

2.0 DESIGN OF ONE WAY SLABS In this section the design of slab for beam slab portion of part -4 is presented. This portion consist of oneway slabs supported by main beams and secondary beams. Slab thickness considered are 200 and 300mm. Analysis and design carried out as per BS 8110. Unit weight of the concrete Loads Considered Superimposed Dead load Live load Soil unit weight (wet) = = = =

3 25 kN/m

2 5.5 kN/m 2 5 kN/m 3 20 kN/m

�LARSEN & TOUBRO LIMITED

ECC Division - GES

PROJECT:

SIDRA MEDICAL & RESEARCH CENTER, DOHA

HOSPITAL BUILDING - DESIGN OF PLAZA BEAMS & SLABS

DOCUMENT NO

DATE

21/0509

1861B-CS-05-00304

TITLE: DESIGNED CHECKED STN CSR/MDS

SHEET

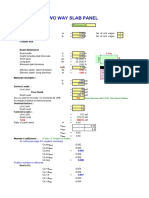

Design of slab panels S5,S6,S7,S8 and S9 The design moments & shear forces are arrived based on clause 3.5.2.4 of BS 8110 Part 1 provisions by considering 1m wide strip of the one way slab. Loads are as follows. Slab thickness Self weight Super imposed dead load (a) Total Dead load (DL) (b) Live load (LL) Design factored load (Fu) =1.4DL+1.6LL Load for serviceability condition, (Fs) =DL+LL Moment and Shear coefificients (Table 3.12, pg 37) = = = = = = = 200 5 5.5 10.5 5 mm kN/m2 kN/m2 kN/m2 kN/m2

2 22.7 kN/m 2 15.5 kN/m

S5

0.086

-0.086

S6

0.063

-0.063

S7

0.063

-0.063

S8

0.063

-0.063

S9

0.063

-0.063

L5= 5.1m

L6=

6m

L7= 6m

L8= 5.2m

L9= 5.2m

(a) Moment coefficients

0.4

S5

0.6

S6

0.5

S7

0.5

S8

0.5

S9

0.5

L5= 5.1m

L6=

6m

L7= 6m

L8= 5.2m

L9= 5.2m

(b) Shear coefficients

10

�LARSEN & TOUBRO LIMITED

ECC Division - GES

PROJECT:

SIDRA MEDICAL & RESEARCH CENTER, DOHA

HOSPITAL BUILDING - DESIGN OF PLAZA BEAMS & SLABS

DOCUMENT NO

DATE

21/0509

1861B-CS-05-00304

TITLE: DESIGNED CHECKED STN CSR/MDS

SHEET

Bending moment and shear force diagram (a) Strength case Bending moment = (FuxL) x L x moment coefficient -70.3 -51.5 -51.5 -38.7 -38.7

50.8

51

51.5 (a) Bending Moment(kN-m)

38.7

38.7

Shear Force = (FuxL) x shear coefficient 46 82 69 68 68 (b) Shear Force(kN) 68 68 59 59 59

(b) Seviceability case Bending moment = (FsxL) x L x moment coefficient -48 -35.2 -35.2 -26.4 -26.4

34.7

35

35.2 (a) Bending Moment(kN-m)

26.4

26.4

Design for Flexure Slab section is designed for maximum moment from the above calculation. 2 Grade of Concrete, fcu = 40 N/mm 2 Yield Strength of Steel, fy = 420 N/mm Cover to reinforcement Slab thickness, D (a) Top Reinforcement (main bars) Maximum Hogging moment Effective depth, d Breadth, b = = = = = 30 mm 200 mm 70.3 kN-m 162 mm

1000 mm

11

�LARSEN & TOUBRO LIMITED

ECC Division - GES

PROJECT:

SIDRA MEDICAL & RESEARCH CENTER, DOHA

HOSPITAL BUILDING - DESIGN OF PLAZA BEAMS & SLABS

DOCUMENT NO

DATE

21/0509

1861B-CS-05-00304

TITLE: DESIGNED CHECKED STN CSR/MDS

SHEET

K = (Mu / fcub * d2 ) Z = Min[0.95d, d{0.5 + sqrt(0.25-K/0.9)}] Area of Steel required, (Mu/(0.87fy*z)

=

= = =

0.07

< K' (0.156)

148.9 mm

2 1292 mm 0.80 % 2 211 mm 2 1340 mm

Req %Pt

Min. Ast required (0.13%) Ast provided Provide 16 mm dia bar at 150

= =

mm C/C as Top reinforcement (main bars)

