Professional Documents

Culture Documents

Amorphous and Semi-Crystalline Engineering Thermoplastics: Materials, Properties and Applications

Amorphous and Semi-Crystalline Engineering Thermoplastics: Materials, Properties and Applications

Uploaded by

Gerardo RiveraOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Amorphous and Semi-Crystalline Engineering Thermoplastics: Materials, Properties and Applications

Amorphous and Semi-Crystalline Engineering Thermoplastics: Materials, Properties and Applications

Uploaded by

Gerardo RiveraCopyright:

Available Formats

The International Association of Plastics Distributors

Amorphous and Semi-Crystalline

Engineering Thermoplastics

Materials, properties and applications.

Prepared by the IAPD Education Committee (Module 4)

Presented courtesy of Modern Plastics Inc.

The IAPD Plastics Primer, Module 4

The International Association of Plastics Distributors

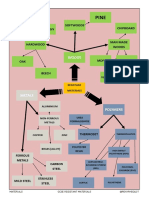

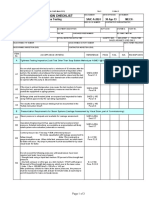

IAPD THERMOPLASTICS RECTANGLE

IMIDE MATERIALS

Key Characteristics: Materials:

Very High Cost Per Pound PI

Excellent Properties Above 400F PAI

Excellent Electrical Properties PBI

Excellent Dimensional Stability

Low Coefficient of Friction

AMORPHOUS HIGH PERFORMANCE PLASTICS SEMI-CRYSTALLINE HIGH PERFORMACE PLASTICS

Key Characteristics Materials: Key Characteristics: Materials:

High Cost Polysulfone High Cost PVDF

High Temperature Polyetherimide High Temperature PTFE

SEM -I CRY STALLINE PLAST ICS

AM OR PHO US PLASTICS

High Strength & Good Stiffness Polyethersulfone High Strength ECTFE

Good Chemical Resistance Polyarylsulfone Good Electrical Properties FEP

Transparency Outstanding Chemical Resistance PFA

Hot Water & Steam Resistance Low Coefficient of Friction PPS

Good Toughness PEEK

AMORPHOUS ENGINEERING PLASTICS SEMI-CRYSTALLINE ENGINEERING PLASTICS

Key Characteristics: Materials: Key Characteristics: Materials:

Moderate Cost Polycarbonate Moderate Cost Nylon

Moderate Temperature Resistance Modified PPO Moderate Temperature Resistance Acetal

Moderate Strength Modified PPE Moderate Strength PET

Good Impact Resistance Thermoplastic Urethane Good Chemical Resistance PBT

Translucency Good Bearing and Wear Properties UHMW-PE

Good Dimensional Stability Low Coefficient of Friction

Good Optical Qualities Difficult to Bond

AMORPHOUS COMMODITY PLASTICS SEMI-CRYSTALLINE COMMODITY PLASTICS

Key Characteristics: Materials: Key Characteristics: Materials:

Low Cost Acrylic Low Cost Polyethylene

Low Temperature Resistance] Polystyrene Low Temperature Resistance Polypropylene

Low Strength ABS Low Strength Polymetnylpentene(TPX)

Good Dimensional Stability PVC Excellent Chemical Resistance

Bond Well PETG Low Coefficient of Friction

Typically Transparent CAB Near Zero Moisture Absorption

Very Good Electrical Properties

Good Toughness

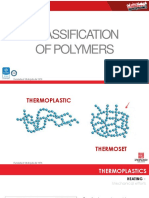

AMORPHOUS PLASTICS KEY CHARACTERISTICS: SEMI-CRYSTALLINE PLASTICS KEY CHARACTERISTICS:

Soften Over a Broad Range Of Temperatures Sharp Melting Point

Easy to Thermoform Difficult to Thermoform

Tend to Be Transparent Tend to Be Opaque

Bond Well Using Adhesives and Solvents Difficult To Bond Using Adhesives and Solvents

