0% found this document useful (0 votes)

616 views39 pagesCanning Food Preservation Techniques

Canning involves preserving foods in hermetically sealed containers through the application of heat. The heat processing kills microorganisms, destroys enzymes, and creates a vacuum seal. There are different methods of canning including hot pack, cold pack, and open kettle. Proper exhausting, filling of containers, addition of brine or syrup, and adequate processing times are required to safely preserve foods. Canning equipment, the types of containers used, and classification of foods by acidity determine the appropriate processing method.

Uploaded by

valerieCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PPTX, PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

616 views39 pagesCanning Food Preservation Techniques

Canning involves preserving foods in hermetically sealed containers through the application of heat. The heat processing kills microorganisms, destroys enzymes, and creates a vacuum seal. There are different methods of canning including hot pack, cold pack, and open kettle. Proper exhausting, filling of containers, addition of brine or syrup, and adequate processing times are required to safely preserve foods. Canning equipment, the types of containers used, and classification of foods by acidity determine the appropriate processing method.

Uploaded by

valerieCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PPTX, PDF, TXT or read online on Scribd

- Introduction to Canning

- Principles of Heat Preservation

- History of Canning

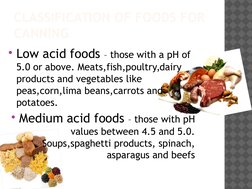

- Classification of Foods for Canning

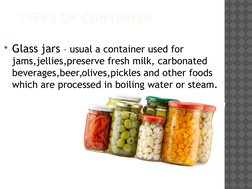

- Types of Containers

- Methods of Canning

- Steps in Canning

- Processing and Cooling

- Canning of Fruits