(b) Bottom Reinforcement (main bars) Maximum Sagging moment Effective depth, d Breadth, b K = (Mu / fcub * d2 ) Z = Min[0.95d, d{0.5 + sqrt(0.25-K/0.9)}] Area of Steel required, (Mu/(0.87fy*z)

= = =

51.5 kN-m

=

= = =

162 mm 1000 mm 0.05 < K' (0.156)

152.6 mm

2 923 mm 0.57 % 2 211 mm 2 1340 mm

Req %Pt

Min. Ast required (0.13%) Ast provided Provide 16 mm dia bar at 150

= =

mm C/C as Bottom reinforcement (main bars)

(c) Secondary reinforcement Minimum reinforcement shall be provided both top and bottom secondary reinforcemet Min Percentage of Ast = 0.13 % mm2 Ast min = 211 mm2 Ast provided = 524 Provide 10 mm dia bar at 150 mm C/C on as secondary bars both at top and bottom

Check for Shear

Allowable shear stress in concrete

vc = 0.79[100As/(bvd)]

(where, As =

1/3

(using Table 3.8, pg 30 BS8110 part1)

1/4 m

(400/d) /

1000

(multiplication factor for concrete grade > 25 = (fcu/25)1/3 )

vc =

2 0.87 N/mm

1340 , bv = Maximum shear, v = Vu/bd (Vu =

d= 162 )

162

, m = 1.25)

82 kN, b=1000, d=

v =

2 0.50 N/mm < vc Hence Safe

Check for deflection (Cl 3.4.6.3 of BS8110 part 1) Basic span/effective depth ratio from table 3.9

(conservatively taken for simply supported condition)

20

Modification factors (a) For Tension reinforcement (Using Table 3.10 of the code)

12

�LARSEN & TOUBRO LIMITED

ECC Division - GES

PROJECT:

SIDRA MEDICAL & RESEARCH CENTER, DOHA

HOSPITAL BUILDING - DESIGN OF PLAZA BEAMS & SLABS

DOCUMENT NO

DATE

21/0509

1861B-CS-05-00304

TITLE: DESIGNED CHECKED STN CSR/MDS

SHEET

Design service stress, fs = 2fyAs req/(3As prov =

b)

161 where,

N/mm2 As req As prov

b

= = =

2 923 mm 2 1340 mm 1.2 for 20%redistribution

Mu/bd2

1.96

Modification factor = 0.55 + (477-fs) / [120(0.9+Mu/bd2] < 2.0 = 1.47 < 2.0 (b) For Compression reinforcement (Using Table 3.11 of the code)

2 100As`prov/bd = 0.83 As`prov 1340 mm = Modification factor = 1 + (100As`prov/bd) / (3+ 100As`prov/bd) < 1.5

= 1.22 < 1.5 Allowable span/effective depth ratio = 20 x 1.47 x 1.22 = 35.8 Actual ratio = 5.1 x 1000 / 162 = 31.5 Check for crack width Crack width is calculated and and attached seperately

Hence safe against deflection

Note: Same design shall be followed for similar one way panals such as S18, S19, S20, S21, S22, S23 S13,S14,S15,S16,S17,S1,S2

13

�LARSEN & TOUBRO LIMITED

ECC Division - GES

PROJECT:

SIDRA MEDICAL & RESEARCH CENTER, DOHA

HOSPITAL BUILDING - DESIGN OF PLAZA BEAMS & SLABS

DOCUMENT NO

DATE

21.05.09

1861B-CS-05-00304

DESIGNED CHECKED STN CSR/MDS

TITLE:

SHEET

Design of slab panels S4 (Refer section 9a-9a) The design moments & shear force are arrived by taking the slab as a simply supported slab considering 1m wide strip of the one way slab. Design loads are as follows. Slab thickness = 300 mm 2 Self weight = 7.5 kN/m 2 Super imposed dead load = 0 kN/m 2 1 m Soil filling (20x1) = 20 kN/m 2 (a) Total Dead load (DL) = 27.5 kN/m 2 (b) Live load (LL) = 5 kN/m Design factored load (Fu) =1.4DL+1.6LL Load for serviceability condition, (Fs) =DL+LL Clear span, L Effective Span Eff ti S Maximum Span moment, Mu = FuL2/8 Maximum Shear force, Vu = FuL/2 Moment under serviceability condition, Mu = FsL2/8 Design for Flexure Slab section is designed for maximum moment. Grade of Concrete, fcu Yield Strength of Steel, fy Cover to reinforcement Slab thickness, D (a) Bottom Reinforcement (main bars) Maximum Sagging moment Effective depth, d Breadth, b K = (Mu / fcub * d2 ) Z = Min[0.95d, d{0.5 + sqrt(0.25-K/0.9)}] Area of Steel required, (Mu/(0.87fy*z) = = = = = = =