Prone To Stress Cracking Good Resistance To Stress Cracking

Poor Fatigue Resistance Good Fatigue Resistance

Stuctural Applications Only (Not for Bearing & Wear) Good For Bearing and Wear, As Well As Structural Applications

The IAPD Plastics Primer, Module 4

The International Association of Plastics Distributors

Amorphous Engineering Thermoplastics

Key Characteristics

Moderate cost, strength and temperature resistance

Good impact resistance

Translucency

Good dimensional stability

Excellent optical qualities

The IAPD Plastics Primer, Module 4

The International Association of Plastics Distributors

Amorphous Engineering Thermoplastics

Materials

Polycarbonate (PC)

Polyphenylene Oxide (PPO)

Polyphenelyne Ether (PPE)

Thermoplastic Urethane (TPU)

The IAPD Plastics Primer, Module 4

The International Association of Plastics Distributors

Polycarbonate (PC)

Strengths

Excellent clarity

Excellent toughness

Good heat resistance

Excellent electrical properties

Intrinsic flame-retardancy

Excellent strength

The IAPD Plastics Primer, Module 4

The International Association of Plastics Distributors

Polycarbonate (PC)

Limitations

Continual exposure to hot water causes gradual

embitterment

Most aromatic solvents, esters and ketones can

cause crazing and cracking

The IAPD Plastics Primer, Module 4

The International Association of Plastics Distributors

Polycarbonate (PC)

Applications

Vandal resistant windows

Machine guards

Outdoor signs

Sky lights

Backboards

Bike, roller blading protective wear

The IAPD Plastics Primer, Module 4

The International Association of Plastics Distributors

Modified Polyphenylene Oxide (Mod PPO)

Modified Polyphenylene Ether (Mod PPE)

Key Characteristics

High dielectric strength

Available in FDA compliant grades

Less expensive than polycarbonate (PC)

Good chemical resistance to strong acids, bases and water

Wide range of processing

Good creep resistance

The IAPD Plastics Primer, Module 4

The International Association of Plastics Distributors

Modified Polyphenylene Oxide (Mod PPO)

Modified Polyphenylene Ether (Mod PPE)

Applications

Electrical housings in appliance, computers, business

equipment, etc.

Water purification equipment parts

Insulators

Gears

The IAPD Plastics Primer, Module 4

The International Association of Plastics Distributors

Thermoplastic Polyurethane (TPU)

Key Characteristics

Wide range of service temperatures

Wide range of harness options

Excellent tear resistance

Excellent compression strength

Excellent resistance to non polar solvents

Excellent electrical properties

Excellent abrasion resistance

High tensile strength

The IAPD Plastics Primer, Module 4

The International Association of Plastics Distributors

Thermoplastic Polyurethane (TPU)

Applications

Impact resistant housings

Valves

Water filter caps

Geophysical cable spacer

The IAPD Plastics Primer, Module 4

The International Association of Plastics Distributors

Semi-Crystalline Engineering

Thermoplastics

Key Characteristics

Moderate cost, strength

Moderate temperature resistance

Good chemical resistance

Good bearing and wear properties

Low COF

Difficult to bond

The IAPD Plastics Primer, Module 4

The International Association of Plastics Distributors

Semi-Crystalline Engineering

Thermoplastics

Materials

Polyamide (PA) Nylon

Polyoxymethylene (POM) Acetal

Polyethylene terephthalate (PET)

Polybutylene terephthalate (PBT)

Ultra high molecular weight polyethylene

(UHMW-PE)

The IAPD Plastics Primer, Module 4

The International Association of Plastics Distributors

Nylon (PA)

Strengths

Good strength

Good toughness

Fair heat resistance

Good chemical resistance

Low COF

The IAPD Plastics Primer, Module 4

The International Association of Plastics Distributors

Nylon (PA)

Limitations

Strong acidic environments

Areas where moisture absorption is of

concern

Areas experiencing high operating

temperatures

The IAPD Plastics Primer, Module 4

The International Association of Plastics Distributors

Nylon (PA)

