Professional Documents

Culture Documents

Steam Condenser

Uploaded by

JomariBobadilla0 ratings0% found this document useful (0 votes)

24 views12 pagesSchool Presentation for Steam Condenser

Copyright

© © All Rights Reserved

Available Formats

PPTX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentSchool Presentation for Steam Condenser

Copyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

24 views12 pagesSteam Condenser

Uploaded by

JomariBobadillaSchool Presentation for Steam Condenser

Copyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

You are on page 1of 12

Steam Condenser

Steam condenser is a device in which the

exhaust steam from steam turbine is

condensed by means of cooling water.

The main purpose of a steam condenser in

turbine is to maintain a low back pressure on

the exhaust side of the steam turbine.

Elements of Steam

Condenser

Condenser chamber where steam gets condensed.

Cooling water supply which provides cold water to

condense steam by heat exchanging.

Wet Air pumps They collect condensed steam, the air

and un-condensed water vapour and gases from

condenser.

Hot well in which the condensed steam is collected and

from it steam boiler feed water may be taken if required.

TYPES

OF

STEAM

CONDENSER

There are mainly three types of jet

condensers.

Low level condenser.

High level condenser.

Ejector condenser.

Low Level Jet Condenser

The cooling water into the

condenser up to a height

of 5.5 m.

It is having disadvantage

of flooding the steam

turbine if the condensate

extraction pump fails.

High Level Jet Condenser

It is also called as

Barometric Jet Condenser

since it is placed above the

atmospheric pressure

equivalent to 10.33 m of

water pressure.

Condensate extraction

pump is not required

because tailpipe has

incorporated in place of it.

Ejector Condenser

A kind of direct contact

condenser in which cooling

water and steam mix in a series

of combining cones

Kinetic energy of steam is

expended to drain off the

condensate and cooling water

from the condenser

Removes the need of air pump

Condensate cannot be used in

boiler since it is contaminated

by cooling water

There are mainly three types of surface

condensers.

Down Flow Surface Condenser

Central Flow Surface Condenser

Inverted Flow Type Condenser

Down Flow Surface Condenser

Exhaust steam enters the top of condenser shell & flows

downward over water tubes

Water tubes are double passed. The cold water flows in

lower side first and then in upper side in the reverse

direction, which enables the maximum heat transfer.

Central Flow Surface Condenser

The steam flows radially

inward.

The condensate is collected at

the bottom of the shell from

where it is taken out by the

condensate extraction pump.

The steam gets access to the

entire periphery of tubes, and

thus a large surface area for the

heat transfer is available as

compared to the down flow,

Inverted Flow Type Condenser

In this condenser the exhaust steam is circulated

through a series of tubes and a thin film of cooling

water is allowed to flow over these tubes. A natural

or force air flow helps rapid evaporation of the film,

which speeds up the condensation process.

Evaporate type steam condenser requires minimum

cooling water. Only the make up water required to

supply to compensate evaporation.

This type of steam

surface condenser is

suitable for small power

plant.

You might also like

- LaplacianDocument4 pagesLaplacianJomariBobadillaNo ratings yet

- Performance of TurbineDocument31 pagesPerformance of TurbineJomariBobadillaNo ratings yet

- PistonDocument1 pagePistonJomariBobadillaNo ratings yet

- Rotating Machine: Cogs Torque TransmissionDocument1 pageRotating Machine: Cogs Torque TransmissionJomariBobadillaNo ratings yet

- Rational NumbersDocument54 pagesRational NumbersJomariBobadillaNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Reference BookDocument313 pagesReference BooknirdeshNo ratings yet

- Porta-Test Whirlyscrub VDocument2 pagesPorta-Test Whirlyscrub VJagadeesh UnnamNo ratings yet

- Lab Report Pump PerformanceDocument20 pagesLab Report Pump Performanceamirshafiq67% (3)

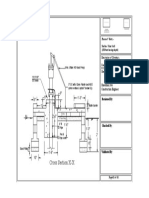

- Shallow Tube Well-Model.2pdfDocument1 pageShallow Tube Well-Model.2pdfIhd ConsultancyNo ratings yet

- ds65 700 PDFDocument4 pagesds65 700 PDFkumar_chemicalNo ratings yet

- General Control Valves TrainingDocument37 pagesGeneral Control Valves TrainingMohd Amani100% (2)