2 46.5 kN/m 2 32.5 kN/m

4.3 4.6 46 107 100

m m kN-m kN

75 kN-m

= = = = = = =

2 40 N/mm 2 420 N/mm

30 mm 300 mm 107 kN-m

=

= = =

262 mm 1000 mm 0.04 < K' (0.156)

249 mm

2 1182 mm 0.45 % 2 341 mm 2 1340 mm

Req %Pt

Min. Ast required (0.13%) Ast provided Provide 16 mm dia bar at 150 (b) Top reinforcement Provide 50% of bottom steel

= =

mm C/C as Bottom reinforcement (main bars) =

2 670 mm

14

�LARSEN & TOUBRO LIMITED

ECC Division - GES

PROJECT:

SIDRA MEDICAL & RESEARCH CENTER, DOHA

HOSPITAL BUILDING - DESIGN OF PLAZA BEAMS & SLABS

DOCUMENT NO

DATE

21.05.09

1861B-CS-05-00304

DESIGNED CHECKED STN CSR/MDS

TITLE:

SHEET

Min Percentage of Ast Ast min Ast provided Provide 16 mm dia bar at

= =

0.13 341 1340

mm2 mm2

150 mm C/C on as top reinforcement (main bars)

(c) Secondary reinforcement Minimum reinforcement shall be provided both top and bottom secondary reinforcemet Min Percentage of Ast = 0.13 % mm2 Ast min = 341 mm2 Ast provided = 524 Provide 10 mm dia bar at 150 mm C/C on as secondary bars both at top and bottom

Check for Shear

Allowable shear stress in concrete

vc = 0.79[100As/(bvd)]1/3 (400/d)1/4/

(where, As = 1340 , bv = Maximum shear, v = Vu/bd

1000

m

(using Table 3.8, pg 30 BS8110 part1)

(multiplication factor for concrete grade > 25 = (fcu/25)1/3 )

vc =

2 0.66 N/mm

d= 262 )

262

, m = 1.25)

(Vu =

100

kN, b=1000, d=

v =

2 0.38 N/mm < vc Hence Safe

Check for deflection (Cl 3.4.6.3 of BS8110 part 1) Basic span/effective depth ratio from table 3.9

(for simply supported condition)

20

Modification factors (a) For Tension reinforcement (Using Table 3.10 of the code) Design service stress, fs = 2fyAs req/(3As prov b) = 247 where, N/mm2 As req As prov

b

= = =

2 1182 mm 2 1340 mm 1

Mu/bd2

1.57

Modification factor = 0.55 + (477-fs) / [120(0.9+Mu/bd2] < 2.0 = 1.33 < 2.0 (b) For Compression reinforcement (Using Table 3.11 of the code) 2 100As`prov/bd = 0.51 As`prov 1340 mm = Modification factor = 1 + (100As`prov/bd) / (3+ 100As`prov/bd) < 1.5 = 1.15 < 1.5 Allowable span/effective depth ratio = 20 x 1.33 x 1.15 = 30.4

15

�LARSEN & TOUBRO LIMITED

ECC Division - GES

PROJECT:

SIDRA MEDICAL & RESEARCH CENTER, DOHA

HOSPITAL BUILDING - DESIGN OF PLAZA BEAMS & SLABS

DOCUMENT NO

DATE

21.05.09

1861B-CS-05-00304

DESIGNED CHECKED STN CSR/MDS

TITLE:

SHEET

Actual ratio = 4.6 x 1000 / 262 Check for crack width

17.6

Hence safe against deflection

Crack width is calculated and and attached seperately. Note: Same design shall be followed for similar one way panals such as S11

16

�LARSEN & TOUBRO LIMITED

ECC Division - GES

PROJECT:

SIDRA MEDICAL & RESEARCH CENTER, DOHA

HOSPITAL BUILDING - DESIGN OF PLAZA BEAMS & SLABS

DOCUMENT NO

DATE

1861B-CS-05-00304

TITLE: DESIGNED CHECKED STN CSR/MDS

21.05.09

SHEET

Design of slab panels S3 (Refer section 20a-20a) The design moments & shear force are arrived by taking the slab as a simply supported slab considering 1m wide strip of the one way slab. Design loads are as follows. Slab thickness = 300 mm 2 Self weight = 7.5 kN/m 2 Super imposed dead load = 5.5 kN/m (a) Total Dead load (DL) (b) Live load (LL) Design factored load (Fu) =1.4DL+1.6LL Load for serviceability condition, (Fs) =DL+LL Clear span, L Effective Span Eff ti S Maximum Span moment, Mu = FuL2/8 Maximum Shear force, Vu = FuL/2 Moment under serviceability condition, Mu = FsL2/8 Design for Flexure Slab section is designed for maximum moment. Grade of Concrete, fcu Yield Strength of Steel, fy Cover to reinforcement Slab thickness, D (a) Bottom Reinforcement (main bars) Maximum Sagging moment Effective depth, d Breadth, b K = (Mu / fcub * d2 ) Z = Min[0.95d, d{0.5 + sqrt(0.25-K/0.9)}] Area of Steel required, (Mu/(0.87fy*z) = = = = = = = = =