Applications

Film

Automotive

Electrical/electronics

Consumer goods

The IAPD Plastics Primer, Module 4

The International Association of Plastics Distributors

Cast PA vs. Extruded PA

Extruded nylon can be produced in almost any grade

Cast nylon grades are limited to Type 6, Type 6 1/2 and some

Type 12

Generally Nylon 6/6 and Nylon 6 (cast or extruded) are

interchangeable in most applications (physical property

differences are minor)

Nylon 6/6 is stronger and stiffer than Nylon 6, and has more

resistance to compression

Nylon 6 has better elongation values than Nylon 6/6, providing

better ductility

Cast Nylon can be produced in large profiles and custom shapes,

and is generally less expensive than extruded grades

The IAPD Plastics Primer, Module 4

The International Association of Plastics Distributors

Acetal (POM)

Strengths

Good dimensional stability

Good wear resistance

Excellent strength

Excellent stiffness

Good rigidity

Low moisture absorption

Low COF

The IAPD Plastics Primer, Module 4

The International Association of Plastics Distributors

Acetal (POM)

Limitations

Centerline porosity in copolymers

Using copolymer in hot water environments

(boiling/steam)

Strong acidic environments

Strong alkali environments

Areas experiencing high operating

temperatures

The IAPD Plastics Primer, Module 4

The International Association of Plastics Distributors

Acetal (POM)

Applications

Bearings

Bushings

Valve seats

Washers

Nozzles

Spools

Cams

The IAPD Plastics Primer, Module 4

The International Association of Plastics Distributors

Thermoplastic Polyesters

Key Characteristics

Good range of mechanical properties

Good dimensional stability

Superior chemical resistance

Good electrical properties

The IAPD Plastics Primer, Module 4

The International Association of Plastics Distributors

Thermoplastic Polyesters

Materials

Polyethylene terephthalate (PET)

Polybutylene terephthalate (PBT)

The IAPD Plastics Primer, Module 4

The International Association of Plastics Distributors

Polyethylene Terephthalate (PET)

Polybutylene Terephthalate (PBT)

Key Characteristics

High dimensional stability under heat

High stiffness and hardness

Good bearing strength

Good electrical properties

Good resistance to chemicals

Good stress-cracking resistance

Excellent flow characteristics

The IAPD Plastics Primer, Module 4

The International Association of Plastics Distributors

Thermoplastic Polyesters

Applications

Pump components

Automotive components

Food packaging components

Insulators

The IAPD Plastics Primer, Module 4

The International Association of Plastics Distributors

Thermoplastic Polyesters

Caution!

Watch high temperature environments!

Use caution when recommending thermoplastic

polyesters in applications requiring high temperature

resistance, above 93-121oC/200-250oF.

The IAPD Plastics Primer, Module 4

The International Association of Plastics Distributors

Ultra High Molecular Weight PE

(UHMW-PE)

Strengths

Highest abrasion resistance and impact strength of

any plastic

Very low COF

Excellent cryogenic (low temperature) material

Self-lubricating

FDA/USDA compliant

The IAPD Plastics Primer, Module 4

The International Association of Plastics Distributors

Ultra High Molecular Weight PE

(UHMW-PE)

Limitations

Only good until 82oC/180oF

Not a self-supporting material

High cost for tooling for custom extrusion and

custom parts

The IAPD Plastics Primer, Module 4

The International Association of Plastics Distributors

Ultra High Molecular Weight PE

(UHMW-PE)

Applications

Guides

Wear strips

Liners

The IAPD Plastics Primer, Module 4

The International Association of Plastics Distributors

IAPD THERMOPLASTICS RECTANGLE

IMIDE MATERIALS

Key Characteristics: Materials:

Very High Cost Per Pound PI

Excellent Properties Above 400F PAI

Excellent Electrical Properties PBI

Excellent Dimensional Stability

Low Coefficient of Friction

AMORPHOUS HIGH PERFORMANCE PLASTICS SEMI-CRYSTALLINE HIGH PERFORMACE PLASTICS

Key Characteristics Materials: Key Characteristics: Materials:

High Cost Polysulfone High Cost PVDF

High Temperature Polyetherimide High Temperature PTFE

SEM -I CRY STALLINE PLAST ICS

AM OR PHO US PLASTICS

High Strength & Good Stiffness Polyethersulfone High Strength ECTFE

Good Chemical Resistance Polyarylsulfone Good Electrical Properties FEP

Transparency Outstanding Chemical Resistance PFA

Hot Water & Steam Resistance Low Coefficient of Friction PPS

Good Toughness PEEK

AMORPHOUS ENGINEERING PLASTICS SEMI-CRYSTALLINE ENGINEERING PLASTICS

Key Characteristics: Materials: Key Characteristics: Materials:

Moderate Cost Polycarbonate Moderate Cost Nylon

Moderate Temperature Resistance Modified PPO Moderate Temperature Resistance Acetal

Moderate Strength Modified PPE Moderate Strength PET

Good Impact Resistance Thermoplastic Urethane Good Chemical Resistance PBT

Translucency Good Bearing and Wear Properties UHMW-PE

Good Dimensional Stability Low Coefficient of Friction

Good Optical Qualities Difficult to Bond

AMORPHOUS COMMODITY PLASTICS SEMI-CRYSTALLINE COMMODITY PLASTICS

Key Characteristics: Materials: Key Characteristics: Materials:

Low Cost Acrylic Low Cost Polyethylene

Low Temperature Resistance] Polystyrene Low Temperature Resistance Polypropylene

Low Strength ABS Low Strength Polymetnylpentene(TPX)

Good Dimensional Stability PVC Excellent Chemical Resistance

Bond Well PETG Low Coefficient of Friction

Typically Transparent CAB Near Zero Moisture Absorption

Very Good Electrical Properties

Good Toughness

AMORPHOUS PLASTICS KEY CHARACTERISTICS: SEMI-CRYSTALLINE PLASTICS KEY CHARACTERISTICS:

Soften Over a Broad Range Of Temperatures Sharp Melting Point

Easy to Thermoform Difficult to Thermoform

Tend to Be Transparent Tend to Be Opaque

Bond Well Using Adhesives and Solvents Difficult To Bond Using Adhesives and Solvents

Prone To Stress Cracking Good Resistance To Stress Cracking

Poor Fatigue Resistance Good Fatigue Resistance

Stuctural Applications Only (Not for Bearing & Wear) Good For Bearing and Wear, As Well As Structural Applications

The IAPD Plastics Primer, Module 4

You might also like

- Comparisons Between GRP Pipes With Various Metallic by NadeemDocument16 pagesComparisons Between GRP Pipes With Various Metallic by NadeemAli ZarehNo ratings yet

- Homework-1 Fall 2021Document1 pageHomework-1 Fall 2021Elif HalıcıNo ratings yet

- MON TUE WED THU FRI SAT SUN Total Notes: 2021 Half Marathon PlanDocument1 pageMON TUE WED THU FRI SAT SUN Total Notes: 2021 Half Marathon PlanDavid ThomsonNo ratings yet

- High Performance Thermoplastics: Materials, Properties and ApplicationsDocument40 pagesHigh Performance Thermoplastics: Materials, Properties and ApplicationsbrotherNo ratings yet

- Amorphous and Semi-Crystalline Commodity Thermoplastics: Materials, Properties and ApplicationsDocument35 pagesAmorphous and Semi-Crystalline Commodity Thermoplastics: Materials, Properties and ApplicationsrajkalmekarNo ratings yet

- Understanding The Basics of Plastic Materials and The IAPD Thermoplastics RectangleDocument20 pagesUnderstanding The Basics of Plastic Materials and The IAPD Thermoplastics RectangleMiranda BenavidesNo ratings yet

- Amorphous and Semi-Crystalline Engineering Thermoplastics: Materials, Properties and ApplicationsDocument30 pagesAmorphous and Semi-Crystalline Engineering Thermoplastics: Materials, Properties and Applicationsjesus MaldonadoNo ratings yet

- 2 Engineering Plastics - PPTDocument28 pages2 Engineering Plastics - PPTApoorva MNNo ratings yet