- Drop Size Distributions and Coalescence Frequencies of Liquid-Liquid Dispersions in Flow VesselsDocument9 pagesDrop Size Distributions and Coalescence Frequencies of Liquid-Liquid Dispersions in Flow VesselsZTINo ratings yet

- SCR PresentationDocument85 pagesSCR PresentationariyaNo ratings yet

- MCQ Unit 2 Fluid Statics, BuoyancyDocument6 pagesMCQ Unit 2 Fluid Statics, BuoyancySiddhantNo ratings yet

- AAE 556 Aeroelasticity: Lectures 22, 23 Typical Dynamic Instability Problems and Test ReviewDocument26 pagesAAE 556 Aeroelasticity: Lectures 22, 23 Typical Dynamic Instability Problems and Test Reviewoigres725No ratings yet

- SIRE EKS July 2023Document2 pagesSIRE EKS July 2023Mohan SNo ratings yet

- Fan SelectionDocument61 pagesFan SelectionJugmohunNo ratings yet

- 7394 - 11 - 8 - 08 - INTEGRATED HEAT RECOVERY SYSTEM INSTALLATION L132 To L250Document7 pages7394 - 11 - 8 - 08 - INTEGRATED HEAT RECOVERY SYSTEM INSTALLATION L132 To L250phuongtrinhxuan91_88No ratings yet

- Kinetics of Formic AcidDocument2 pagesKinetics of Formic AcidhafizahmacheNo ratings yet

- Gujarat Technological UniversityDocument2 pagesGujarat Technological Universityfeyayel988No ratings yet

- Impact of Flowfield-Radiation Coupling On AeroheatingDocument11 pagesImpact of Flowfield-Radiation Coupling On Aeroheatingmiquelbs2001No ratings yet

- Protego PDFDocument18 pagesProtego PDFNemezis1987No ratings yet

- MEGECHA Head WORK (Revised) 2Document159 pagesMEGECHA Head WORK (Revised) 2Abiued EjigueNo ratings yet

- CHE411 Fall 2010-Chemical Reaction Engineeirng-Ahmed A AbdalaDocument206 pagesCHE411 Fall 2010-Chemical Reaction Engineeirng-Ahmed A AbdalaYayan IndrayaniNo ratings yet

- 2019-01 RS-6C005-2019 AhuDocument18 pages2019-01 RS-6C005-2019 Ahushant_m100% (1)

- Design Criteria Eria: Guide For The Preparation of Process Flow Diagrams On of Process Flow DiagramsDocument16 pagesDesign Criteria Eria: Guide For The Preparation of Process Flow Diagrams On of Process Flow DiagramsGabriele GabrieleNo ratings yet

- Design and Construction of A Heat Exchanger With TPMS StructureDocument4 pagesDesign and Construction of A Heat Exchanger With TPMS StructureMary BolañosNo ratings yet

- Heat Exchanger Application Data SheetDocument2 pagesHeat Exchanger Application Data SheetRobin Wijaya NgNo ratings yet

- Manual Operacion y MantenimientoDocument30 pagesManual Operacion y MantenimientoDaniel Alejandro García PérezNo ratings yet

- Drag Lab Graphs Log of Terminal Velocity Vs Log of TimeDocument2 pagesDrag Lab Graphs Log of Terminal Velocity Vs Log of TimekatwasnothereNo ratings yet

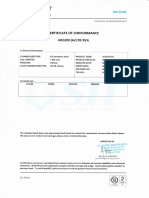

- COC Ar35 WG 47L 18-02-IX-14Document1 pageCOC Ar35 WG 47L 18-02-IX-14Tirtana PrasetiaNo ratings yet

- GPD Ultra FiltrationDocument9 pagesGPD Ultra FiltrationArfeen HussainNo ratings yet

- Fact Sheets On Air Emission Abatement Techniques - Final 2009 02 20 PDFDocument152 pagesFact Sheets On Air Emission Abatement Techniques - Final 2009 02 20 PDFAini Zahra100% (1)

- Log Sheet Engineering Gumaya Tower Hotel Semarang Water Storage & Pool Treatment B2 Month Of: 2018Document11 pagesLog Sheet Engineering Gumaya Tower Hotel Semarang Water Storage & Pool Treatment B2 Month Of: 2018faiz budiNo ratings yet

- CS2500Document528 pagesCS2500David Muñoz CastroNo ratings yet