2 13 kN/m 2 5 kN/m 2 26.2 kN/m 2 18 kN/m

5.5 5.8 58 99 72

m m kN-m kN

68 kN-m

= = = = = = =

2 40 N/mm 2 420 N/mm

30 mm 300 mm 99 kN-m

=

= = =

262 mm 1000 mm 0.04 < K' (0.156)

249 mm

2 1089 mm 0.42 % 2 341 mm 2 1340 mm

Req %Pt

Min. Ast required (0.13%) Ast provided Provide 16 mm dia bar at 150 (b) Top reinforcement Provide 50% of bottom steel

= =

mm C/C as Bottom reinforcement (main bars) =

2 670 mm

17

�LARSEN & TOUBRO LIMITED

ECC Division - GES

PROJECT:

SIDRA MEDICAL & RESEARCH CENTER, DOHA

HOSPITAL BUILDING - DESIGN OF PLAZA BEAMS & SLABS

DOCUMENT NO

DATE

1861B-CS-05-00304

TITLE: DESIGNED CHECKED STN CSR/MDS

21.05.09

SHEET

Min Percentage of Ast Ast min Ast provided Provide 16 mm dia bar at

= =

0.13 341 1340

mm2 mm2

150 mm C/C on as top reinforcement (main bars)

(c) Secondary reinforcement Considering the irregular shape and support conditions for this slab, provide higher reinforcement Min Percentage of Ast = 0.13 % mm2 Ast min = 341 mm2 Ast provided = 1340 Provide 16 mm dia bar at 150 mm C/C on as secondary bars both at top and bottom

Check for Shear

Allowable shear stress in concrete

vc = 0.79[100As/(bvd)]1/3 (400/d)1/4/

(where, As = 1340 , bv = Maximum shear, v = Vu/bd

1000

m

(using Table 3.8, pg 30 BS8110 part1)

(multiplication factor for concrete grade > 25 = (fcu/25)1/3 )

vc =

2 0.66 N/mm

d= 262 )

262

, m = 1.25)

(Vu =

72 kN, b=1000, d=

v =

2 0.28 N/mm < vc Hence Safe

Check for deflection (Cl 3.4.6.3 of BS8110 part 1) Basic span/effective depth ratio from table 3.9

(for simply supported condition)

20

Modification factors (a) For Tension reinforcement (Using Table 3.10 of the code) Design service stress, fs = 2fyAs req/(3As prov b) = 228 where, N/mm2 As req As prov

b

= = =

2 1089 mm 2 1340 mm 1

Mu/bd2

1.44

Modification factor = 0.55 + (477-fs) / [120(0.9+Mu/bd2] < 2.0 = 1.44 < 2.0 (b) For Compression reinforcement (Using Table 3.11 of the code) 2 100As`prov/bd = 0.51 As`prov 1340 mm = Modification factor = 1 + (100As`prov/bd) / (3+ 100As`prov/bd) < 1.5 = 1.15 < 1.5 Allowable span/effective depth ratio = 20 x 1.44 x 1.15 = 32.9

18

�LARSEN & TOUBRO LIMITED

ECC Division - GES

PROJECT:

SIDRA MEDICAL & RESEARCH CENTER, DOHA

HOSPITAL BUILDING - DESIGN OF PLAZA BEAMS & SLABS

DOCUMENT NO

DATE

1861B-CS-05-00304

TITLE: DESIGNED CHECKED STN CSR/MDS

21.05.09

SHEET

Actual ratio = 5.8 x 1000 / 262 Check for crack width

22.1

Hence safe against deflection

Crack width is calculated and and attached seperately.