- ACRALOCK PP 1-02 Karta Techniczna ENGDocument3 pagesACRALOCK PP 1-02 Karta Techniczna ENGJoanna SąsaraNo ratings yet

- Présentation 2Document19 pagesPrésentation 2selma tiguiniNo ratings yet

- FRP / GRP Cable Trays: Ladder Type & Perforated TypeDocument4 pagesFRP / GRP Cable Trays: Ladder Type & Perforated TypesaravanakumarpalaniNo ratings yet

- CEM-001 CelaneseQuickRefTrifold AM 0913Document3 pagesCEM-001 CelaneseQuickRefTrifold AM 0913cesaroleinikNo ratings yet

- 1.3 PolymersDocument10 pages1.3 PolymersHady JawadNo ratings yet

- Ghid Mase PlasticeDocument3 pagesGhid Mase PlasticeLavinia CalinNo ratings yet

- Everything You Need To Know About TPE Compounds, Chemistry, and CapabilitiesDocument14 pagesEverything You Need To Know About TPE Compounds, Chemistry, and CapabilitiesRajiv DubeyNo ratings yet

- All PlasticsDocument11 pagesAll PlasticsSaNam KhanNo ratings yet

- Plastic Injection Molding EDocument9 pagesPlastic Injection Molding Egopal06No ratings yet

- Technical Yarns: Nahida Akter Ela Assistant Professor, AUSTDocument30 pagesTechnical Yarns: Nahida Akter Ela Assistant Professor, AUSTimranNo ratings yet

- 1.4 CompositesDocument3 pages1.4 CompositesFuzail NaseerNo ratings yet

- Polyplastics General Plastics InfoDocument56 pagesPolyplastics General Plastics InfoSARAI MARINNo ratings yet

- V4.0 Common Polymers Selection and PropertiesDocument1 pageV4.0 Common Polymers Selection and PropertiesКрасимир ГеоргиNo ratings yet

- Plastics Sterilization Compatibility Chart From Is Med SpecialtiesDocument2 pagesPlastics Sterilization Compatibility Chart From Is Med SpecialtiesLaboratory Plant 7No ratings yet

- Extra Notes For PolymerDocument8 pagesExtra Notes For PolymerNHNo ratings yet

- Plastics Sterilization Compatibility ChartDocument2 pagesPlastics Sterilization Compatibility ChartLászló SágiNo ratings yet

- ISM - Plastics Compatability With Sterilization MethodsDocument2 pagesISM - Plastics Compatability With Sterilization MethodsHenrique Ribeiro Piaggio CardosoNo ratings yet

- Aesthetic Topcoat Guide SWDocument8 pagesAesthetic Topcoat Guide SWjennifergiannouNo ratings yet

- Polymers in Civil EngineeringDocument34 pagesPolymers in Civil EngineeringSiriluck NevestNo ratings yet

- 2957K TDSDocument1 page2957K TDSWelt GeistNo ratings yet

- Plastics Compatibility With Sterilization Methods From ISMDocument2 pagesPlastics Compatibility With Sterilization Methods From ISMJohn SmithNo ratings yet

- Polytone: ABR Series/Thermoplastic Acrylic ResinsDocument7 pagesPolytone: ABR Series/Thermoplastic Acrylic ResinsAdhvik PuriNo ratings yet

- 01 PlasticDocument14 pages01 PlasticsnagareddyNo ratings yet

- Material Selection Task - Wind TurbineDocument12 pagesMaterial Selection Task - Wind TurbineVishwajit GaunsNo ratings yet

- Specification Sheet For Aeron Make FRP/GRP Gratings Molded & PultrudedDocument19 pagesSpecification Sheet For Aeron Make FRP/GRP Gratings Molded & PultrudedYatendra TyagiNo ratings yet

- Week-10 PolymersDocument40 pagesWeek-10 PolymersMoey RenNo ratings yet

- Plastics Sterilization Compatibility ChartDocument3 pagesPlastics Sterilization Compatibility ChartAhmad AbdalraheemNo ratings yet