19

�LARSEN & TOUBRO LIMITED

ECC Division - GES

PROJECT: DOCUMENT NO

SIDRA MEDICAL AND RESEARCH CENTER,QATAR Hospital Building - Crack width calculation

DATE

21/0509

SHEET

1861B-CS-05-00304

DESIGNED STN CHECKED CSR/MDS

TITLE:

Calculation for crack width Moment due to service load Width of slab (b) Overall depth of slab (h) Area of steel provided (As)

(For slab panal - S5) = 48.0 = 1000 mm = 200 mm mm2 = 1340 = 30 mm = 16 mm 200-30-16/2 = 162 mm = 150 mm c/c kNm

Clear cover to tension steel provided (c) Diameter of bar provided on the tension face (I) Effective depth of slab (d) = Spacing of steel (s)

As per BS8110-2:1985 Design Surface Crack Width Wcr = 3acrHm/(1+2(acr-Cmin)/(h-x)) Where

x fs

= depth of neutral axis axis. = the tensile stress in the reinforcement. = M(d-x)/I = Strain at the level considered, calculated ignoring the stiffening of the concrete in the tension zone.

= 61 6 61.6 = 253

mm N/mm2

H1

Hm

a

H1 = (h-x)fs/Es(d-x)

= average steel strain at the level considered, H1 - b(h-x)(a-x)/(3EsAs(d-x)) = distance from the compression face to the point at which crack width is being calculated, and

= =

0.00174 0.00151

= 200 mm

Actual crack width:

acr

= distance from the point considered to the surface of the nearest longitudinal bar = 76.1 mm

W cr

= Crack width Allowable crack width

= 0.206 mm = 0.300 mm

HENCE SAFE

20

�LARSEN & TOUBRO LIMITED

ECC Division - GES

PROJECT: DOCUMENT NO 1861B-CS-05-00304 DESIGNED STN CHECKED CSR/MDS DATE

SIDRA MEDICAL AND RESEARCH CENTER,QATAR Hospital Building - Crack width calculation

21/5/09

SHEET

TITLE:

Calculation for crack width Moment due to service load Width of slab (b) Overall depth of slab (h) Area of steel provided (As)

(For slab panal - S4) = 75.1 = 1000 mm = 300 mm mm2 = 1340 = 30 mm = 16 mm 300-30-16/2 = 262 mm = 150 mm c/c kNm

Clear cover to tension steel provided (c) Diameter of bar provided on the tension face (I) Effective depth of slab (d) = Spacing of steel (s)

As per BS8110-2:1985 Design Surface Crack Width Wcr = 3acrHm/(1+2(acr-Cmin)/(h-x)) Where

x fs

= depth of neutral axis axis. = the tensile stress in the reinforcement. = M(d-x)/I = Strain at the level considered, calculated ignoring the stiffening of the concrete in the tension zone.

= 82 4 82.4 = 239

mm N/mm2

H1

Hm

a

H1 = (h-x)fs/Es(d-x)

= average steel strain at the level considered, H1 - b(h-x)(a-x)/(3EsAs(d-x)) = distance from the compression face to the point at which crack width is being calculated, and

= =

0.00145 0.00112

= 300 mm

Actual crack width:

acr

= distance from the point considered to the surface of the nearest longitudinal bar = 76.1 mm

W cr

= Crack width Allowable crack width

= 0.179 mm = 0.300 mm

HENCE SAFE

21

�LARSEN & TOUBRO LIMITED

ECC Division - GES

PROJECT: DOCUMENT NO 1861B-CS-05-00304 DESIGNED STN CHECKED CSR/MDS DATE

SIDRA MEDICAL & RESEARCH CENTER, DOHA Hospital Building - Crack width calculation

21/5/09

SHEET

TITLE:

Calculation for crack width Moment due to service load Width of slab (b) Overall depth of slab (h) Area of steel provided (As)

(For slab panal - S3) = 68.1 = 1000 mm = 300 mm mm2 = 1340 = 30 mm = 16 mm 300-30-16/2 = 262 mm = 150 mm c/c kNm

Clear cover to tension steel provided (c) Diameter of bar provided on the tension face (I) Effective depth of slab (d) = Spacing of steel (s)

As per BS8110-2:1985 Design Surface Crack Width Wcr = 3acrHm/(1+2(acr-Cmin)/(h-x)) Where

x fs

= depth of neutral axis axis. = the tensile stress in the reinforcement. = M(d-x)/I = Strain at the level considered, calculated ignoring the stiffening of the concrete in the tension zone.

= 82 4 82.4 = 216

mm N/mm2

H1

Hm

a

H1 = (h-x)fs/Es(d-x)

= average steel strain at the level considered, H1 - b(h-x)(a-x)/(3EsAs(d-x)) = distance from the compression face to the point at which crack width is being calculated, and

= =

0.00131 0.00098

= 300 mm

Actual crack width:

acr

= distance from the point considered to the surface of the nearest longitudinal bar = 76.1 mm

W cr

= Crack width Allowable crack width

= 0.158 mm = 0.300 mm

HENCE SAFE

22