- Gasket T LimitDocument2 pagesGasket T LimitGama TeknikalNo ratings yet

- High Density Polyethylene - HdpeDocument2 pagesHigh Density Polyethylene - HdpeVENKATESAN JNo ratings yet

- CE336 12 Polymer CompositesDocument34 pagesCE336 12 Polymer CompositesAmit karNo ratings yet

- Denure Base ResinDocument94 pagesDenure Base ResinVishnu S Pattath100% (1)

- Introduction To Polymers, Properties & SelectionDocument101 pagesIntroduction To Polymers, Properties & SelectionakashnirmalyamNo ratings yet

- Polymer in Civil EngineeringDocument33 pagesPolymer in Civil Engineeringlimbong budimanNo ratings yet

- 05 Modern and Smart MaterialsDocument5 pages05 Modern and Smart MaterialsroxyNo ratings yet

- Industrial Hose Chemical Resistance GuideDocument32 pagesIndustrial Hose Chemical Resistance Guidemat gaiatoNo ratings yet

- Chemical Resistance of Rubbers (AIP)Document7 pagesChemical Resistance of Rubbers (AIP)윤병택No ratings yet

- Elevating Polymeric Compounds With Enhanced Scratch and Abrasion Resistance Using Silicon Additives OCTOBER 2023Document24 pagesElevating Polymeric Compounds With Enhanced Scratch and Abrasion Resistance Using Silicon Additives OCTOBER 2023enbuscadepalabrasbookNo ratings yet

- ELASTO Sweden AB - Sådan Vælger Du Termoplastiske Elastomerer (TPE)Document29 pagesELASTO Sweden AB - Sådan Vælger Du Termoplastiske Elastomerer (TPE)SkylarNo ratings yet

- Rubber Compounds TableDocument2 pagesRubber Compounds TableSrikanth Pothapragada100% (2)

- POLYMERS - ApplicationDocument54 pagesPOLYMERS - ApplicationkavineshpraneetaNo ratings yet

- Roof FlyerDocument2 pagesRoof FlyerSmith JohnNo ratings yet

- W10-PALOVCAK Pipe Welding Techniques PVDFDocument20 pagesW10-PALOVCAK Pipe Welding Techniques PVDFAnand KPNo ratings yet

- Ens TecDocument28 pagesEns TecBorja CanalsNo ratings yet

- Tipos de PolímerosDocument34 pagesTipos de PolímerosCARLOS ALFREDO FRANCIS CABRERANo ratings yet

- 15-Ktp PRR PipesDocument46 pages15-Ktp PRR PipesmohammedNo ratings yet

- Selection of PP MaterialsDocument8 pagesSelection of PP MaterialswinstonmechNo ratings yet

- Research Article 1Document31 pagesResearch Article 1Rohit SachdevNo ratings yet

- Filament Vs Convolute TubesDocument1 pageFilament Vs Convolute TubesGanesh.MahendraNo ratings yet

- Polyethylene (PE) - Properties, Uses & ApplicationDocument19 pagesPolyethylene (PE) - Properties, Uses & ApplicationMagamba MirandaNo ratings yet

- Tds e DF605Document1 pageTds e DF605尹燕祥No ratings yet

- EP PPT 1Document88 pagesEP PPT 1satyam parasharNo ratings yet

- A Comparative Study of Mechanical Properties of Zinc Acrylate Epoxy nanocomposites Reinforced by AL2O3 and Cloisite®30B and Their Mixture: Tensile Strength and Fracture Toughness: A Comparative Study of Mechanical Properties of Zinc Acrylate Epoxy nanocomposites Reinforced by AL2O3 and Cloisite®30B and Their Mixture: Tensile Strength and Fracture ToughnessFrom EverandA Comparative Study of Mechanical Properties of Zinc Acrylate Epoxy nanocomposites Reinforced by AL2O3 and Cloisite®30B and Their Mixture: Tensile Strength and Fracture Toughness: A Comparative Study of Mechanical Properties of Zinc Acrylate Epoxy nanocomposites Reinforced by AL2O3 and Cloisite®30B and Their Mixture: Tensile Strength and Fracture ToughnessNo ratings yet

- Disinfectants Meeting British Standard As of 23 July 2012Document3 pagesDisinfectants Meeting British Standard As of 23 July 2012karen_meadows2782No ratings yet

- SAIC-A-2024 Rev 6 Leakness Tightness TestDocument3 pagesSAIC-A-2024 Rev 6 Leakness Tightness Testpookkoya thangalNo ratings yet

- Central Ideas Questions HardDocument20 pagesCentral Ideas Questions Hardhsnovo896No ratings yet

- 2 Workforce Safety and WellnessDocument124 pages2 Workforce Safety and Wellnessanmz09No ratings yet

- Development Agreement: Former Macy's HQDocument10 pagesDevelopment Agreement: Former Macy's HQWVXU NewsNo ratings yet

- Electricity WS3Document2 pagesElectricity WS3visit.rgNo ratings yet

- Atlas CopcoDocument9 pagesAtlas Copcojrsdve100% (1)

- Introduction To Community Based ProgramDocument6 pagesIntroduction To Community Based ProgramSenpai Aris AriasNo ratings yet

- 9010 9020 9020 4 LCD Data SheetDocument8 pages9010 9020 9020 4 LCD Data SheetBD MNNo ratings yet

- Pe 022-3 - 87Document20 pagesPe 022-3 - 87Radu NanuNo ratings yet

- Third Floor Sanitary Lauout Roof Level Sanitary LayoutDocument1 pageThird Floor Sanitary Lauout Roof Level Sanitary LayoutAbebe MuluyeNo ratings yet

- ManzanaDocument9 pagesManzanaDevendra AherNo ratings yet

- NSO Level 1 Class 5 Question Paper 2019 Set B Part 2Document5 pagesNSO Level 1 Class 5 Question Paper 2019 Set B Part 2Anubhuti GhaiNo ratings yet

- FEMA Acronyms, Abbreviations, and Terms (FAAT) List 2005 PDFDocument160 pagesFEMA Acronyms, Abbreviations, and Terms (FAAT) List 2005 PDFlavrik100% (1)

- Chronic PeriodontitisDocument14 pagesChronic PeriodontitisNami RajpootNo ratings yet

- Reforestation Grant ApplicationDocument13 pagesReforestation Grant ApplicationjnakakandeNo ratings yet

- Compact Stainless Steel Water Regulators Specification SheetDocument2 pagesCompact Stainless Steel Water Regulators Specification SheetWattsNo ratings yet

- CHEMISTRY-XI - (Chapter-2-Liquid & Solid State) SINDH ACADEMYDocument7 pagesCHEMISTRY-XI - (Chapter-2-Liquid & Solid State) SINDH ACADEMYAnusha HussainNo ratings yet

- Ayesha Amanat (Roll No. 48)Document4 pagesAyesha Amanat (Roll No. 48)Sikandar SaneenNo ratings yet

- 03 MFDS Regulations & Syllabus 2011Document15 pages03 MFDS Regulations & Syllabus 2011FarahMohammed1No ratings yet

- KfactorDocument2 pagesKfactorengsoon_tNo ratings yet

- Part 8 Wastewater CharacterizationDocument8 pagesPart 8 Wastewater CharacterizationAhmad Mohmmed Jaradat0% (1)

- Electrochemical CellDocument9 pagesElectrochemical CellchethanNo ratings yet

- Administrative Law Judge Opinion On NorthMet Permit To MineDocument40 pagesAdministrative Law Judge Opinion On NorthMet Permit To MineDuluth News TribuneNo ratings yet

- Final Report - Electrochemistry Lab, JUDocument49 pagesFinal Report - Electrochemistry Lab, JUChayon Mondal50% (2)

- Heat Exchanger Design Q. PaperDocument5 pagesHeat Exchanger Design Q. PaperSunil KumarNo ratings yet

- Arg Hydr Aufzuege 300 FL 9010501 enDocument20 pagesArg Hydr Aufzuege 300 FL 9010501 enthrivenNo ratings yet

- Marijuana LegalizationDocument10 pagesMarijuana Legalizationapi-253373502No ratings yet